Patents

Literature

78results about How to "Large latent heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy-saving temperature-control phase-change material

InactiveCN102827588ARaw materials are easy to getLarge latent heatScarvesHead-scarvesMaterials scienceWater of crystallization

The invention relates to an energy-saving temperature-control phase-change material. The energy-saving temperature-control phase-change material is characterized by comprising compositions in percentage by weight: 50-90% of phase-change host, 1-40% melting point control agent, 0.1-10% nucleating agent, 5-15% of crystal modifier and the balance of water. Crystallized hydrated salt phase-change material has the advantages that raw materials are easily available, the price is low, the energy density is large and the like, and the defects of being supercooling, carrying out phase separating, blocking and the like also seriously hinders the popularization and application. The phase-change host is of crystallized hydrated salt, has fixed melting point, the phase-change temperature is regulated through adding the melting point control agent so as to be capable of completing meeting the requirement of normal application. The phase-change crystal particles are fine through adding the crystal modifier, phase separation can also be prevented, attenuation is slowed down, the stability of the phase-change materials is improved, and the service life of the product is prolonged.

Owner:杨宁

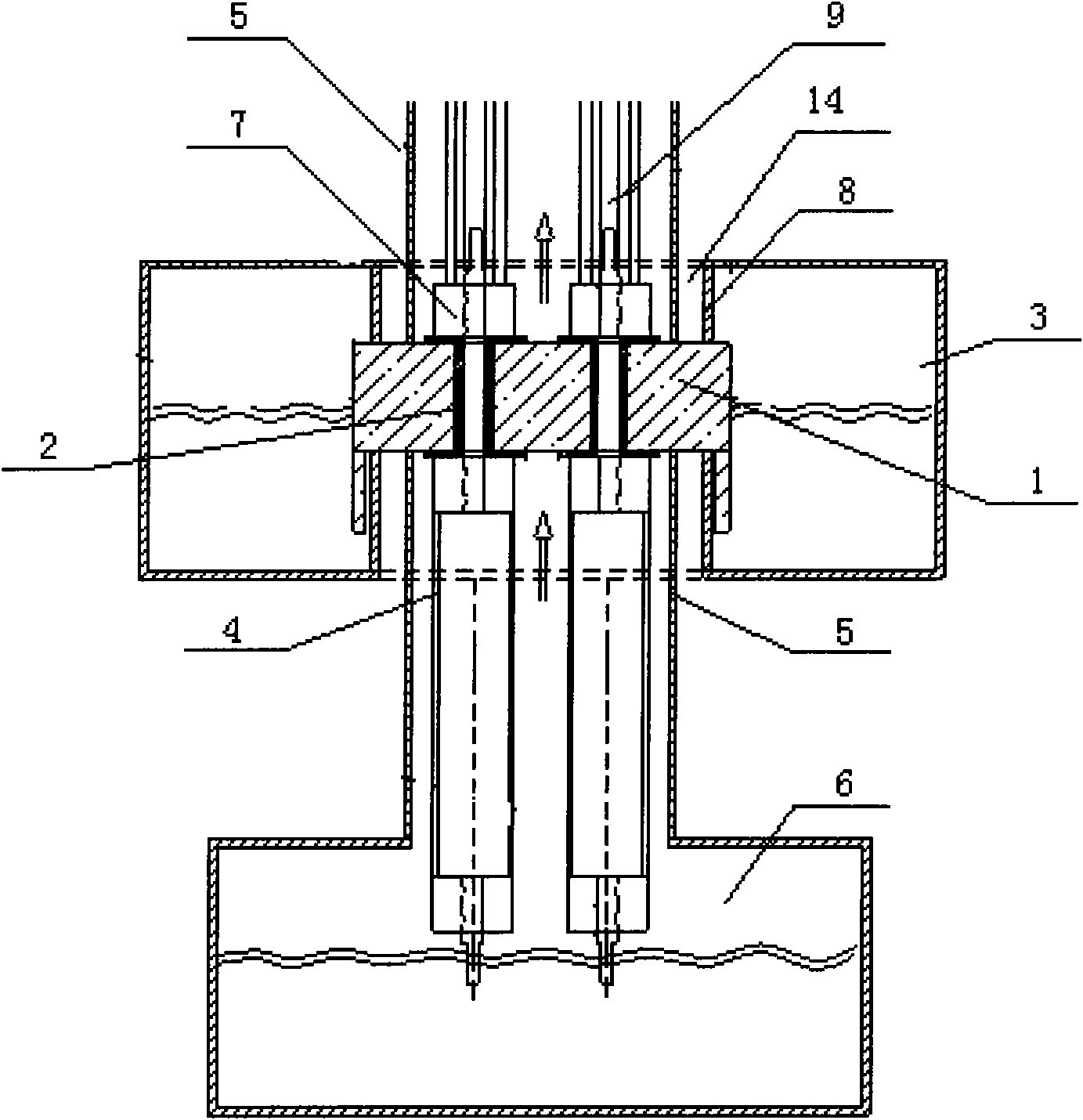

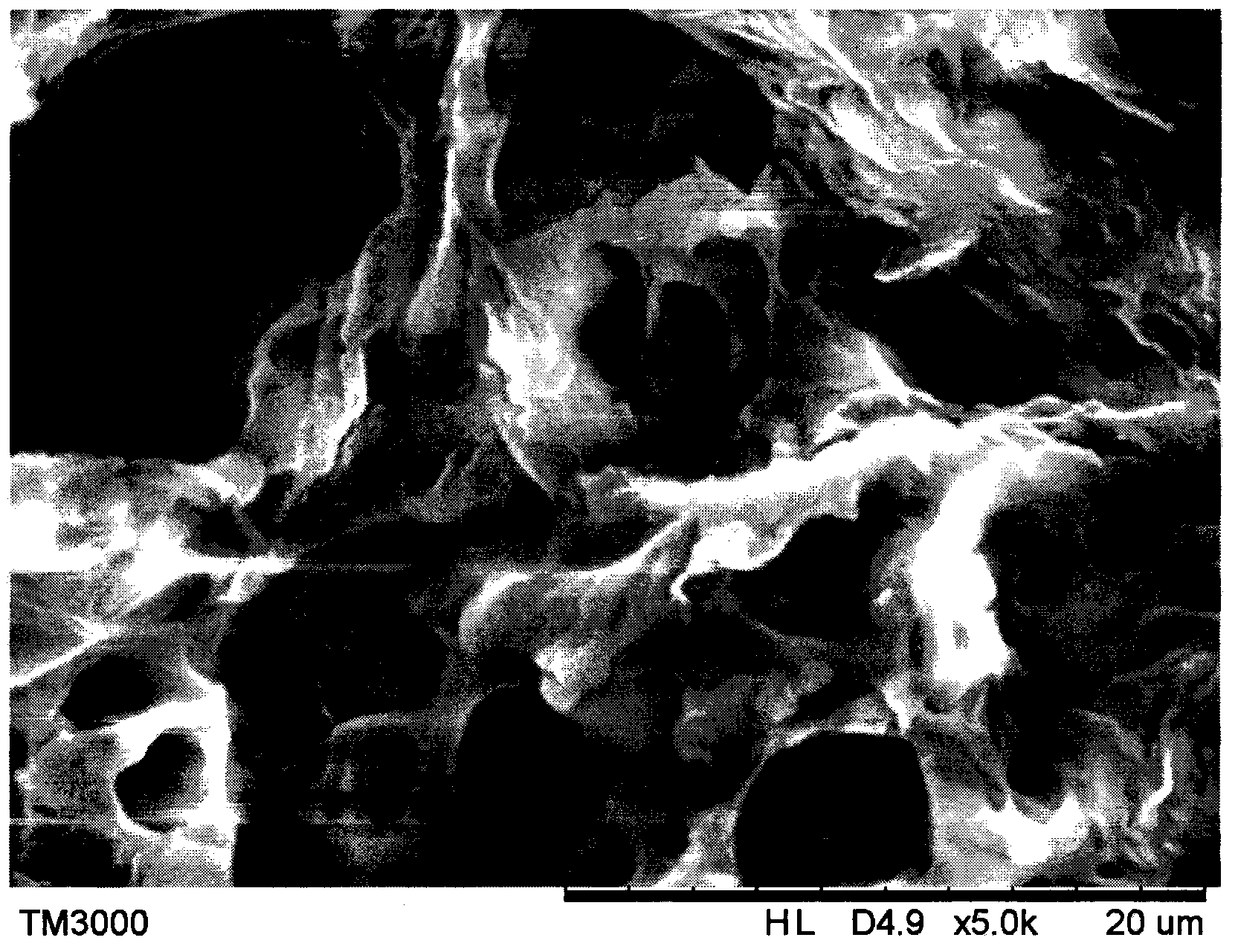

Packaging shape-stabilizing method of inorganic hydrated salt phase-change heat storage material

InactiveCN104371658AImprove thermal conductivitySimple structureHeat-exchange elementsMolten stateHydration reaction

The invention provides a packaging shape-stabilizing method of an inorganic hydrated salt phase-change heat storage material, which comprises the following steps: (1) adding a nucleator and deionized water into the inorganic hydrated salt phase-change material, and heating until the inorganic hydrated salt phase-change material achieves the molten state; (2) adding a porous propping material into the molten-state inorganic hydrated salt phase-change material, and stirring sufficiently and uniformly; (3) putting the molten-state mixture obtained in the step (2) in a vacuum environment to enhance the adsorptivity of the porous propping material for the inorganic hydrated salt phase-change material; and (4) moving the molten-state mixture out of the vacuum environment, and immediately putting the molten-state mixture into a low-temperature environment suitable for crystallization to perform recrystallization. The composite shape-stabilized phase-change material obtained by the method has the advantages of stable structure, high latent heat, no toxicity, simple preparation process, short time consumption and low cost.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Composite phase-change material for mobile heat supply and preparation method thereof

ActiveCN103113854ANo precipitationFast heat storage and releaseChemical industryHeat-exchange elementsMolten stateMass ratio

The invention discloses a composite phase-change material for mobile heat supply and a preparation method thereof. The composite phase-change material is formed by compounding 97.5-99.5 wt% of mixed inorganic salts and 0.5-2.5 wt% of non-metal nano material. The preparation method comprises the following steps: mixing a plurality of inorganic salts according to mass ratio, stirring, adding into a vacuum heating furnace, and heating into a molten state, wherein the temperature of the vacuum heating furnace is controlled at 40-50 DEG C higher than the phase-change temperature of the mixed inorganic salts; and adding the non-metal nano material into the molten salts, and magnetically stirring for more than half an hour to prepare the uniform and stable molten-state composite phase-change material. Compared with the prior art, the composite phase-change material disclosed by the invention has the advantages of high heat-conducting property, high heat accumulation density, small volume shrinkage and the like, can satisfy different application requirements, and is especially suitable for moderate-temperature waste heat recovery.

Owner:QINGDAO AOHUAN NEW ENERGY GRP CO LTD

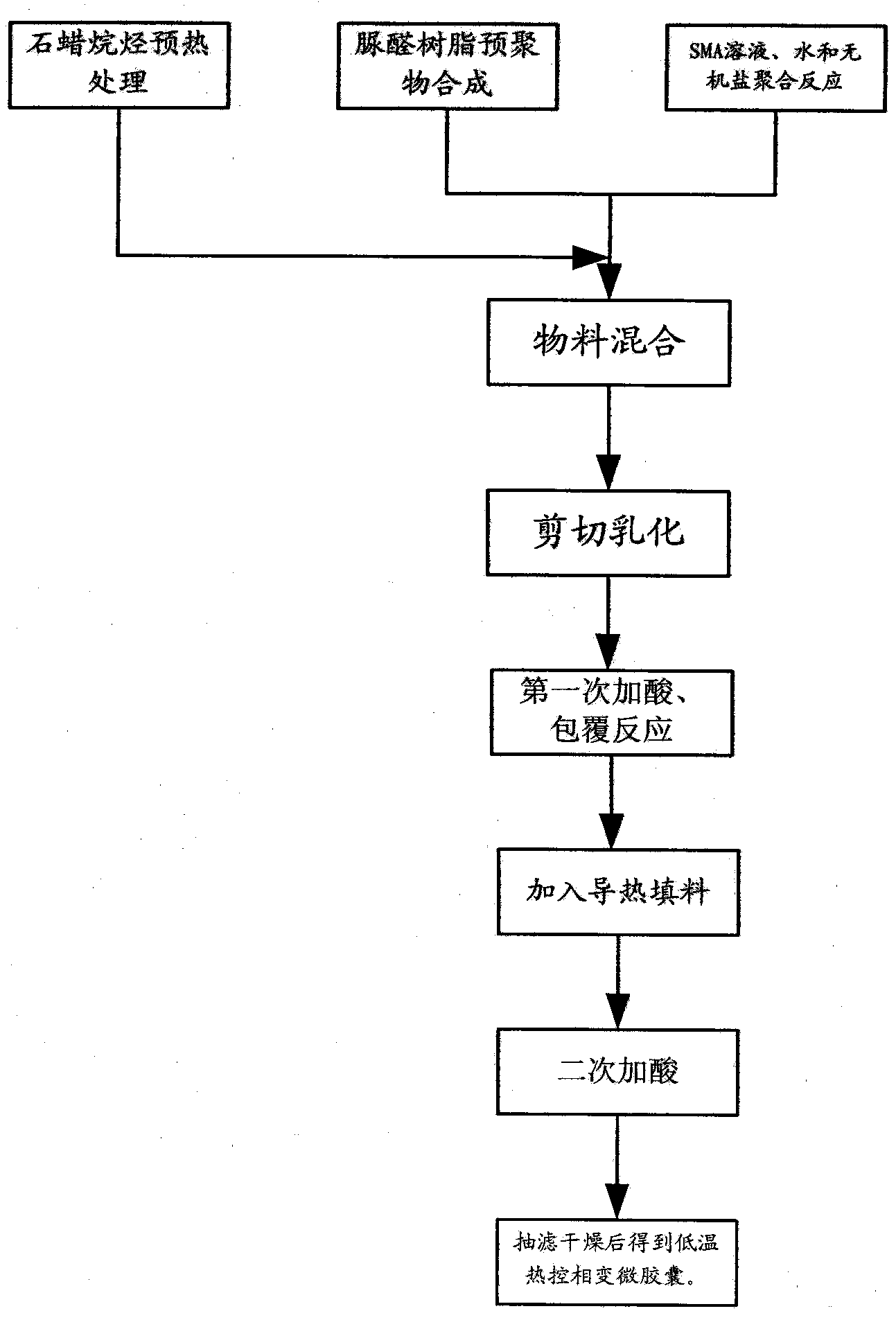

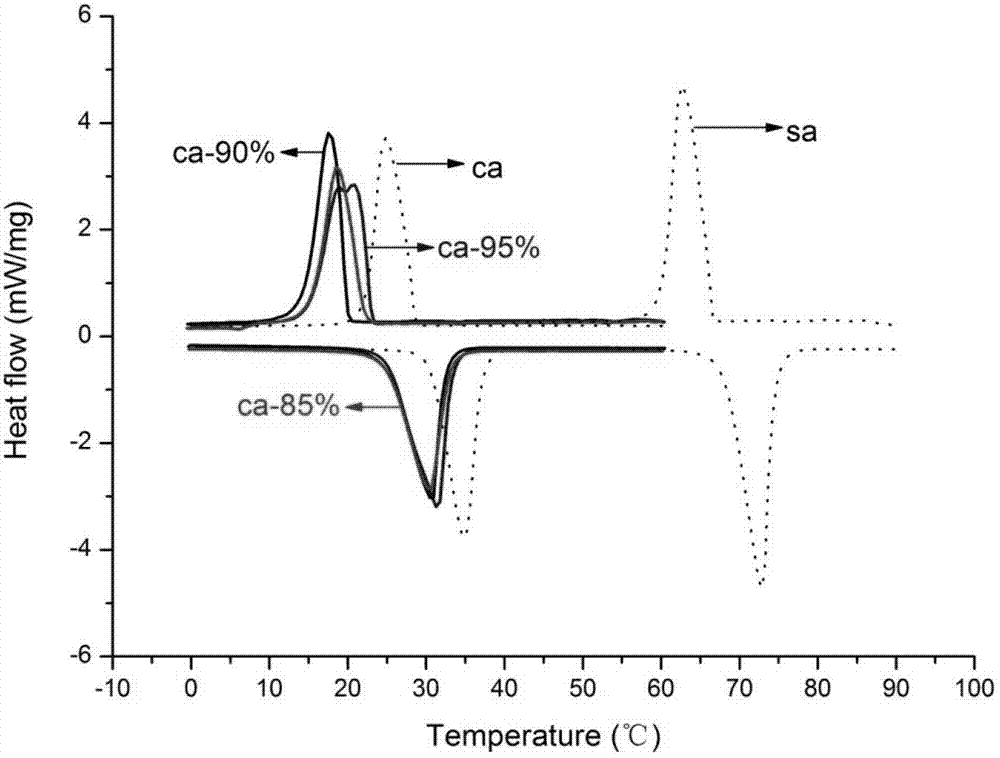

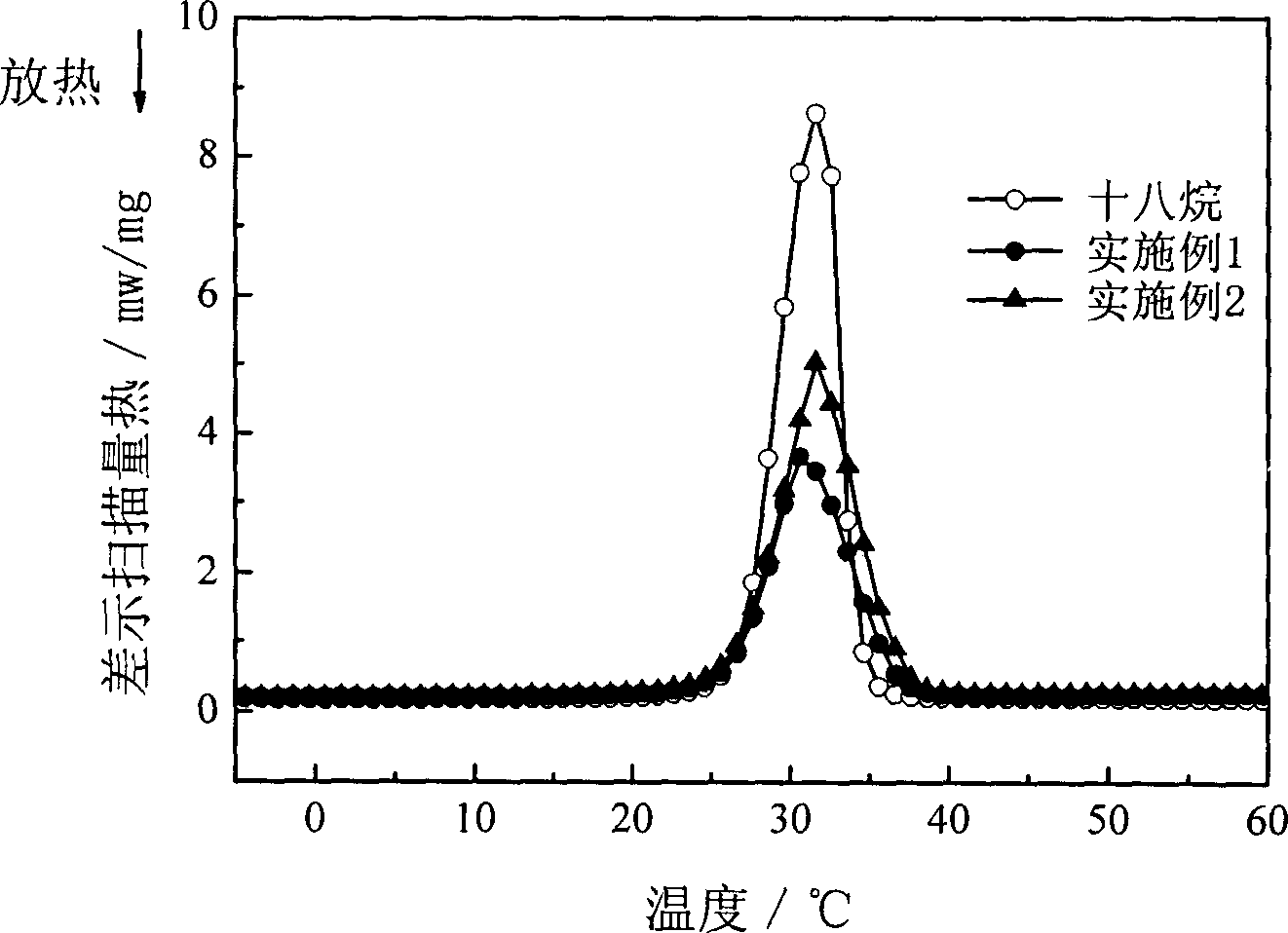

Low-temperature thermal control phase change microcapsule and preparation method thereof

ActiveCN104357019AImprove thermal conductivityEvenly dispersedHeat-exchange elementsMicroballoon preparationAlkanePermeation

The invention provides a low-temperature thermal control phase change microcapsule and a preparation method thereof. The low-temperature thermal control phase change microcapsule takes paraffin alkane as a core material and urea resin as a shell, and further comprises a heat conduction filler, the heat conduction filler is added in the process of coating the paraffin alkane by the urea resin, and the amount of the added heat conduction filler is 5%-30% that of the paraffin alkane. The low-temperature thermal control phase change microcapsule prepared by the invention is solid-solid phase change, the problems of fusion flowing and permeation migration are avoided, the range of phase change temperature is wide, the latent heat is large, the condensate depression is small, the phase change process is stable, the phase change is reversible, the material further has a higher heat conduction property, and as a relatively ideal thermal control phase change material, the low-temperature thermal control phase change microcapsule can be widely used in the fields of thermal protection, like aerospace, precise instruments, and electron devices.

Owner:海鹰空天材料研究院(苏州)有限责任公司

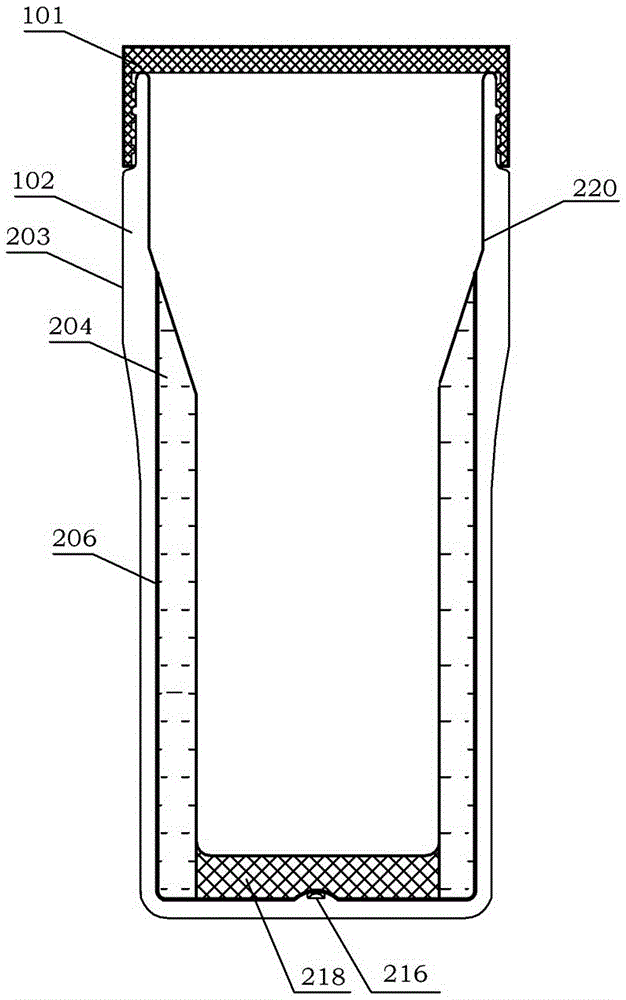

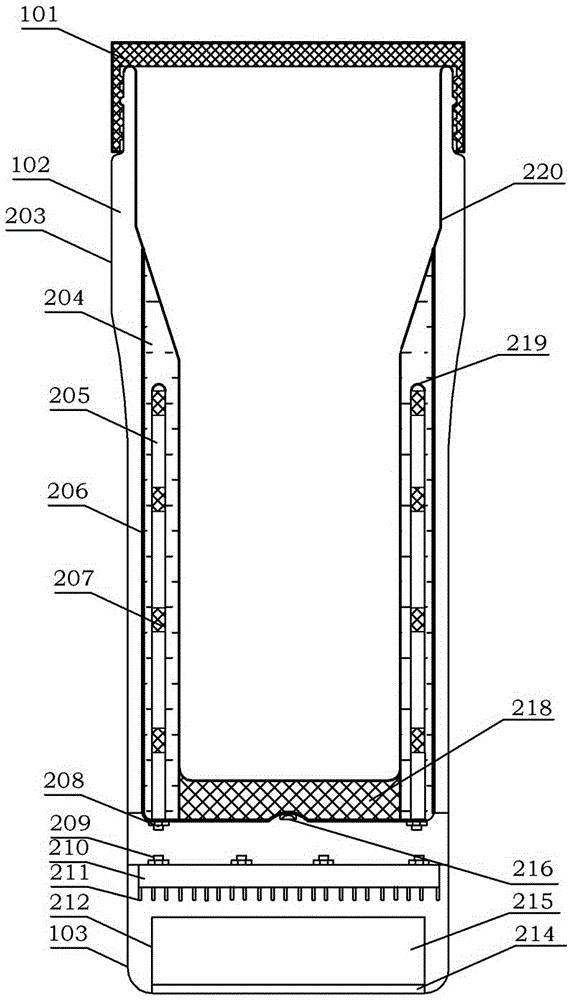

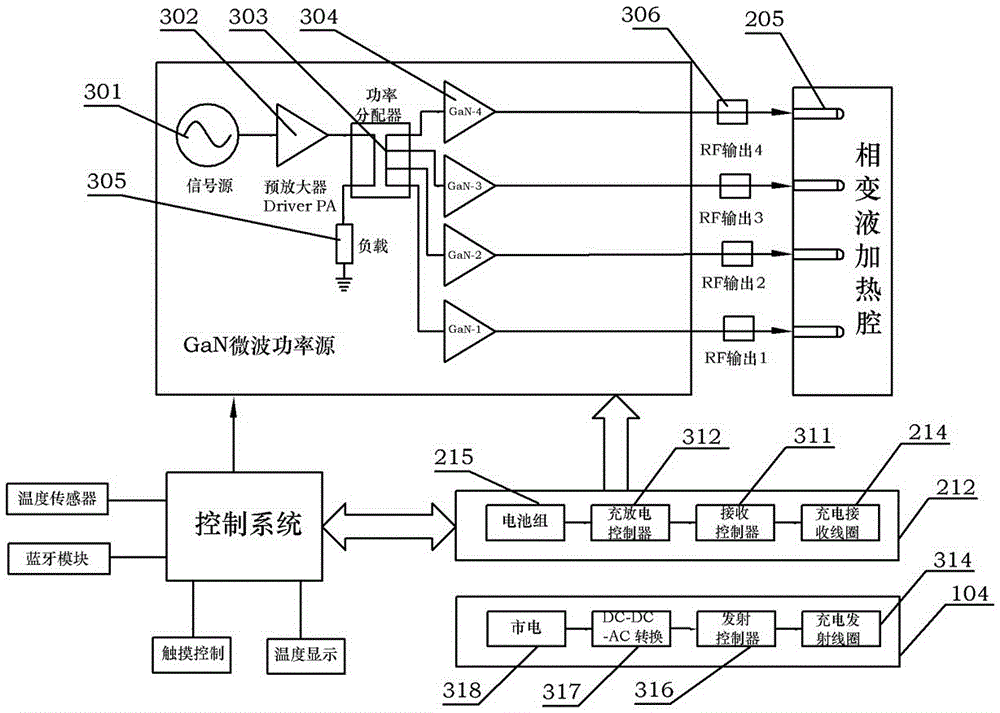

Solid-liquid compound-phase variable-speed cooling constant-temperature cup and microwave heating constant-temperature cup

ActiveCN106361101AEasy to useLarge latent heat of phase changeDwelling equipmentWarming devicesSolid-stateInternal cavity

The invention relates to a daily used vacuum cup, in particular to a compound-phase variable-speed cooling constant-temperature cup. The solid-liquid compound-phase variable-speed cooling constant-temperature cup comprises a cup lid and a cup body, wherein the cup lid is in sealed connection with the cup body, the cup body comprises an inner cup wall, a middle cup wall and an outer cup wall, the internal cavity of the inner cup wall forms a beverage containing cavity, the airtight cavity between the inner cup wall and the middle cup wall is filled with inorganic hydrous salt compound phase change liquid, the airtight cavity between the bottom of the inner cup wall and the bottom of the middle cup wall is designed into a phase change alloy rapid-cooling interlayer, and the phase change alloy rapid-cooling interlayer is provided with built-in low-melting-point phase change alloy. In a solid-liquid compound-phase variable-speed cooling microwave heating constant-temperature cup, the airtight cavity between the inner cup wall and the middle cup wall is filled with inorganic hydrous salt compound phase change liquid to form a phase change liquid heating cavity, one or more distributed rod-like microwave antennae are arranged in the phase change liquid heating cavity, and a solid-state microwave power source, a power supply part and a control system are arranged in a cup base.

Owner:陈鹏

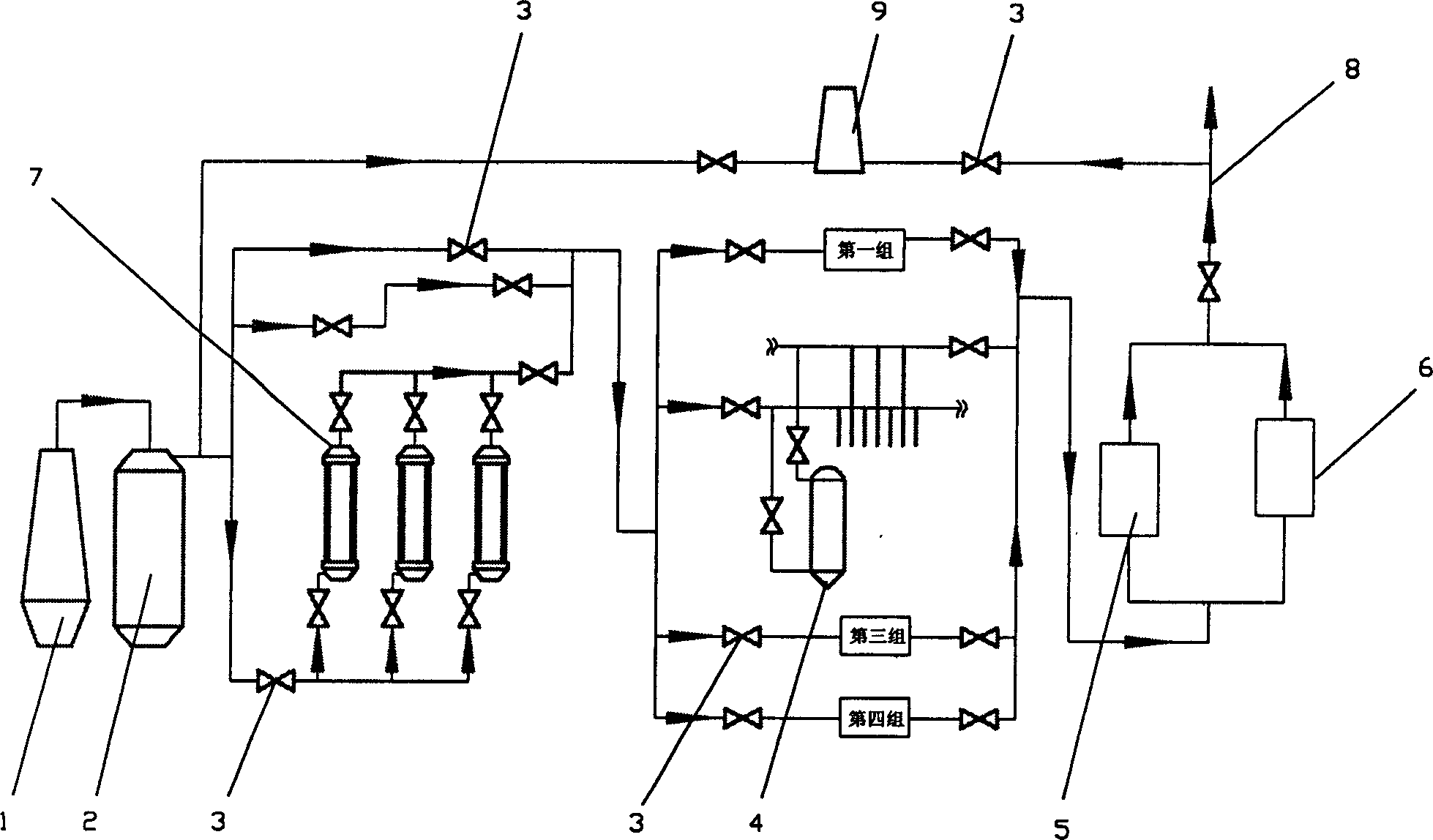

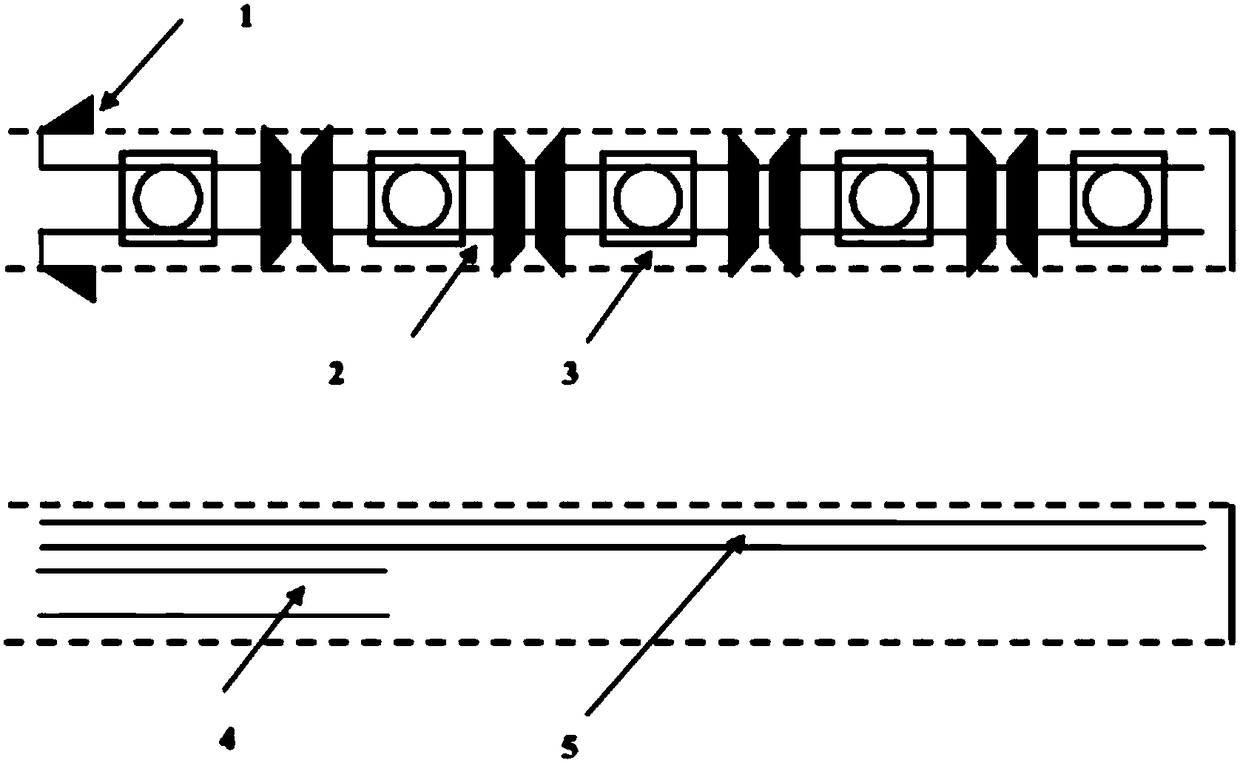

Gas totally-drying purifying dust-collecting process of blast-furnace

InactiveCN1818080AAchieve coke savingsRealize water savingCombination devicesBlast furnace detailsBaghouseProcess engineering

The invention is about the blast furnace gas oven-dry decontamination dedusting technology. The dust-laden gas enter the gravity dust separator firstly, then enter the every dedusting subsystem pipes through the main pipe, next to enter the every bag-type dust collector to remove the dust precisely, then the cleaning gas enter the system purified gas pipe to enter the supplying purified gas pipe net through the dry-type turbine or the reducing valve. The bag-type dust collector system includes at least more than three dedusting subsystems which include at least more than five dedusting boxes, and the shutoff device is installed in the gas pipe. The invention achieves the blast furnace gas oven-dry bag-type dedusting, so it can increase the gas latent heat and the electric power generation ratio.

Owner:SGIS SONGSHAN CO LTD

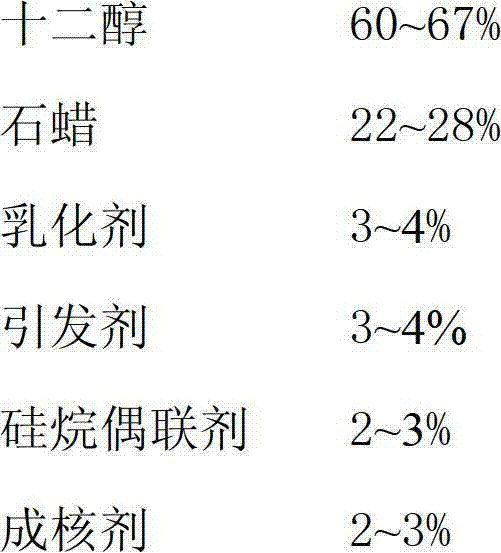

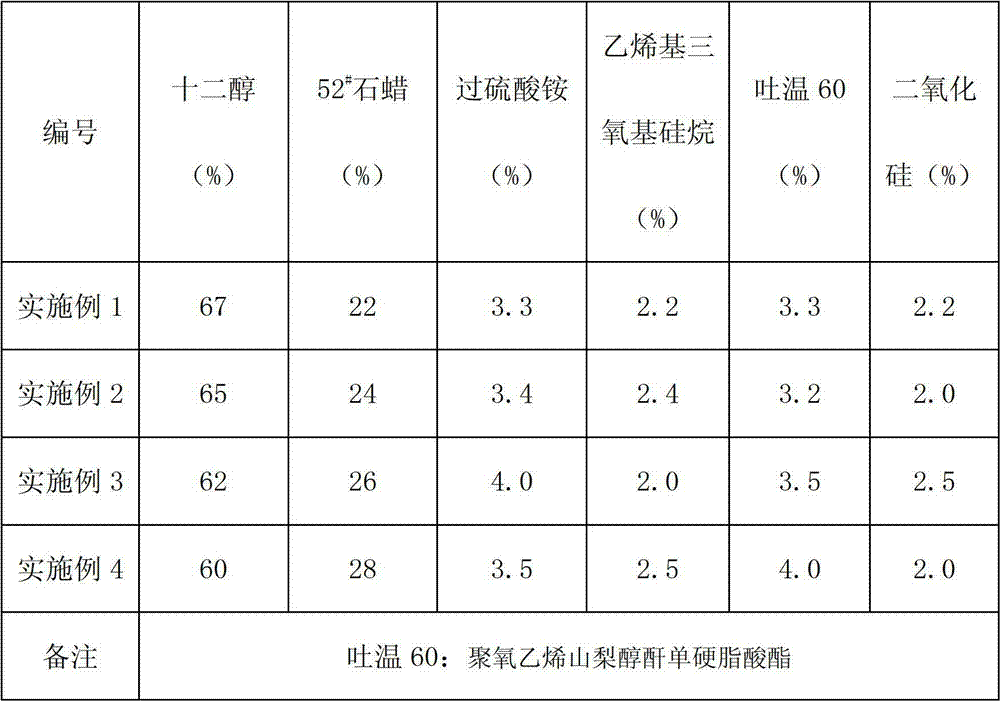

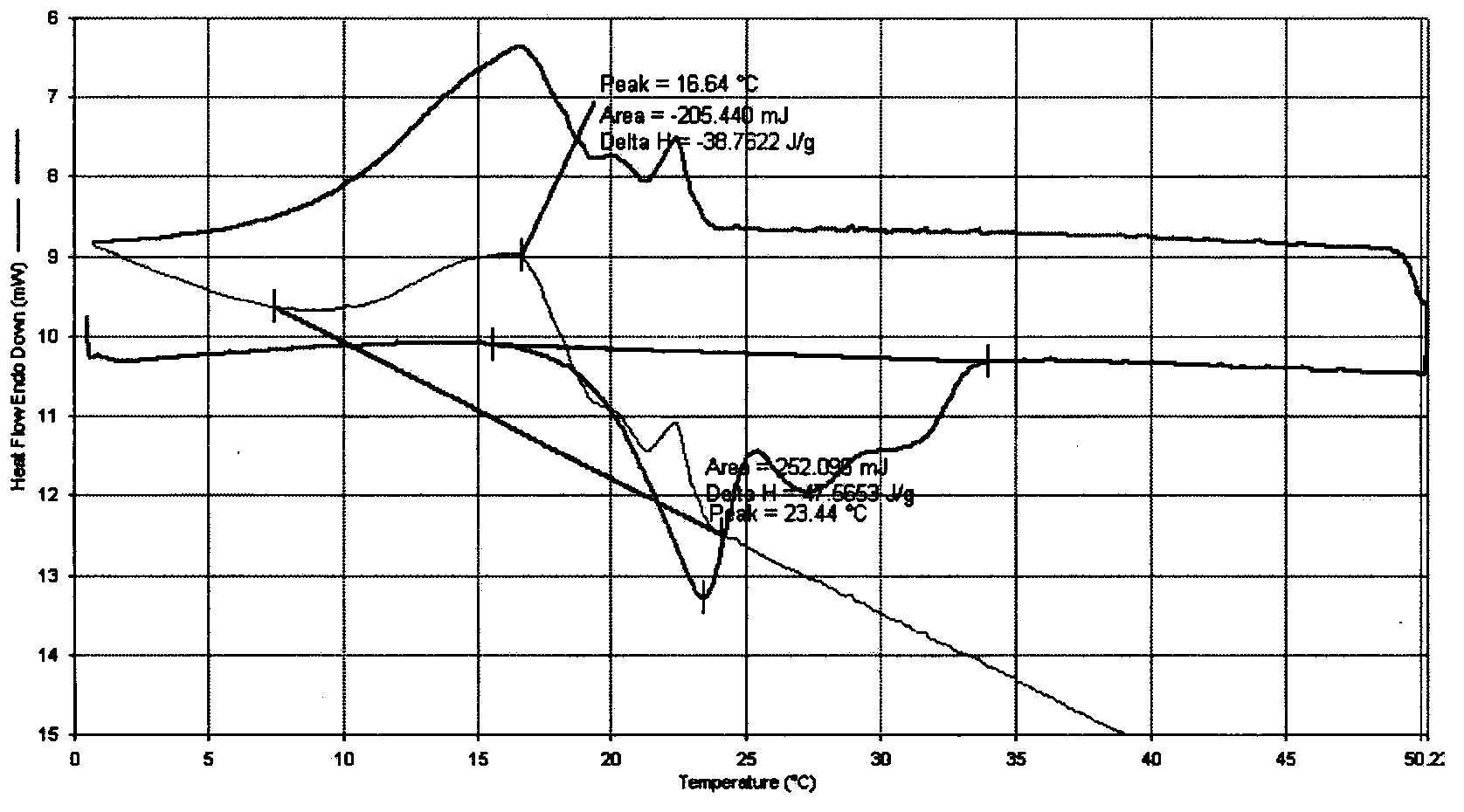

Constant-temperature phase change energy storage material

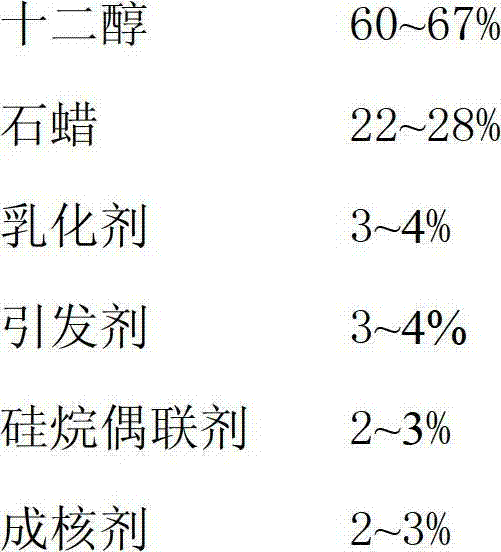

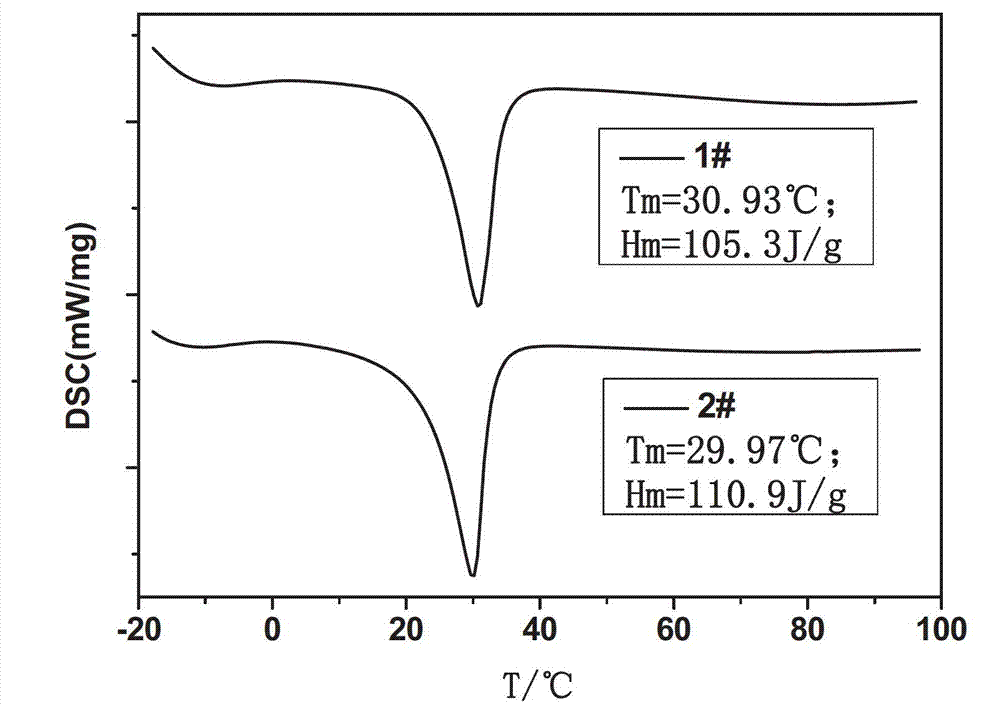

ActiveCN102732228AReduce subcoolingLarge latent heatHeat-exchange elementsBuilding constructionsCarbon chainPhase change temperature

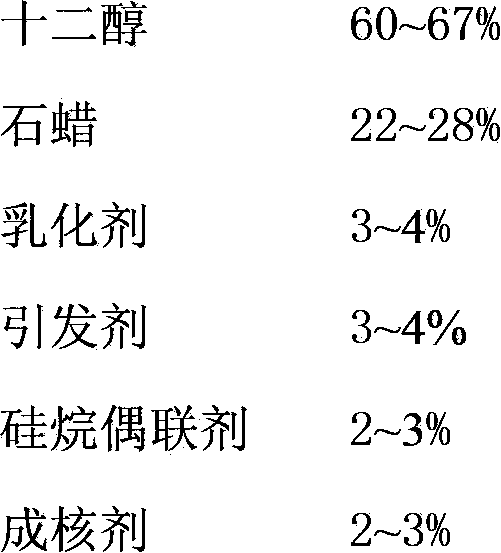

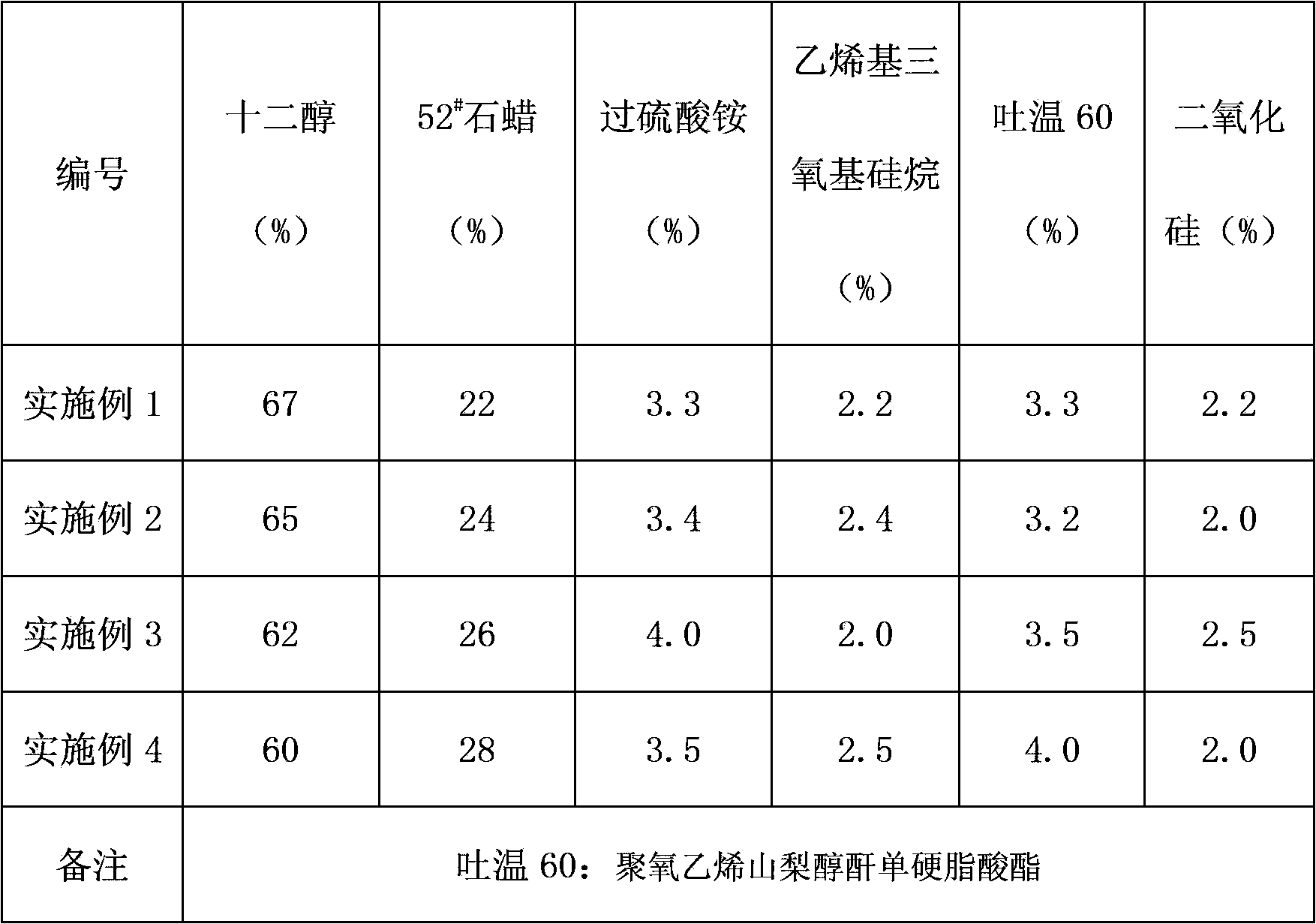

The invention provides a phase change energy storage material which has the characteristics of phase change temperature of 25-28 DEG C, great potential heat, small super-cooling degree and high stability. The phase change energy storage material is at a solid state at the temperature which is lower than 25-28 DEG C; when the temperature is higher than 25-28 DEG C, the potential heat is absorbed to carry out phase change to be changed into a liquid state. Dodecanol and paraffin are used as main raw materials, and a cross-linking agent, an initiator, an emulsifying agent and a nucleating agent are used as auxiliary materials, the main raw materials are reacted with the auxiliary materials, and then carbon chain recombination happens under the effect of the initiator, a silane coupling agent, the emulsifying agent and the like to prepare the product. The phase change temperature is 25-28 DEG C and the phase change potential heat is 156-163 KJ / Kg. The phase change energy storage material has the characteristics that the phase change temperature is the room temperature, the potential heat is high and the raw materials are wide and cheap; the material is not layered and has no sediments after being repeatedly subjected to the phase change for a plurality of times; and the potential heat value is stable and the super-cooling degree is less than 1 DEG C. After the material is packaged, the material can be combined with a building wall body and the property of absorbing the potential heat enables the wall body to have the function of adjusting the temperature.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

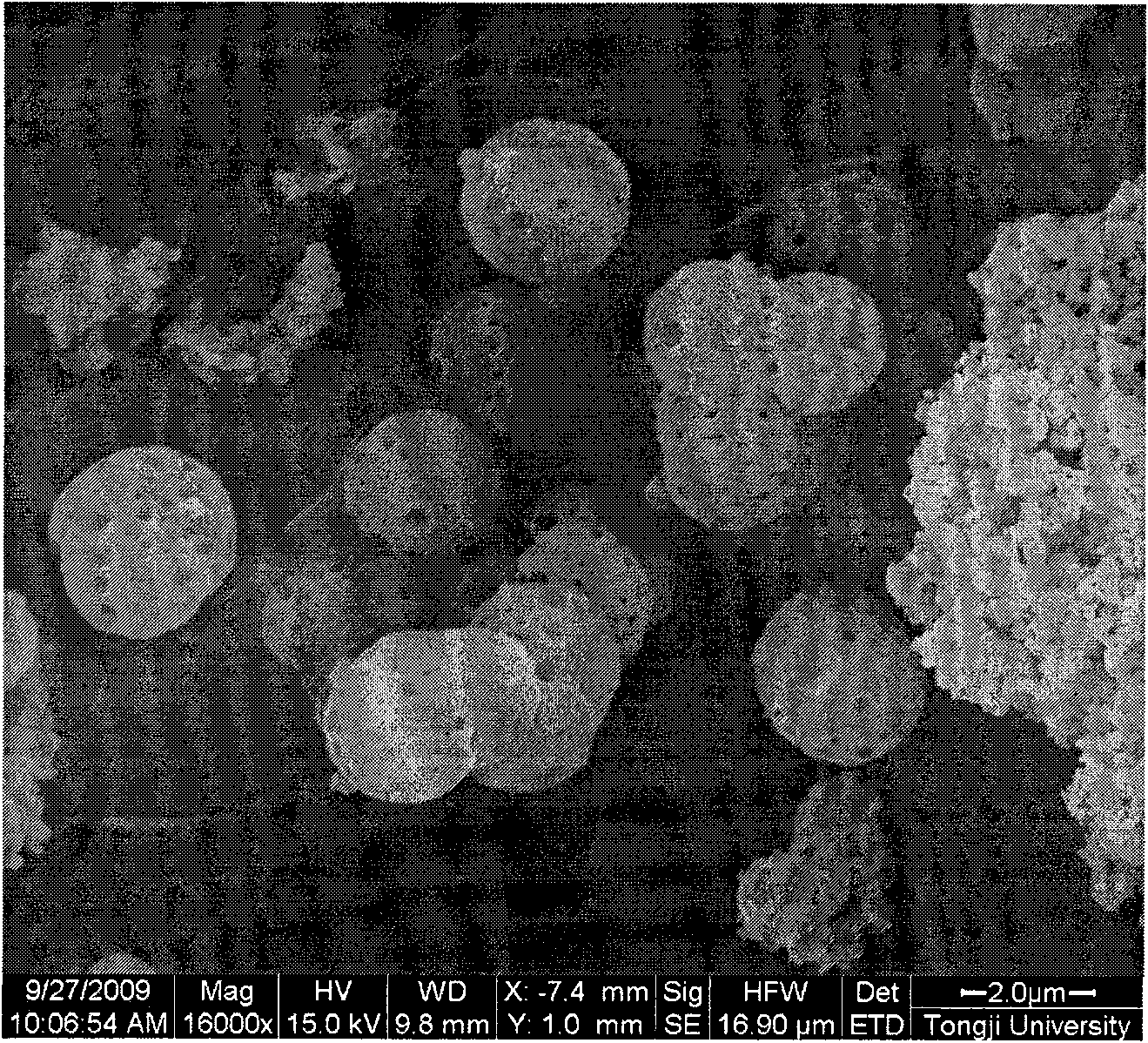

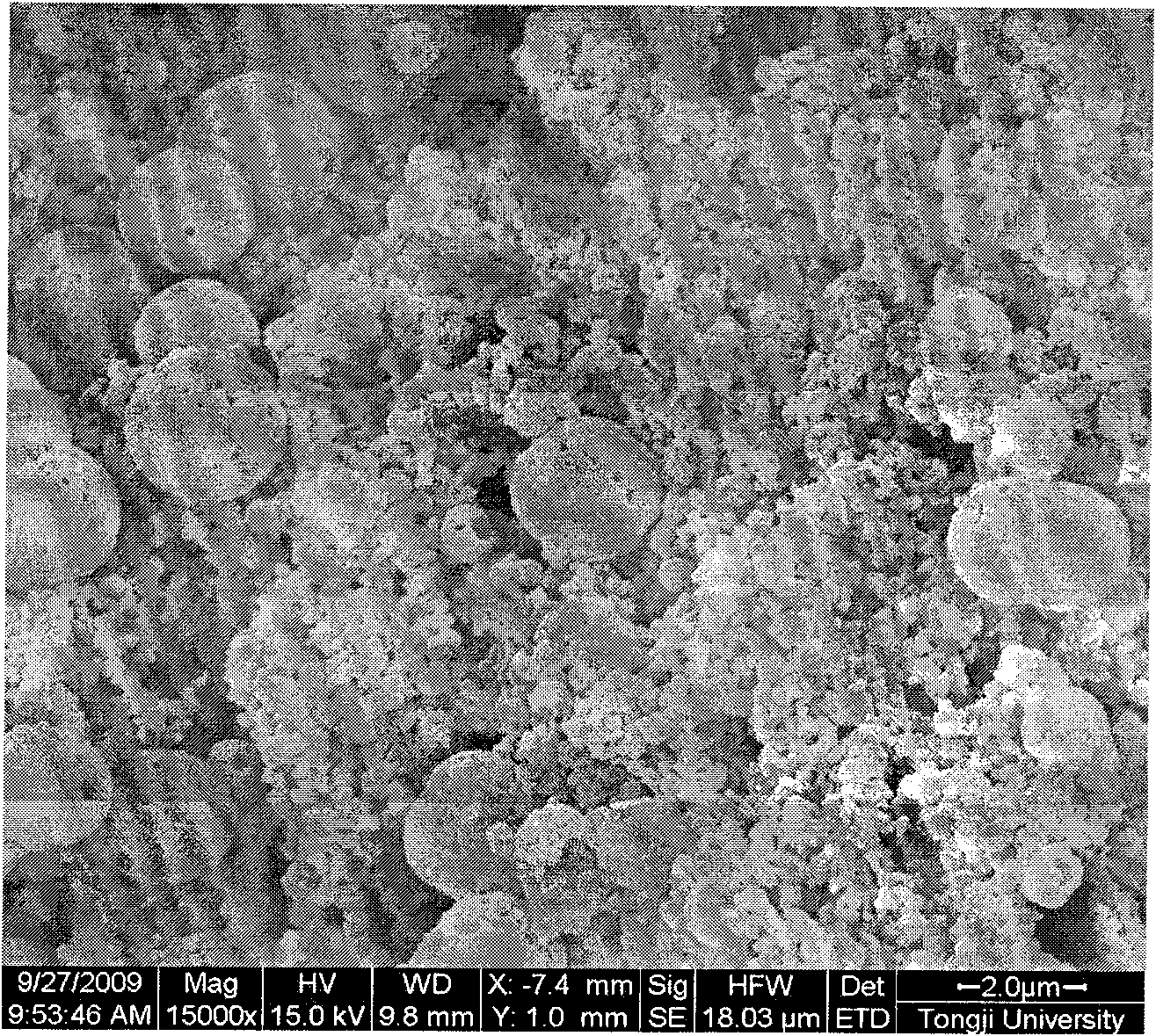

High-thermal-conductivity composite phase change energy storage microcapsules used at normal temperature and preparation method thereof

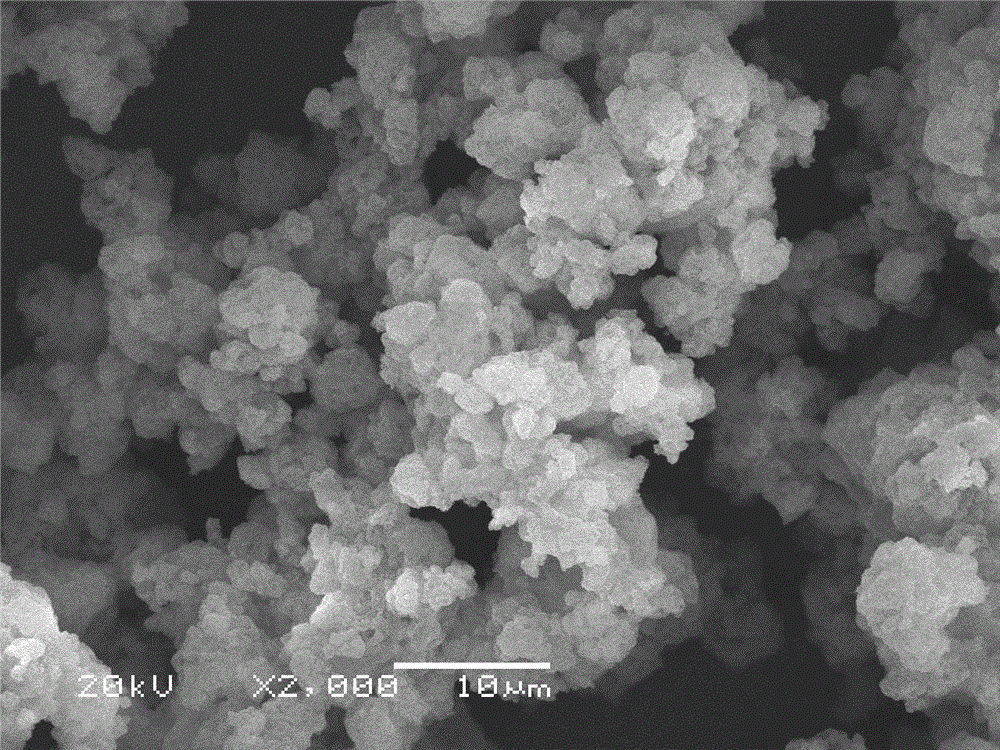

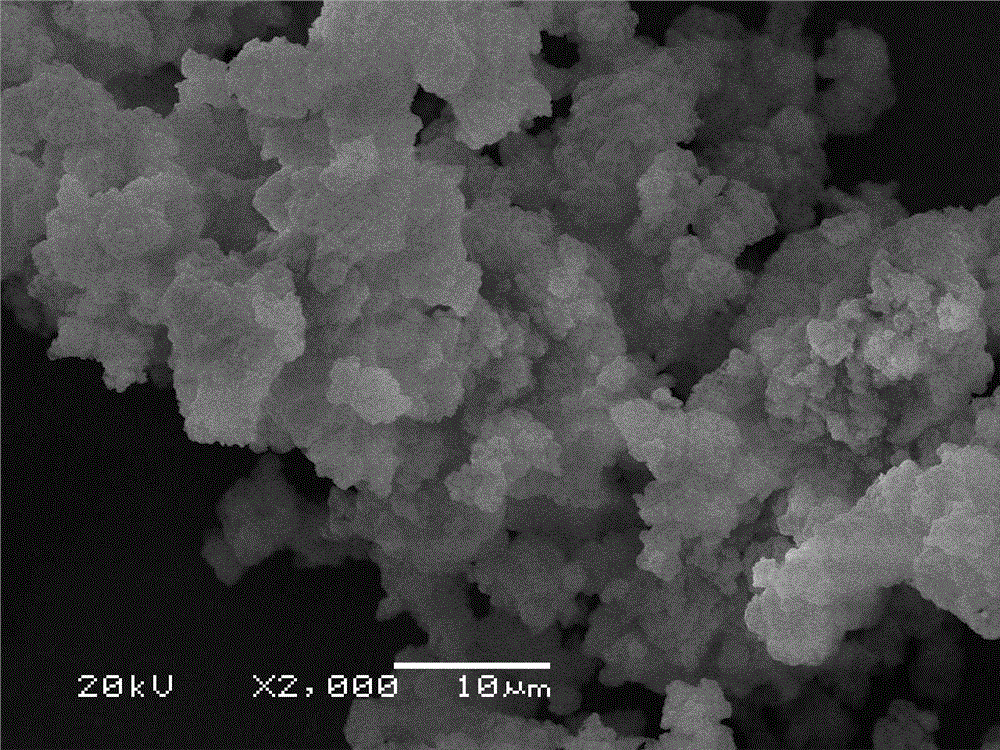

InactiveCN103031114ALarge latent heatGood energy storageHeat-exchange elementsMicroballoon preparationAlkaneMedical equipment

The invention relates to high-thermal-conductivity composite phase change energy storage microcapsules used at normal temperature and a preparation method thereof. The high-thermal-conductivity composite phase change energy storage microcapsules comprise organic phase change capsule cores and inorganic high-thermal-conductivity capsule walls, wherein the organic phase change capsule cores are prepared from two or more than two of alkane, fatty acids, polyether and derivatives of the polyether. The preparation method comprises the steps of: (1) preparing a capsule core material with an adjustable phase-transition temperature, (2) preparing an O / W (oil-in-water) emulsion; and (3) preparing the phase change energy storage microcapsules: dropwise adding tetraethylortho silicate to the emulsion, stirring for 1-6 hours at a speed of 300-1000rpm, aging and drying, thus obtaining the stable phase change energy storage microcapsules. The high-thermal-conductivity composite phase change energy storage microcapsules have the characteristics of high energy storage, high thermal conductivity, stable performance, designable and adjustable phase change temperature, suitability for various processing and the like and can be popularized and applied in industries such as energy-saving walls of buildings, commodity storage and transportation, medical equipment, food packaging and thermoregulation clothes.

Owner:EAST CHINA UNIV OF SCI & TECH

Hydrocarbon phase change heat storage materials and preparation method using natural acid as raw material

ActiveCN103773315AHigh selectivityReduce dosageHydrocarbonsHeat-exchange elementsAlkaneCarbon number

The invention discloses hydrocarbon phase change heat storage materials and a preparation method using natural acid as a raw material. A natural acid raw material is mixed with a solvent for hydrogenation reaction in the presence of a catalyst and hydrogen to prepare corresponding high-purity even-carbon-number n-alkanes, the even-carbon-number n-alkanes and mixtures thereof are the high-performance hydrocarbon phase change heat storage materials, and the preparation method is particularly applicable to preparing of the hydrocarbon phase change heat storage materials at 36-45 DEG C. Compared with the prior art, the preparation method is simple, and the latent heat of phase change of a product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermal cut-off equipment of high-temperature superconducting binary current lead

InactiveCN101630561ALarge latent heatGood heat sink effectSuperconducting magnets/coilsHigh-temperature superconductivityLiquid nitrogen cooling

The invention discloses thermal cut-off equipment of a high-temperature superconducting binary current lead, which comprises a liquid nitrogen tank and a liquid helium tank, wherein liquid nitrogen and liquid helium are respectively filled in the liquid nitrogen tank and the liquid helium tank. The invention is characterized in that the liquid helium tank is communicated with a current lead neck tube, and a high-temperature superconducting lead is arranged in the current lead neck tube; the middle part of the current lead neck tube is connected with a heat conducting disk which is embedded in a center hole of the liquid nitrogen tank, and the upper end surface and the lower end surface of the heat conducting disk are respectively connected fixedly with the tank wall of the center hole of the liquid nitrogen tank; a plurality of vertical through holes are arranged between the upper end surface and the lower end surface of the heat conducting disk and are respectively used as a current lead channel, a measuring lead channel and a cold helium returning channel; and a plurality of liquid nitrogen cooling tanks are arranged at the cylindrical side surface of the heat conducting disk along the horizontal direction, and the horizontal liquid nitrogen cooling tanks are communicated with the liquid nitrogen tank. The thermal cut-off equipment of the high-temperature superconducting binary current lead performs the characteristics of large potential heat and good heat sink effect in the process of liquid nitrogen cooling to improve the temperature margin of the high-temperature superconducting lead, thereby greatly increasing the operating stability and the security of the high-temperature superconducting lead, and reducing the heat leakage of the current lead, the measuring lead and the current lead neck tube for the liquid helium tank.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

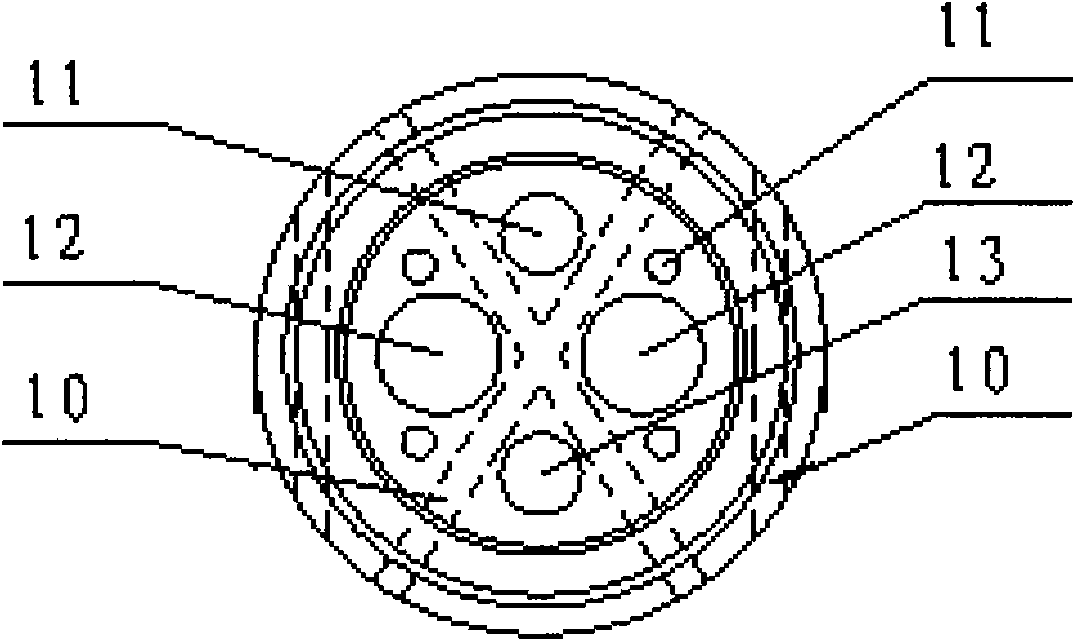

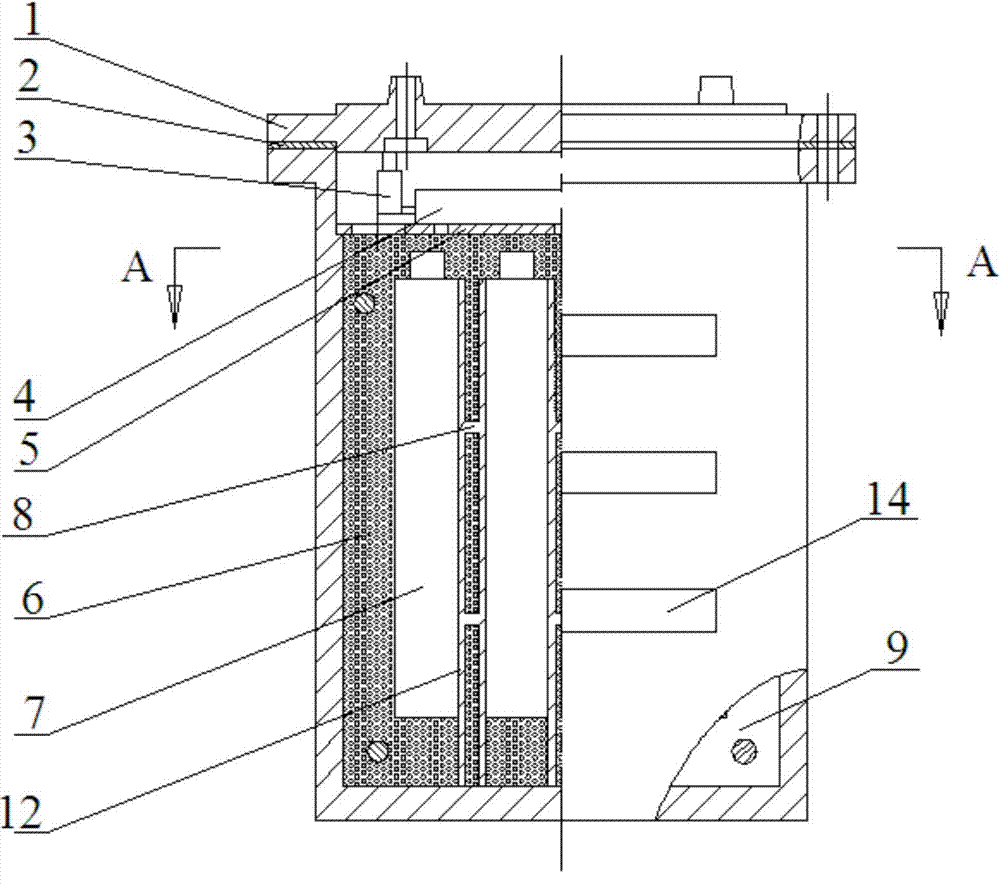

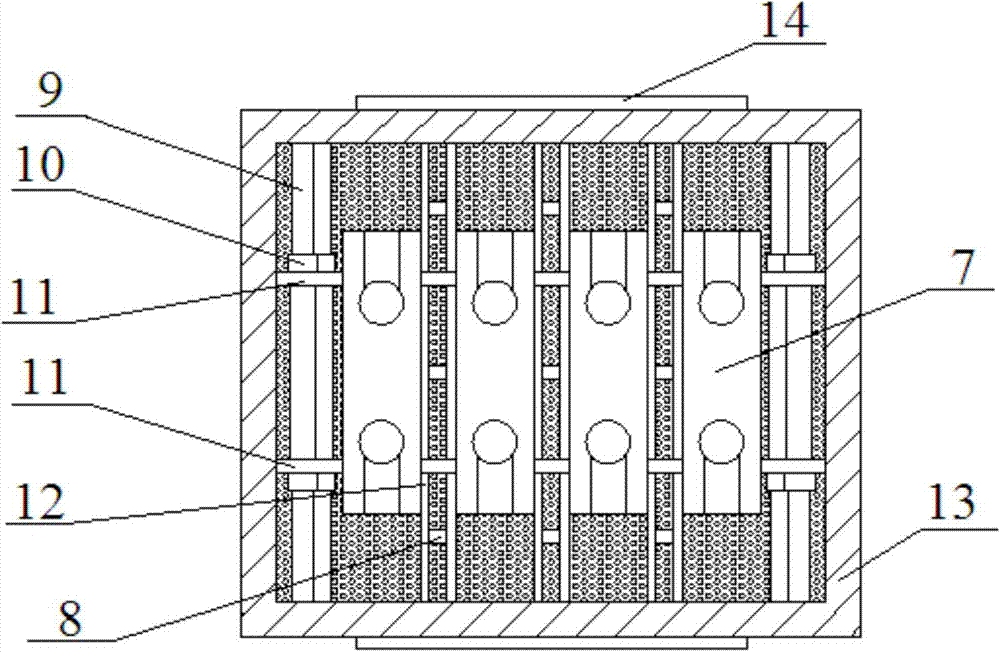

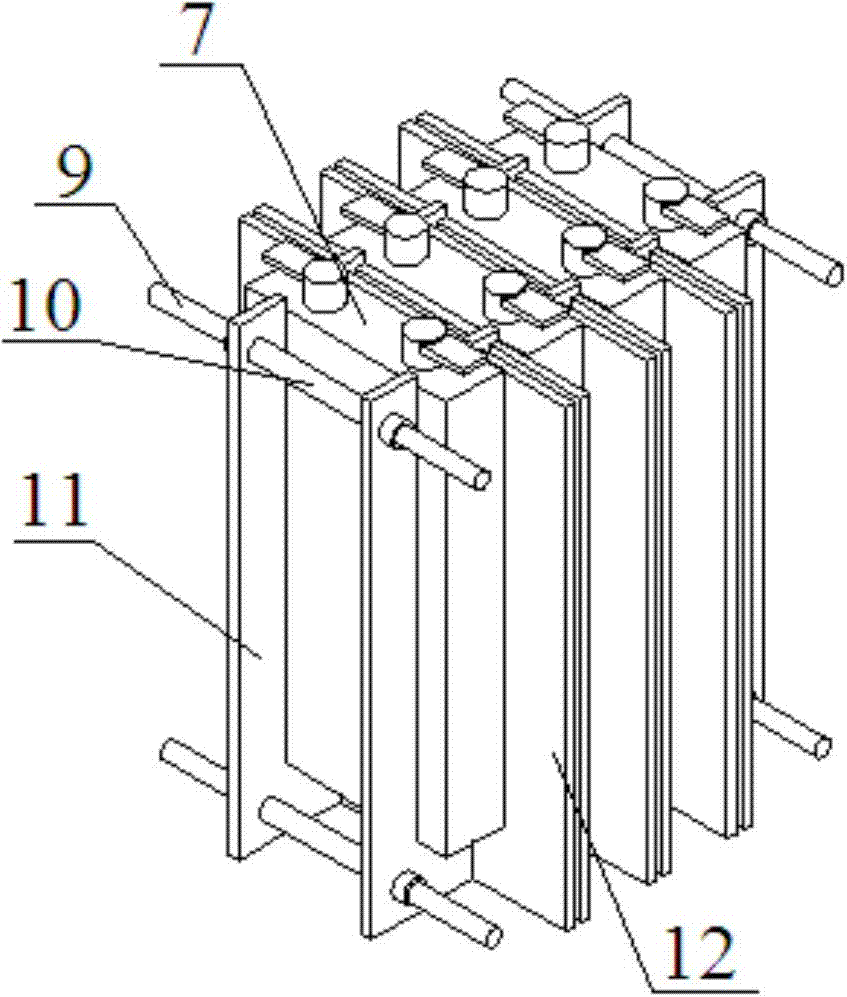

Lithium battery module for replacing lead-acid storage battery of automobile

ActiveCN103500807AImprove securityReduce volumeCell component detailsSecondary cells servicing/maintenanceElectrical batteryEngineering

The invention relates to a lithium battery module for replacing a lead-acid storage battery of an automobile. The lithium battery module comprises an upper cover, a shell, a seal grid plate, lithium batteries, insulated phase-change materials, a battery fixedly-held assembly, heat-conducting rib plates, a battery protection plate and a self-restoring circuit protector, wherein the upper cover and the shell are mechanically connected to form a seal cavity, the seal grid plate is arranged in the shell and divides the seal cavity into an upper-half seal cavity and a lower-half seal cavity, the insulated phase-change materials are filled in the lower-half seal cavity, multiple lithium batteries are fixedly connected through the battery fixedly-held assembly and are arranged in the insulated phase-change materials, the heat-conducting rib plates are arranged between each two adjacent lithium batteries, and the battery protection plate and the self-restoring circuit protector are arranged in the upper-half seal cavity; a circuit is mounted in the upper-half seal cavity, one end of the circuit penetrates through the seal grid plate and is connected with the electrodes of the lithium batteries, and the other end of the circuit is connected with an external pole column through the upper cover. Compared with the prior art, the lithium battery module has the advantages of long service life, good power property, small volume, high integration and the like.

Owner:TONGJI UNIV

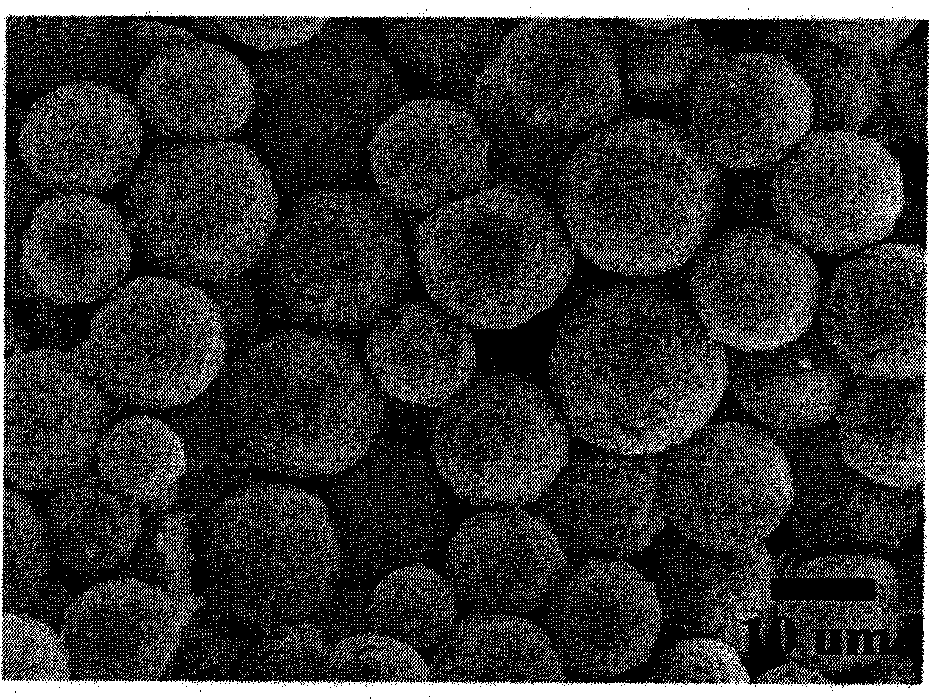

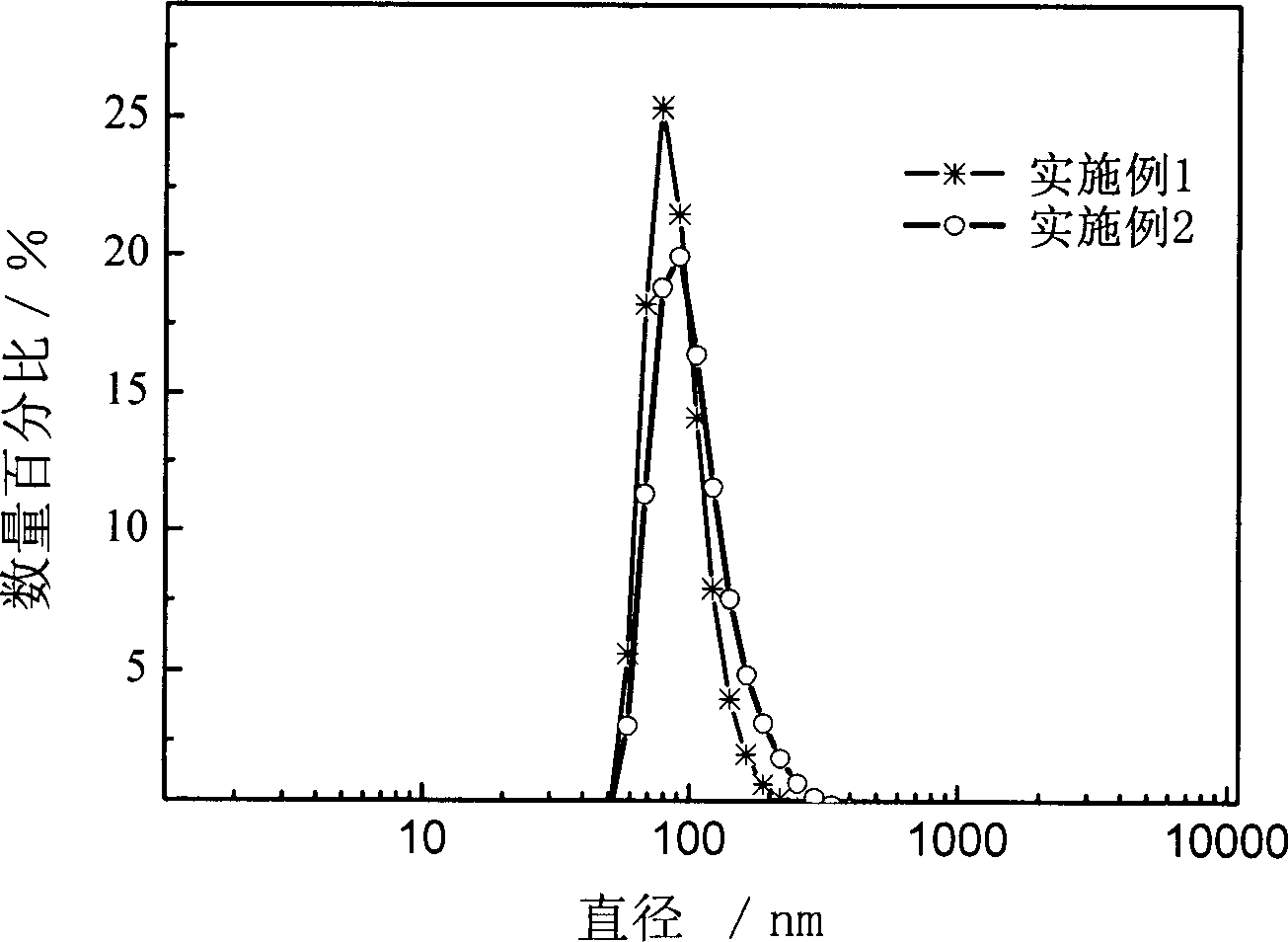

Process for preparing nano capsule phase change material emulsion

InactiveCN1900209ASmall particle sizeUniform dispersionHeat-exchange elementsAlkanePhase change enthalpy

The process of preparing nanometer capsule phase change material emulsion includes adding the oil phase liquid compounded with olefin monomer, hydrophilic monomer, alkane, initiator and n-lauryl mercaptan into the mixed liquid of emulsifier and deionized water via stirring and ultrasonic dispersing to obtain micro emulsion, introducing nitrogen to the micro emulsion system to eliminate oxygen via stirring, reflux condensing, heating to 65 deg.c and constant temperature polymerization reaction for 5 hr, and cooling naturally to room temperature to obtain the nanometer capsule phase change material emulsion. Thus prepared nanometer capsule phase change material emulsion has nanometer size, stable performance, great phase change enthalpy and wide application in latent heat functional hot fluid, heat accumulating and temperature regulating fabric, energy saving building wall and other fields.

Owner:SOUTH CHINA UNIV OF TECH

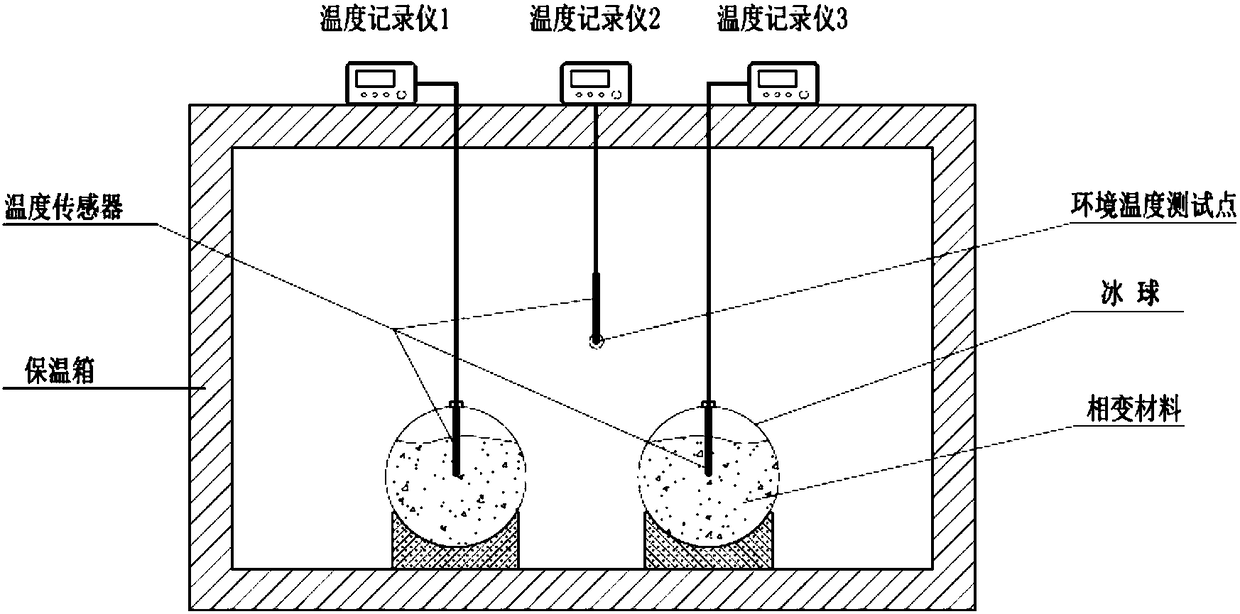

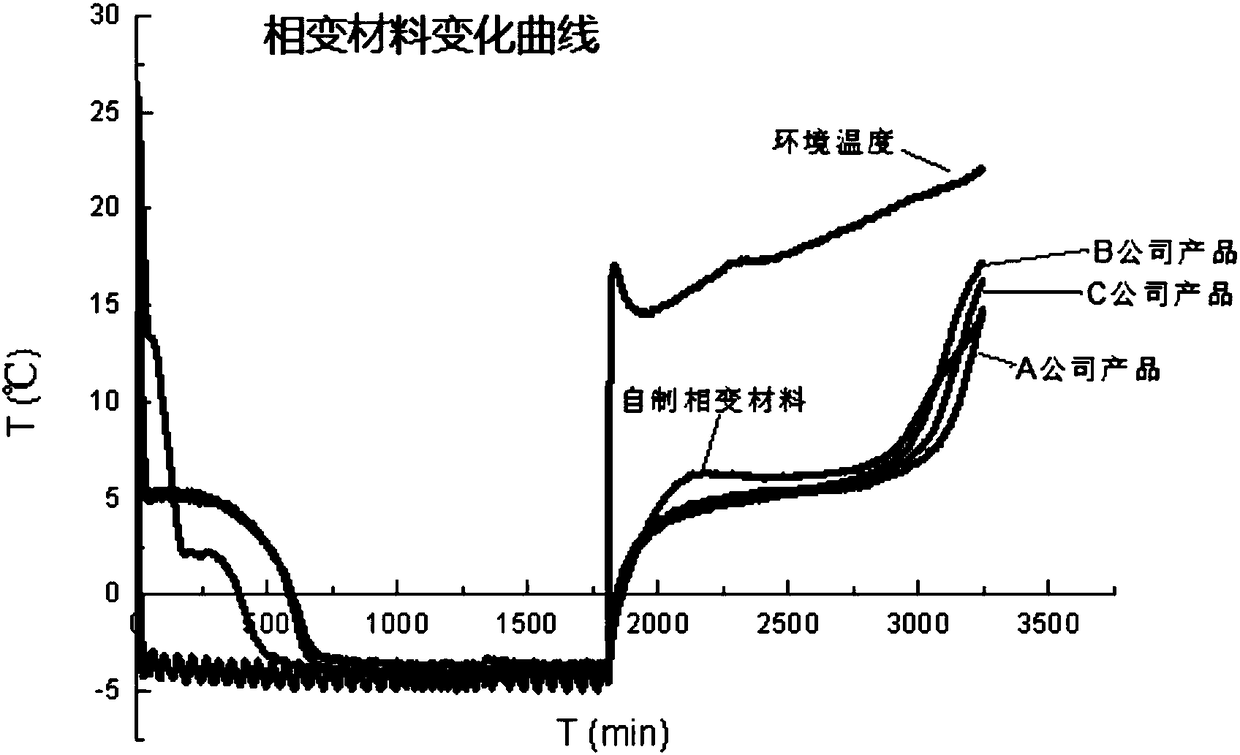

Composite phase-change material used at temperature of 2-8 DEG C and preparation method thereof

The invention discloses a method for preparing a composite phase-change material used at a temperature of 2-8 DEG C. The method comprises the following steps of: (1) placing an anhydrous-sodium-sulfate raw material in a blast drying oven, and drying to be constant weight at a temperature of 90-110 DEG C; (2) according to the parts by mass of all raw materials, respectively weighing 30-50 parts ofanhydrous sodium sulfate, 5-10 parts of sodium chloride, 10-20 parts of potassium chloride, 10-20 parts of ammonium chloride, 1-5 parts of boric acid, 1-5 parts of borax, 0.5-5 parts of sodium carboxymethyl cellulose, 0.5-5 parts of hydrophilic aerogel for mixing, grinding in a ball grinder till the granularity of the mixture is 50-300mu m; (3) adding 20-50 parts of distilled water into the groundmxiture, stirring to be fused slurry at a temperature of 40-60 DEG C. The method disclosed by the invention has the advantages of simple process and lower cost; the prepared phase-change material hasthe advantages of low supercooling degree, high energy-storage density, no-phase separation, stable property and capabilities of fast cold storage and slow cold release.

Owner:四川微松新材料有限公司 +1

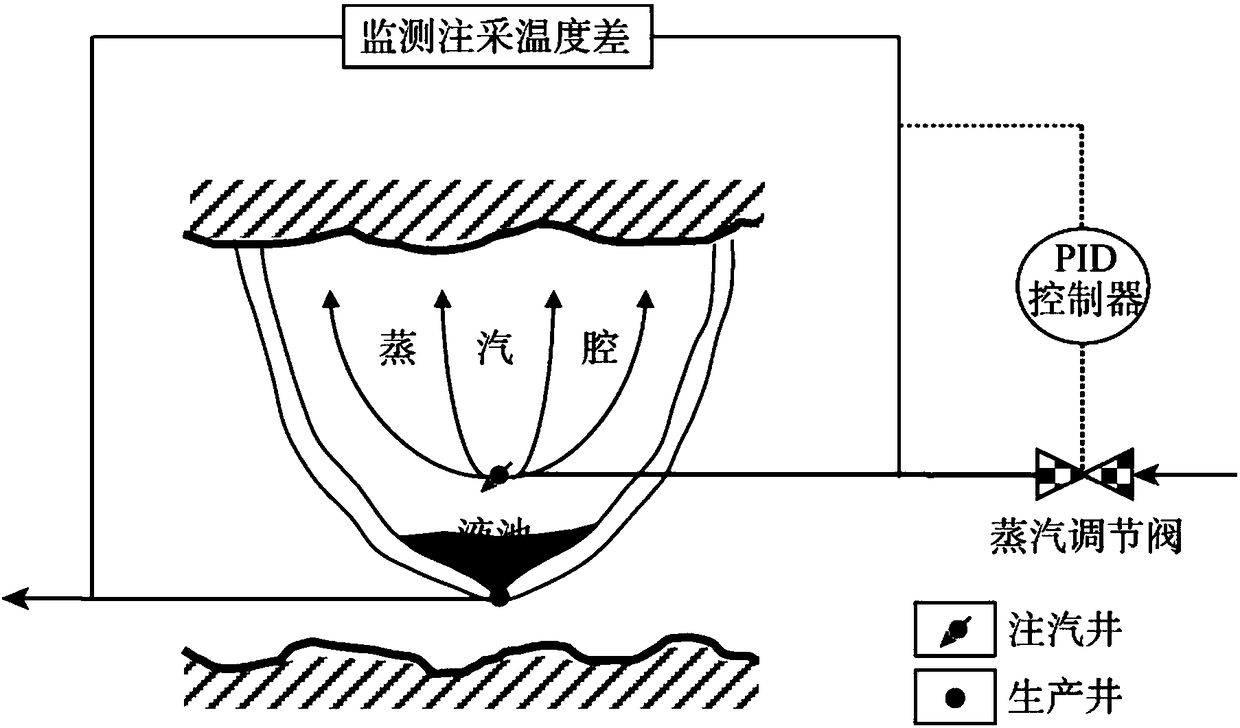

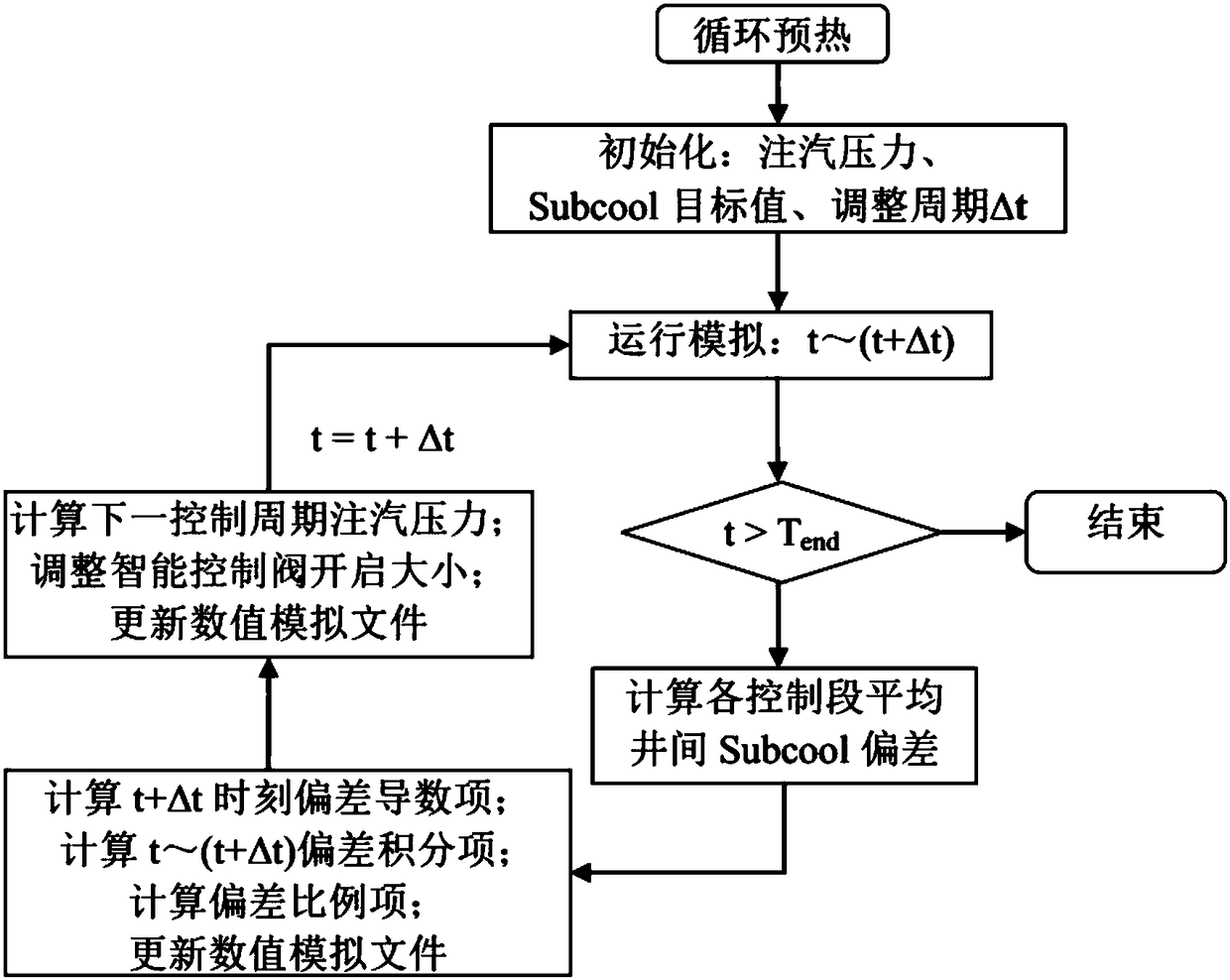

Method for assisting gravity drainage by means of solvent and superheated steam

InactiveCN108131124AShorten warm-up timeReduce the amount of steam injection for circulating preheatingFluid removalEconomic benefitsEngineering

The invention provides a method for assisting gravity drainage by means of a solvent and superheated steam. The method comprises the steps that injection-production pattern deployment is conducted; injection-production pattern is preheated, so that hot inter-well communication and pressure communication are built; an SAGD stage is started, wherein the stage comprises the steps of injecting the superheated steam and conducting SAGD initial production; after SAGD initial production is finished, the vaporized solvent and the superheated steam are injected, and SAGD mid-term production is conducted; after SAGD mid-term production is finished, the superheated steam is injected till the SAGD life cycle is finished. According to the technical scheme, the synergistic effects of solvent dilution solution viscosity reduction and permeable mudstone thin interlayer and superheated steam thermal viscosity reduction are fully played, the preheating time is greatly shortened, the oil production is increased, the steam injection and sewage treatment capacity are lowered, and the economic benefit is improved finally.

Owner:PETROCHINA CO LTD

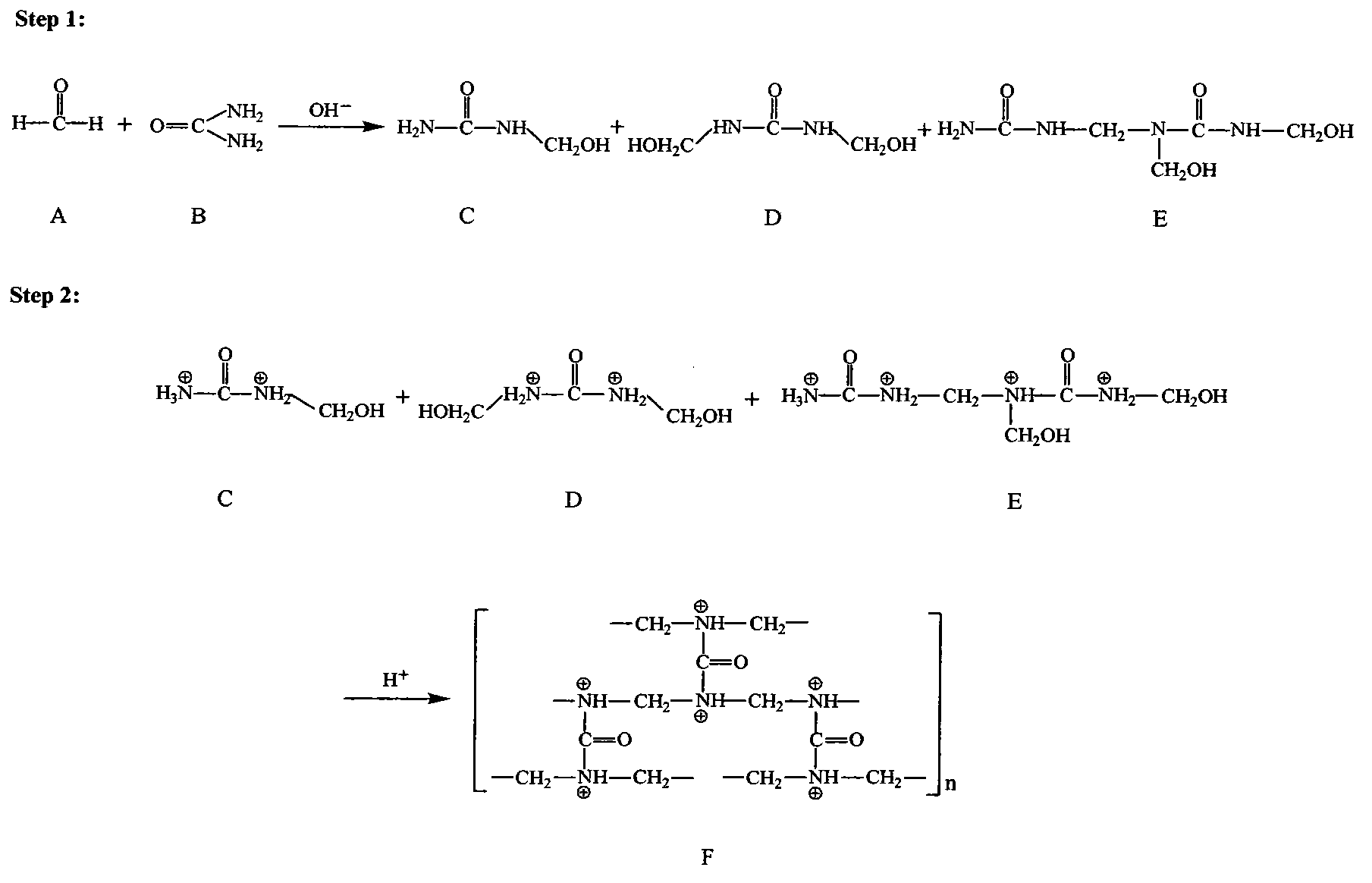

Method for preparing nanocapsule powder of urea-formaldehyde-resin-encapsulated phase-change material

InactiveCN102049229ALow costLarge latent heatMicroballoon preparationMicrocapsule preparationPhase changePhase-change material

The invention relates to a method for preparing nanocapsule powder of a urea-formaldehyde-resin-encapsulated phase-change material, which comprises the following four steps: (1) preparing prepolymer; (2) preparing miniemulsion; (3) carrying out a polymerization reaction; and (4) extracting capsule powder. Compared with the prior art, the product obtained through the method provided by the invention has great latent heat and high thermal conductivity; and the adopted urea-formaldehyde-resin shell material is very cheap, so that the cost for encapsulation of the phase-change material is greatlylowered, and the encapsulated phase-change material can not outflow when the phase change occurs. The product can be applied to the fields of coating, spinning and the like.

Owner:TONGJI UNIV

Cold accumulation material, cold accumulator and cold accumulation type refrigeration device

InactiveCN107474800ALarge latent heatLarge latent heat of solid-liquid phase transitionDomestic cooling apparatusLighting and heating apparatusDisiloxaneNonane

The invention provides a cold accumulation material, which is prepared from at least one of a first group of substances, a second group of substances, a third group of substances, a fourth group of substances and a fifth group of substances, wherein the first group of substances comprise n-nonane, n-octane and hexamethyl disiloxane; the second group of substances comprise p-cymol and decamethyl tetrasiloxane; the third group of substances comprise o-cymol, vinyltoluene, ammonia and R1233ze(E); the fourth group of substances comprise 1,1,2,2,3-pentafluoropropane, 2H,3H-perfluoropentane, butylbenzene and octamethyl trisiloxane; the fifth group of substances comprise tetrafluoromonochlorethane, 1,1,1,3,3,3-hexafluoropropane, propanone, perfluoroethane and pentafluoroethane. Through the cold accumulation material, according to a different required temperature zone, the cold accumulation material which is prepared from a different monomer or a plurality of substances can be selected, can be used for meeting the demand of the temperature of subzero 60 to subzero 100 DEG C, and adapts to a plurality of scenes. In addition, the invention also provides a cold accumulator and a cold accumulation type refrigeration device.

Owner:北京赛科凌科技有限责任公司

Preparation method of binary aliphatic acid/PMMA shape-stabilized phase change material

InactiveCN104059615AImprove corrosion resistanceGood chemical stabilityHeat-exchange elementsWater bathsThermal stability

The invention provides a binary aliphatic acid / PMMA shape-stabilized phase change material and a preparation method thereof. The shape-stabilized phase change material is prepared from the following raw materials: 30 wt%-70 wt% of a binary aliphatic acid eutectic mixture, 30 wt%-70 wt% of MMA (methyl methacrylate), and 0.3 wt%-0.7 wt% of AIBN (azodiisobutyronitrile). The preparation method comprises adding MMA and AIBN in a water bath of 80 DEG C, stirring for 25 min, then adding molten binary aliphatic acid, intensely stirring for 5 min; pouring the mixture into a die, sealing the die, putting the die in a water bath of 60 DEG C for 2 hours, and then putting the die in a water bath of 90 DEG C for 1 hour to obtain the binary aliphatic acid / PMMA shape-stabilized phase change material. The shape-stabilized phase change material has an appropriate phase change temperature and large phase change latent heat, is good in heat stability, and has good application prospects.

Owner:NANJING UNIV OF TECH

Cold accumulating agent and preparation method thereof

The invention provides a cold accumulating agent and a preparation method thereof. The cold accumulating agent is composed of, by mass, 1%-8% of glycerol, 1%-5% of inulin, 1%-5% of gelatin, 1%-5% of thickening agent and a sodium chloride water solution. When the cold accumulating agent is prepared, the sodium chloride water solution is heated in a bath to be at the temperature of 70 DEG C, the temperature is kept constant, sodium alginate tech grade, gelatin, inulin and glycerol are sequentially added into the sodium chloride water solution, adding and stirring are performed at the same time when each component is added, and the next component is added after the added component is dissolved evenly; after all the components are added, uniform stirring is performed, the temperature is kept constant for 10 min, and cooling is performed to obtain the cold accumulating agent. The cold accumulating agent can be used repeatedly, and is thick, colloidal, good in fitness, large in latent heat, long in low-temperature duration time, easy to manufacture, low in cost, safe and free of toxicity.

Owner:SHANDONG PROVINCIAL HOSPITAL

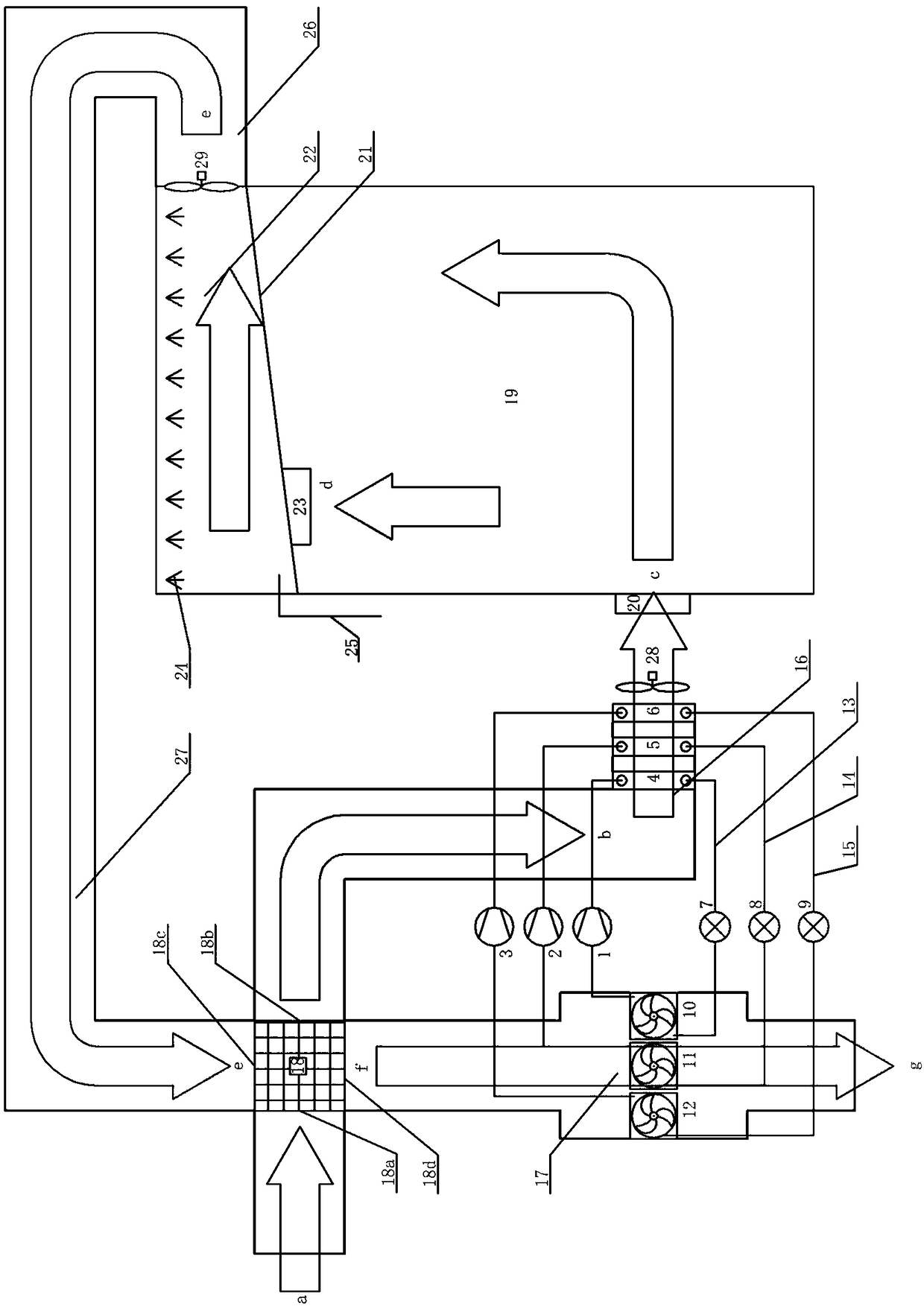

Multistage high-efficiency heat recovery type air source heat pump grain drying machine

PendingCN108759170AIncrease temperatureLarge latent heatHeat pumpsHeat recovery systemsEvaporationProcess engineering

The invention provides a multistage high-efficiency heat recovery type air source heat pump grain drying machine. Moisture removal air is dedusted through spray water, and exhaust dustless hot air enters a drying unit through an air total-heat exchanger so as to provide a heat source for drying. The multistage high-efficiency heat recovery type air source heat pump grain drying machine is high inheating capacity, high in evaporation efficiency and simple to operate, and comprises N compressors which are the first compressor, the second compressor to the N compressor, wherein N is a natural number not less than 2. A corresponding condenser, an expansion valve and an evaporator are independently arranged for each compressor; an outlet of each compressor is connected with a working medium inlet of the corresponding condenser; a working medium outlet of each condenser is connected with the corresponding expansion valve and then is connected with the corresponding evaporator; a working medium outlet of each evaporator is connected with a working medium inlet of the corresponding compressor; all condensers are arranged in the corresponding condenser areas; and a first heat exchange pipeline sequentially covers a shell area of each condenser.

Owner:苏州聚焓新能源科技有限公司

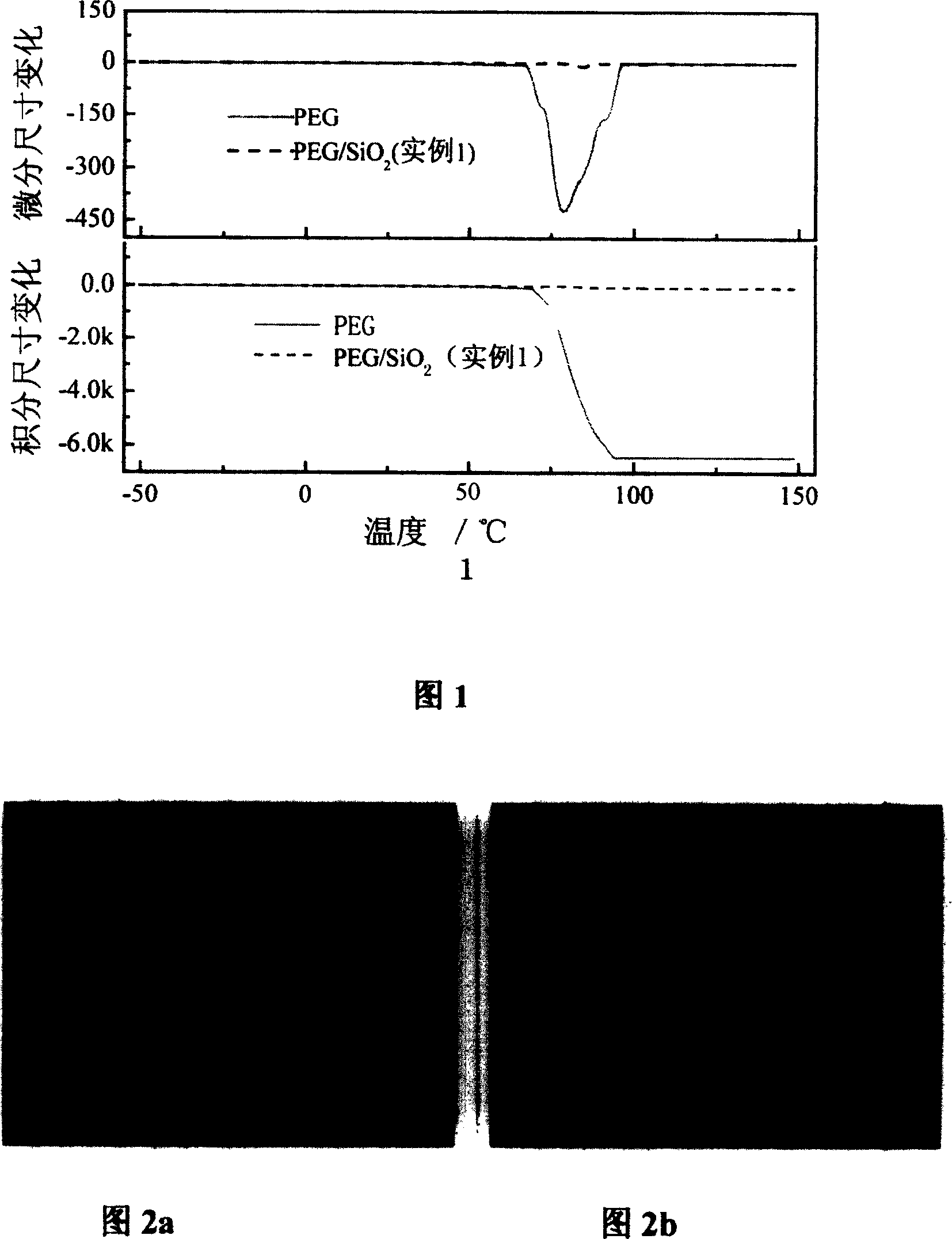

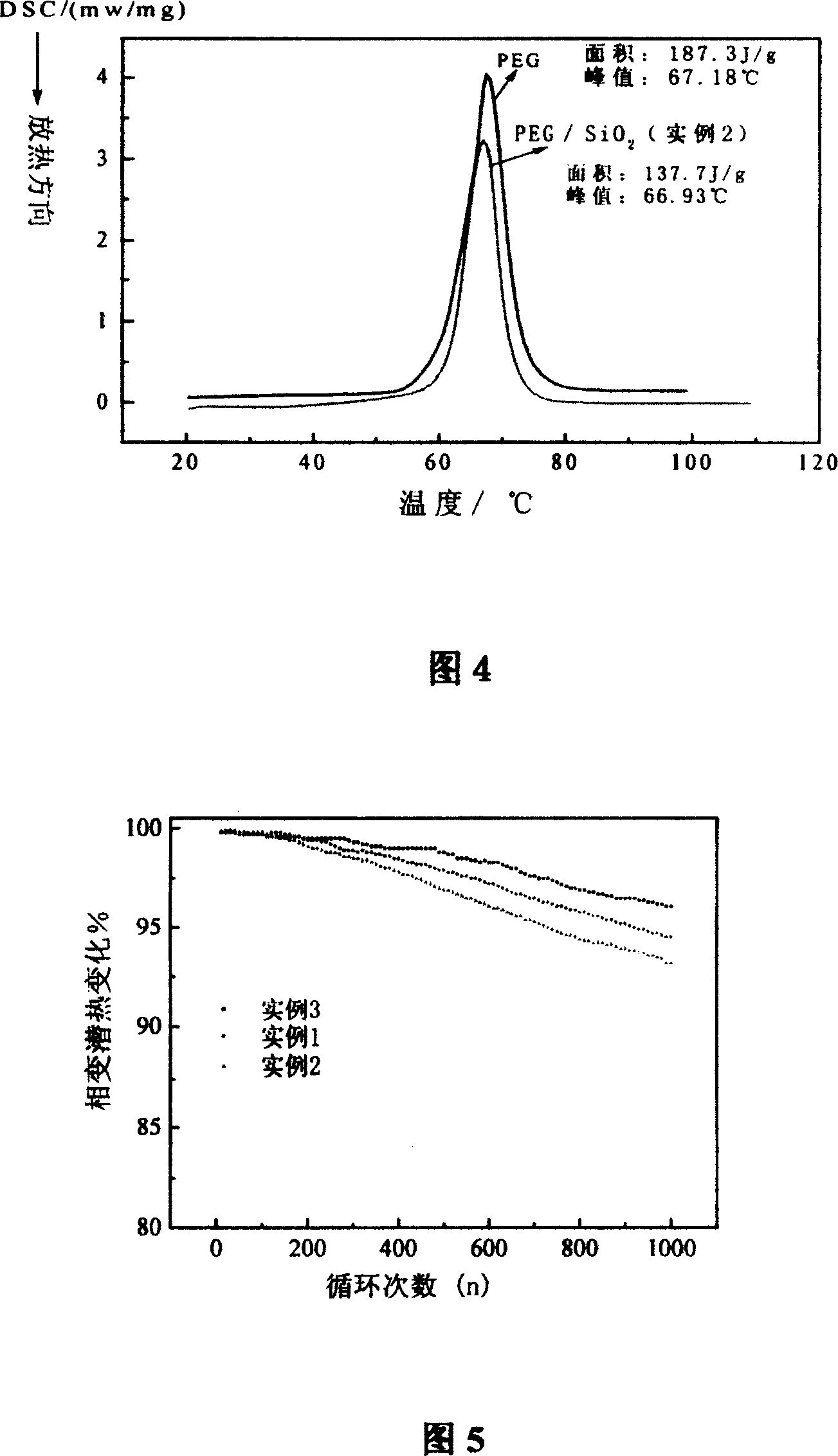

Process for preparing compound forming phase changing material of polyethyldiol/silicon dioxide

InactiveCN1322091CEvenly dispersedLarge latent heatHeat-exchange elementsBuilding energyPolyethylene glycol

The invention offers polyethylene glycol / silicon dioxide composite forming phase-change material manufacturing method. It includes the following steps: adding polyethylene glycol flour body into silica sol, and dipping accelerating agent to happen sol-gel reaction to form three-dimensional network gel; drying, smashing to form flour body; removing water and adding modifier. The formed product has high latent heat of phase change 60-140 kJ / kg, good forming capability, and stable capability while temperature is higher than phase-change by 20-50 centigrade degree, the polyethylene glycol does not leak out; thus it can be applied to electronic component thermal adjusting and controlling material, heat storage tempering textile goods, and building energy conservation wall body fields, and so on.

Owner:SOUTH CHINA UNIV OF TECH

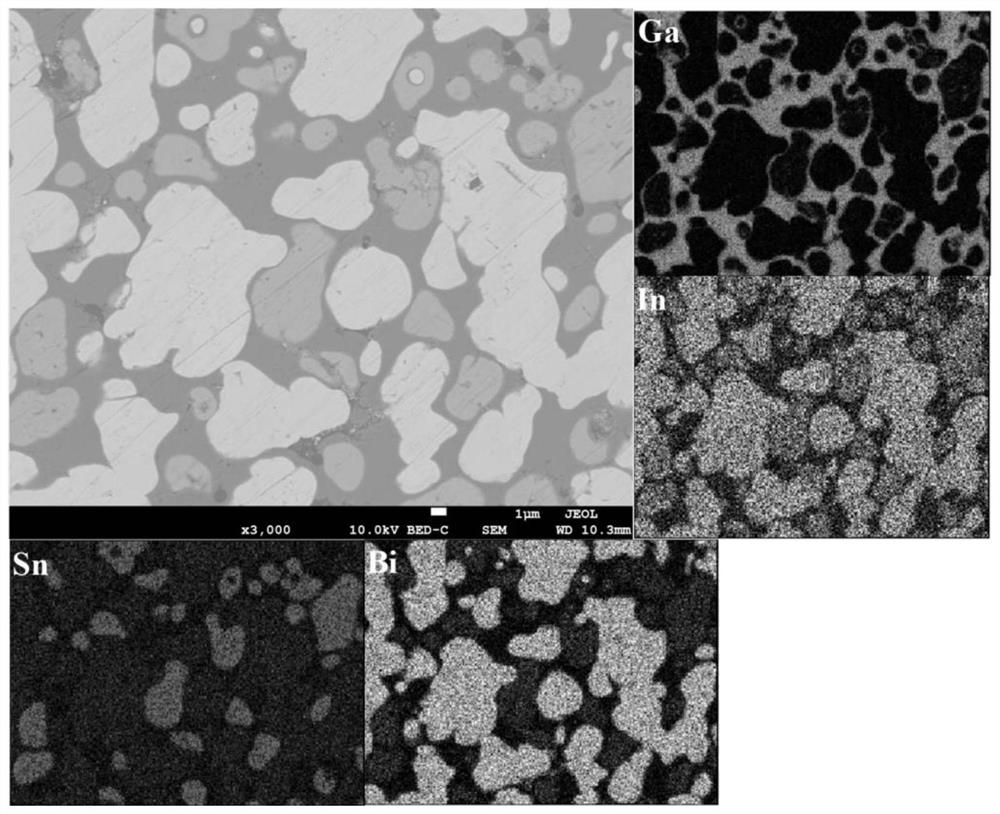

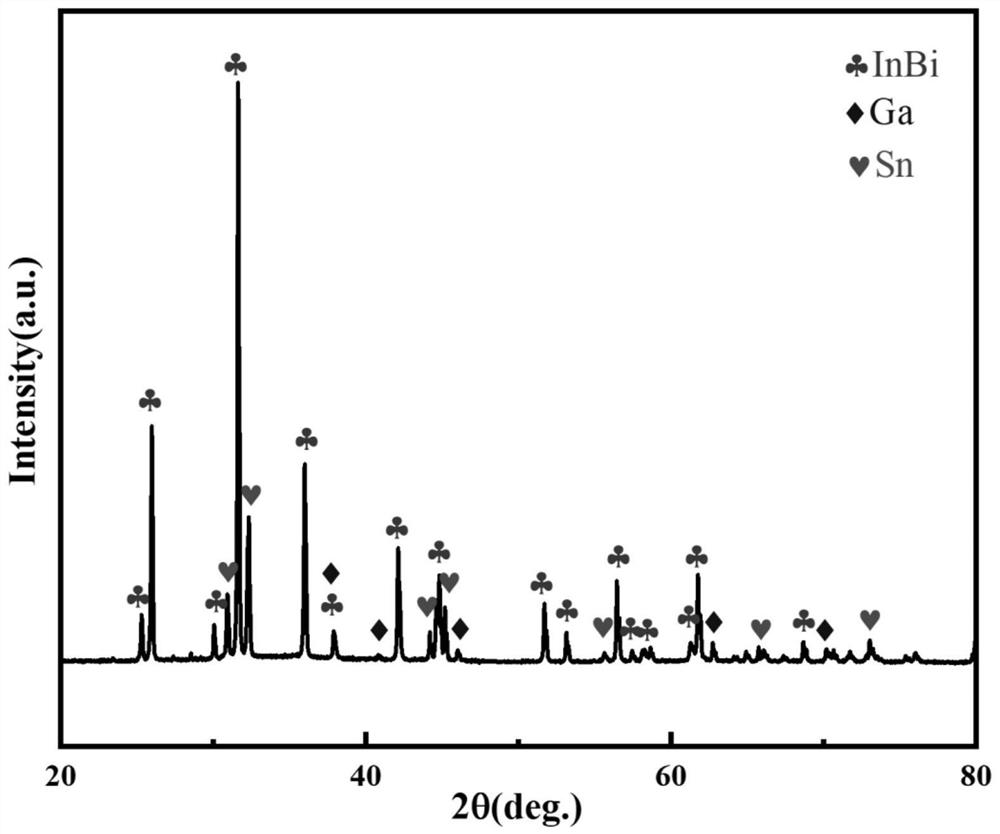

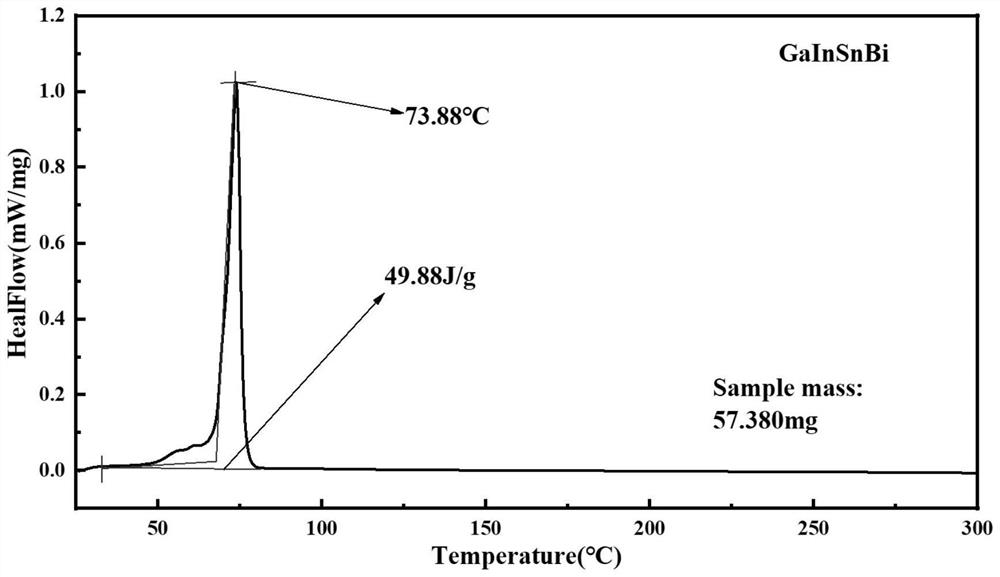

Preparation method of low-melting-point alloy phase change material

ActiveCN113881887AMelting point adjustmentSolve Oxidation ProblemsHeat-exchange elementsIce waterMetal alloy

The invention relates to a preparation method of a low-melting-point alloy phase change material, and belongs to the technical field of preparation of phase change materials. The method comprises the following steps: removing surface oxides of raw materials Ga, In and metal A, wherein the metal A is one or more of Sn, Bi, Zn and Al; adding Ga, In and metal A into a smelting medium, increasing the temperature to a preset temperature at a constant speed, conducting heat preservation for 4-6 hours, and conducting metal alloying to obtain an alloying system, wherein the smelting medium is glycerol or silicone oil; and heating the alloying system to the preset temperature, performing uniform stirring and mixing to performing full alloying, and then adding an ice-water mixture into the alloying system to quickly cool an alloy sample and obtain the low-melting-point alloy phase change material. According to the method, the glycerol or silicone oil is adopted as the smelting medium, the problems of oxidation, insufficient alloying and the like of low-melting-point alloy in the smelting process can be effectively solved, the low-melting-point alloy phase change material has greater latent heat in unit volume, the heat capacity of the low-melting-point alloy phase change material can be greatly improved, the volume proportion of the phase change material is effectively reduced, and better stability and higher heat conductivity are achieved.

Owner:KUNMING UNIV OF SCI & TECH

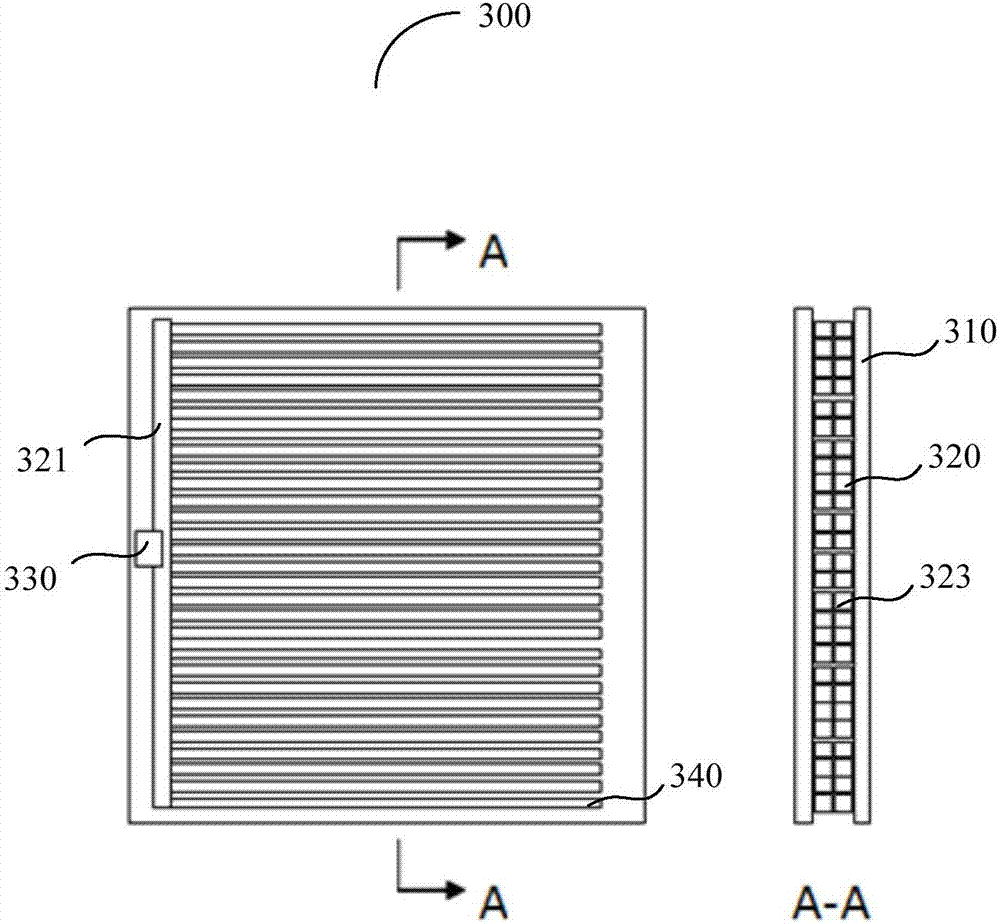

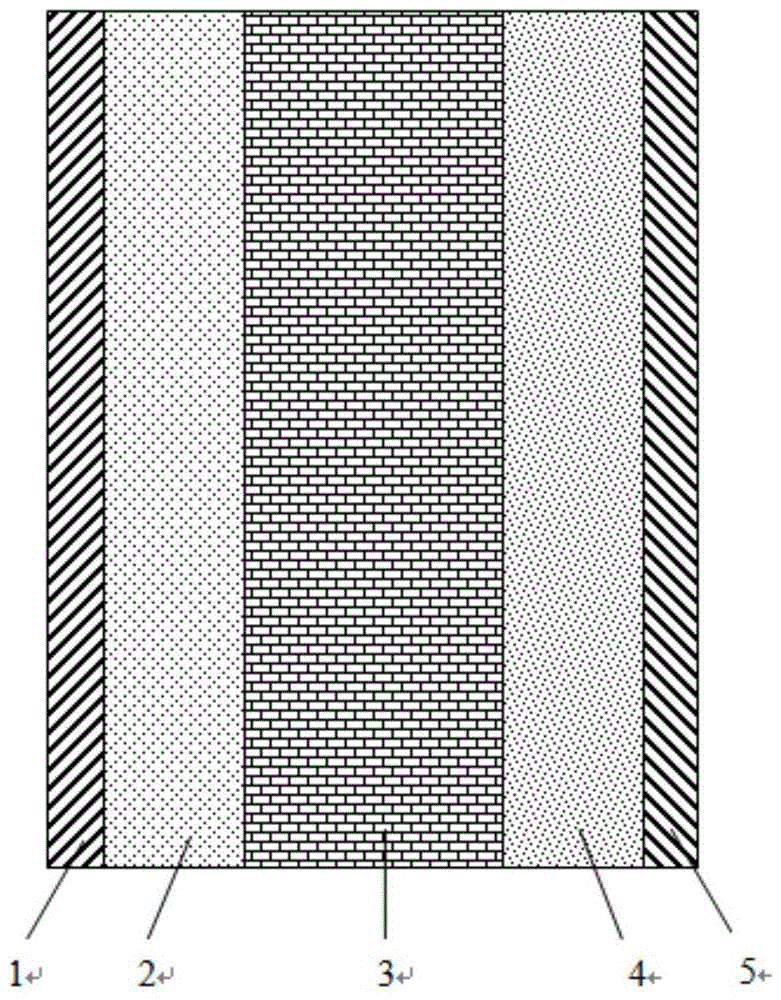

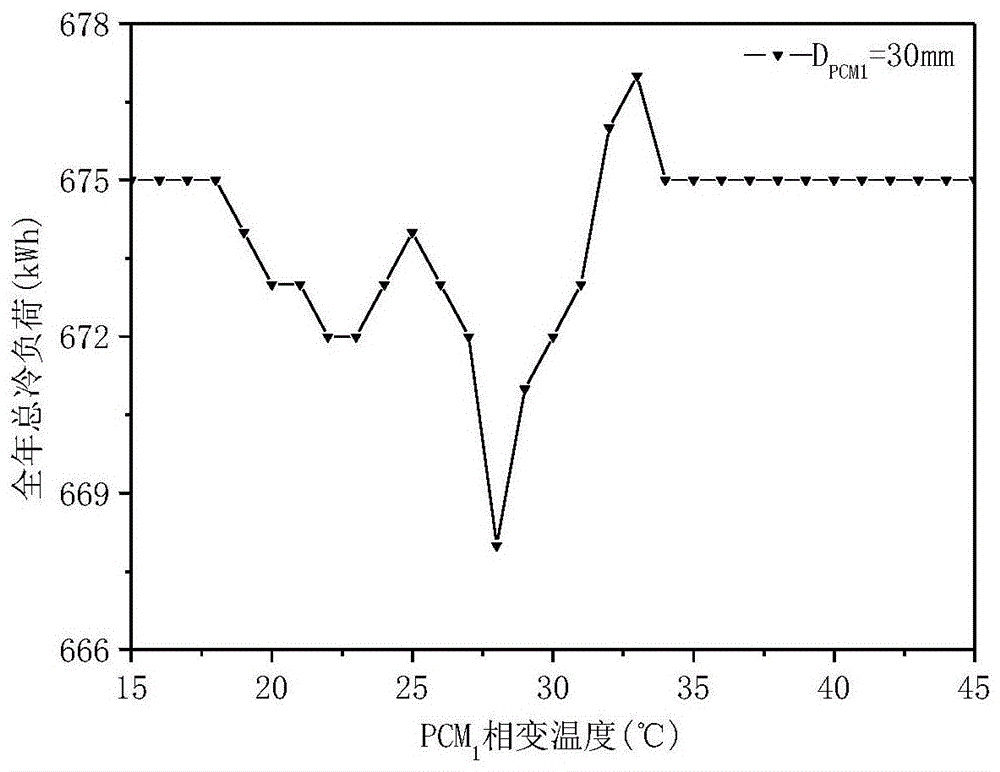

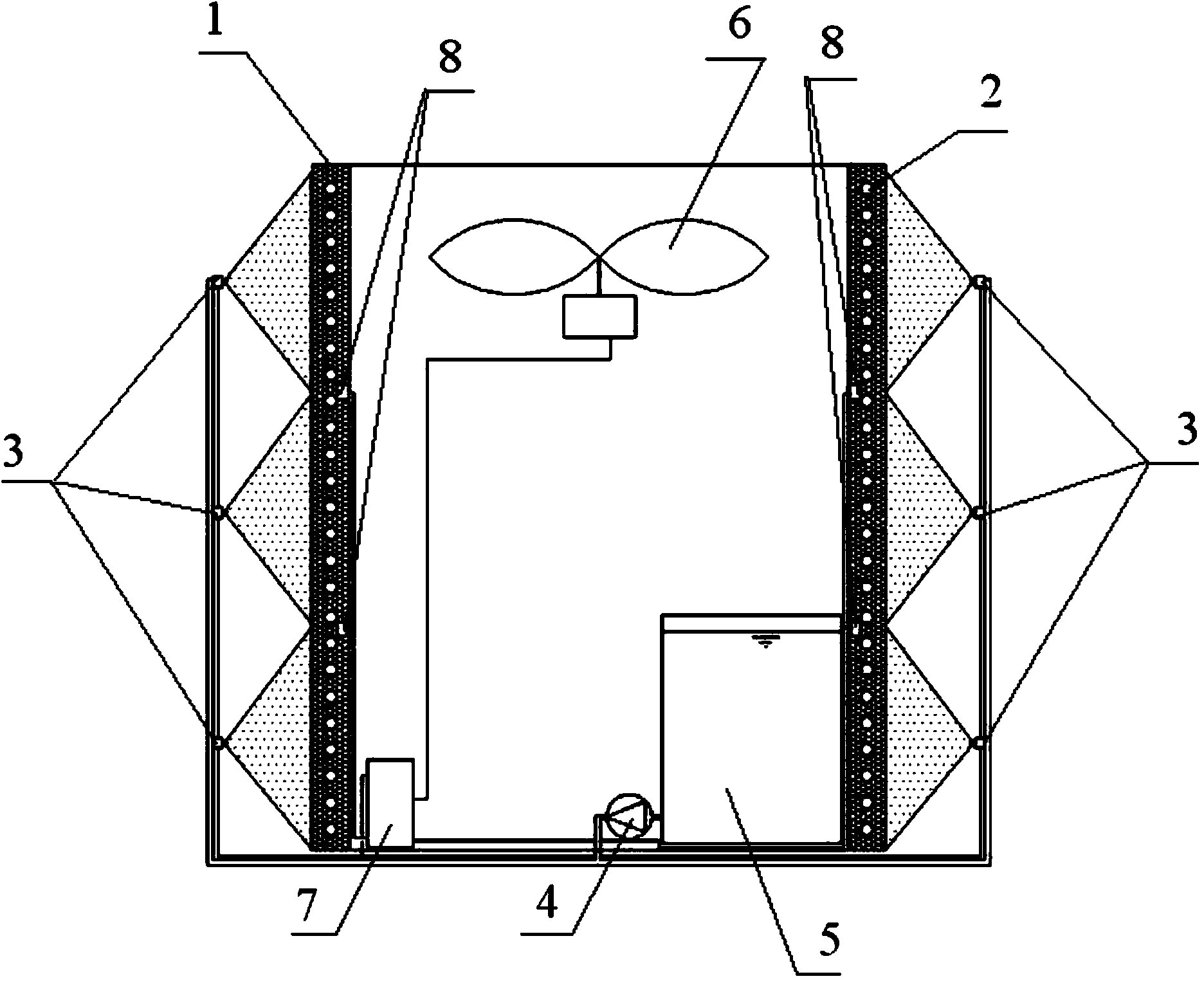

A building exterior wall structure with double-layer stereotyped phase-change material layers

InactiveCN104674978BLarge latent heatEasy processing and maintenanceWallsHeat-exchange elementsThermal insulationAmorphous phase

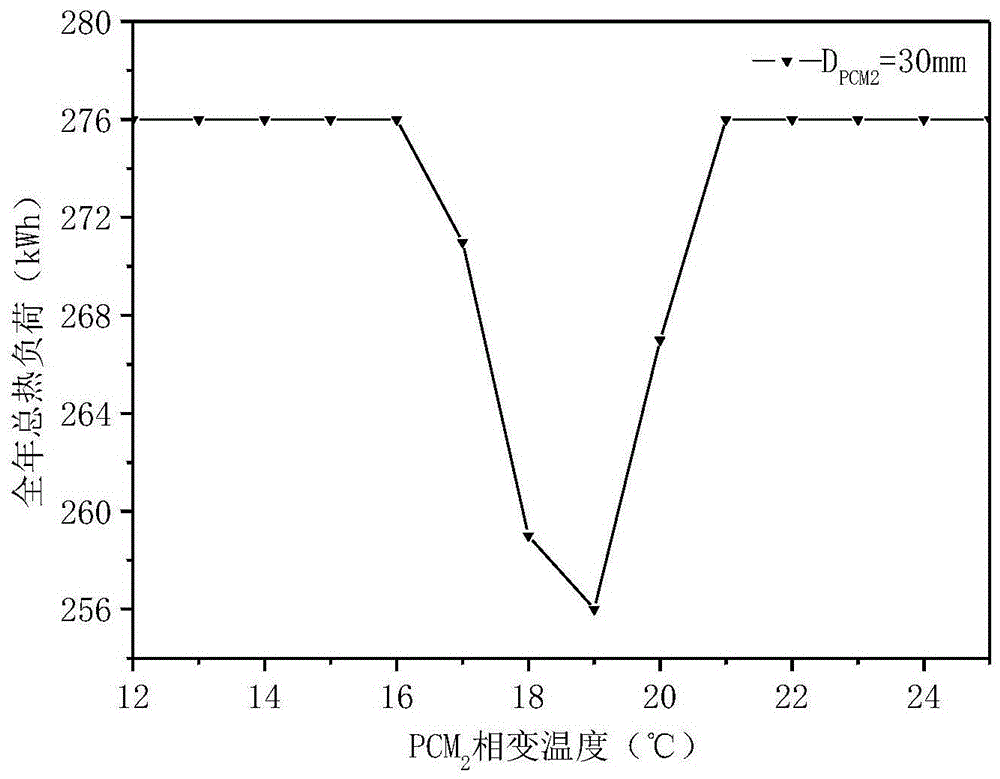

The invention discloses a building outer wall structure with double shaping phase change material layers. The building outer wall structure sequentially comprises the outer shaping phase change wall board layer, a first thermal insulation layer, a wall body layer, a second thermal insulation layer, the inner shaping phase change wall board layer from outside to inside, wherein the outer shaping phase change wall board layer and the inner shaping phase change wall board layer are respectively made of phase change materials of phase change temperatures of Tm1 and Tm2, the phase change temperature Tm1 is set to be minimum in cold load all year round in the expositing environment of the phase change temperature Tm1, and the solid phase change materials melt into liquid phase change materials when the wall board layer temperature is equal to or higher than Tm1; the phase change temperature Tm2 is set to be minimum in heat load all year round in the exposing environment of the phase change temperature Tm2, and the solid phase change materials melt into liquid phase change materials when the wall board layer temperature is equal to or higher than Tm2. The invention further designs the components and proportion of the phase change materials of the two shaping phase change wall board layers. By the building outer wall structure which is compact, high in adaptability, convenient to manufacture and maintain later, and the like, outer wall cold load and heat load can be lowered effectively, and overall energy consumption is lowered evidently.

Owner:HUAZHONG UNIV OF SCI & TECH

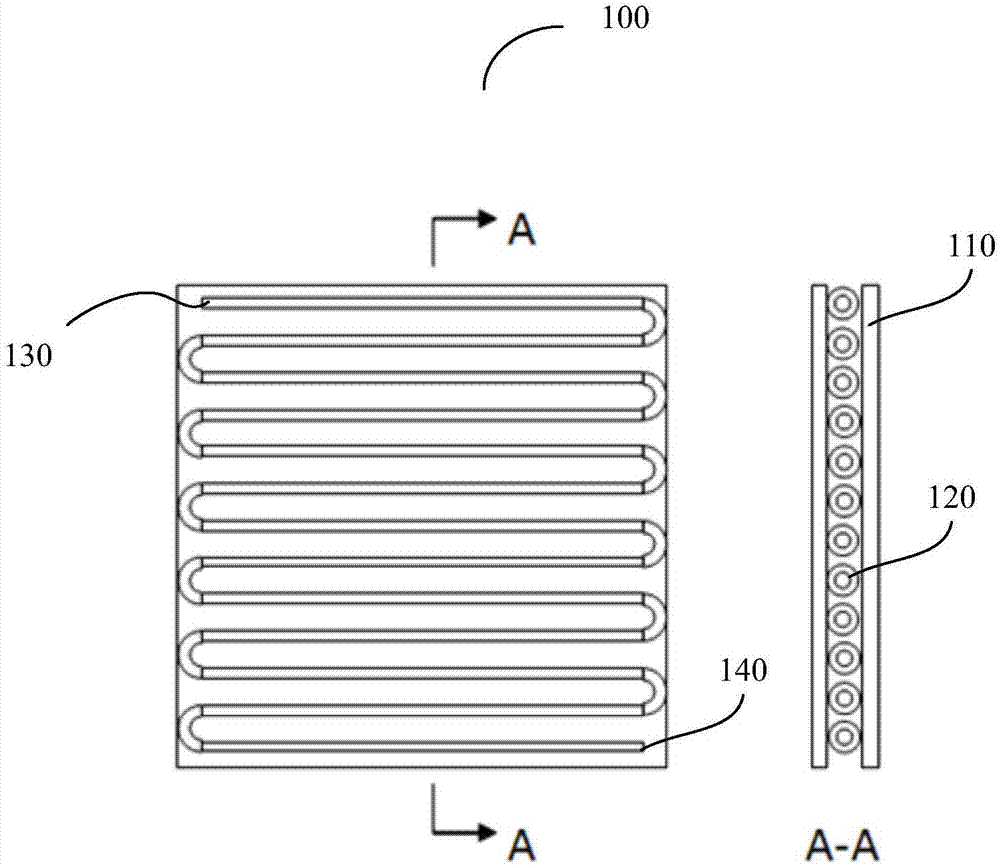

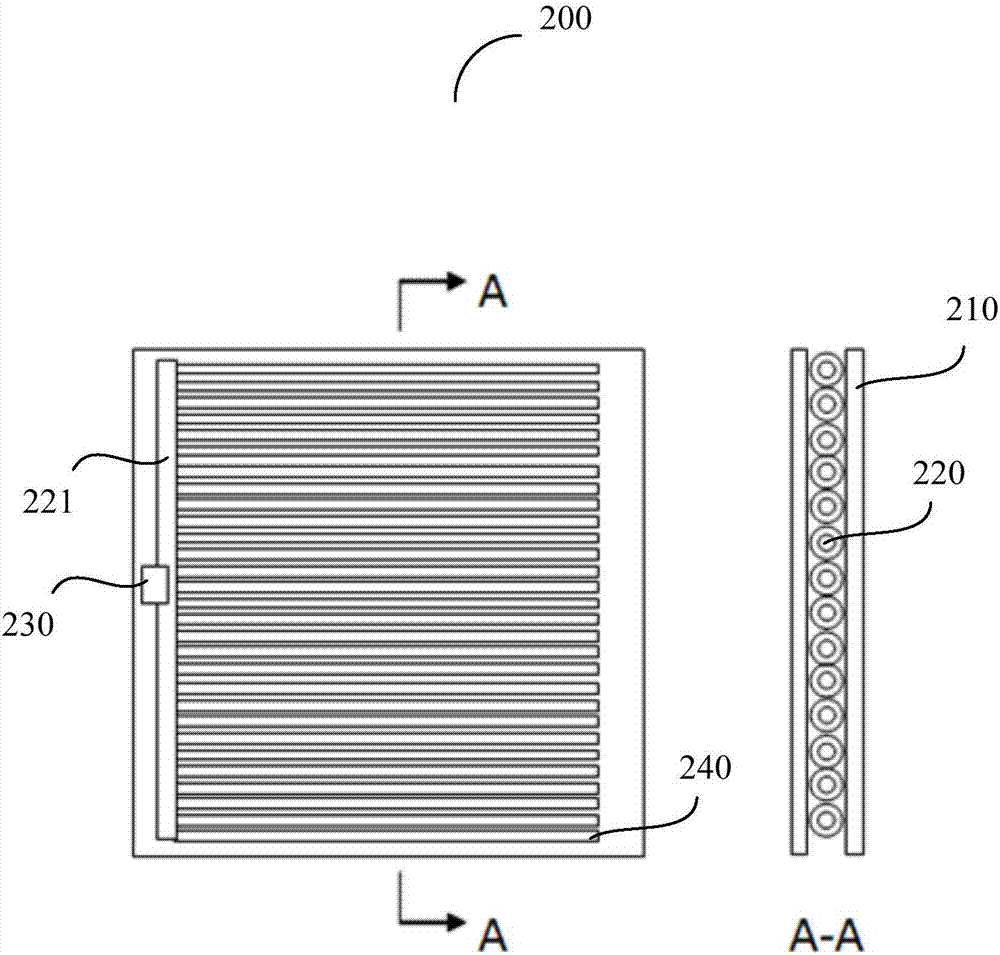

Ground heat exchanging system capable of operating all year round

InactiveCN109539612AImplement storageAchieve releaseHeat storage plantsGeothermal collectorsThermal energy storageEngineering

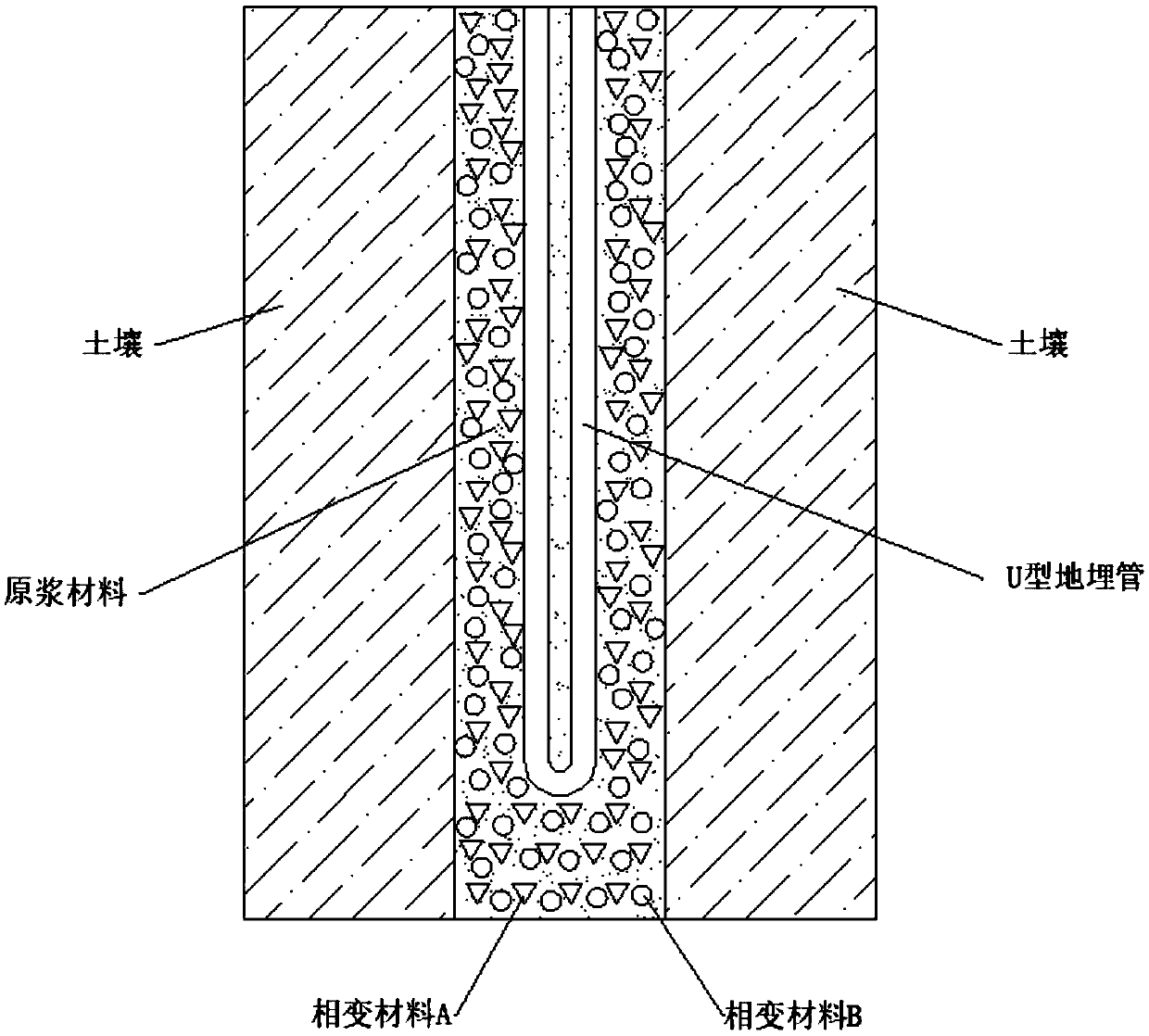

The invention belongs to the field of renewable energy sources and phase change thermal energy storage application, and particularly relates to a ground heat exchanging system capable of operating allyear round. The heat exchanging system comprises a U-shaped buried pipe and backfill materials, and the U-shaped buried pipe and the backfill materials are buried in soil; the backfill materials comprise a phase change material A, a phase change material B and a normal backfill material, wherein the phase change temperature of the phase change material A is higher than the temperature of the soilin summer and is lower than the temperature of water at an inlet of the buried pipe during operating in summer; and the phase change temperature of the phase change material B is lower than the phasechange temperature of the phase change material A, lower than the temperature of the soil in winter, and higher than the temperature of the water at the inlet of the buried pipe during operating in winter. According to the ground heat exchanging system capable of operating all year round, composition and proportions of two microcapsule phase change materials are further designed. According to theground heat exchanging system capable of operating all year round, the backfill diameter and pipe burying depth can be effectively reduced, the system operation COP can be improved, integral energy consumption is significantly reduced, and meanwhile, the ground heat exchanging system capable of operating all year round has the characteristics that the structure is compact, the adaptability is high, and the use period is long.

Owner:HUAZHONG UNIV OF SCI & TECH

Spray evaporation foam metal heat transfer enhancement device for air conditioning condenser

InactiveCN104315695AIncrease the heat exchange areaCompact installationMechanical apparatusSpace heating and ventilation safety systemsVibration attenuationCooling effect

The invention discloses a spray evaporation foam metal heat transfer enhancement device for an air conditioning condenser, and the device is composed of a shell, a condenser coil, a shower nozzle, a water pump, a water tank, a cooling fan and a controller, wherein the condenser coil passes through the heat transfer surface of the shell, the shower nozzle is arranged on the air inlet side of the heat transfer surface and connected with the shower nozzle, the pump is connected with the water tank, the heat transfer surface of the shell cavity is provided with a temperature sensor, the cooling fan is arranged above the space surrounded by the shell, the temperature sensor and the water pump and the cooling fan are controlled by the controller; the heat transfer enhancement device has the beneficial effect of simple structure and being convenient to use, besides the device is characterized by large potential heat, small granule and large surface area due to water drop gasification, the foam metal has the excellent physical properties such as multiple pores, vibration attenuation, damping, sound absorption, sound insulation and heat dissipation and has the strong capillary action, thereby effectively improving the problem that the condenser has the the weak cooling effect and the great noise and realizing the high-efficiency heat transfer requirement of the air conditioning condenser.

Owner:CHANGCHUN INST OF TECH

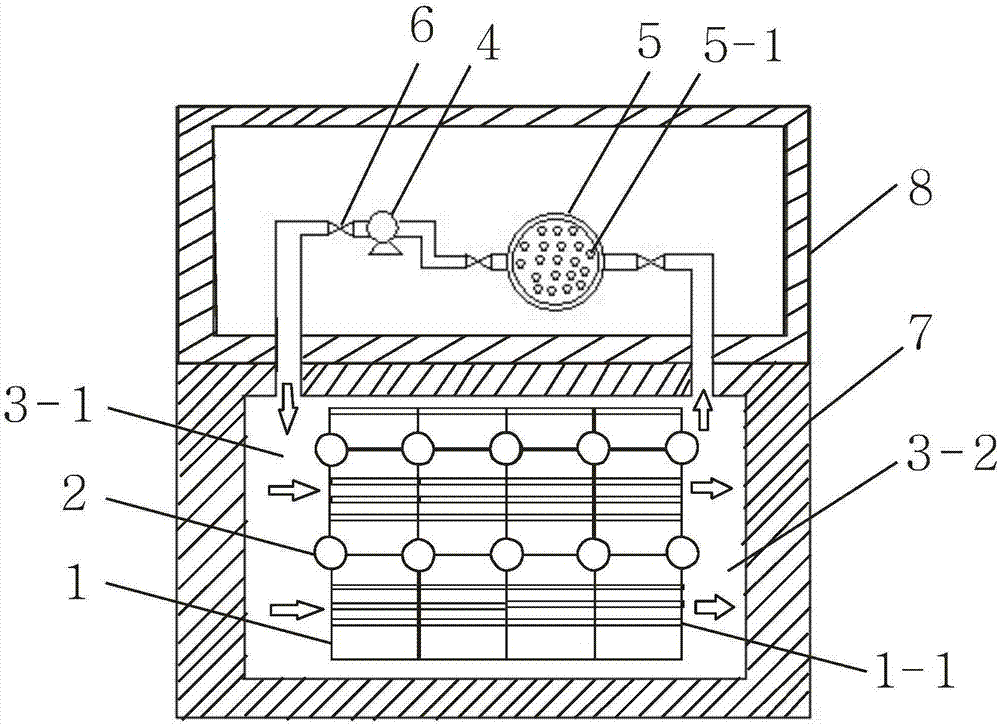

Energy-storage heat exchange device

ActiveCN107167013ARealize the purpose of energy storage and heat exchangeLow melting pointHeat storage plantsCold airElectricity

The invention relates to an energy-storage heat exchange device. The energy-storage heat exchange device comprises an energy storage pile, a heat exchanger, a heating tube and a fan, wherein a thermal insulation layer A is arranged at the periphery of the energy storage pile; a gap between the energy storage pile and the thermal insulation layer A is taken as an air flue; a ventilating groove is formed in the energy storage pile; the fan is connected with the heat exchanger through a pipeline; the other end of the fan is accessed into the air flue A through a pipeline; the other end of the heat exchanger is accessed into an air flue B through a pipeline; the air flue A and the air flue B refer to air flues formed between opposite two ends in the energy storage pile and the thermal insulation layer A; an electric heating tube is arranged in the energy storage pile in a penetrating mode for heating the energy storage pile; under driving of the fan, air flow enters the energy storage pile through the air flue A; and air flow is heated by the energy storage pile. The energy-storage heat exchange device utilizes off-peak electricity to heat the energy storage pile, and utilizes the energy storage pile to slowly release heat for heating air flow to form hot air; and after entering the heat exchanger to exchange heat, hot air is changed into cold air for being blown into the fan, and re-enters the air flue A under driving of the fan in a circulating mode, so that the energy-storage heat exchange purpose is realized.

Owner:天津朗华科技发展有限公司

Cold chain coolant and preparation method thereof

InactiveCN110484215AEasy to operateSuitable for large-scale productionOrganic compound preparationHeat-exchange elementsCold chainPolyethylene glycol

The invention discloses a cold chain coolant that is characterized by being prepared from, by mass, 5%-10% of metal chloride, 1%-4% of ammonium chloride, 1%-3% of alcohol, 0.1%-0.3% of active silicon,2%-5% of borax, 0.3%-1% of docusate sodium, 5%-10% of amino-terminated polyethylene glycol amidated pectic acid, 2%-4% of aleuritic acid group organic salt and the balance water, wherein the aleuritic acid group organic salt is prepared by carrying out ion exchange reaction on aleuritic acid and choline. The invention further discloses a preparation method of the cold chain coolant. The cold chain coolant disclosed by the invention has the advantages of large latent heat, small supercooling degree, good heat transfer, good cold chain effect, small toxicity and pollution, high cold chain efficiency and long cold storage time.

Owner:HUNAN QIWEI TECH CO LTD

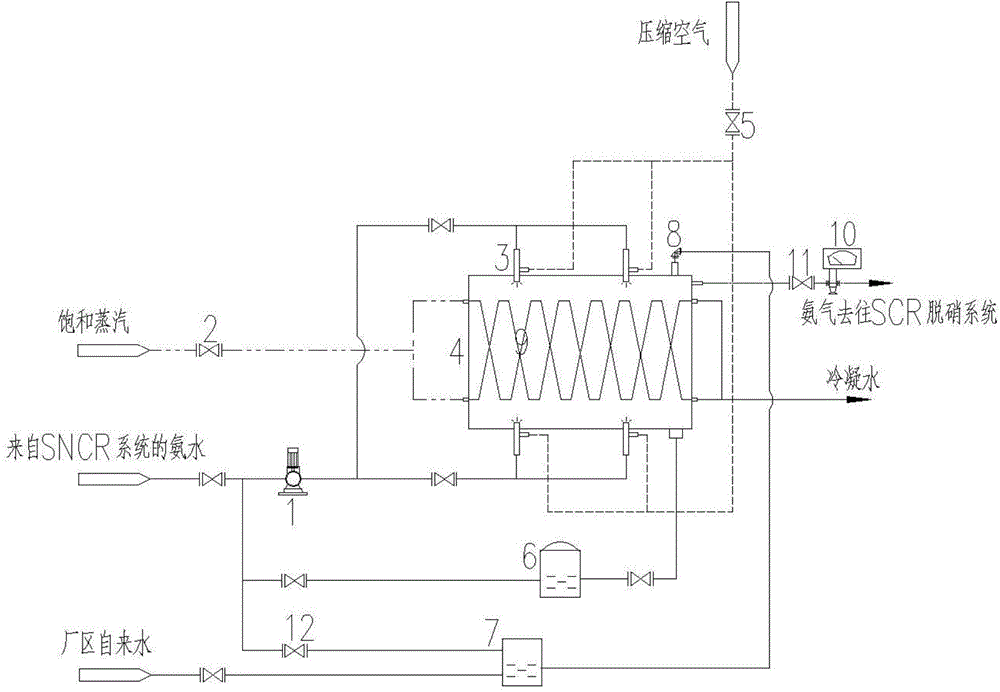

System and method for preparing ammonia gas by using ammonia water for cement plant SCR denitration

InactiveCN106145159AIncrease the heat exchange areaIncrease evaporation rateDispersed particle separationAmmonia preparation/separationWater vaporEvaporation

The invention relates to a system and method for preparing ammonia gas by using ammonia water for cement plant SCR denitration and belongs to the technical field of environmental protection. In the system for preparing ammonia gas by using ammonia water for cement plant SCR denitration, an ammonia water delivery pump and a compressed air inlet valve are communicated with a double-fluid atomization spray gun through pipes, the double-fluid atomization spray gun is installed on an evaporator for atomization, the lower portion of the evaporator is communicated with an intermediate tank through a pipe, the upper portion of the evaporator is communicated with an ammonia gas absorption tank through an evaporator safety valve, and the evaporator is communicated with an ammonia gas outlet valve. The method for preparing ammonia gas by using ammonia water for cement plant SCR denitration comprises the steps that the ammonia water is fed into the ammonia water-compressed air double-fluid atomization spray gun through the ammonia water delivery pump for atomization, atomized micron-grade-particle-size liquid drops enter the evaporator, latent heat of saturated vapor is utilized to evaporate the ammonia water, ammonia-water vapor mixed gas is led to a cement plant SCR denitration system. The system has the advantages of being simple in structure, reliable in performance, accurate in control, flexible, convenient, safe, reliable, stable in process, low in operation cost, high in evaporation efficiency and the like.

Owner:SINOMA TECH & EQUIP GRP +1

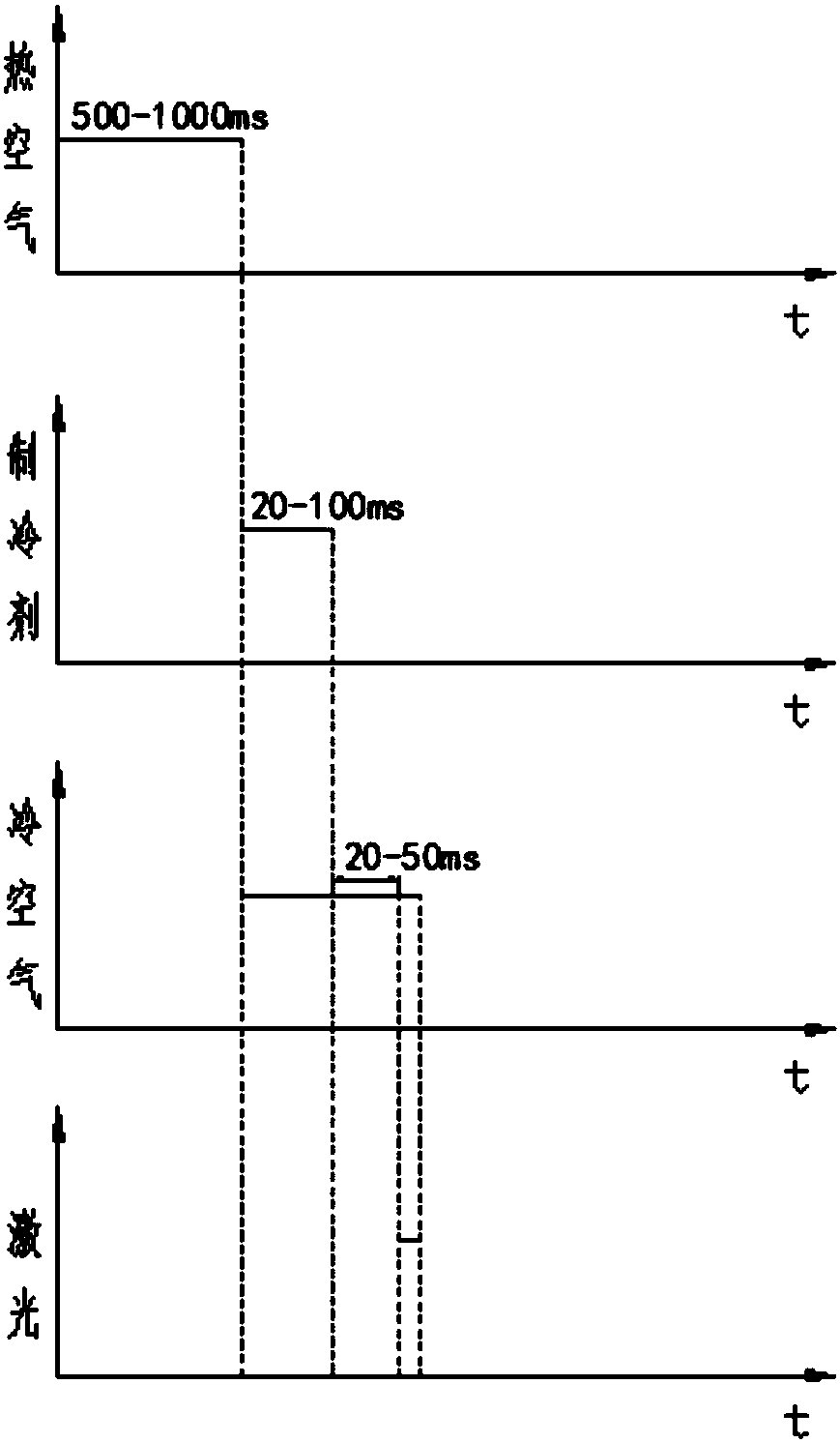

Hot-cold dual-gas-coupled refrigerant-spraying cooling system for treatment of nevus of Ota

ActiveCN107929953AIncrease temperaturePromote absorptionRadiation therapyElectrical resistance and conductanceTherapeutic effect

The invention discloses a hot-cold dual-gas-coupled refrigerant-spraying cooling system for treatment of nevus of Ota. The system is composed of a refrigerant reservoir, a first electromagnetic valve,a second electromagnetic valve, a third electromagnetic valve, a first nozzle, a second nozzle, a third nozzle, a high-pressure air storage tank, and a resistance wire heating device. The refrigerantreservoir is connected with an inlet end of the first electromagnetic valve by a first flexible pipe; the first nozzle is installed at an outlet end of the first electromagnetic valve; the high-pressure air storage tank is connected with the second electromagnetic valve and the third electromagnetic valve by a second flexible pipe and a third flexible pipe; the second nozzle and the third nozzleare installed at outlet ends of the second electromagnetic valve and the third electromagnetic valve; and the resistance wire heating device is installed at the position, approaching the second electromagnetic valve, of the second flexible pipe. Therefore, the laser is assisted well for good treatment; and the skin is protected and the treatment effect is ensured.

Owner:XI AN JIAOTONG UNIV

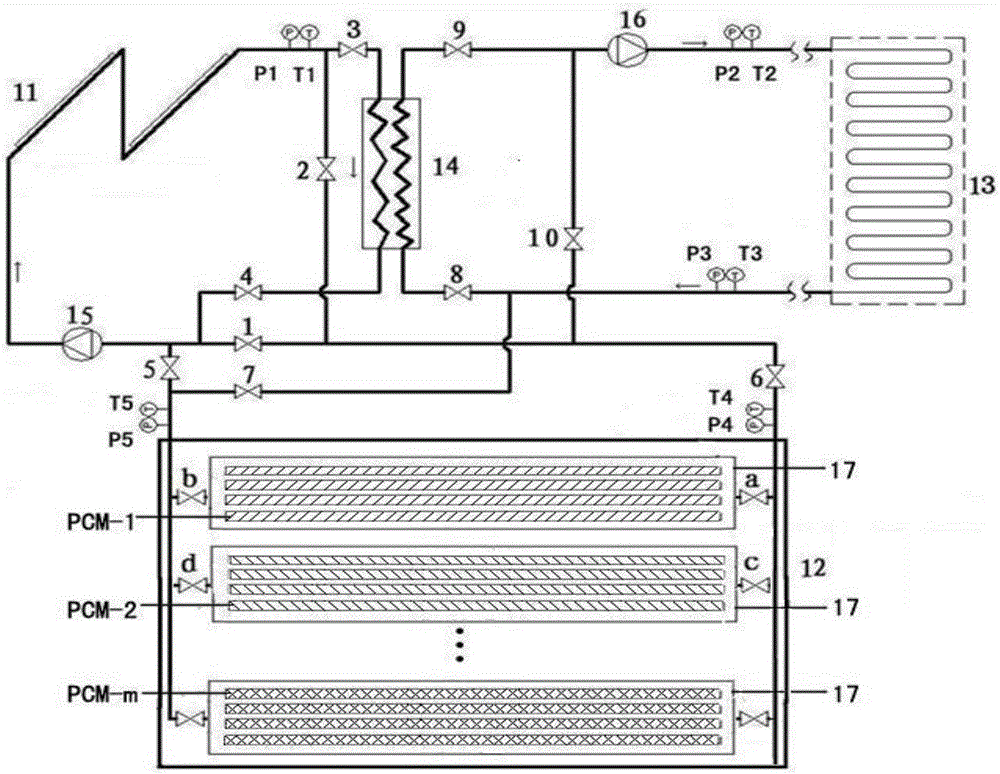

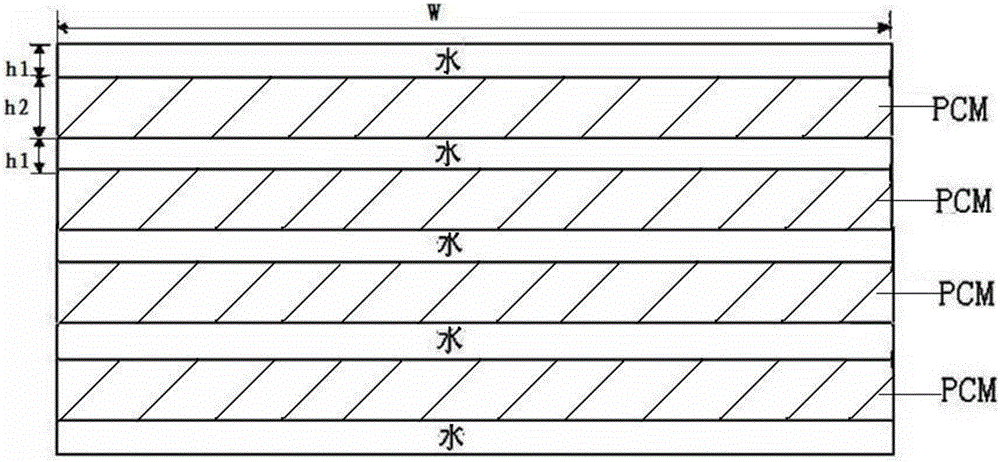

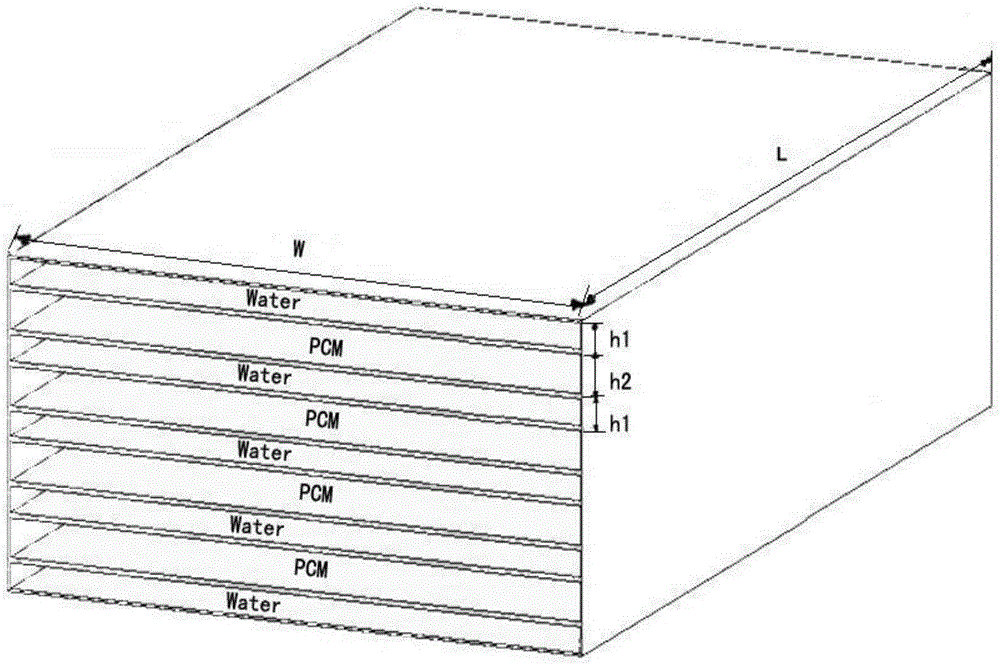

A cross-seasonal solar energy-phase change energy storage graded release energy heating system and method

InactiveCN103712255BReduce dependenceMitigating the problem of large heat loss across seasonsHeat storage plantsEnergy storageThermal energyCollector device

The invention belongs to the field of seasonal energy accumulation heating, and particularly relates to a seasonal solar energy-phase change energy accumulation graded energy-releasing heating system and method. The system mainly comprises a solar heat collector, a phase change energy accumulation heat exchanger, a heating module and a heat exchanger, all of which are connected together through a pipeline, a valve and a circulating pump. According to the system, in non-heating season, solar heat is stored in phase change materials with different temperature levels capable of realizing stable undercooling, so as to stand in an undercooling liquid state; in heating season, two modes, namely, heating load supply by direct heat exchange between heating medium water and the heat collector and heating load supply by direct heat exchange between the heating medium water and the phase change heat exchanger, can be adopted and the phase change material units with different temperature levels are triggered by grades to be solidified and release energy according to loads in different stages. By utilizing the conception that the seasonal phase change energy accumulation graded released energy is utilized to provide heating load in winter, the system has the characteristics of being large in phase change latent heat, stable in heat release temperature, capable of being adjusted by grades, and the like, thus having wide application prospects in a seasonal heat accumulation heat supply system.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Constant-temperature phase change energy storage material

ActiveCN102732228BSmall latent heatReduce subcoolingHeat-exchange elementsBuilding constructionsCross-linkCarbon chain

The invention provides a phase change energy storage material which has the characteristics of phase change temperature of 25-28 DEG C, great potential heat, small super-cooling degree and high stability. The phase change energy storage material is at a solid state at the temperature which is lower than 25-28 DEG C; when the temperature is higher than 25-28 DEG C, the potential heat is absorbed to carry out phase change to be changed into a liquid state. Dodecanol and paraffin are used as main raw materials, and a cross-linking agent, an initiator, an emulsifying agent and a nucleating agent are used as auxiliary materials, the main raw materials are reacted with the auxiliary materials, and then carbon chain recombination happens under the effect of the initiator, a silane coupling agent, the emulsifying agent and the like to prepare the product. The phase change temperature is 25-28 DEG C and the phase change potential heat is 156-163 KJ / Kg. The phase change energy storage material has the characteristics that the phase change temperature is the room temperature, the potential heat is high and the raw materials are wide and cheap; the material is not layered and has no sediments after being repeatedly subjected to the phase change for a plurality of times; and the potential heat value is stable and the super-cooling degree is less than 1 DEG C. After the material is packaged, the material can be combined with a building wall body and the property of absorbing the potential heat enables the wall body to have the function of adjusting the temperature.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com