Exposed type modified asphalt waterproof coiled material and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in the field of building waterproof materials, and can solve problems such as shale shedding, difficulty in oil production, and poor heat resistance of modified asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

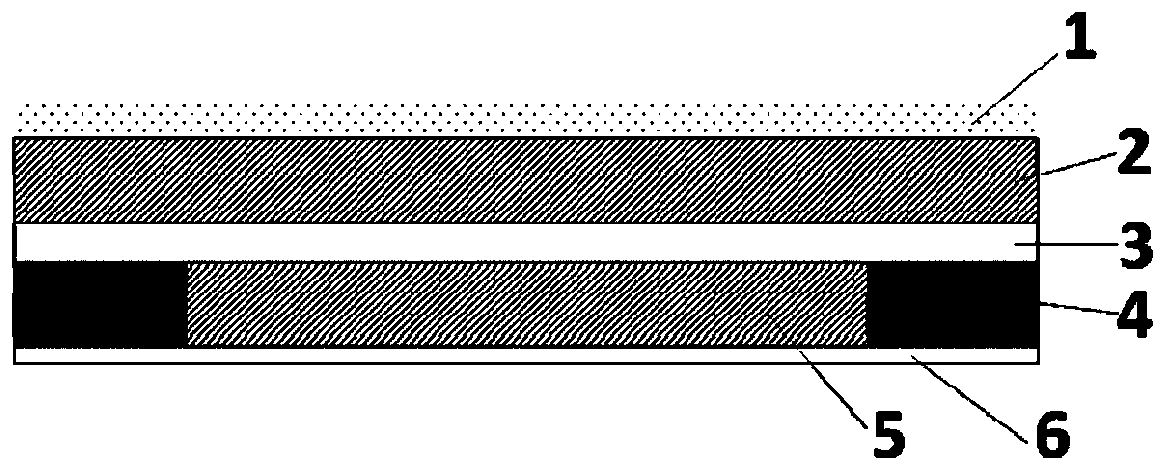

Image

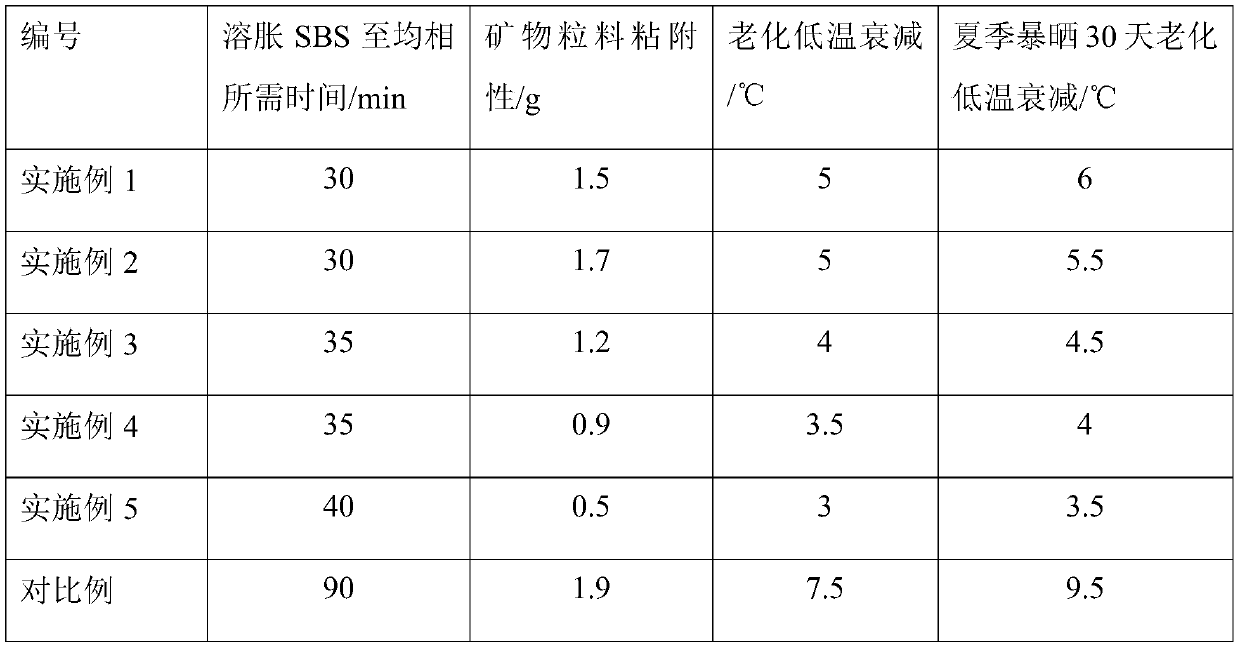

Examples

Embodiment 1

[0080] Mix and heat 30 parts by weight of 90# bitumen and 30 parts by weight of 200# bitumen to 150-160°C, add 2 parts by weight of SBR, shear and grind for 20-40 minutes, add 9 parts by weight of 25-35wt% star-shaped SBS and 3.5 parts by weight SIBS, heat up to 180-195°C, continue shearing and grinding for 40-70min, until the system becomes homogeneous, add 1.5 parts by weight of lake asphalt, 3 parts of anti-ultraviolet agent and 23 Parts by weight of filler, stirred for 30 to 50 minutes, to prepare a coating covering material with high adhesion modified asphalt layer on the upper surface;

[0081] Mix and heat 45 parts of 90# asphalt and 13 parts of softener to 150-160°C, stir for 20 minutes, add 12 parts of star-shaped SBS with a molecular weight of 280,000-350,000 and a styrene content of 30-40 wt%, and heat up to 185-160°C. 195°C, shear and grind for 60-80 minutes until the system is completely homogeneous, add 3 parts of viscosity reducer, 8 parts of C9 petroleum resin ...

Embodiment 2

[0085] The difference with Example 1 is:

[0086] Coating material for the high-adhesion modified asphalt layer on the upper surface: the star-shaped SBS with a molecular weight of 200,000 to 250,000 and a styrene content of 25 to 35 wt% increases by 1 part, SIBS decreases by 0.5 parts, and lake asphalt increases by 0.5 parts. Anti-ultraviolet agent reduced by 1 part;

[0087] Coating material for the lapping edge of the modified asphalt layer on the lower surface: 2 parts of star-shaped SBS with a molecular weight of 280,000 to 350,000 and a styrene content of 30 to 40 wt%, and 2 parts of C9 petroleum resin;

[0088] Coating materials for parts other than the lapped side of the modified asphalt layer on the lower surface: star-shaped SBS with a molecular weight of 200,000-250,000 and a styrene content of 30-35wt%, add 2 parts for star-shaped SBS, add 2 parts for linear SBS, APAO Reduced by 2 parts, fillers reduced by 2 parts;

Embodiment 3

[0090] The difference with Example 1 is:

[0091] Coating material for the high-adhesion modified asphalt layer on the upper surface: 5 parts of 90# asphalt, 1 part of SBR, 2 parts of star-shaped SBS with a molecular weight of 200,000 to 250,000 and a styrene content of 25 to 35 wt%. , SIBS increased by 0.5 parts, lake asphalt increased by 1.5 parts, anti-ultraviolet agent decreased by 1 part, filler decreased by 9 parts;

[0092] Coating material for the lapped side of the modified asphalt layer on the lower surface: add 2 parts of viscosity reducer, add 2 parts of star-shaped SBS with a molecular weight of 280,000 to 350,000 and a styrene content of 30 to 40 wt%, and reduce the amount of C9 petroleum resin 2 parts filler reduces 2 parts;

[0093] Coating material for parts other than the lapped side of the lower surface modified asphalt layer: 5 parts of 90# asphalt, 10 parts of 200# asphalt, star-shaped SBS with a molecular weight of 200,000 to 250,000 and a styrene conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com