System and method for preparing ammonia gas by using ammonia water for cement plant SCR denitration

A cement plant and ammonia water technology, applied in the direction of ammonia preparation/separation, separation methods, chemical instruments and methods, etc., can solve the problems of ammonia water spray gun, heat exchanger wear, large tower body, etc., to increase heat exchange area, evaporate Increased speed and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

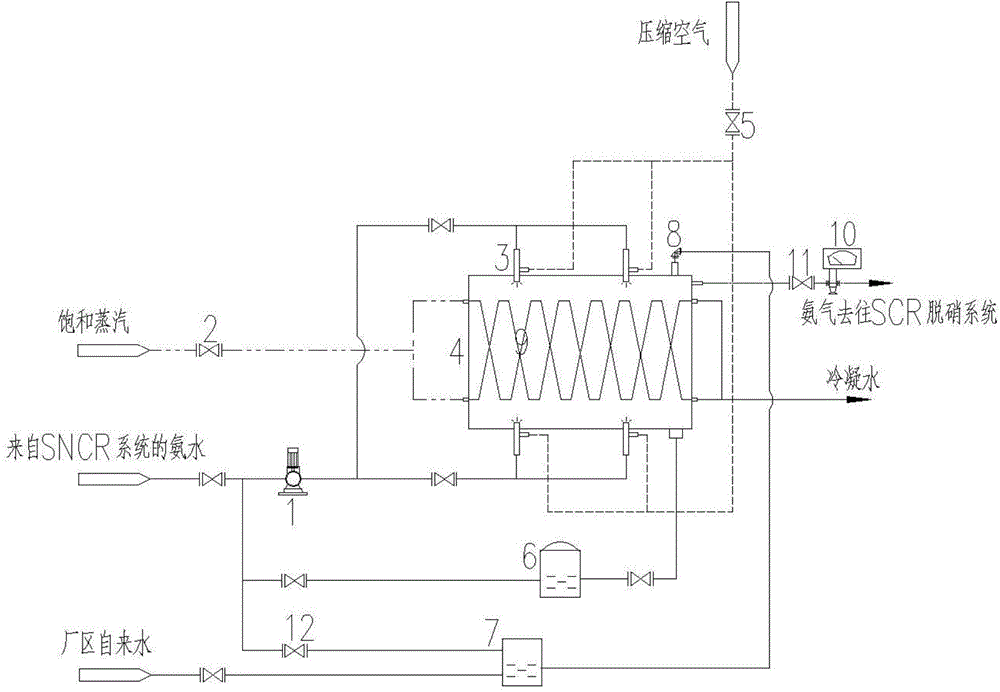

[0030] A system for preparing ammonia gas from ammonia water for SCR denitrification in a cement plant, including: ammonia water delivery pump, evaporator, saturated steam inlet valve, heat exchange tube, two-fluid atomizing spray gun, ammonia gas outlet valve, ammonia gas outlet flowmeter, intermediate tank , Ammonia absorption tank, compressed air inlet valve, etc. The ammonia water delivery pump and the compressed air inlet valve are connected to the dual-fluid atomizing spray gun through the pipeline, and the dual-fluid atomizing spray gun is installed on the evaporator for atomization. For the heat pipe, the nozzle head of the two-fluid atomizing spray gun faces the evaporator cavity outside the heat exchange tube. The lower part of the evaporator is connected to the intermediate tank by a pipeline, and the intermediate tank is connected to the inlet of the ammonia delivery pump by a valve and a pipeline. The ammonia water that is not completely evaporated passes through...

Embodiment 2

[0032] A method for preparing ammonia gas from ammonia water for SCR denitrification in a cement plant. The process of ammonia water preparation includes ammonia water passing through an ammonia water delivery pump and entering an ammonia water-compressed air dual-fluid atomization spray gun for atomization, and the atomized droplets with micron-sized particles After entering the evaporator, the atomized ammonia water and saturated steam conduct indirect heat exchange in the evaporator, and the latent heat of saturated steam is used to evaporate the ammonia water, and the evaporated ammonia-water steam mixture goes to the SCR denitrification system of the cement plant.

[0033] The unevaporated ammonia water in the evaporator flows back into the intermediate tank, and enters the evaporator again through the ammonia water delivery pump for circular evaporation. The evaporator is equipped with a safety valve. The ammonia-water vapor exceeding the pressure of the evaporator enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com