A Microscopic Wall Slip Model Establishment Method for Injection Molding

A technology for wall slip and model building, which is applied in special data processing applications, instruments, calculations, etc., can solve the problem of large simulation error values of pressure difference and filling rate, cannot accurately simulate the flow characteristics of polymer materials, and does not take into account Issues such as the size of micro-injection molded parts, to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

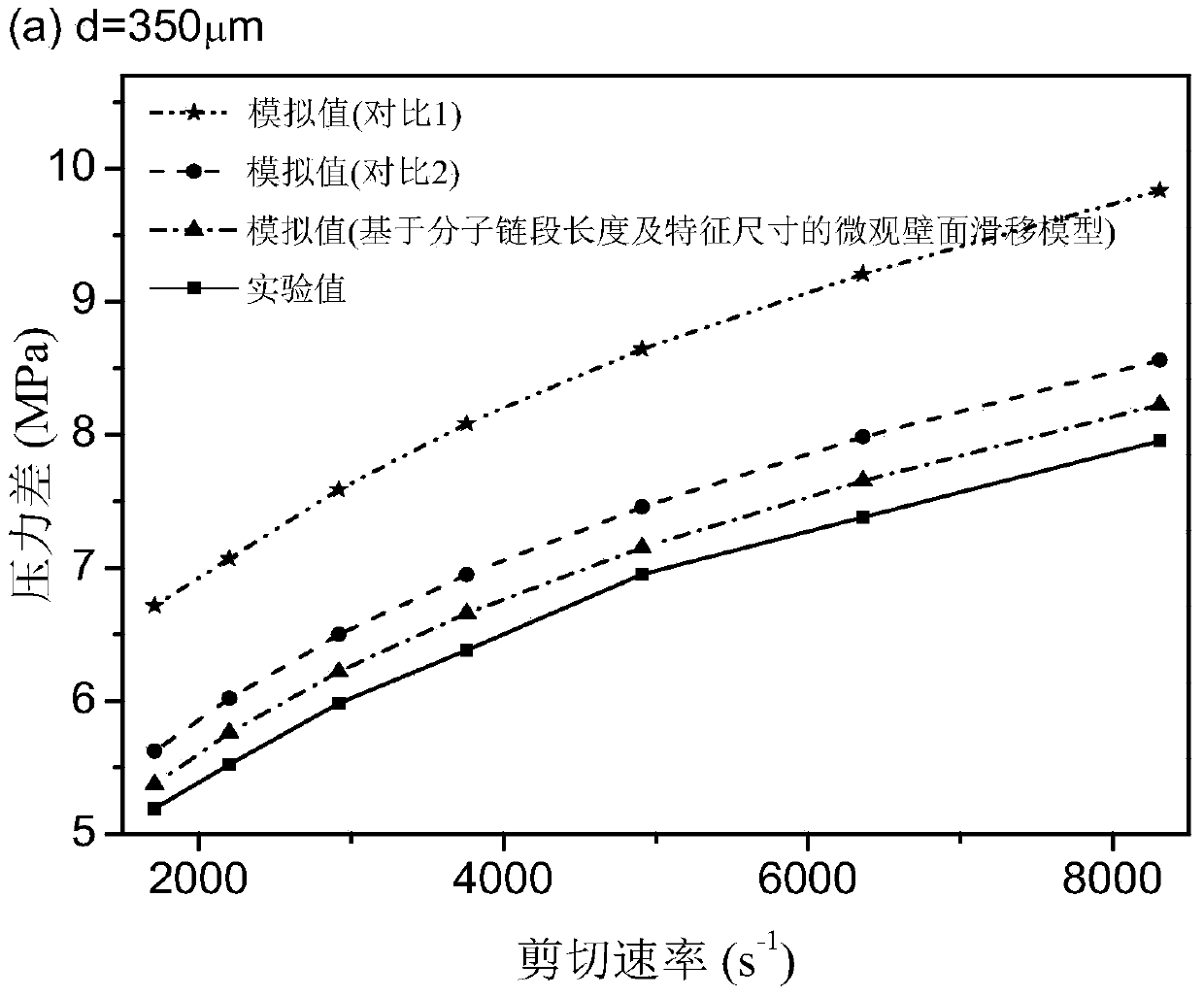

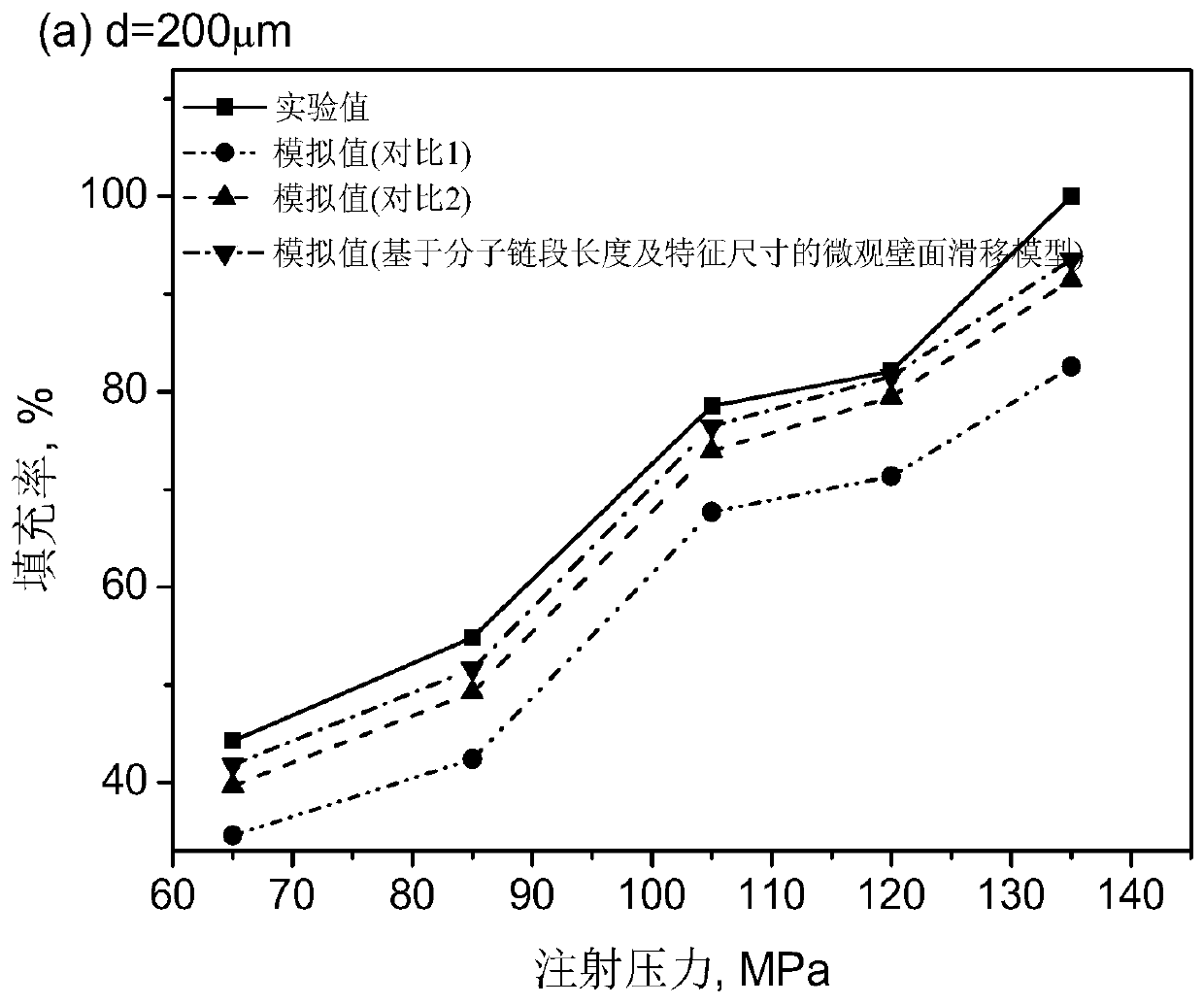

[0071] A method for establishing a microscopic wall slip model for injection molding, based on the molecular segment length and part feature size microscopic wall slip model established by polystyrene (Polystyrene, abbreviation PS) material, the steps are as follows:

[0072] 1) Based on the macroscopic viscosity model, a microscopic correction factor ψ is introduced;

[0073] Determine the capillary rheology experiment plan, conduct injection molding experiments at shear rates of 1700, 2200, 2900, 3700, 4900, 6300, and 8300s-1 respectively, and measure the actual viscosity value η of injection molding of micro parts micro ; Then, under the same parameter conditions, based on the Cross macroscopic viscosity model, a set of injection molding macroscopic viscosity values η of micro parts are simulated macro , where η 0 =2992.498Pa·s,τ * =27360Pa, n=0.24; According to the actual viscosity value η of injection molding of micro parts micro Injection molding macroscopic viscosi...

specific Embodiment approach 2

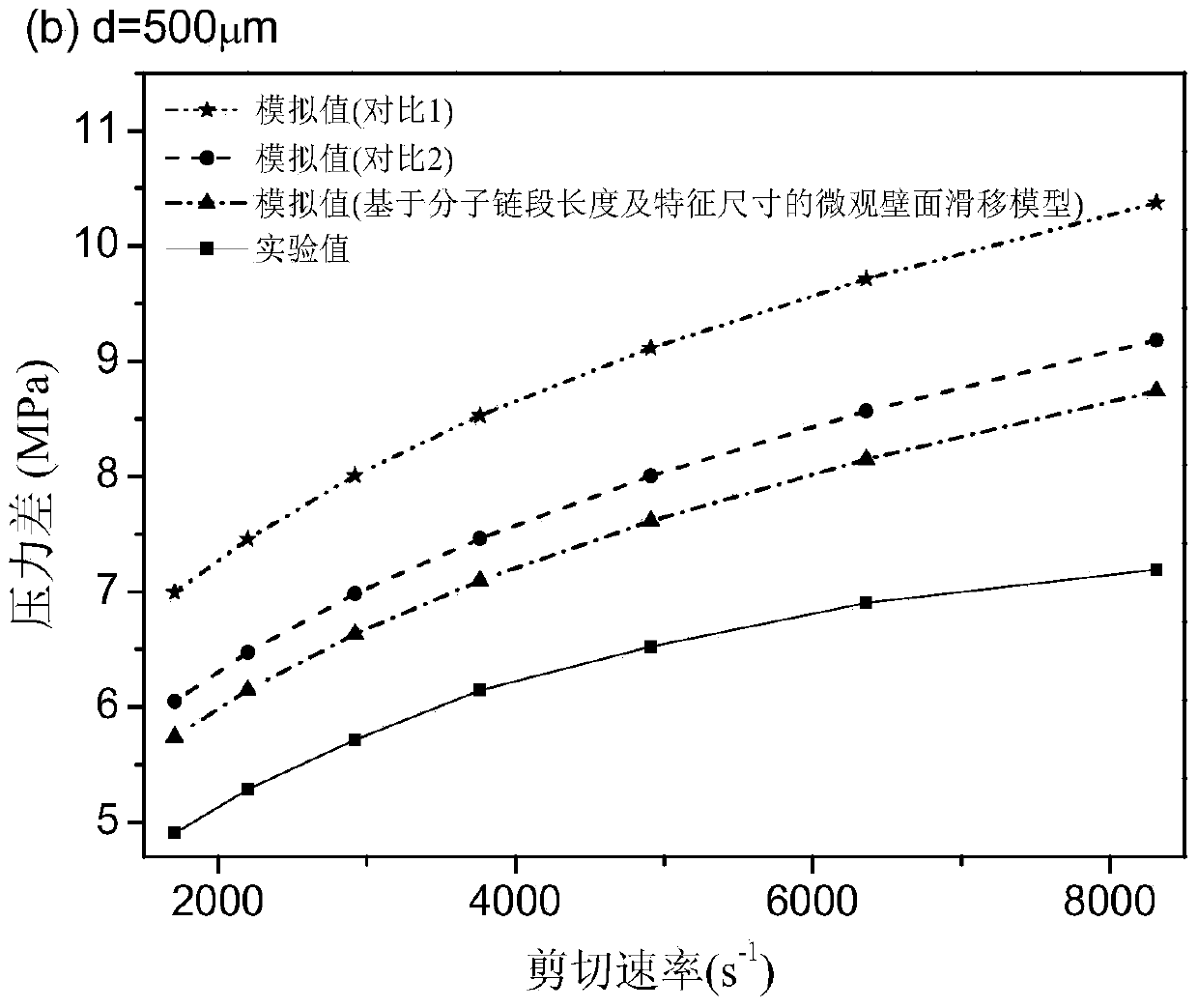

[0090] A method for establishing a microscopic wall slip model for injection molding, based on the molecular segment length and part feature size microscopic wall slip model established by polypropylene (Polyprolene, abbreviation PP), the steps are as follows:

[0091] 1) Based on the macroscopic viscosity model, a microscopic correction factor ψ is introduced;

[0092] Determine the capillary rheology experiment plan, carry out injection molding experiments at injection pressures of 85, 105, and 135 MPa, and measure the actual viscosity value η of micro-injection molding micro ; Then under the same parameter conditions, based on the Cross macroscopic viscosity model, simulate a set of macroscopic viscosity values η macro , where η 0 =2500Pa·s,τ * =23841Pa, n=0.311; According to the actual viscosity value η of injection molding of micro parts micro Injection molding macroscopic viscosity value η with miniature parts macro A set of microscopic correction factor ψ values ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com