Device and method for measuring steady-state extrusion viscous dissipation of micro-scale polymer fused mass

A viscous dissipation, polymer technology, applied in the field of polymer rheology testing, can solve the problem of no micro-scale polymer melt viscosity dissipation measurement device, etc., achieve a high measurement shear rate range, easy loading and unloading, temperature control accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

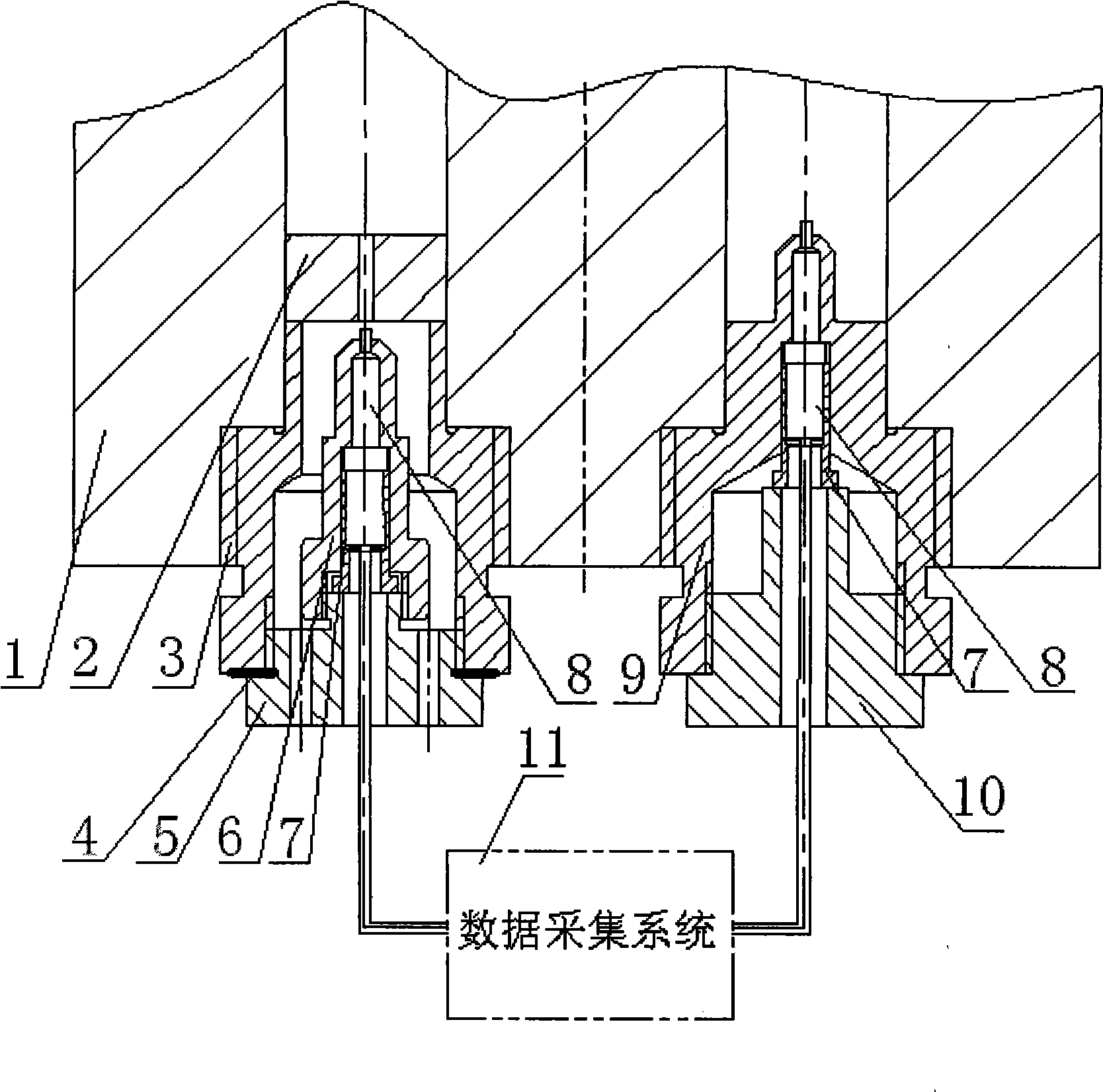

[0010] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0011] Measure the polymer material high-density polyethylene (HDPE) at a temperature of 200°C and an apparent shear rate of 10,000s -1 , the steady-state extrusion flows through the viscous dissipation of a capillary die with a diameter of 500 μm and an aspect ratio of 16.

[0012] Embodiment steps are as follows:

[0013] Step 1. First heat up the capillary rheometer, and when the set temperature reaches 200°C, install the outer hexagonal mold support (a) on the left side of the rheometer with a wrench, and install the capillary port from the inlet of the barrel Die, feed material into the barrel, install the plunger rod to pressurize and plasticize;

[0014] Step 2. Use the base (d) and the open top sleeve to install the temperature sensor into the outer hexagonal die holder (b) and press it tightly. Use a wrench to ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com