Energy-storage heat exchange device

A technology of heat exchange device and heat exchanger, which is applied in the direction of heat storage equipment, heat exchanger type, indirect heat exchanger, etc., can solve the problems of restricting large-scale application, poor heat storage capacity, etc., and avoid excessive phase transition temperature. High, heat-resistant temperature increase, the effect of improving elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

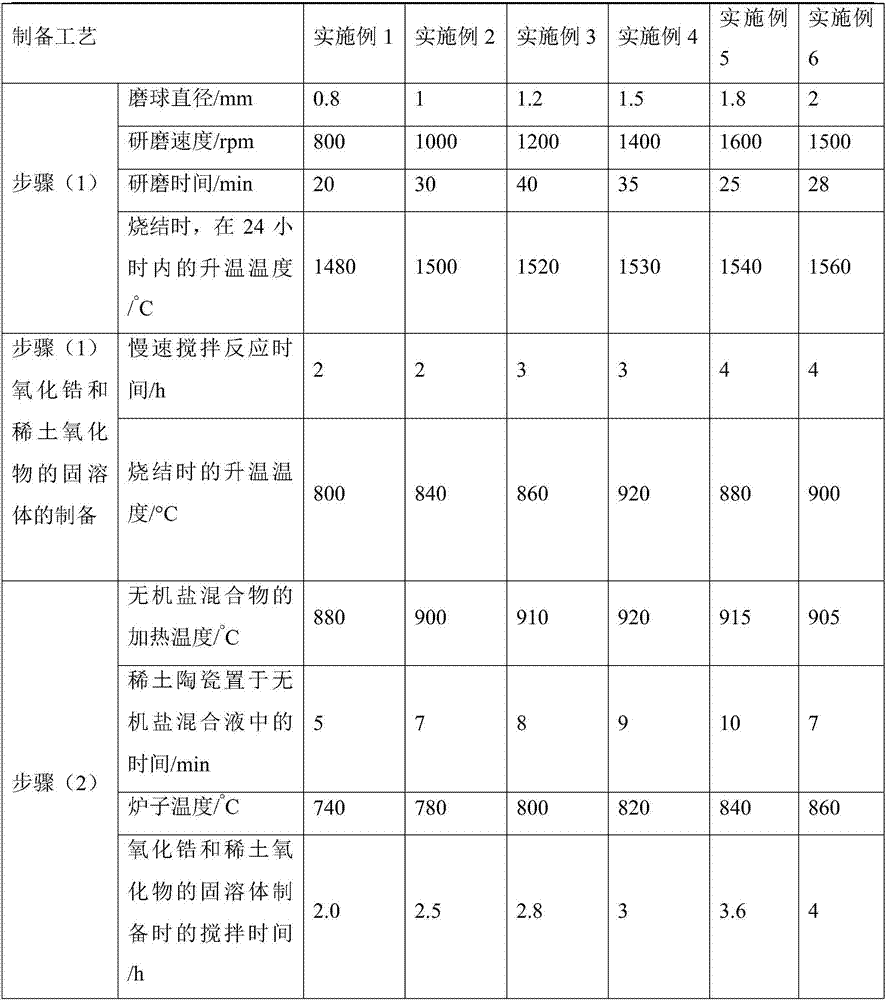

[0058] The preparation method of the rare earth ceramic high-temperature energy storage and discharge material of the present invention comprises the following steps:

[0059] (1) Put 92-98 parts of alumina, 5-8 parts of solid solution of zirconia and rare earth oxides, 1-3 parts of magnesium oxide, 60-80 parts of cellulose solution and 100-150 parts of deionized water into the grinder Mix and grind in the middle, and then make a mixed slurry, and then inject the mixed slurry into a mold to make a mold, and after the molded product is dried, it is sintered at a high temperature to make a rare earth ceramic;

[0060] (2) Mix the inorganic salt mixture in the phase change material, heat and dissolve at a constant temperature to obtain a mixed solution, then place the rare earth ceramics in the above mixed solution and cook for 5-10 minutes, then take out the rare earth ceramics and place them in a refrigerator at 740-860°C The furnace cools down naturally with the furnace to pro...

Embodiment 7-12

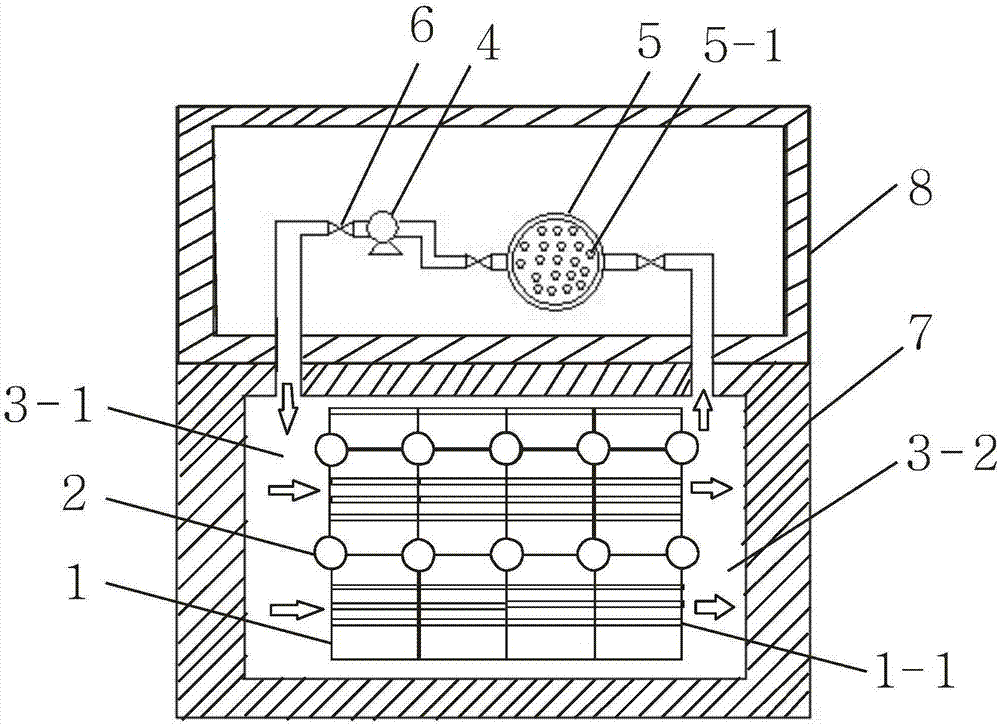

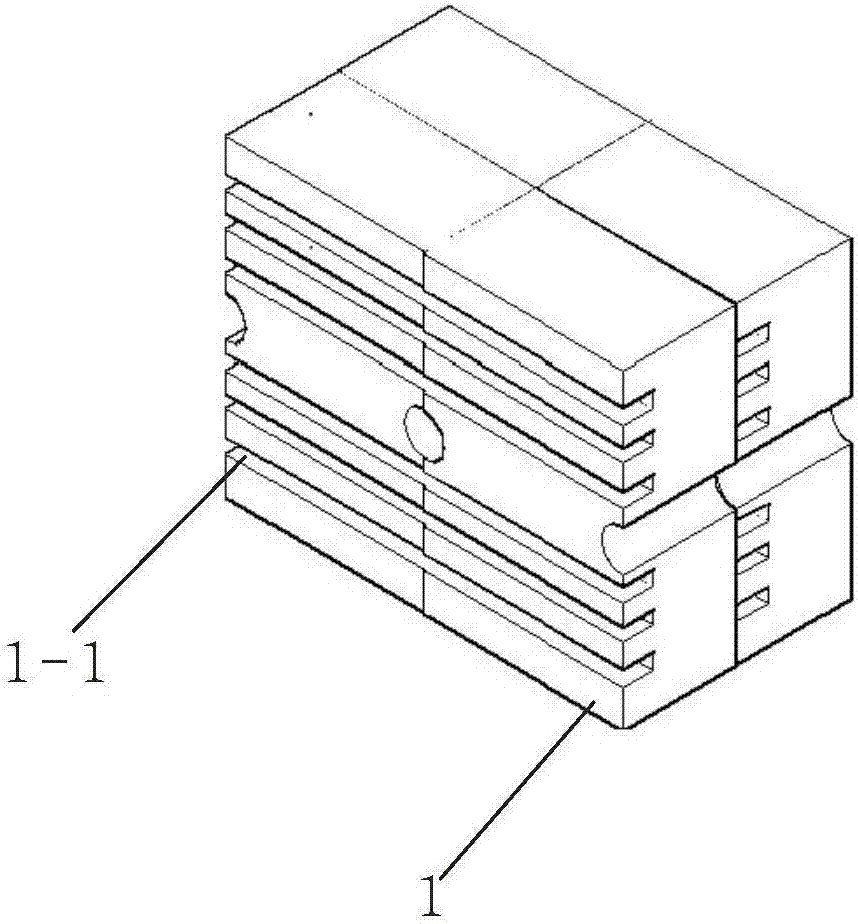

[0100] like Figure 1-2 Shown is the energy storage heat exchange device of the present invention, the energy storage heat exchange device includes an energy storage pile 1, a heat exchanger 5, a heating pipe 2 and a blower fan 4; The gap left between the energy stack 1 and the insulation layer A7 is used as an air duct, and the energy storage stack 1 is provided with a groove 1-1 for ventilation;

[0101] The fan 4 and the heat exchanger are connected through pipelines, the other end of the fan 4 is connected to the air duct A 3-1 through the pipeline, and the other end of the heat exchanger is connected to the air duct B 3-2 through the pipeline, wherein the air The channel A 3-1 and the air channel B 3-2 refer to the air channel formed between the opposite ends of the energy storage pile 1 and the insulation layer A 7;

[0102] The heating pipe is installed in the energy storage stack 1 to heat the energy storage stack 1. Driven by the fan 4, the air flow enters the energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com