Low-temperature thermal control phase change microcapsule and preparation method thereof

A technology of phase-change microcapsules and low-temperature heat, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., can solve the problems of low thermal conductivity and achieve high thermal conductivity, large latent heat, and high thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

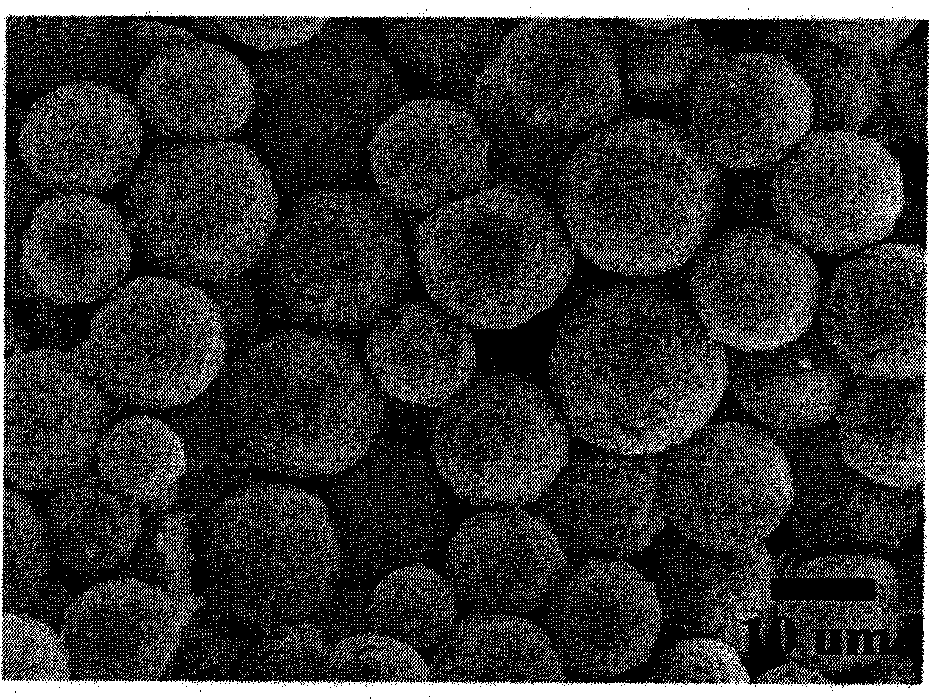

Image

Examples

Embodiment 1

[0051] Core material: n-tetradecane, shell: urea-formaldehyde resin, thermally conductive filler: high thermally conductive carbon powder and carbon fiber, the mass of carbon fiber accounts for 50% of the mass of the thermally conductive filler; the thermally conductive filler accounts for 20% of the mass of the core material.

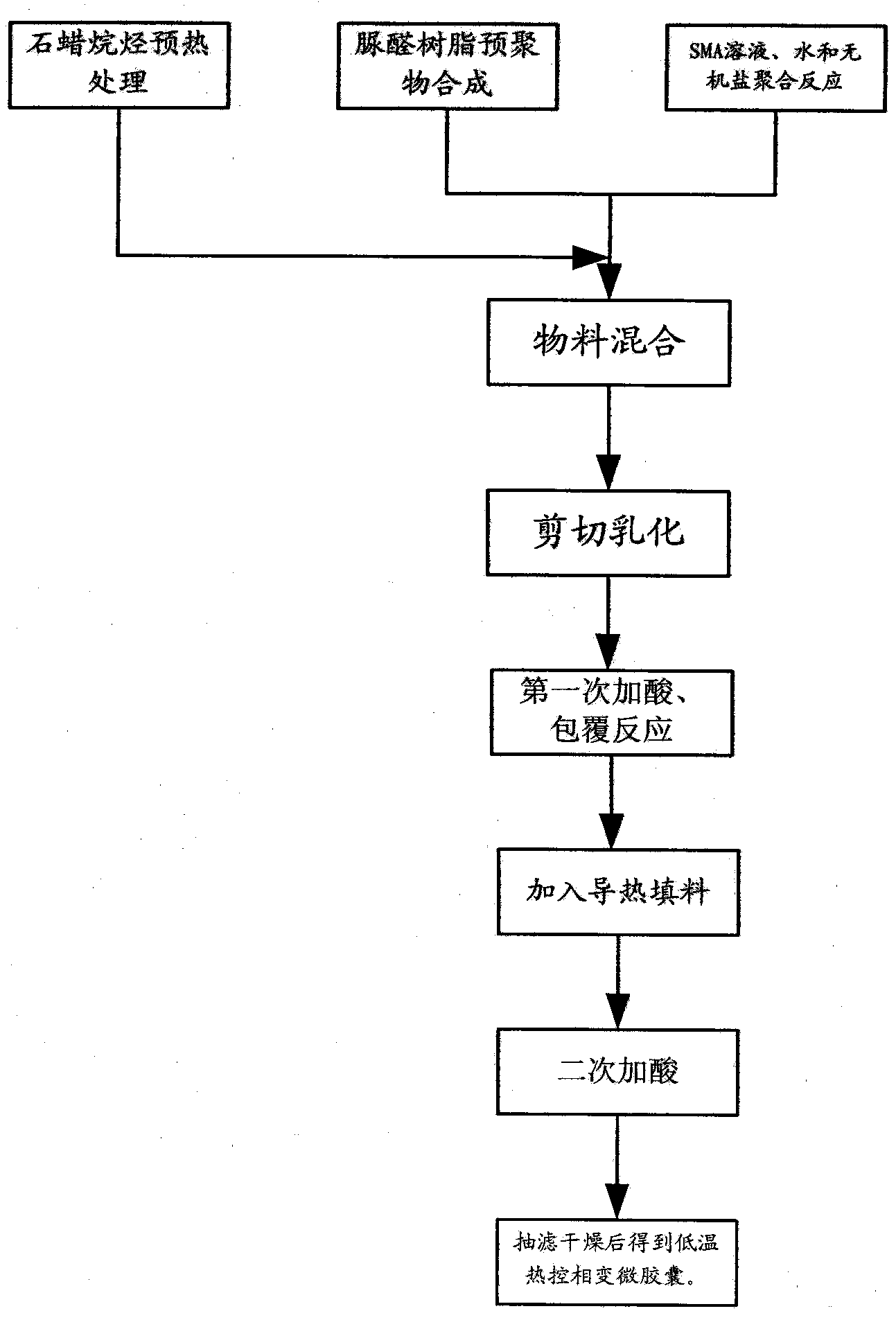

[0052] Concrete preparation process is as follows:

[0053] (1) Paraffin alkane preheating treatment

[0054] Preheat 2000g of n-tetradecane phase change raw material (Alfalfa reagent, purity ≥ 99%) in a 60°C water bath for 1 hour to ensure that the system temperature does not drop after the materials are mixed in the later stage.

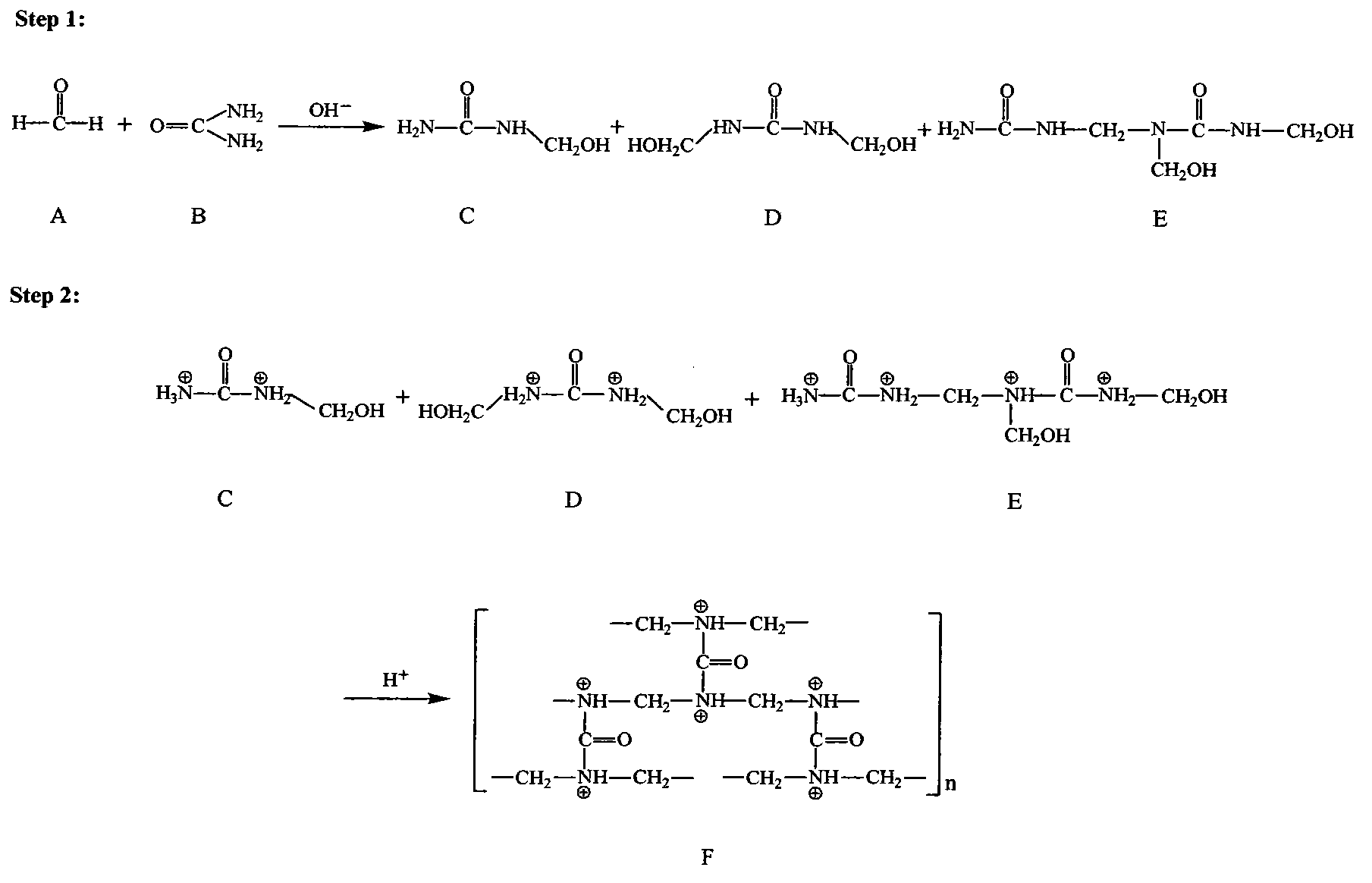

[0055] (2) Prepolymer synthesis

[0056] Weigh 750g of urea into a 5L three-neck bottle, add 1700g of formaldehyde and 164g of melamine with a concentration of 37% respectively, set the temperature of the water bath at 70°C, stir and heat for 1h, add 8.0g of triethanolamine reagent, and adjust the pH value of the reaction ...

Embodiment 2

[0071] Core material: n-pentadecane, shell: urea-formaldehyde resin, thermally conductive filler: high thermally conductive carbon powder and carbon fiber, the mass of carbon fiber accounts for 17.5% of the mass of the thermally conductive filler; the thermally conductive filler accounts for 5% of the mass of the core material.

[0072] The specific preparation process is the same as in Example 1. The performance test was carried out on the phase change microcapsules after drying, and its parameters are shown in Table 2.

Embodiment 3

[0074] Core material: n-heptadecane, shell: urea-formaldehyde resin, thermally conductive filler: high thermally conductive carbon powder and carbon fiber, the mass of carbon fiber accounts for 32.5% of the mass of the thermally conductive filler; the thermally conductive filler accounts for 30% of the mass of the core material.

[0075] The specific preparation process is the same as in Example 1. The performance test was carried out on the phase change microcapsules after drying, and its parameters are shown in Table 2.

[0076] Table 2

[0077]

[0078] Note: The enthalpy values of n-pentadecane and n-heptadecane in Table 2 are the effective enthalpy values in the DSC test.

[0079] As can be seen from Table 2, along with the increase of thermally conductive fillers, the better the thermal conductivity of the phase change material, the lower the phase change enthalpy. Control, so the content of thermally conductive fillers cannot be added indefinitely, and the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com