Thermal cut-off equipment of high-temperature superconducting binary current lead

A binary current lead and high-temperature superconducting technology, which is applied in the direction of superconducting magnets/coils, circuits, electrical components, etc., can solve the problem of increased heat leakage of liquid helium, high and uneconomical evaporation of liquid helium, and insufficient cooling power to fully bring Problems such as heat load of copper leads, etc., achieve the effect of increasing operation stability and safety, increasing temperature margin, and good heat sink effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

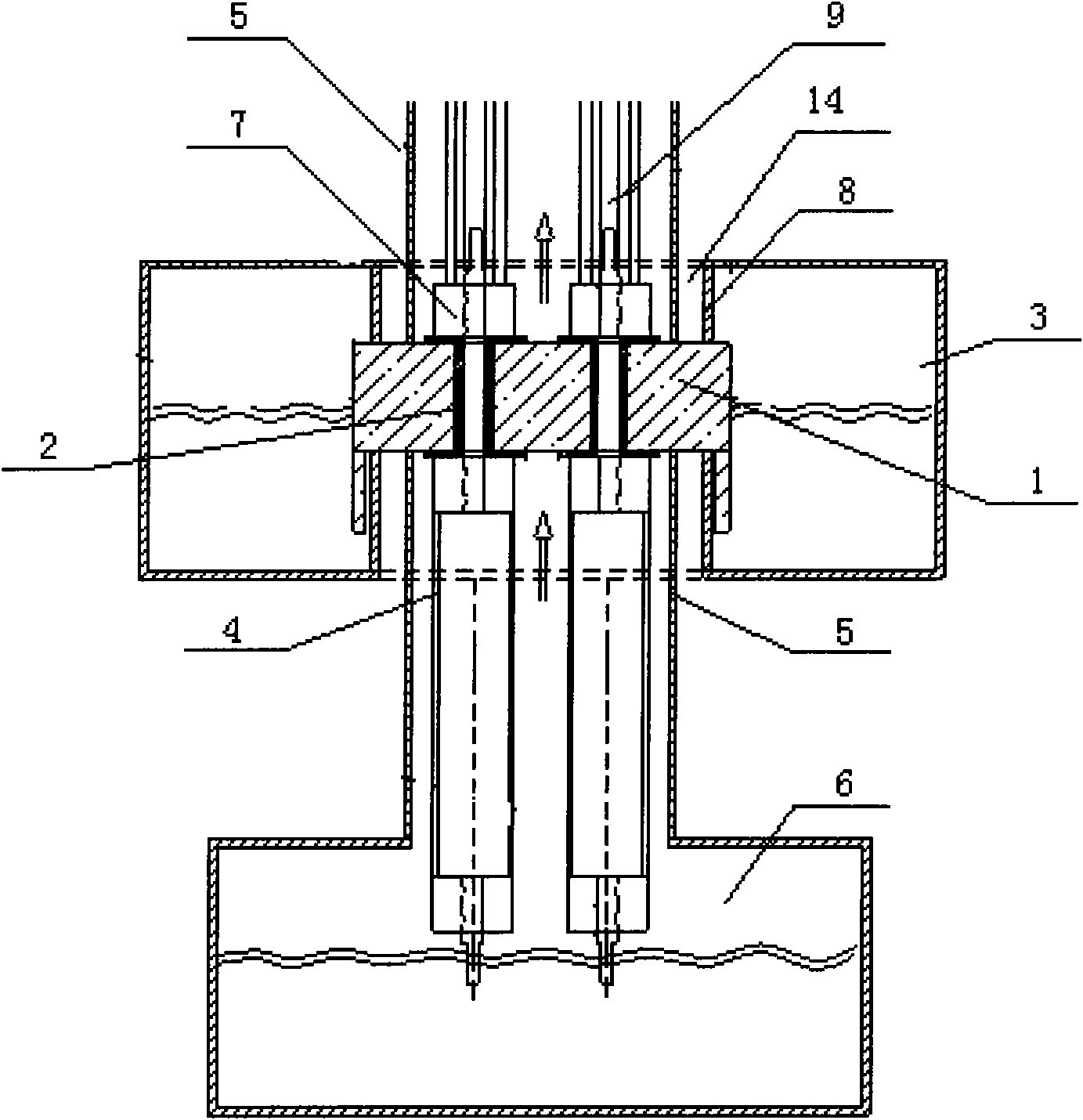

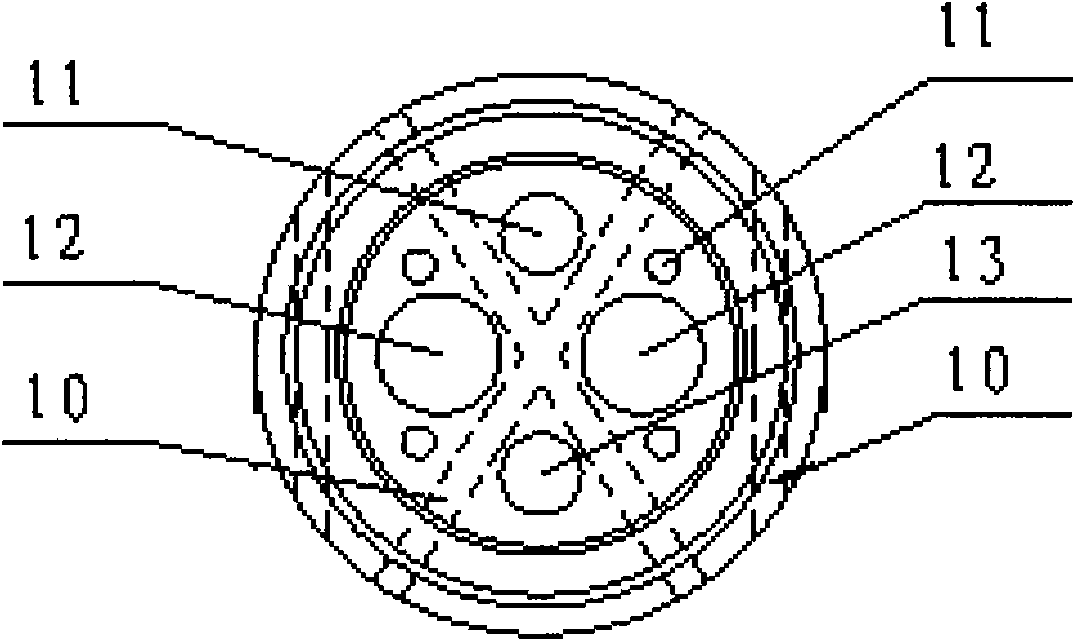

[0014] The high-temperature superconducting binary current lead thermal cut-off device includes a liquid nitrogen tank 3 and a liquid helium tank 6, and the liquid nitrogen tank 3 and the liquid helium tank 6 are respectively equipped with liquid nitrogen and liquid helium, and is characterized in that: the liquid The helium tank 6 is connected with a current lead neck tube 5, and the current lead neck tube 5 is provided with a high temperature superconducting lead wire 4; the middle part of the current lead neck tube 5 is connected with a heat conduction plate 1, and the heat conduction plate 1 is embedded in the liquid nitrogen In the central hole 14 of the tank, the upper and lower end surfaces of the heat conduction plate 1 are fixedly connected with the tank wall 8 of the central hole 14 of the liquid nitrogen tank respectively; a plurality of vertical through holes are opened between the upper and lower end surfaces of the heat conduction plate 1 as The current lead chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com