Concrete silo inner lining steel rail and warehouse wall slip form integrated construction method

A construction method and concrete technology, applied in building types, buildings, large-capacity bulk material storage, etc., can solve the problems of poor integrity of rails and warehouse walls, easy loosening and falling off, and long construction period, so as to improve the quality of the entity and prolong the use. Life, life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

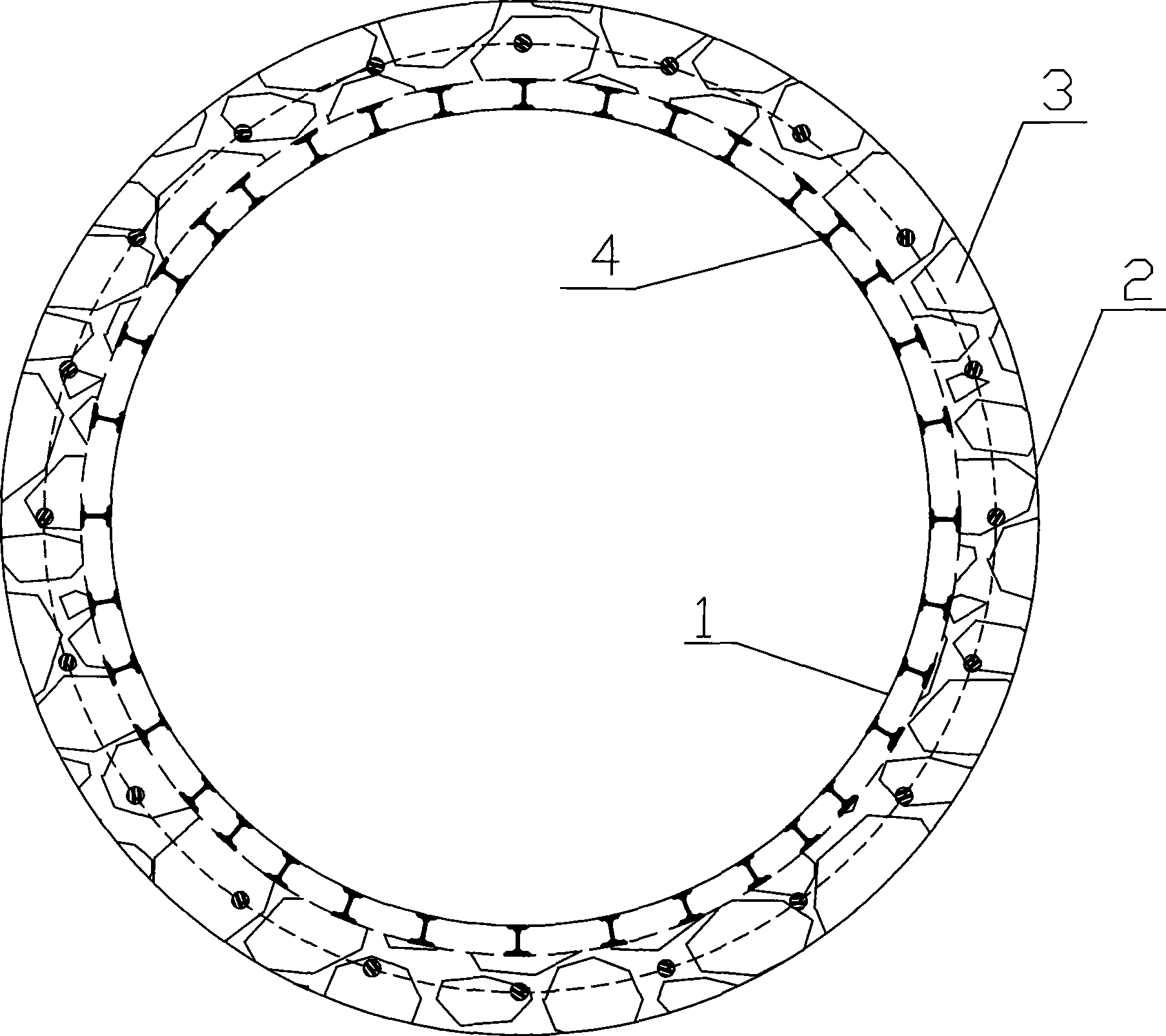

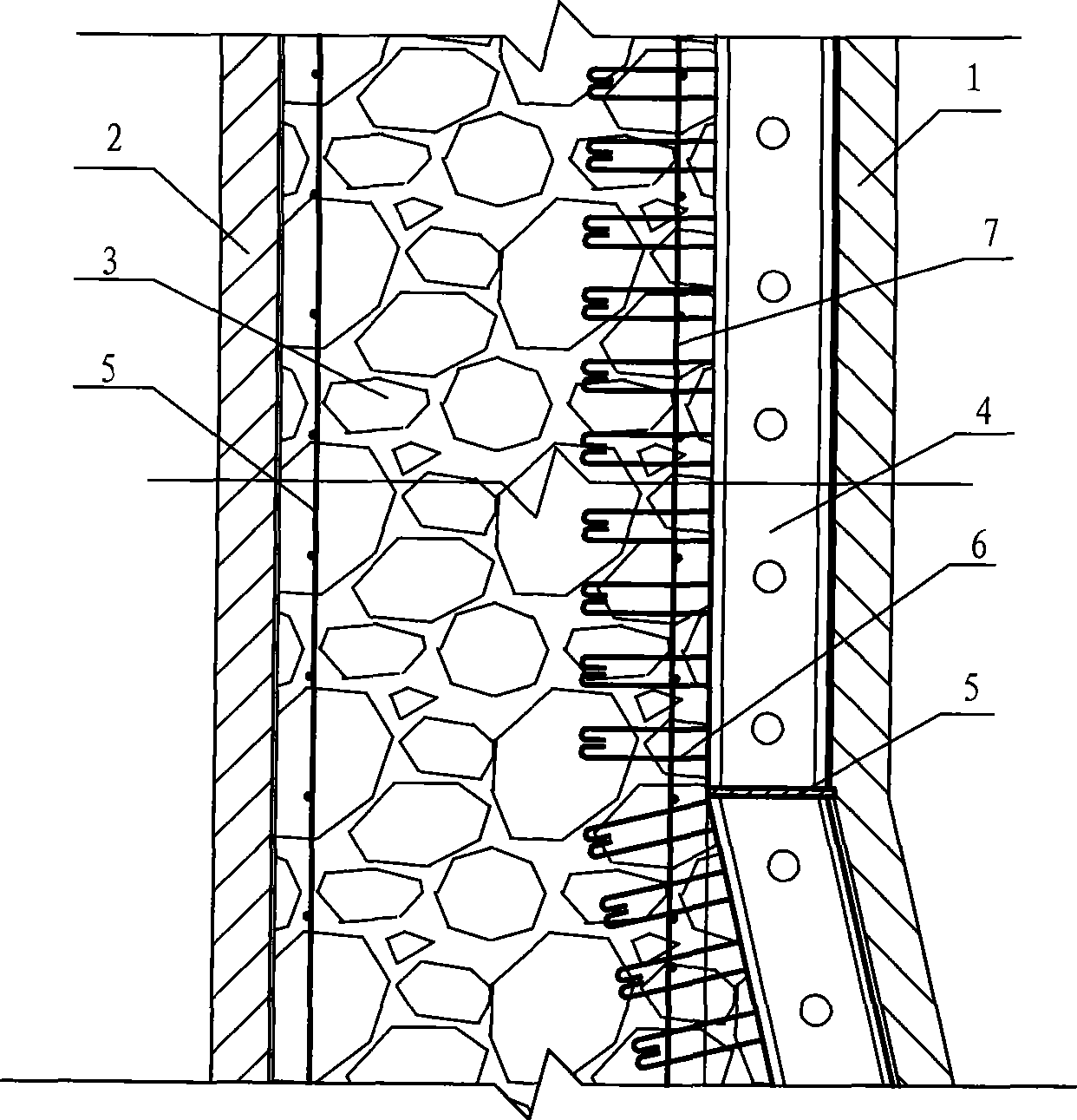

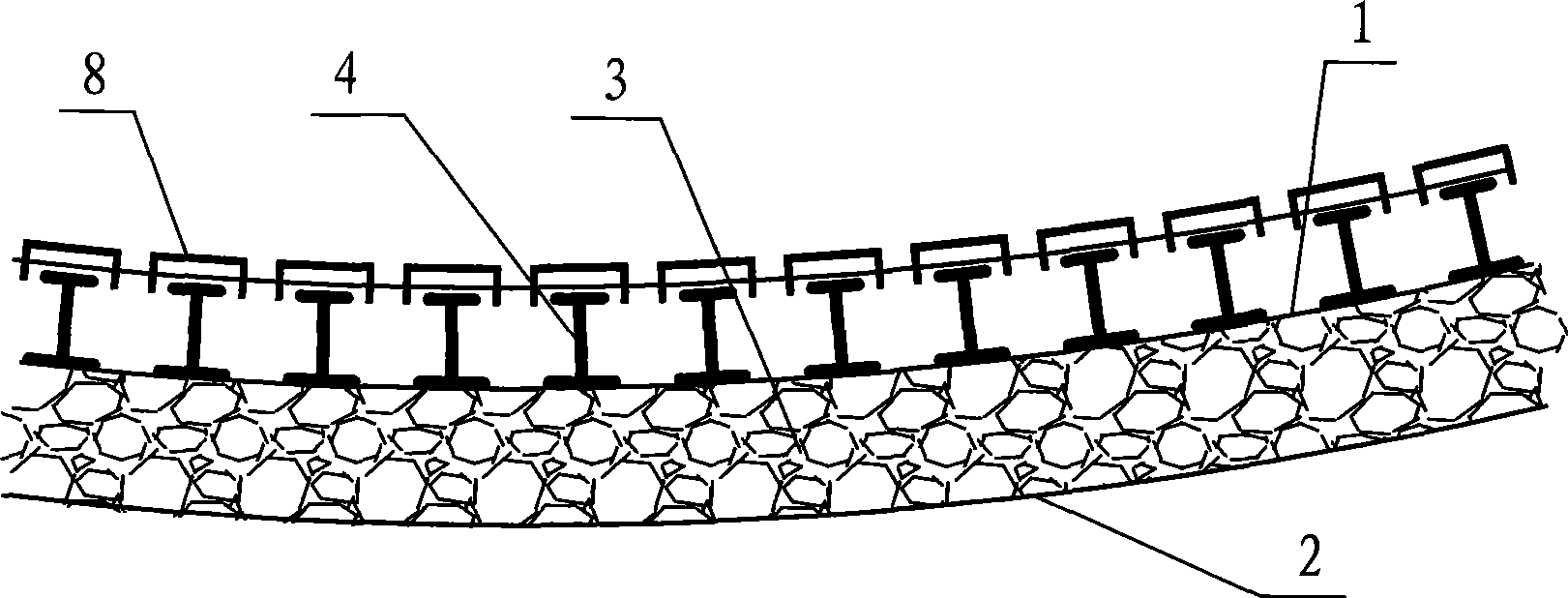

[0019] Such as figure 1 , figure 2 , image 3 Shown, the present invention is the improvement carried out on the basis of existing limestone silo construction technology, and the improved method comprises the following steps:

[0020] a. When the limestone silo is constructed to the height required by the design to install the lined steel rail, that is, the height of the silo base, remove the inner formwork 1 of the silo wall of the sliding formwork, and then weld and install an annular steel plate 5 on the inner wall of the silo base;

[0021] b. Install an effective number of steel rails 4 upright on the above-mentioned annular steel plate 5, wear the steel rails 4 arranged in a ring together with steel bars, and the steel rails 4 are welded with anchoring steel bars 6 connected with the warehouse wall steel bars 7, wherein the steel rails 4 are installed At the same time, the steel bar threading work can be carried out; the number of installed rails 4 is determined accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com