Solid-liquid compound-phase variable-speed cooling constant-temperature cup and microwave heating constant-temperature cup

A microwave heating and composite phase technology, applied in the field of thermos cups, can solve the problems of long-term heat preservation, inability to drink directly, temperature reduction, etc., and achieve the effect of good user experience, large latent heat of phase change, and strong thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

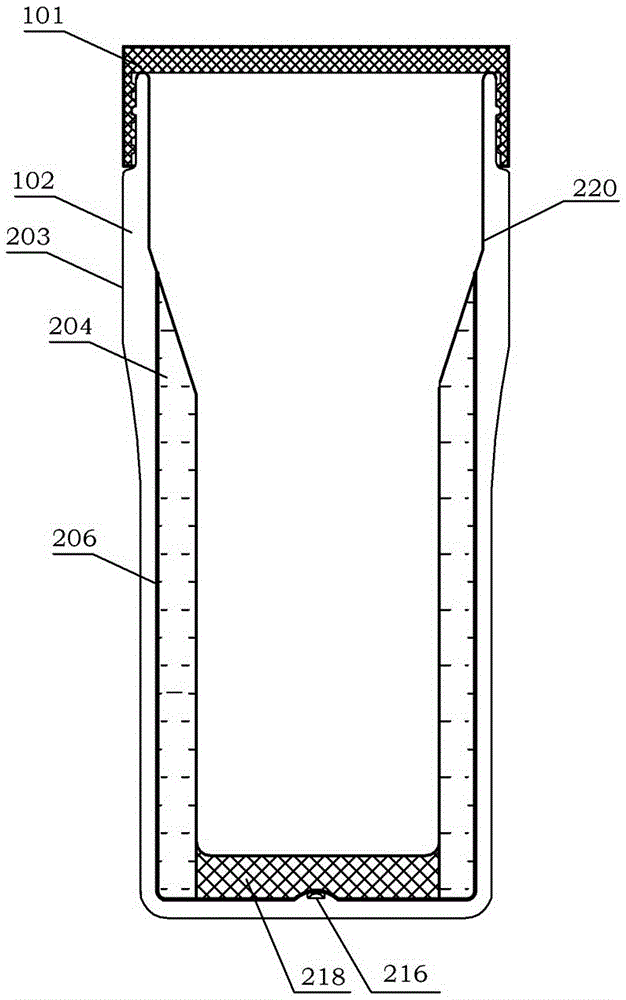

[0023] see figure 1 , the solid-liquid composite phase variable speed cooling constant temperature cup of the present invention includes a cup cover 101 and a cup body 102, the cup cover 101 and the cup body 102 are connected by thread sealing, and the cup body 102 includes an inner cup wall 220, a middle cup Wall 206 and outer cup wall 203, the inner cavity of inner cup wall 220 constitutes a drink volume cavity, and the airtight cavity between inner cup wall 220 and middle cup wall 206 is filled with inorganic hydrate salt composite phase change liquid 204, and the inner cup wall The airtight cavity between the bottom of the 220 and the bottom of the middle cup wall 206 is designed as a phase-change alloy rapid cooling interlayer, and the interlayer is built with a low-melting point phase-change alloy 218 .

[0024] The bottom of the middle cup wall 206 communicates with the phase-change alloy rapid cooling interlayer and is provided with an injection hole and a closing devi...

Embodiment 2

[0026] see figure 1 , the solid-liquid composite phase variable speed cooling constant temperature cup of this embodiment is different from Embodiment 1 in that: the cup lid 101 is designed as a press-open type cup lid; between the inner cup wall 220 and the middle cup wall 206 A temperature sensor is provided in the airtight cavity of the cup body 102, and a temperature display screen is provided on the cup body 102, and the temperature sensor is connected with the temperature display screen. By measuring the temperature of the inorganic hydrated salt composite phase change liquid 204, the temperature of the drink in the cup is indirectly displayed.

Embodiment 3

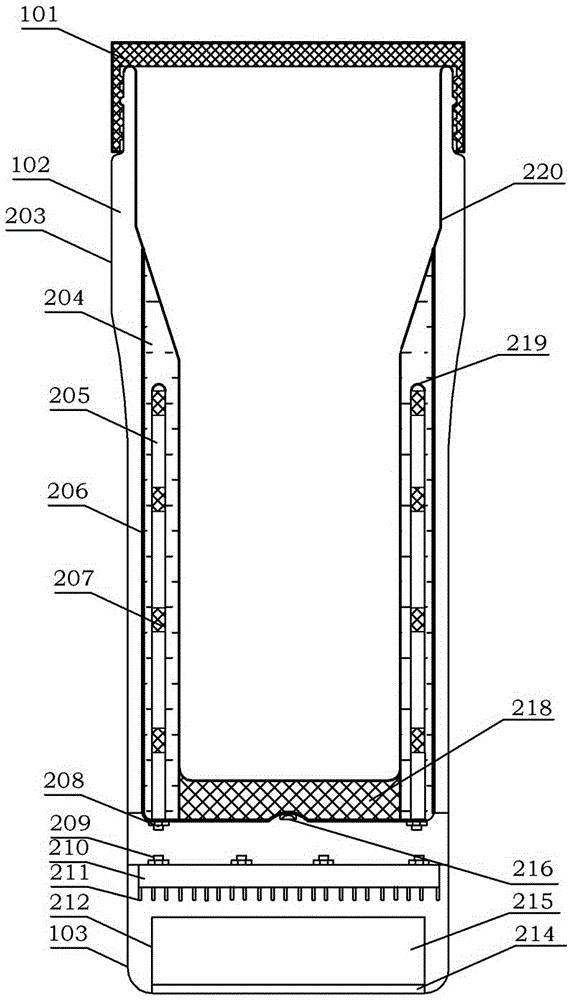

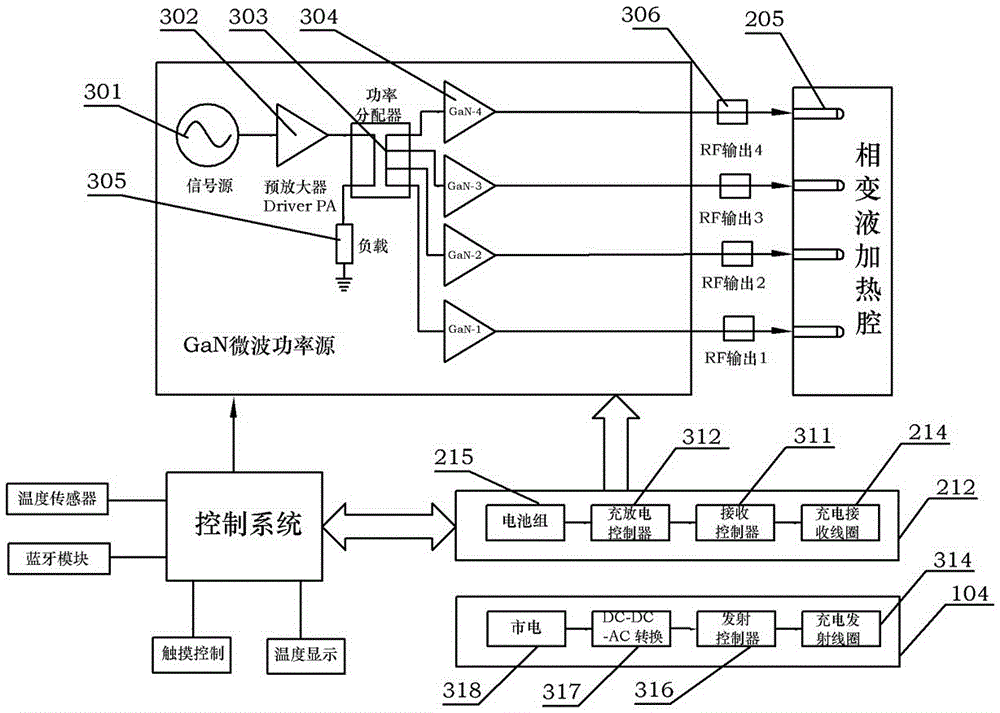

[0028] see figure 2 In this embodiment, the solid-liquid composite phase variable speed cooling microwave heating constant temperature cup includes a cup cover 101, a cup body 102, and a cup holder 103. The cup cover 101 is sealed and connected to the cup body 102, and the cup body 102 includes an inner cup wall. 220, the middle cup wall 206 and the outer cup wall 203, the inner cavity of the inner cup wall 220 constitutes a beverage volume cavity, and the airtight cavity between the inner cup wall 220 and the middle cup wall 206 is filled with an inorganic hydrated salt composite phase transition The liquid 204 constitutes a phase-change liquid heating chamber, and one or more distributed rod-shaped microwave antennas 205 are arranged in the phase-change liquid heating chamber, and a temperature sensor for measuring the temperature of the phase-change liquid is arranged on the top of the rod-shaped microwave antenna 205 219, a solid-state microwave power source 210, a power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com