Novel solid phase change cold storage agent for cold chain transportation at temperature of 2-8 DEG C and preparing method and application of novel solid phase change cold storage agent

A solid-state phase change, cold chain transportation technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of corrosiveness of inorganic cold storage agents, ultra-low temperature and low temperature of transported goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

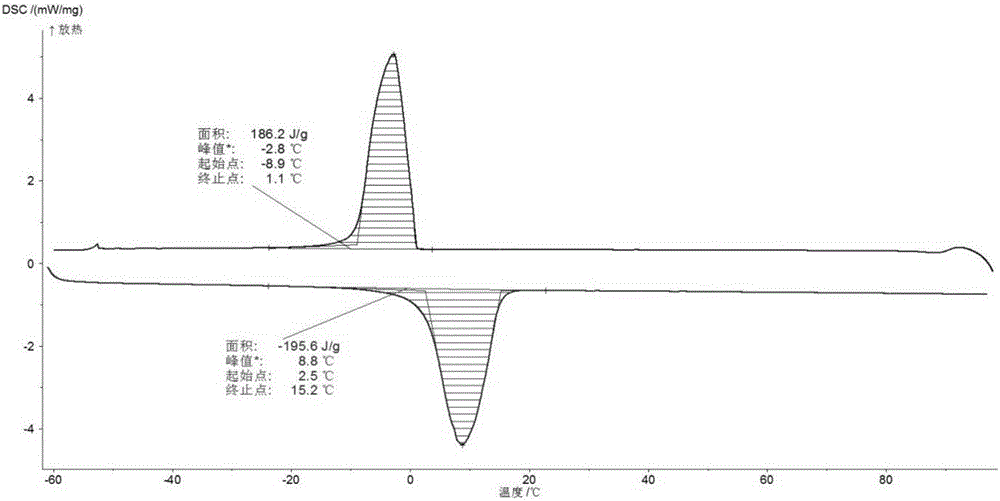

Embodiment 1

[0026] A solid phase change cold storage agent is prepared by the following method:

[0027] (1) Heat the single-layer glass reactor to about 50°C; weigh 724.8g of n-tetradecane and pour it into the reactor, heat and stir until the temperature in the reactor reaches 80°C;

[0028] (2) Weigh the thermoplastic elastomer YH-501 32g of Baling Petrochemical and YH-602 38.4g of Baling Petrochemical, pour them into the reaction kettle, and add them while stirring. Among them, YH-501 should be added first, and wait for YH-501 is completely dissolved before adding YH-602;

[0029] (3) Weigh 1.6g of Aidike antioxidant AO-60 and 3.2g of 2112, add them to the reaction kettle, and add while stirring;

[0030] (4) Raise the temperature in the reaction kettle to 90°C, and stir for 30 minutes while soaking; continue to raise the temperature to 100°C, decompress the reaction kettle through a circulating water vacuum pump, and remove the bubbles in the process of stirring and dissolving;

[0...

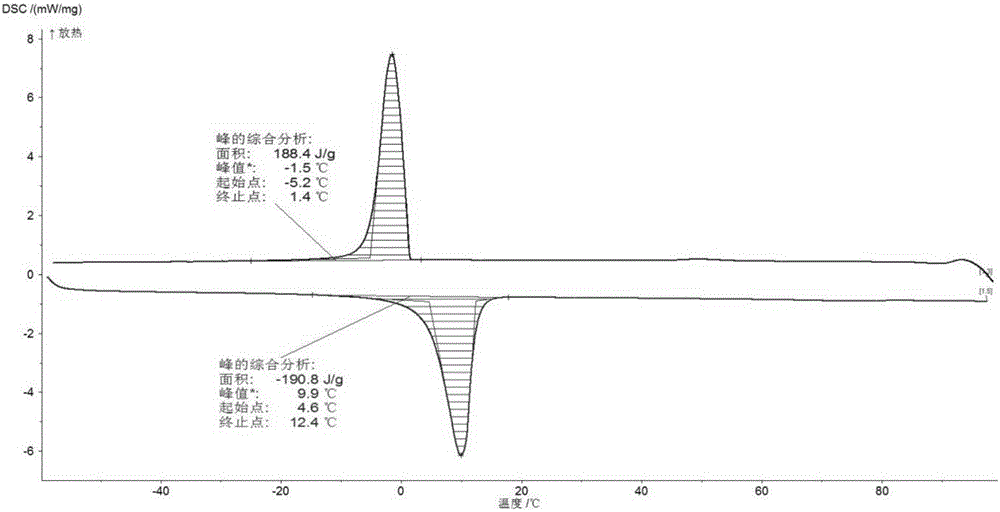

Embodiment 2

[0034] A novel solid-state phase-change cold storage agent is prepared by the following method:

[0035] (1) Heat the single-layer glass reactor to about 50°C; weigh 689.6g of n-tetradecane into the reactor, heat and stir until the temperature in the reactor reaches 80°C;

[0036] (2) Weigh the thermoplastic elastomer YH-501 48g of Baling Petrochemical and YH-602 57.6g of Baling Petrochemical, pour them into the reaction kettle, and add them while stirring. Among them, YH-501 should be added first, and wait for YH-501 is completely dissolved before adding YH-602;

[0037] (3) Weigh 1.6g of Aidike antioxidant AO-60 and 3.2g of 2112, add them to the reaction kettle, and add while stirring;

[0038] (4) Raise the temperature in the reactor to 90°C, and stir for 30 minutes while soaking; continue to raise the temperature to 100°C, start dissolving and degassing, decompress the reactor through a circulating water vacuum pump, and remove the stirring and dissolving process. bubble...

Embodiment 3

[0042] A novel solid-state phase-change cold storage agent is prepared by the following method:

[0043] (1) Heat the single-layer glass reactor to about 50°C; weigh 676.2g of n-tetradecane and pour it into the reactor, heat and stir until the temperature in the reactor reaches 80°C;

[0044] (2) Weigh the thermoplastic elastomer YH-501 65g of Baling Petrochemical and YH-602 54g of Baling Petrochemical, pour them into the reaction kettle, and add them while stirring. Among them, YH-501 should be added first, and YH -501 is completely dissolved before adding YH-602;

[0045] (3) Weigh 1.6g of Aidike antioxidant AO-60 and 3.2g of 2112, add them to the reaction kettle, and add while stirring;

[0046] (4) Raise the temperature in the reactor to 90°C, and stir for 30 minutes while soaking; continue to raise the temperature to 100°C, start dissolving and degassing, decompress the reactor through a circulating water vacuum pump, and remove the stirring and dissolving process. bubb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com