Construction platform and construction method for integrating silo roof and silo wall slip form

A construction method and construction platform technology, applied in the field of silos, can solve the problems of multiple turnover materials and labor, difficulty in reverse transportation of turnover materials, and high labor intensity of workers, so as to reduce the input of turnover materials and labor, save support materials, shorten The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

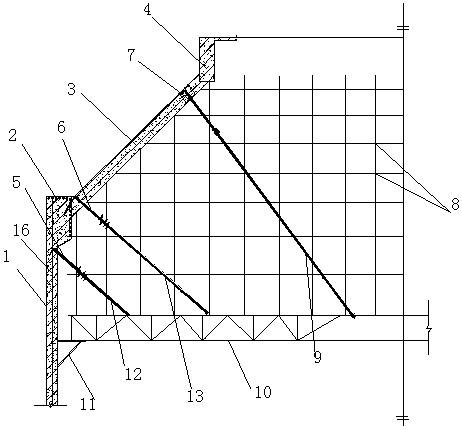

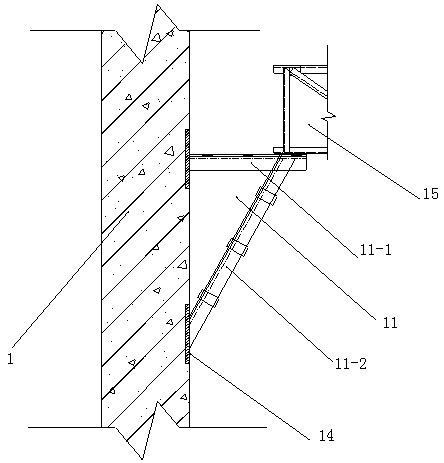

[0031] Such as figure 1 , figure 2 As shown, the integrated construction platform includes a sliding formwork, and the truss 15 of the sliding formwork is arranged on the steel corbel 11 fixed on the warehouse wall 1, and the trusses 15 are laterally connected and fixed to form a support platform 10; A support frame body 8 for supporting the roof of the warehouse is set up; the upper surface of the truss 15 is fixed with three unloading diagonal tie rods, the first pull rod 12, the second pull rod 13 and the third pull rod 9, and the other end of the first pull rod 12 is connected to the The first round steel 5 on the support rod 16 in the warehouse wall 1 is welded and fixed, and the other ends of the second tie rod 13 and the third tie rod 9 are respectively anchored on the lower ring beam 2 and the main steel bar of the cone shell 3 on the warehouse roof. The second round steel 6 and the third round steel 7 are welded and fixed, and the distance between the third round st...

Embodiment 2

[0033] The invention provides an integrated construction method of a silo roof and a silo wall sliding form, comprising the following steps:

[0034] (1) When the sliding form construction of the warehouse wall is carried out to a height of 200mm from the bottom of the warehouse roof, the embedded parts are buried on the inner side of the warehouse wall, and the steel corbels are welded obliquely upward on the embedded parts; The quantity corresponds, and each truss corresponds to two (one set) of embedded parts.

[0035] (2) After the construction of the warehouse wall is completed, the sliding formwork is lowered to the position of the steel corbel, and the truss is set on the upper end of the steel corbel, and short steel bars are welded on the side of the steel corbel to fix the truss. Steel pipes are used to connect horizontally to form a supporting platform.

[0036] (3) Set up a supporting frame body for supporting the warehouse roof on the supporting platform, set up ...

Embodiment 3

[0042] The invention provides an integrated construction method of a silo roof and a silo wall sliding form, comprising the following steps:

[0043] (1) When the sliding form construction of the warehouse wall is carried out to a height of 500mm from the bottom of the warehouse roof, the embedded parts are buried inside the warehouse wall, and the steel corbels are welded obliquely upward on the embedded parts; the number of embedded parts and the truss The quantity corresponds, and each truss corresponds to two (one set) of embedded parts.

[0044] (2) After the construction of the warehouse wall is completed, the sliding formwork is lowered to the position of the steel corbel, and the truss is set on the upper end of the steel corbel, and short steel bars are welded on the side of the steel corbel to fix the truss. Steel pipes are used to connect horizontally to form a supporting platform.

[0045] (3) Set up a supporting frame body for supporting the warehouse roof on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com