Patents

Literature

61 results about "Heptadecane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heptadecane is an organic compound, an alkane hydrocarbon with the chemical formula C₁₇H₃₆. The name may refer to any of 24894 theoretically possible structural isomers, or to a mixture thereof. The unbranched isomer is normal or n-heptadecane, CH₃(CH₂)₁₅CH₃. In the IUPAC nomenclature, the name of this compound is simply heptadecane, since the other isomers are viewed and named as alkyl-substituted versions of smaller alkanes.

Method for producing heptadecanedioic acid by fermenting and converting n-heptadecane

ActiveCN102115765AScale upImprove conversion rateMicroorganism based processesFermentationCandida tropicalisCarboxylic acid

The invention discloses a method for producing long-chain alpha,omega-dicarboxylic acid by fermenting and converting an n-alkane with microbes, particularly a method for producing high-yield heptadecanedioic acid, which comprises the following steps: inoculating seed liquor, which is cultured from a Candida tropicalis mutant strain ly-7 which is obtained by mutagenesis by an N<+> injection technique and subjected to oxidase activity screening and culture, into mixed liquor of an n-alkane and a fermentation medium; fermenting and converting at 25-32 DEG C for 48-168 hours; and separating and purifying the generated long-chain alpha,omega-dicarboxylic acid. When n-heptadecane is fermented and converted to produce the heptadecanedioic acid in a 5-ton fermentation tank for 144 hours, the content of the heptadecanedioic acid can reach 163 g / l.

Owner:青岛智库生物科技有限公司

Method for detecting atomization homogeneity of electronic cigarette atomizer

ActiveCN103940602AThe inspection method is accurate and reliableHuman factors are smallMachine part testingComponent separationNebulizerInternal standard

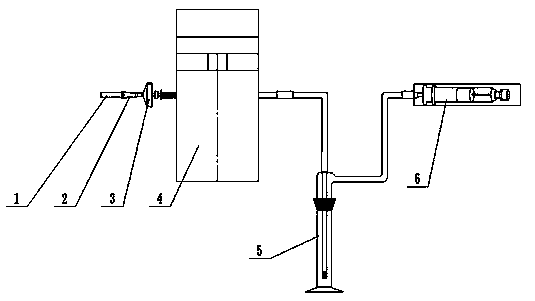

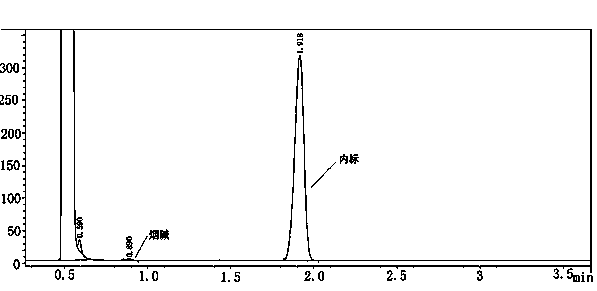

The invention relates to a method for detecting atomization homogeneity of an electronic cigarette atomizer. A linear smoking machine is adopted to smoke electronic cigarettes of the same specification and the same type in an ISO smoking mode, 44 mm Cambridge filters are used for trapping total particulate matter of smoke release matter after an electronic cigarette is smoked by 50 times continuously, an absorption bottle is connected between a catcher and a smoking needle cylinder, and 20 mL isopropyl alcohol extraction agents with 0.2-0.5 mg / mL n-heptadecane as internal standard substance is accurately added in the absorption bottle. After smoking, the absorption liquid in the absorption bottle is used for extracting nicotine in the Cambridge filters, and the gas chromatographic method is adopted to measure the nicotine content in the extraction agents according to the GB / T 23355-2009. The nicotine content in the smoke release matter of all electronic cigarette samples is calculated to obtain the SD, and the value of the SD responds the atomization homogeneity of the electronic cigarette atomizer in the batch. The method can quantitatively research the atomization homogeneity of the electronic cigarette atomizer, and is a practical and scientific method for estimation on the atomization homogeneity of the electronic cigarette atomizer.

Owner:CHINA TOBACCO YUNNAN IND

Preparation method of clay-based composite phase-change energy storage deicing (snow melting) material

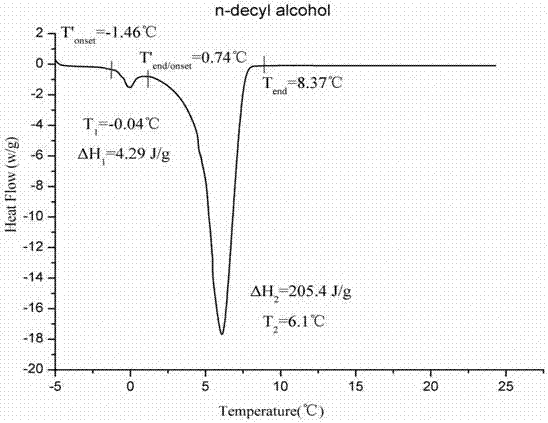

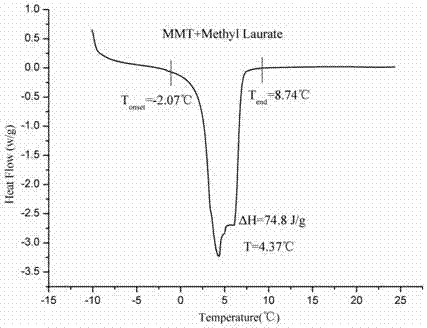

The invention discloses a preparation method of a clay-based composite phase-change energy storage deicing (snow melting) material. The preparation method is characterized in that a composite phase-change energy storage material is prepared from a low-temperature organic phase-change material and a clay material, wherein the low-temperature organic phase-change material is prepared by single-element or multi-element mixing of various organic phase-change materials and is then physically compounded with the treated clay to prepare the clay-based composite phase-change energy storage deicing (snow melting) material. The low-temperature organic phase-change material is selected from polyethylene glycol-300, polyethylene glycol-400, polyethylene glycol-500, polyethylene glycol-600, decyl alcohol, undecanol, dodecanol, heptylic acid, octanoic acid, nonanoic acid, capric acid, methyl laurate, methyl myristate, methyl palmitate, tetradecane, pentadecane, hexadecane, heptadecane, octodecane, nonadecane and the like. The clay material is selected from kaolinite, montmorillonite, bentonite, vermiculite, halloysite, sepiolite, attapulgite, perlite, diatomite, rectorite, zeolite, silicon dioxide, dolomite, calcite and illite. The prepared composite phase-change energy storage deicing (snow melting) material is proper in phase-change temperature (0-5 DEG C), high in phase-change latent heat and high in heat stability.

Owner:CENT SOUTH UNIV

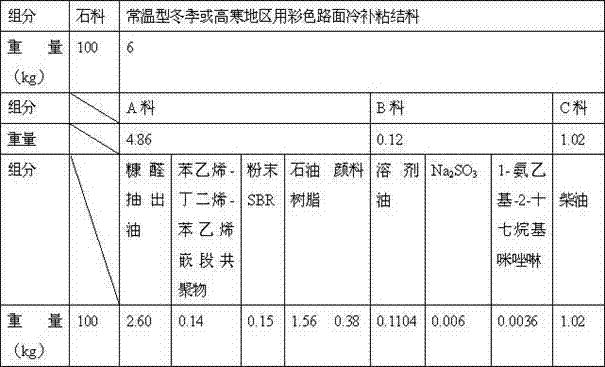

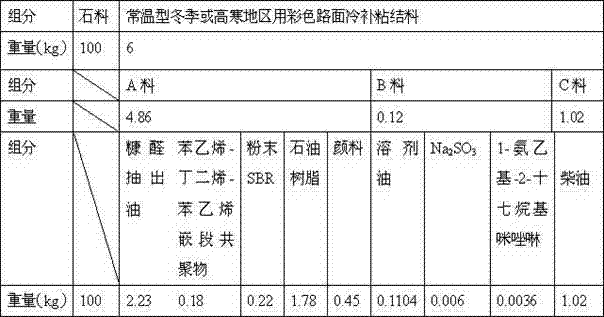

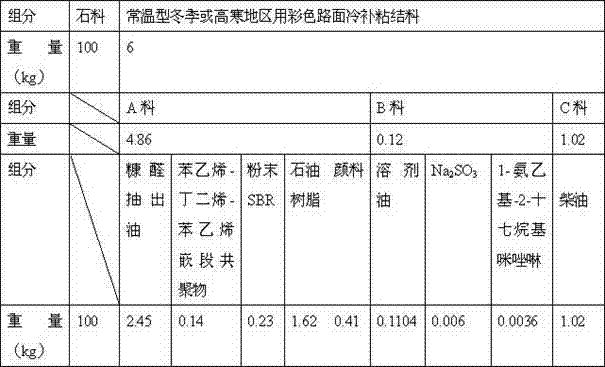

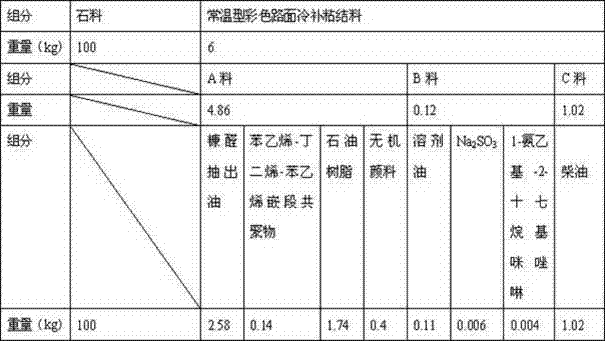

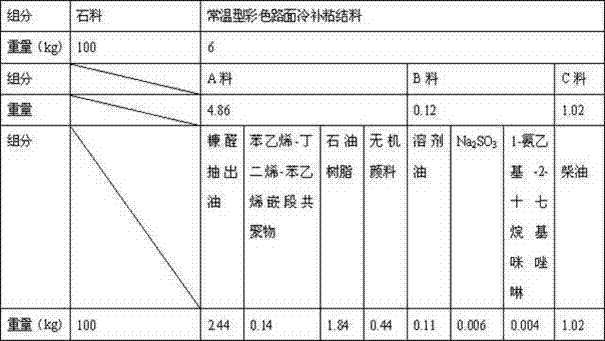

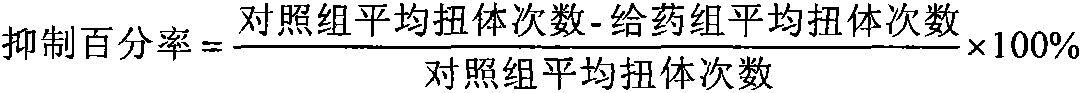

Normal-temperature color pavement cold paving material used in winter or high-cold areas and preparation technology thereof

The invention discloses a normal-temperature color pavement cold paving material used in winter or high-cold areas and a preparation technology thereof. The cold paving material is prepared by mixing a normal-temperature color pavement cold paving adhesive material used in winter or high-cold areas and dried stone according to the weight ratio of 6: 100, wherein the normal-temperature color pavement cold paving adhesive material used in winter or high-cold areas is prepared by uniformly mixing an A material, a B material and C material according to the weight ratio of 81: 2: 17. The A material is made from the following ingredients of: by weight, 50-55 parts of furfural extract oil, 3-4 parts of a styrene-butadiene-styrene segmented copolymer, 4-5 parts of a powder SBR, 33-40 parts of a petroleum resin and 8-10 parts of a pigment. The B material is made from the following ingredients of: by weight, 92 parts of solvent naphtha, 5 parts of Na2SO3 and 3 parts of 1-aminoethyl-2-heptadecylimidazoline. The C material is diesel oil. The normal-temperature color pavement cold paving material requires low cost, is convenient to use, has strong performance in winter or high-cold areas, and simultaneously has the same color with the color pavement and has the same properties with the adhesive material. In addition, the traffic situation will not be influenced during construction.

Owner:河南金欧特实业集团股份有限公司

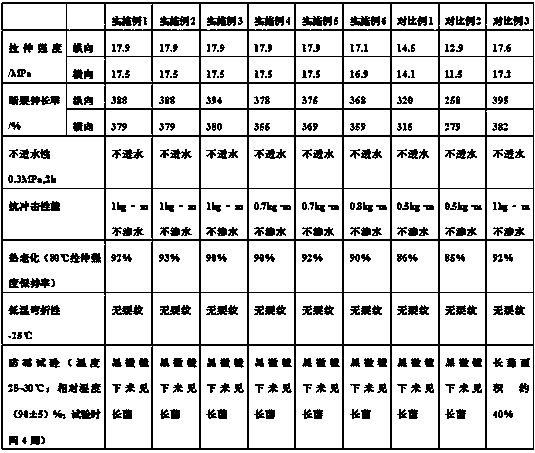

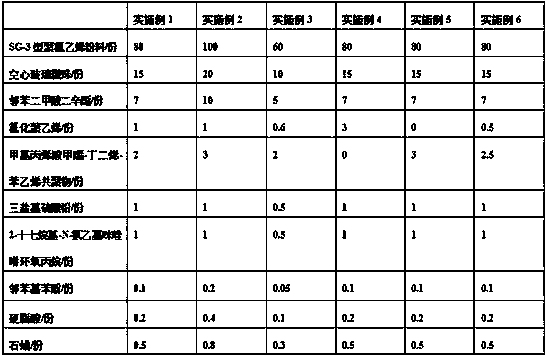

Polyvinyl chloride waterproof coiled material and production technology thereof

InactiveCN108485117AImprove impact resistanceImprove high temperature and fire resistance performance and thermal insulation performanceParaffin waxPlasticizer

The invention discloses a polyvinyl chloride waterproof coiled material and a production technology thereof, and belongs to the field of macromolecular structural waterproof coiled materials. The polyvinyl chloride waterproof coiled material disclosed by the invention comprises polyvinyl chloride, inorganic filler, plasticizer, impact modifier, stabilizer, lubricant, and further comprises anti-mildew agent and softener, wherein the lubricant is composed of stearic acid and paraffin, the inorganic filler is hollow glass beads, the anti-mildew agent is o-phenylphenol, and the softener is 2-heptadecyl-N-aminoethyl imidazoline propylene epoxide. The tensile property, the anti-impact property, the biological ageing resistance property, the high-temperature thermal ageing resistance property andthe heat insulation property of the obtained polyvinyl chloride waterproof coiled material are all significantly improved, and meanwhile, the hollow glass beads obtained by treating coal ash are usedas raw material, so that the cost of the coiled material is reduced, and thus the coiled material is suitable for application and popularization.

Owner:鑫宝防水材料股份有限公司

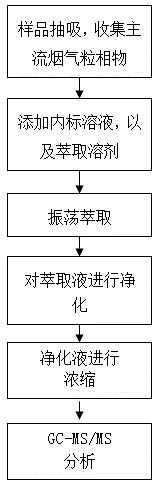

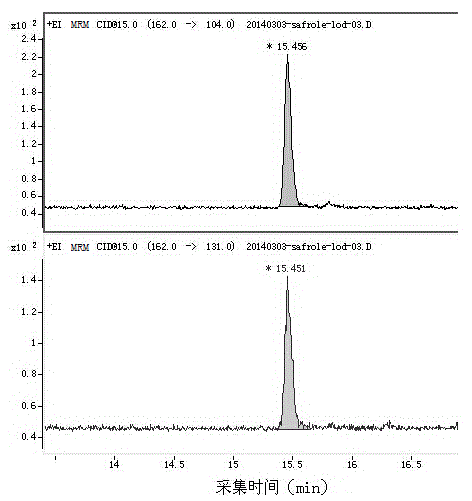

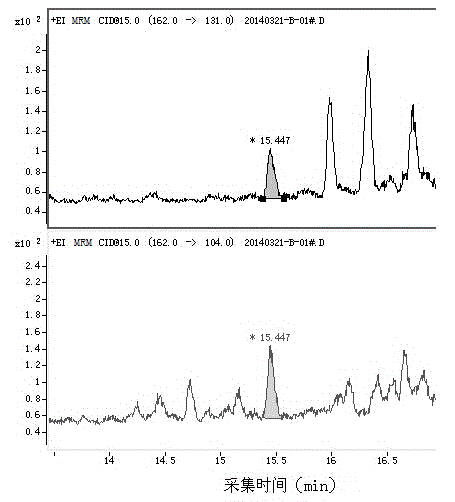

Method for measuring safrole in mainstream smoke of cigarettes

InactiveCN104090042ASolve the impact of factors such as serious interference analysisHigh sensitivityComponent separationLinear correlationRelative standard deviation

The invention discloses a method for measuring safrole in mainstream smoke of cigarettes. The method comprises the steps of preparation of an internal standard solution, a standard working solution and a sample solution, gas chromatography-tandem mass spectrometry analysis, calculation of measurement results and the like. According to the invention, N-heptadecane is used as an internal standard substance for quantifying, the optimized detection method is extremely sensitive in response and accurate in quantitative analysis and effectively reduces the interference caused by complex sample matrix; the adopted chromatography and mass spectrometry conditions enable the target substance to have good signal response and good linear correlation, the detection limit is 0.015ng / cigarette, the relative standard deviation (RSD) is 6.35%, and the adding standard recovery is 87.78-110.9%, thus the method is high in sensitivity, good in repeatability and high in recovery rate and is suitable for quantitative analysis of the safrole serving as a trace target substance in the complex matrix of the smoke.

Owner:CHINA TOBACCO JIANGSU INDAL

Aromatic composition extracted from Cymbidium goeringii Rchb. f. and extracting method therefor

This invention discloses an aroma-producing compound from Cymbidium goeringii and the extraction method thereof. The compound comprises octadecatrienoic aldehyde,nerolidol,dibutylphthalate,heptacosane,pentadecanoic acid,pentadecanoic acid,hexadecanoic acid(palmic acid),oleic acid,linolic acid and cyclohexadecane. The aroma-producing compound is extracted from the flowers of Cymbidium goeringii by the following steps: leaching and filtering, reflux leaching, filtering, combined seperation, volatilized speration, concentration and drying. The main discovery is the octadecatrienoic aldehyde, a critical aroma-producing substance. Besides, the extraction rate of the aroma-producing substances is pretty high, with the content upto 30% by using octadecatrienoic aldehyde and nerolidol as the major aroma-producing product. The components of this invention has satisfied the basic requirements as natural flavoring, and can be used in flavoring agents, perfume, scent emitting objects and bath articles, allowing this natural perfume for industrial application.

Owner:魏平飞 +3

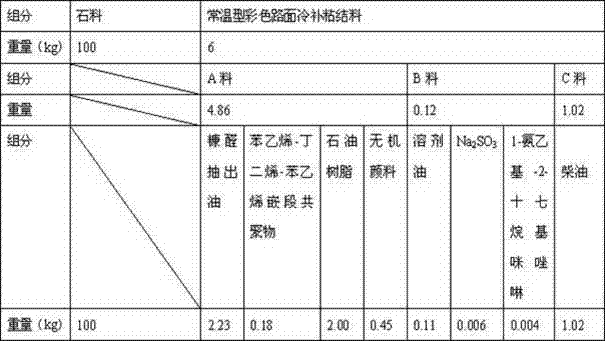

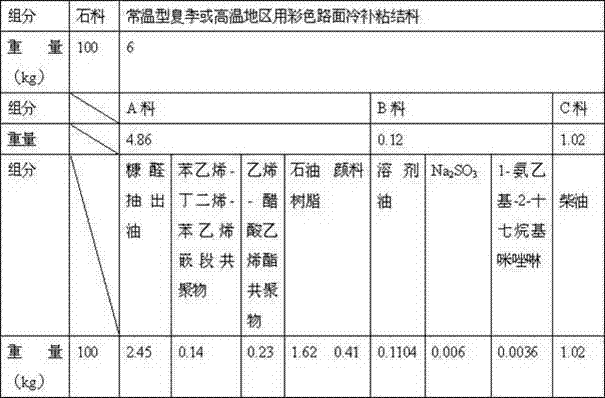

Constant-temperature colored pavement cold repair material and preparation process thereof

ActiveCN102399070ASimple preparation processSimple preparation conditionsPetroleum resinRepair material

The invention discloses a constant-temperature colored pavement cold repair material and a preparation process thereof. The cold repair material is prepared by blending a constant-temperature colored pavement cold repair binding material and dried stone according to a weight ratio of 6:100, wherein the constant-temperature colored pavement cold repair binding material is prepared by uniformly mixing a material A, a material B and a material C according to a weight ratio of 81:2:17; the material A is prepared from the following components in parts by weight: 50-55 percent of furfural extract oil, 3-4 percent of styrene-butadiene-styrene block copolymer, 37-45 percent of petroleum resin and 8-10 parts of inorganic pigment; the material B is prepared from the following components in parts byweight: 92 parts of solvent oil, 5 parts of Na2SO3 and 3 parts of 1-aminoethyl-2-heptadecylimidazoline; and the material C is diesel oil. The cold repair material has the advantages of low cost, convenience in use, no influence on traffic during construction and capability of keeping the same color and binding material property as the colored pavement.

Owner:河南金欧特实业集团股份有限公司

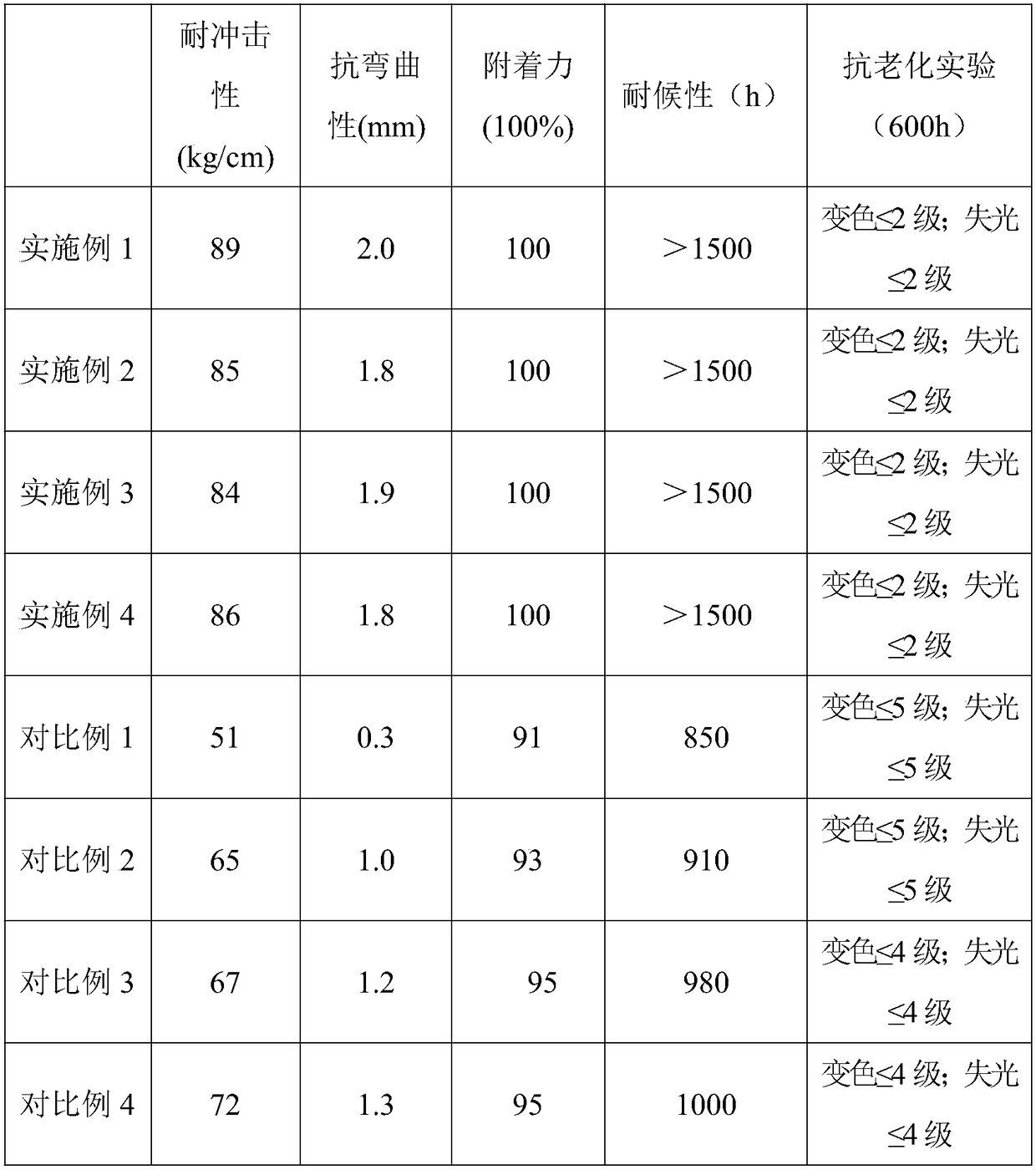

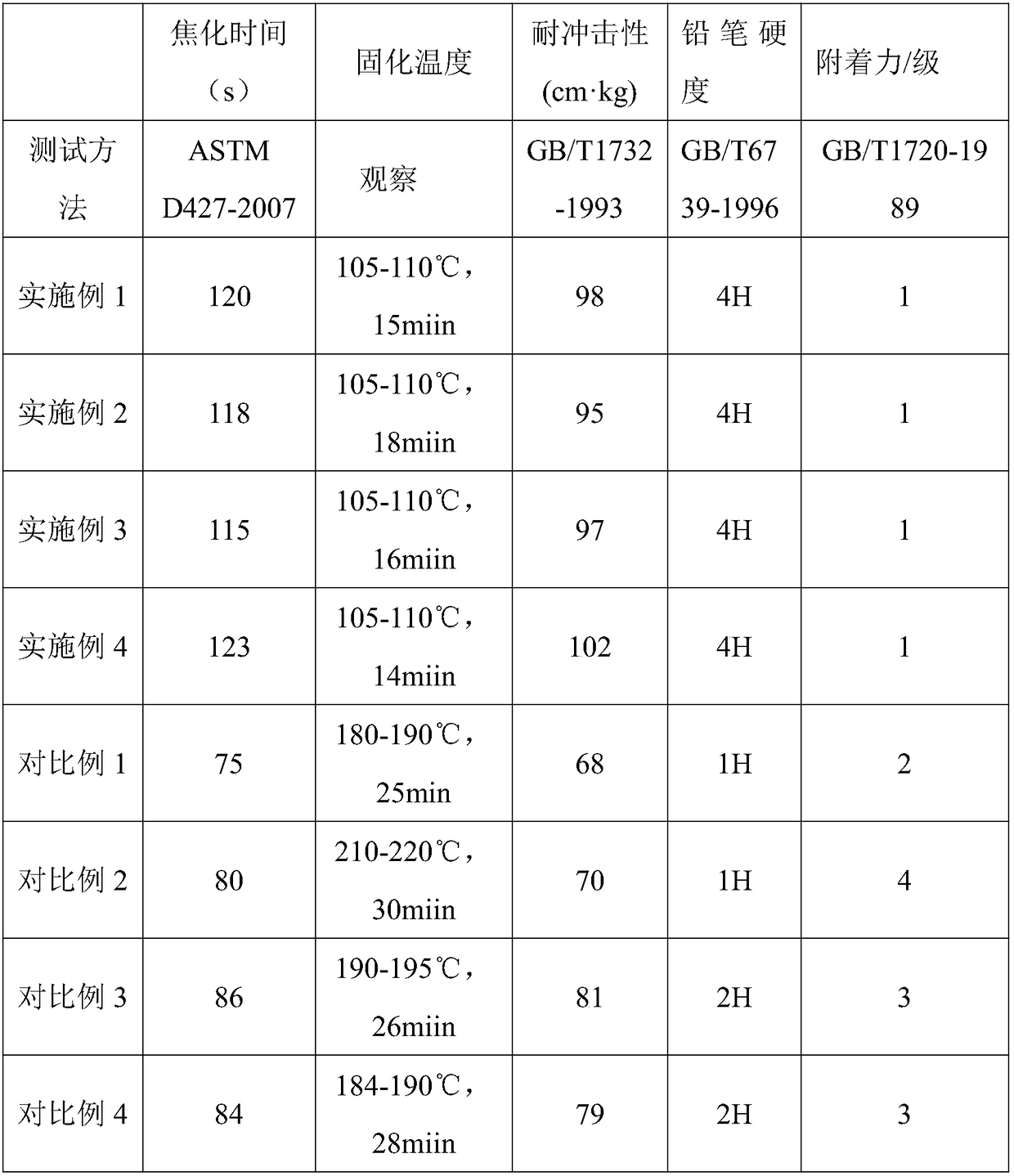

Sand-textured powder coating prepared through modified polyester resin and processing method thereof

InactiveCN108219632AAddress impact resistanceSolve weather resistancePowdery paintsGrain treatmentsAntioxidantPolyvinyl chloride

The invention provides a sand-textured powder coating prepared through modified polyester resin. The sand-textured powder coating is prepared from the following raw materials in parts by weight: 20 to25 parts of the modified polyester resin, 1 to 3 parts of sand texturing agent, 1 to 3 parts of bentonite, 0.5 to 1 part of charge increasing agent, 1 to 2 parts of pigment, 0.5 to 1 part of degasifying agent, 0.2 to 0.5 part of dispersant, 0.5 to 1 part of toughening agent, 0.2 to 0.5 part of brightener, 0.1 to 0.5 part of wetting agent, 0.1 to 0.3 part of preservative, 0.1 to 0.3 part of antioxidant and 0.2 to 0.5 part of light stabilizer, wherein the charge increasing agent is beta-hydroxyalkylamide; the degasifying agent is stearic acid; the dispersant is sulfur zinc; the toughening agentis a pvc (polyvinyl chloride) toughening agent; the wetting agent is heptadecyl imidazoline; the preservative is 5-chloro-2-methyl-4-isothiazolin-3-one. The raw materials are crushed, then are extruded, and afterwards, are sliced, shorn, pulverized and sieved to prepare the sand-textured powder coating. According to the coating provided by the invention, through adding the modified polyester resin and introducing the antioxidant and the light stabilizer, the problems that a sand-textured powder coating is poor in impact resistance in practical application, and is easy to discolor, and the like, are solved.

Owner:广西福宝信科技有限公司

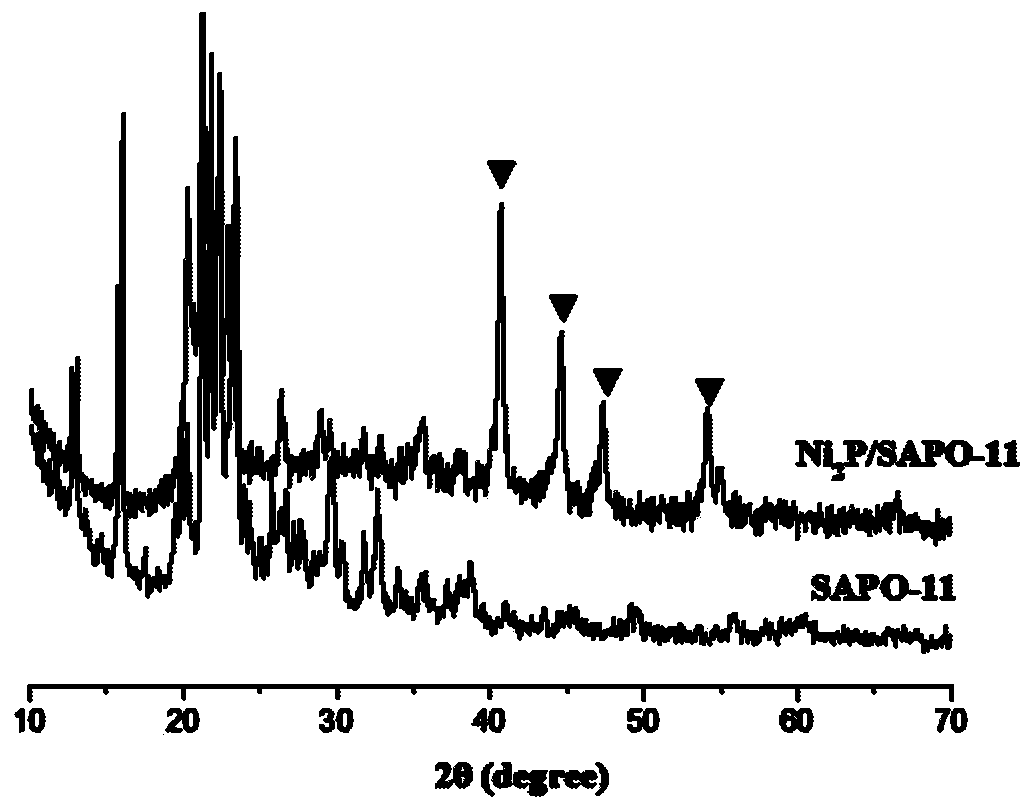

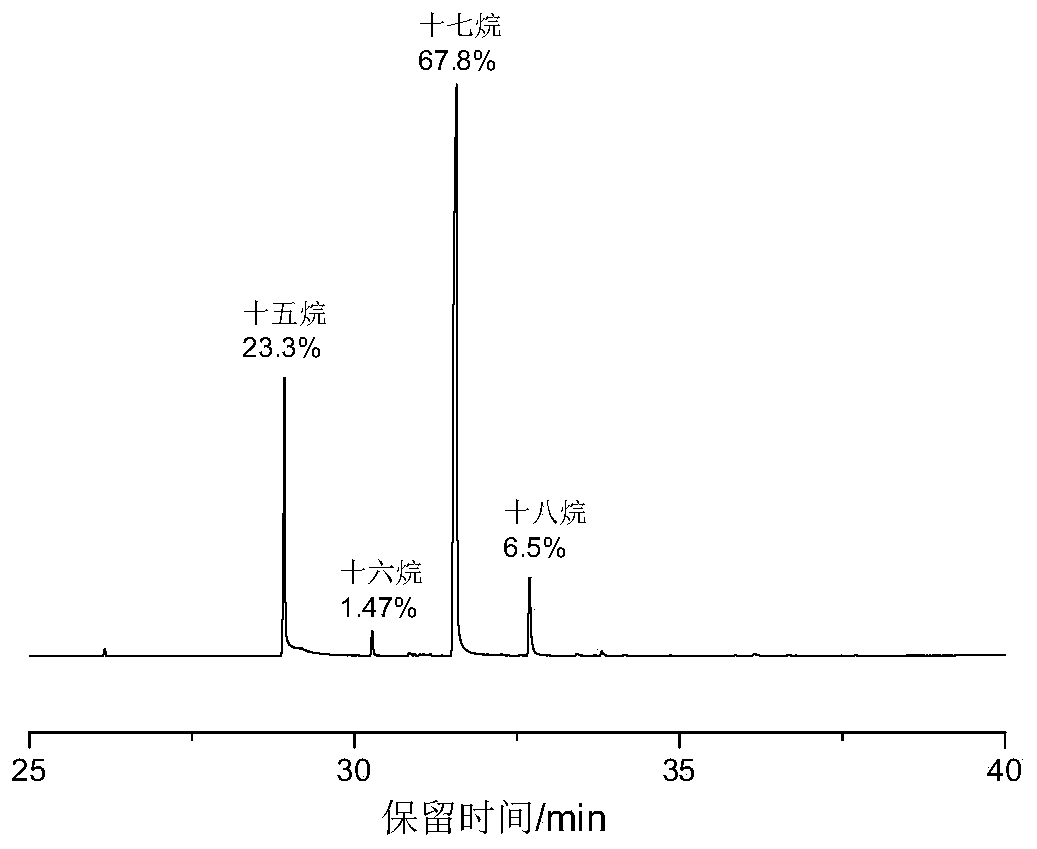

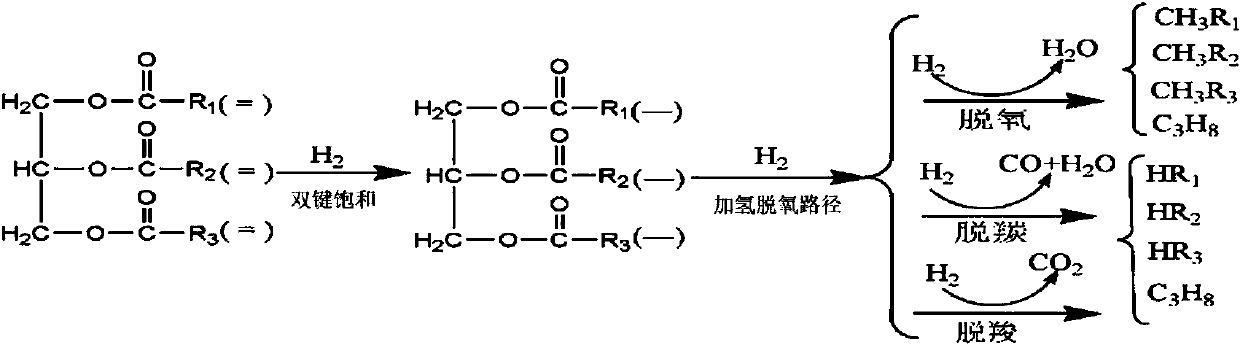

Method for preparing hydrogenated biodiesel by catalyzing directional hydrodeoxygenation of grease

PendingCN110862873AReduce the temperatureShorten the timeFatty acid hydrogenationMolecular sieve catalystsBiodieselPtru catalyst

The invention discloses a method for preparing hydrogenated biodiesel by catalyzing directional hydrodeoxygenation of grease, and belongs to the technical field of preparation of hydrogenated biodiesel. A molecular sieve supported catalyst is adopted to catalyze a hydrodeoxygenation reaction of a grease raw material in a hydrodecarboxylation / decarbonylation mode to obtain hydrogenated biodiesel, and the total content of pentadecane and heptadecane in the hydrogenated biodiesel is greater than 85%; the active component of the catalyst is Ni2P, and the dosage of the catalyst is 5%-10% of the weight of the reaction grease raw material; the main components of the hydrogenated biodiesel are pentadecane and heptadecane, and the selectivity of directional hydrodecarboxylation / decarbonylation is greater than 80%, the generation of reaction moisture is reduced, the defect that the catalyst is easily inactivated when meeting water is avoided, and the service life of the catalyst is prolonged; the reaction conversion rate of the prepared hydrogenated biodiesel is greater than 95%, the temperature and time of the grease hydrodeoxygenation reaction are greatly reduced, and the reaction energy consumption and cost are significantly reduced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

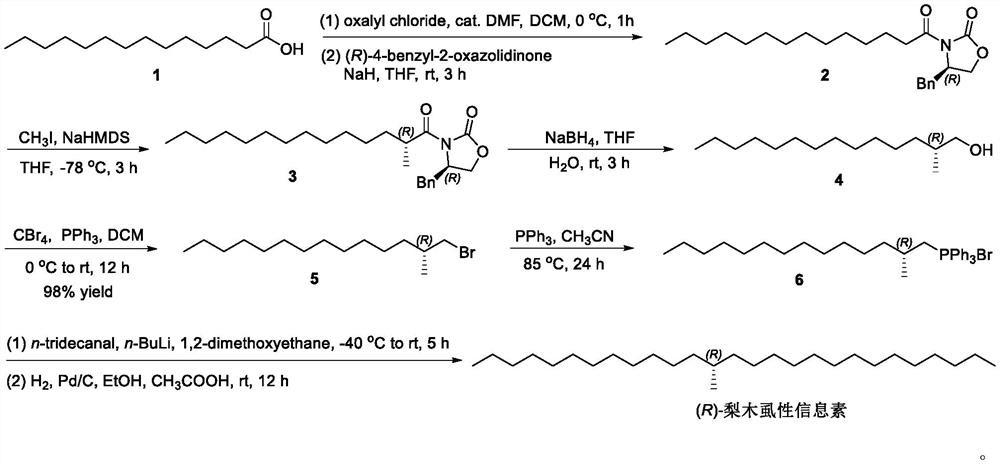

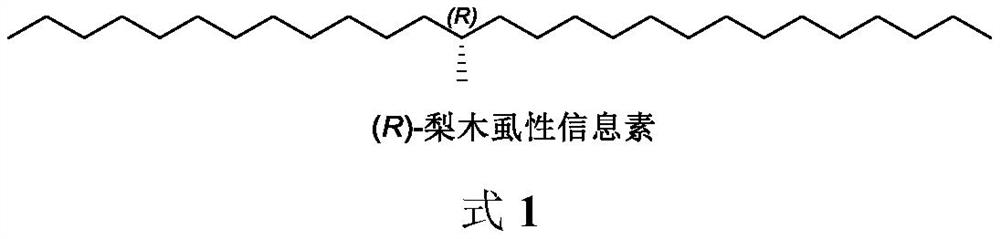

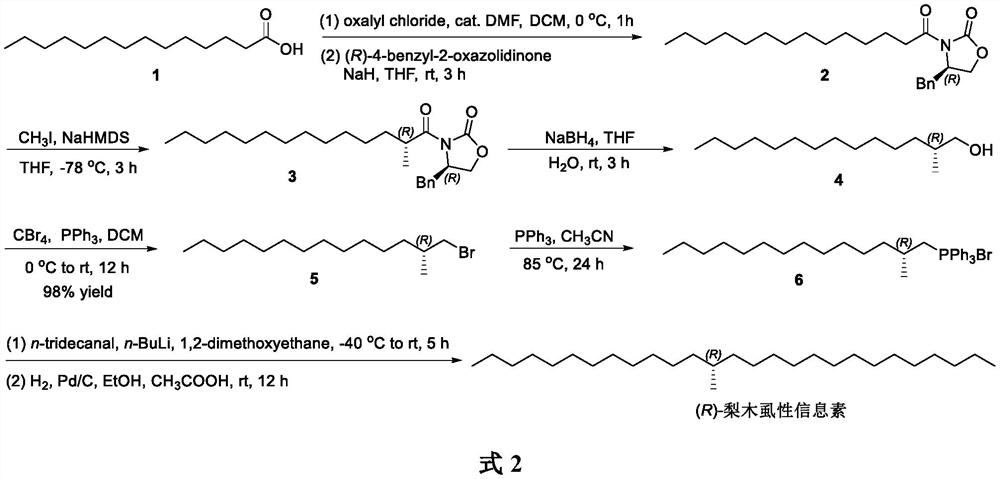

Method for synthesizing (R)-cacopsylla pyricola sex pheromone

InactiveCN113004111AOrganic compound preparationOrganic chemistry methodsPhosphonium saltHeptadecane

The invention belongs to the technical field of green pesticides, and discloses a novel method for synthesizing (R)-cacopsylla pyricola sex pheromone. The method comprises the steps: by taking n-tetradecanoic acid 1 as an initial raw material, firstly reacting with oxalyl chloride to generate n-tetradecanoyl chloride, and then reacting with (R)-4-benzyl-2-oxazolidinone to generate oxazolidinone amide 2; reacting with CH3I in the presence of NaHMDS to generate oxazolidinone amide 3 with one or more methyl groups, and reducing the oxazolidinone amide 3 into chiral alcohol 4 through sodium borohydride; carrying out bromination, and reacting with PPh3 to generate quaternary phosphonium salt 6; and finally carrying out Wittig reaction and catalytic hydrogenation to prepare the (R)-cacopsylla pyricola sex pheromone, namely (R)-13-methylheptacosanoic acid. The chiral methyl is constructed by using an Evans chiral induction method, and the method has the advantages of simple synthetic route, mild reaction conditions, easiness in amplification and the like.

Owner:CHINA AGRI UNIV

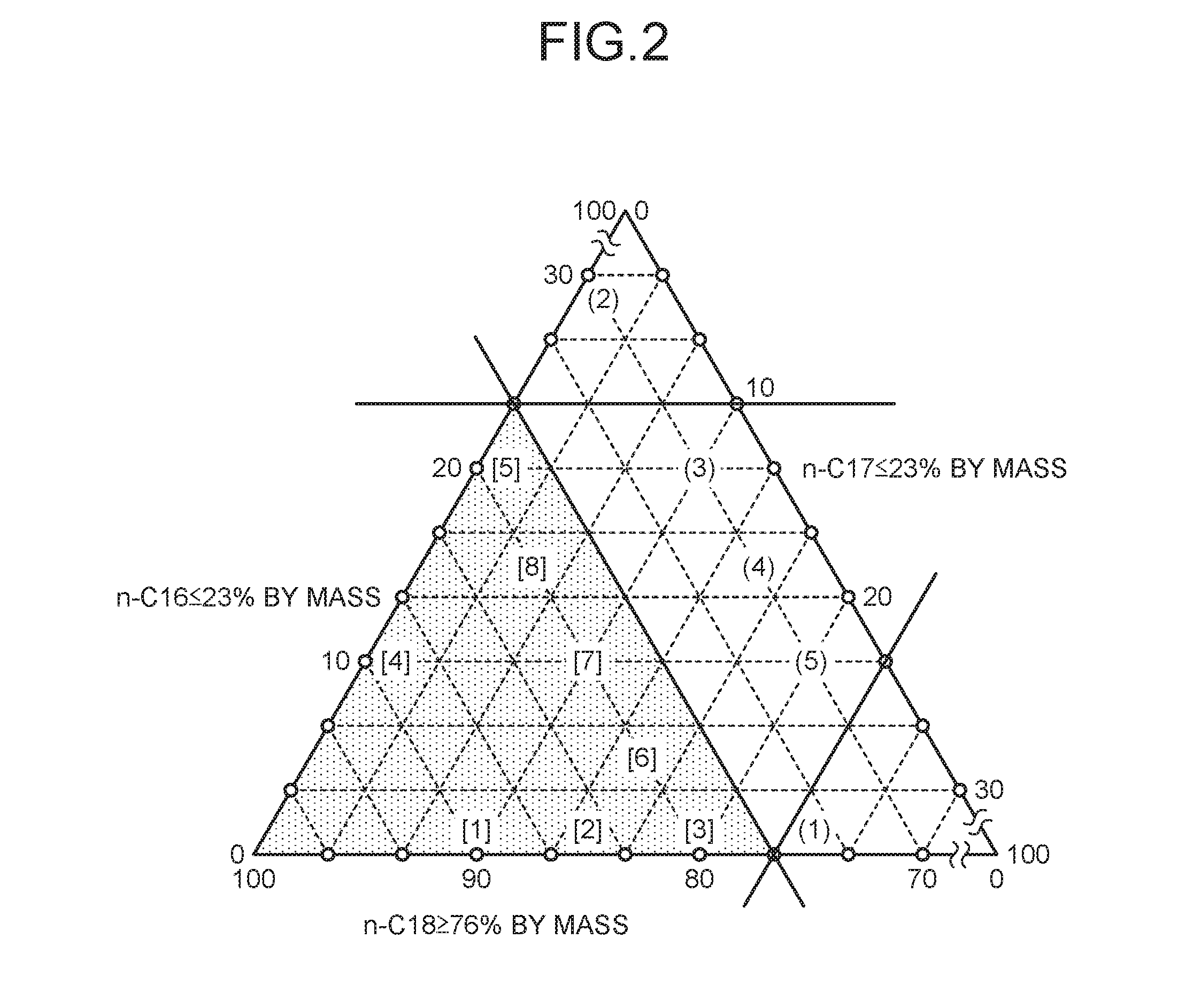

Composite phase-change temperature-adjusting material and preparation method thereof, multi-phase-change temperature-adjusting fiber and preparation method and application of multi-phase-change temperature-adjusting fiber

ActiveCN112961656AImprove durabilityEnhance the adsorption forceMonocomponent cellulose artificial filamentHeat-exchange elementsFiberN-hexadecane

The invention belongs to the technical field of fibers, and particularly relates to a composite phase-change temperature-adjusting material and a preparation method thereof, and a multi-phase-change temperature-adjusting fiber and a preparation method and application of the multi-phase-change temperature-adjusting fiber. The provided composite phase-change temperature-regulating material comprises phase-change energy-storage microcapsules and phase-change energy-storage aerogel which are dispersed in a dispersing agent; the capsule core material of the phase-change energy-storage microcapsules is n-hexadecane or n-heptadecane, and the capsule wall material is gelatin and Arabic gum; and the phase-change energy-storage aerogel comprises graphene aerogel and a phase change compound adsorbed in pores of the graphene aerogel, and the phase change compound comprises n-nonadecane, n-eicosane or n-heneicosane. In the invention, the composite phase-change temperature-regulating material comprises two phase-change temperature-regulating materials, has two phase-change temperature-regulating temperatures, and can meet the requirements of different temperatures and multiple application fields.

Owner:青岛尼希米生物科技有限公司

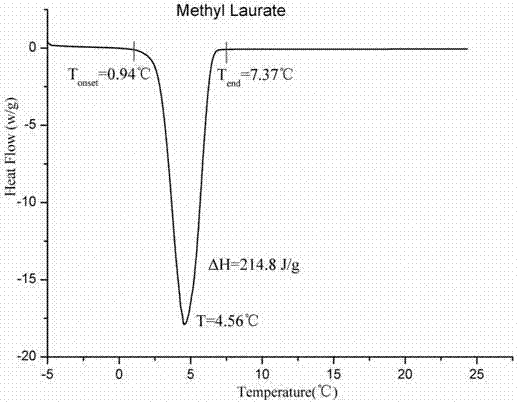

Paraffin-based composition and latent heat storage material

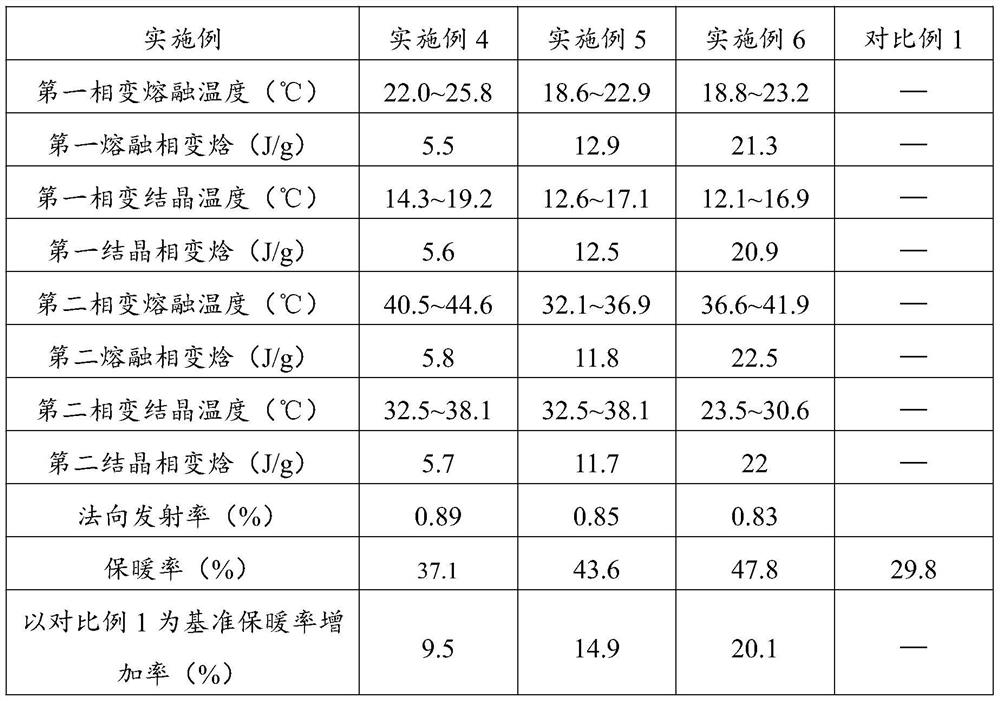

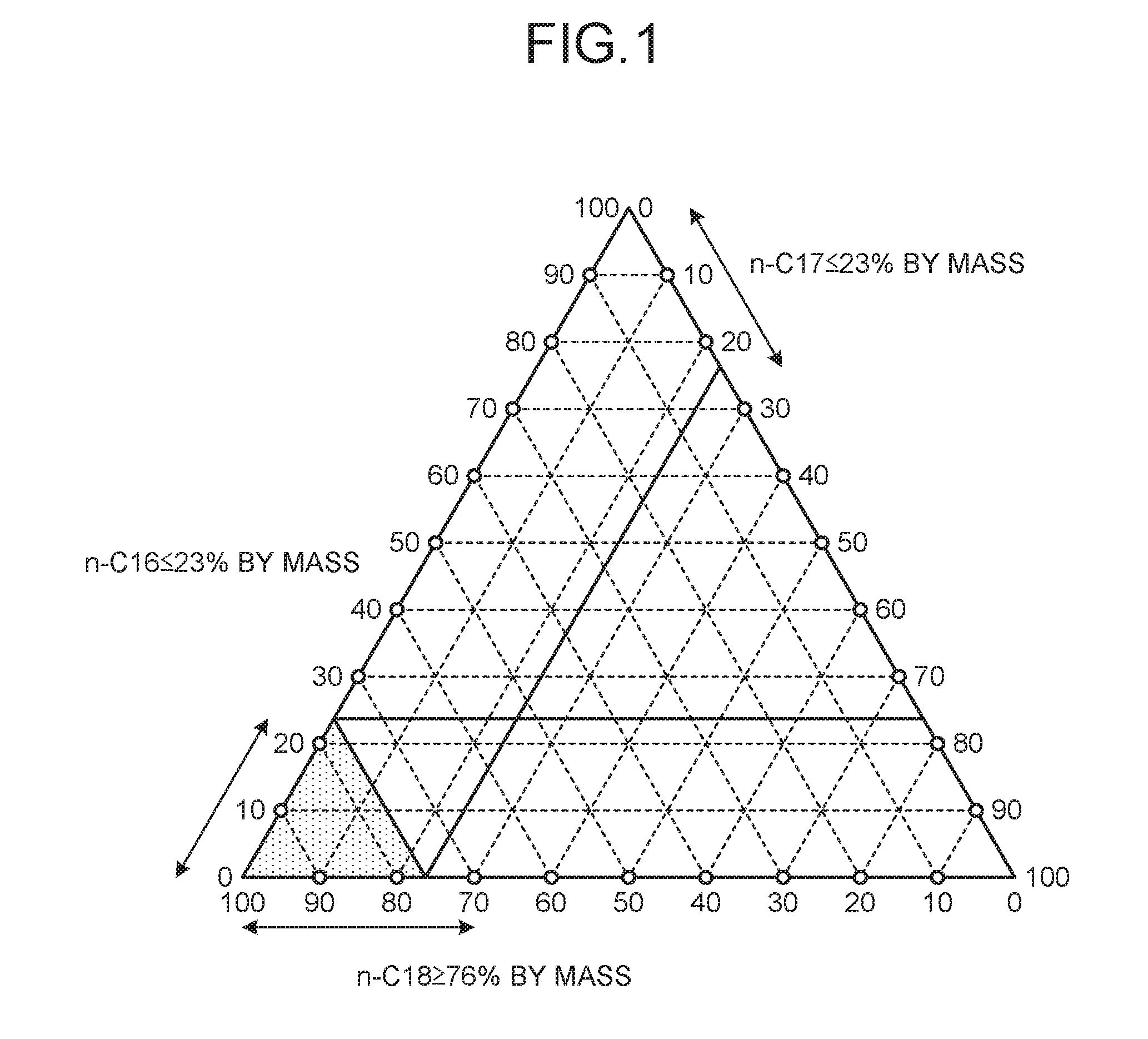

A paraffin-based latent heat storage material composition is provided which has a melting point close to the melting point of n-heptadecane and has a high latent heat of fusion. The paraffin-based latent heat storage material composition of the present invention substantially includes n-octadecane, and n-hexadecane and / or n-heptadecane. The paraffin-based latent heat storage material composition contains not less than 76% by mass of n-octadecane, not more than 23% by mass of n-hexadecane, and not more than 23% by mass of n-heptadecane (the total of the three is set to 100% by mass) and has a melting point lower than that of n-octadecane and latent heat of fusion of 210 J / g or more.

Owner:JX NIPPON OIL & ENERGY CORP

SEBS rubber additive, preparation method and SEBS rubber thereof

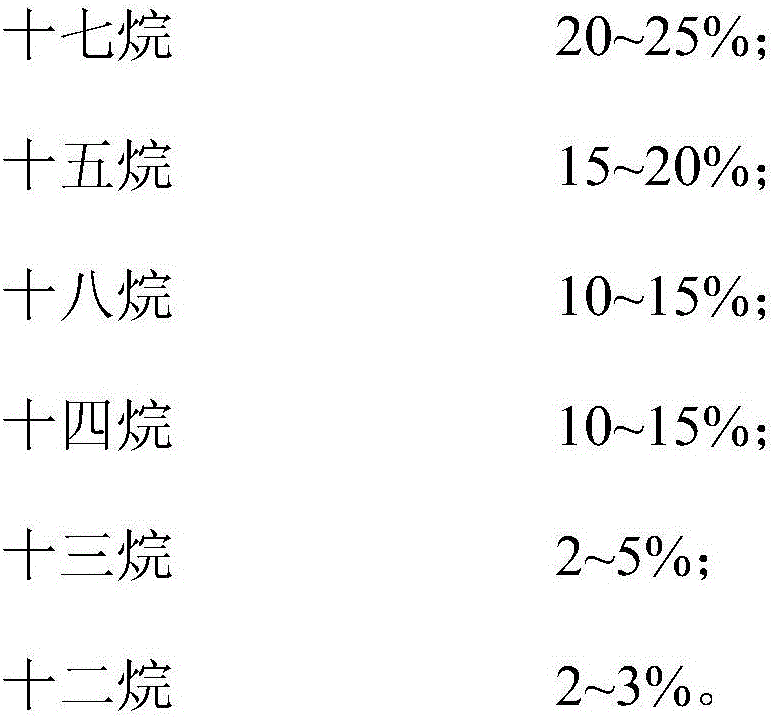

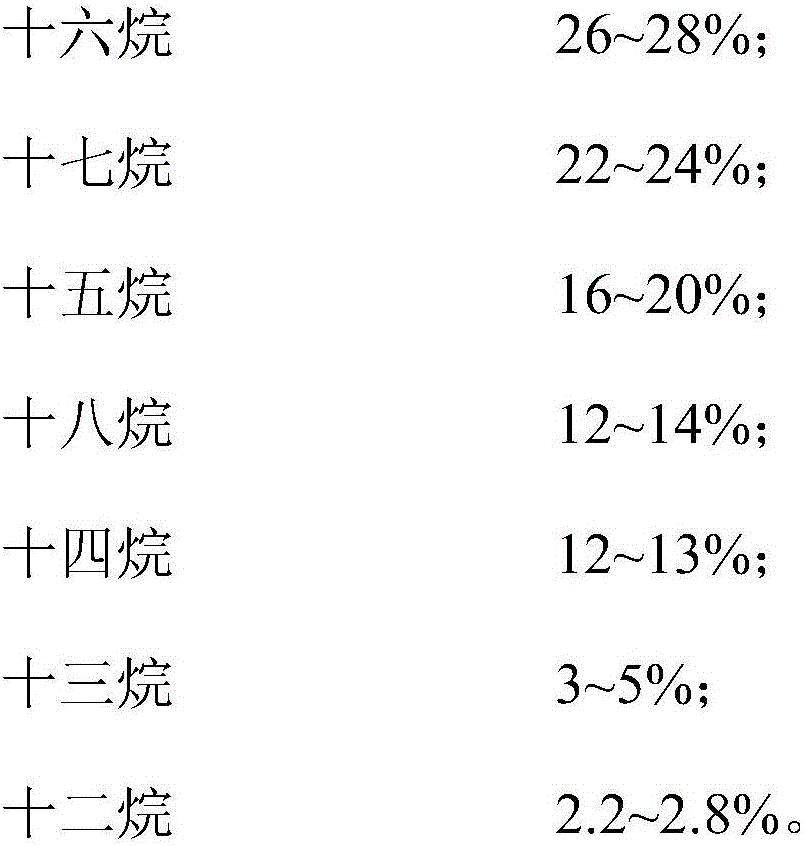

The invention provides an SEBS rubber additive, a preparation method and the SEBS rubber thereof. The SEBS rubber additive comprises the following components in weight percentage: 25-30% of hexadecane, 20-25% of heptadecane, 15-20% of pentadecane, 10-15% of octodecane, 10-15% of tetradecane, 2-5% of tridecane, and 2-3% of dodecane. When the SEBS rubber additive and the SEBS together form the rubber and a thermoplastic elastomer, the diluted smell generated at a high temperature is removed. Meanwhile, the odor is eliminated.

Owner:深圳市前海龙达新能源有限公司

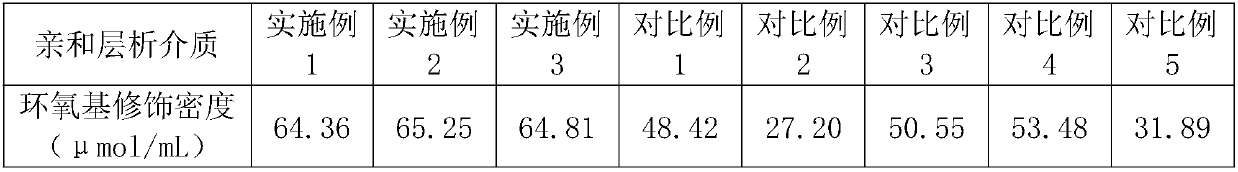

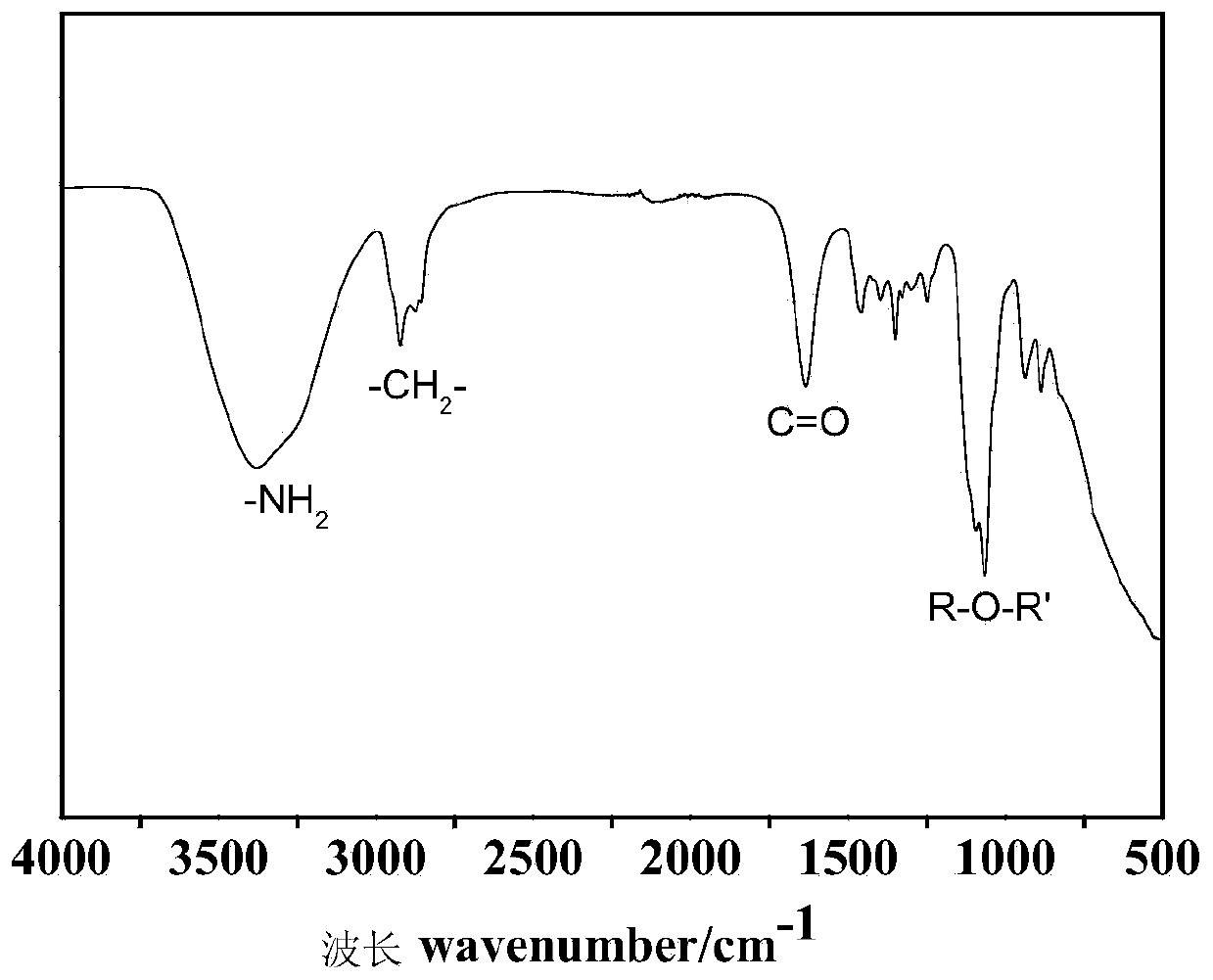

Epoxy activated affinity chromatography medium

ActiveCN107866206AChemically stableImprove activation efficiencyOther chemical processesSolid sorbent liquid separationAlkaneHexadecane

The invention relates to an epoxy activated affinity chromatography medium. Cellulose microspheres are taken as a matrix, a compound comprising 1,2-epoxy alkane, polylactic-co-glycolic acid and polyethylene glycol is crosslinked on the surfaces of the cellulose microspheres, and 1,2-epoxy alkane is linked with ligand, wherein 1,2-epoxy alkane comprises one or more of 1,2-epoxy dodecane, 1,2-epoxytridecane, 1,2-epoxy tetradecane, 1,2-epoxy pentadecane, 1,2-epoxy hexadecane, 1,2-epoxy heptadecane and 1,2-epoxy octodecane. The affinity chromatography medium has high epoxy density on the surface,contains numerous coupling ligands and has high affinity chromatography efficiency; meanwhile, the preparation process is simple and favorable for large-scale popularization and application.

Owner:SUZHOU BOJIN BIOLOGICAL TECH

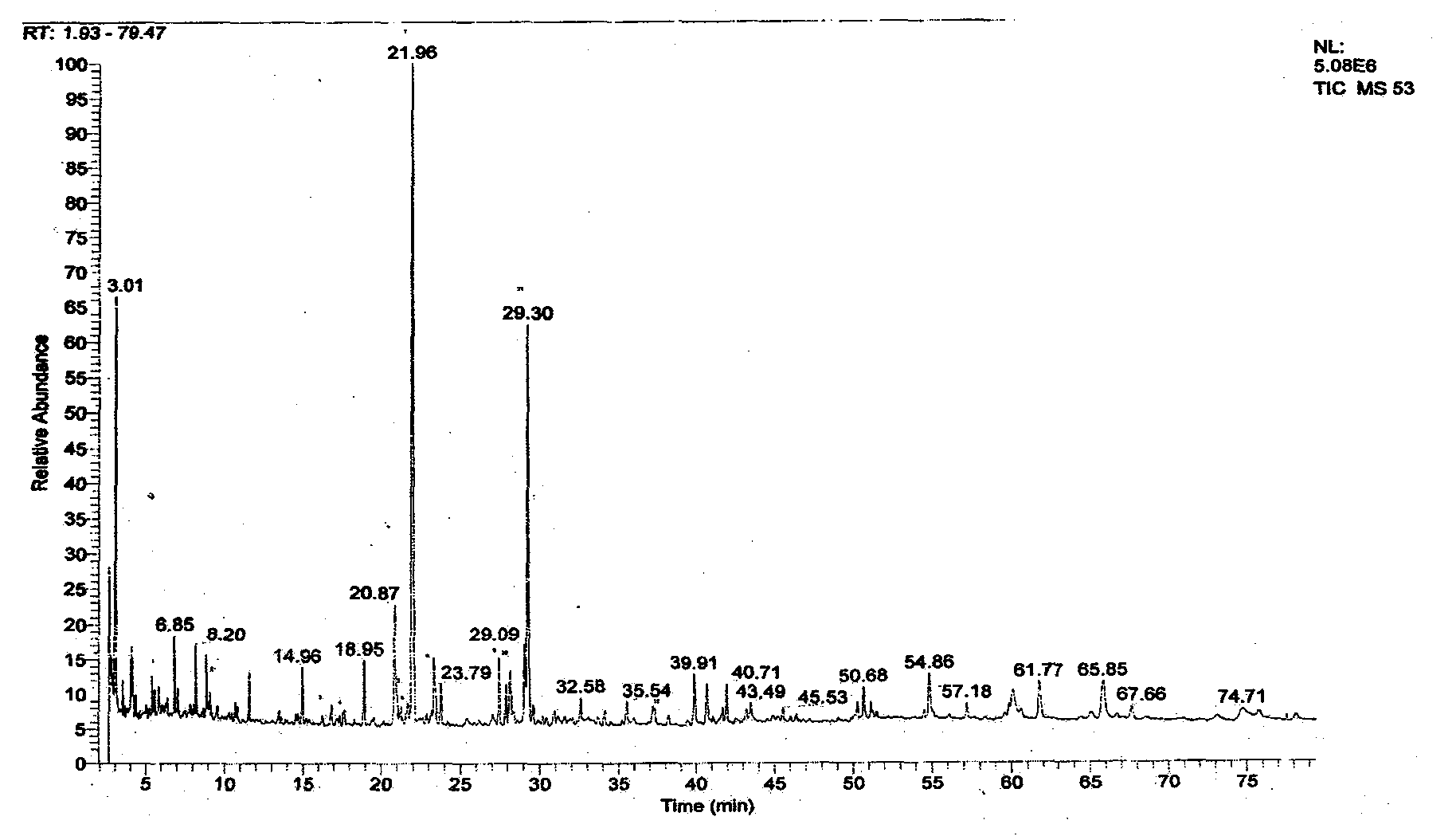

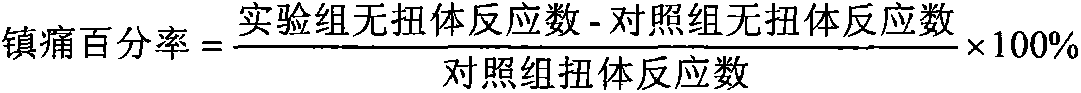

Effective part of cheezheng pain relieving plaster and preparation method therefor

The invention discloses an effective part of a cheezheng pain relieving plaster, a preparation method therefor and characteristic chemical composition. Efficacy of an external preparation prepared from the effective part is better than that of an original preparation. Adverse effects of existing preparations are overcome, namely, the effective part has no sensitization side effects. The effective part contains the following 9 kinds of chemical ingredients at the same time, and the chemical ingredients are phenethyl alcohol, phenylpyruvic acid, calamenene, 1,4-dimethyl-2,5-diisopropyl benzene, atractylol, eudesmol, heptadecane, 2,6,10-trimethyl dodecane and eicosane. The effective part can be prepared into external preparations of an ointment, an emplastrum, a poultice, a spray, a liniment and the like with supplement of pharmaceutically common auxiliary materials.

Owner:ZHEJIANG FORESTRY UNIVERSITY

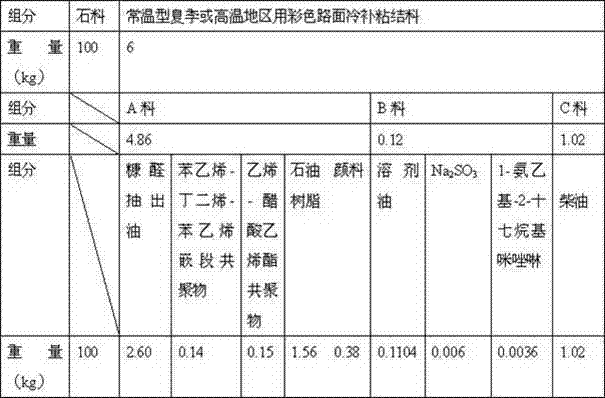

Normal-temperature color pavement cold paving material used in summer or high-temperature areas and preparation technology thereof

The invention discloses a normal-temperature color pavement cold paving material used in summer or high-temperature areas and a preparation technology thereof. The cold paving material is prepared by mixing a normal-temperature color pavement cold paving adhesive material used in summer or high-temperature areas and dried stone according to the weight ratio of 6: 100, wherein the normal-temperature color pavement cold paving adhesive material used in summer or high-temperature areas is prepared by uniformly mixing a material A, a material B and a material C according to the weight ratio of 81: 2: 17. The material A is made from the following ingredients of: by weight, 50-55 parts of furfural extract oil, 3-4 parts of a styrene-butadiene-styrene segmented copolymer, 4-5 parts of an ethene-vinyl acetate copolymer, 33-40 parts of a petroleum resin and 8-10 parts of a pigment. The material B is made from the following ingredients of: by weight, 92 parts of solvent naphtha, 5 parts of Na2SO3 and 3 parts of 1-aminoethyl-2-heptadecylimidazoline. The material C is diesel oil. The normal-temperature color pavement cold paving material requires low cost, is convenient to use, is resistant to high temperature, and has the same color with the color pavement and has the same properties with the adhesive material. In addition, the traffic situation will not be influenced during construction.

Owner:河南金欧特实业集团股份有限公司

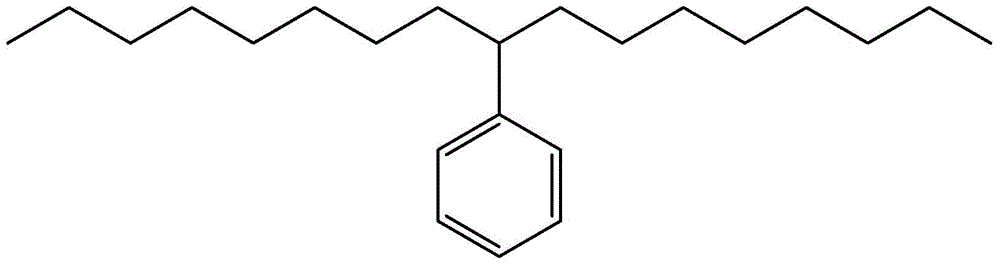

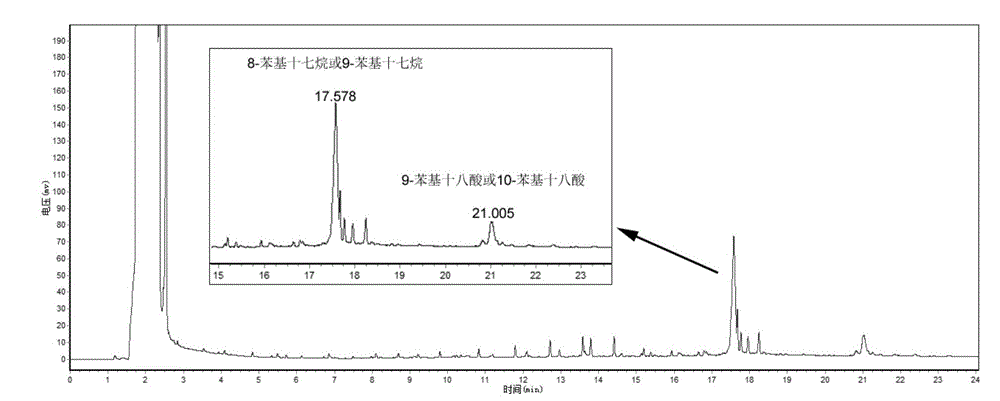

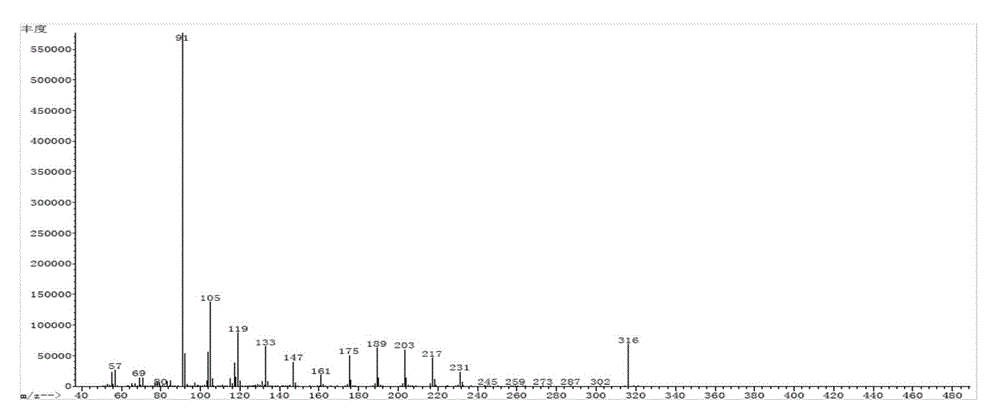

Preparation method for phenyl heptadecane

ActiveCN104610011AWide variety of sourcesLow priceHydrocarbon from oxygen organic compoundsBenzeneReaction temperature

The invention relates to a preparation method for phenyl heptadecane. The preparation method comprises the following steps: (1) by taking 9-phenyl octadecanoic acid or 10-pheyl octadecanoic acid as a raw material, adding the raw material and a catalyst into a reaction kettle; (2) sealing the reaction kettle, heating, stirring and reacting to obtain 8-pheyl heptadecane or 9-pheyl heptadecane. Compared with the prior art, a synthesis raw material for alkyl benzene can be from modified oleic acid and is wide in source; the catalyst in decarboxylic reaction is hydrotalcite containing common metals and low in price; the reaction temperature is relatively low, the energy consumption is less and the safety is high; the reaction is complete, the side reactions are less, and the obtained 8-pheyl heptadecane or 9-pheyl heptadecane product is high in content.

Owner:EAST CHINA UNIV OF SCI & TECH

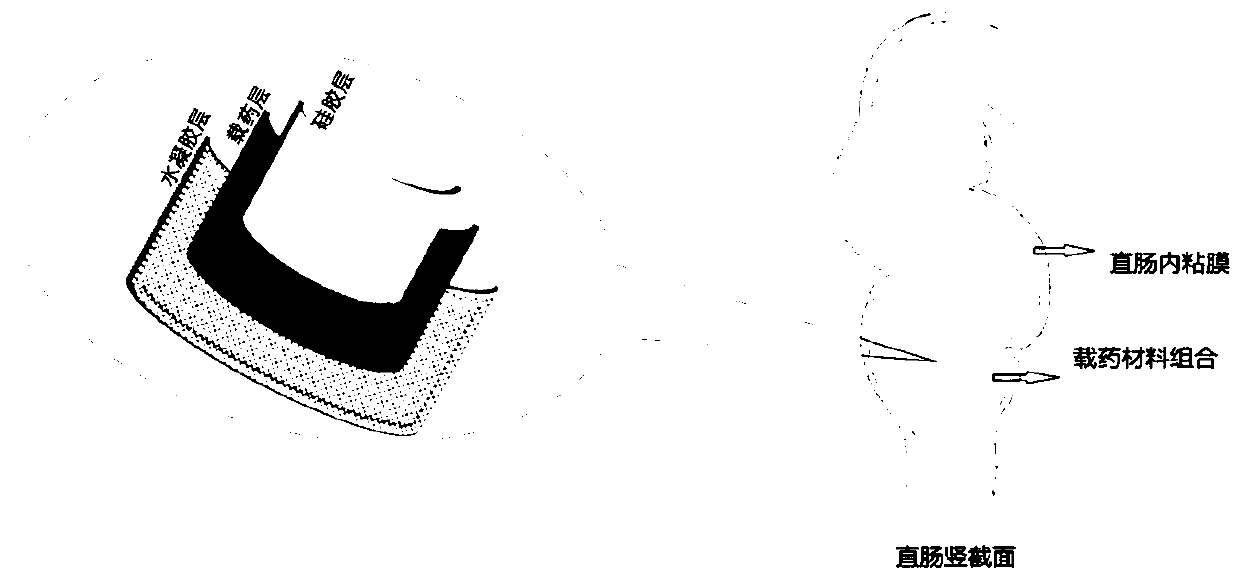

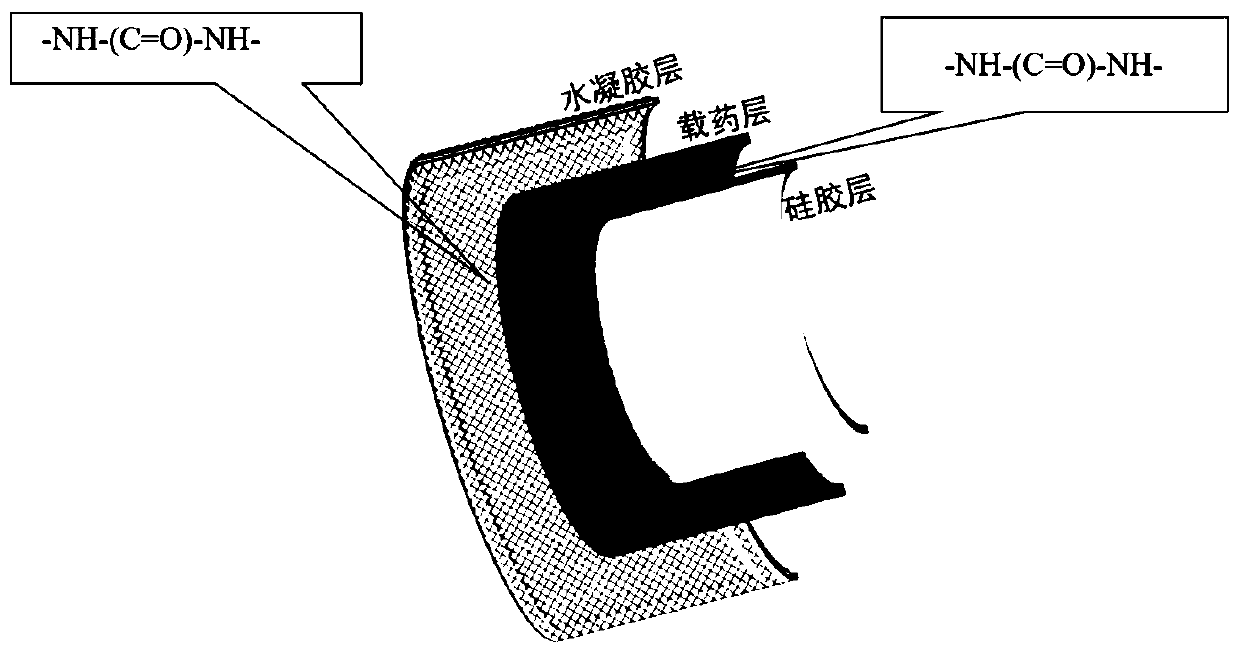

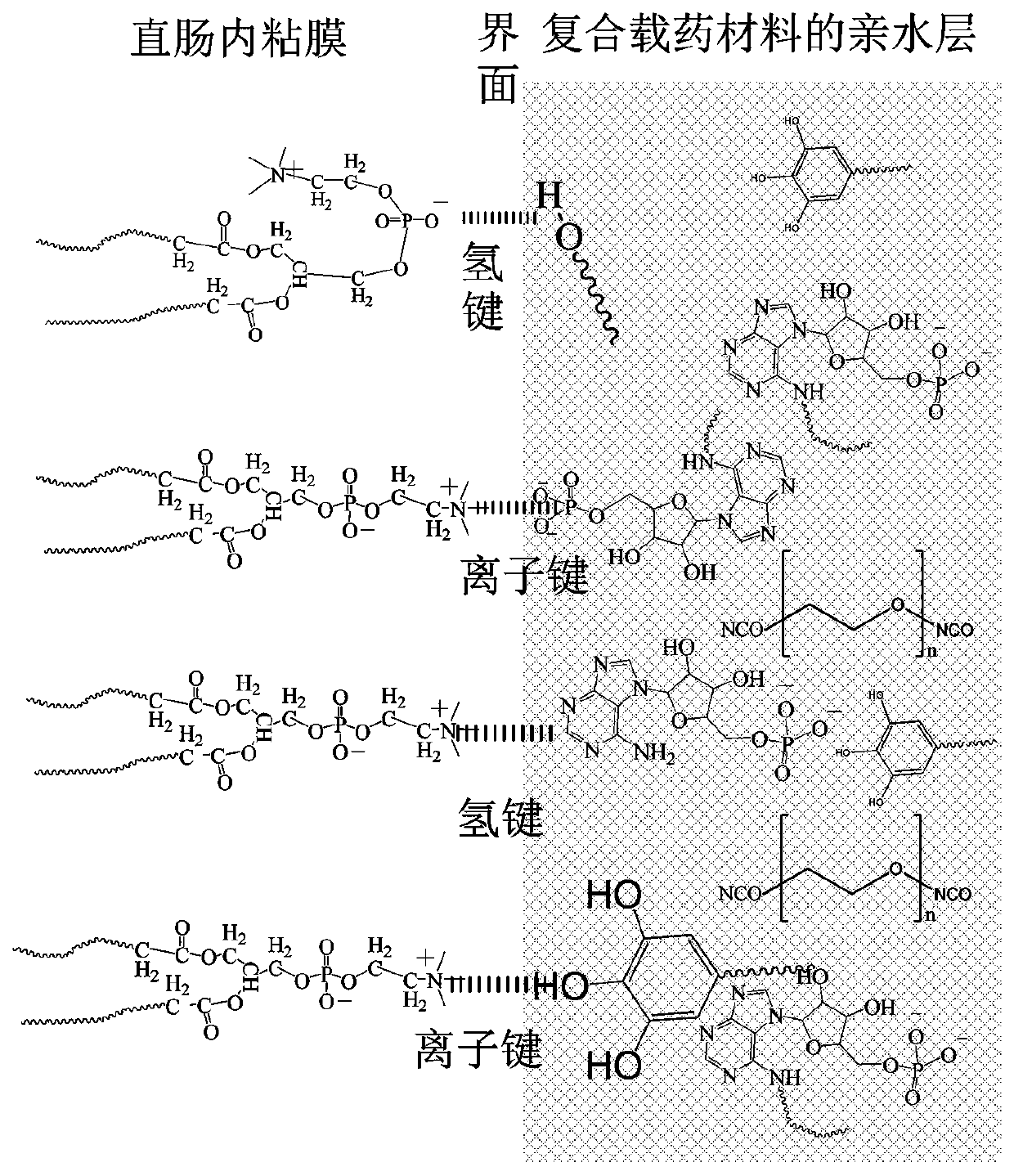

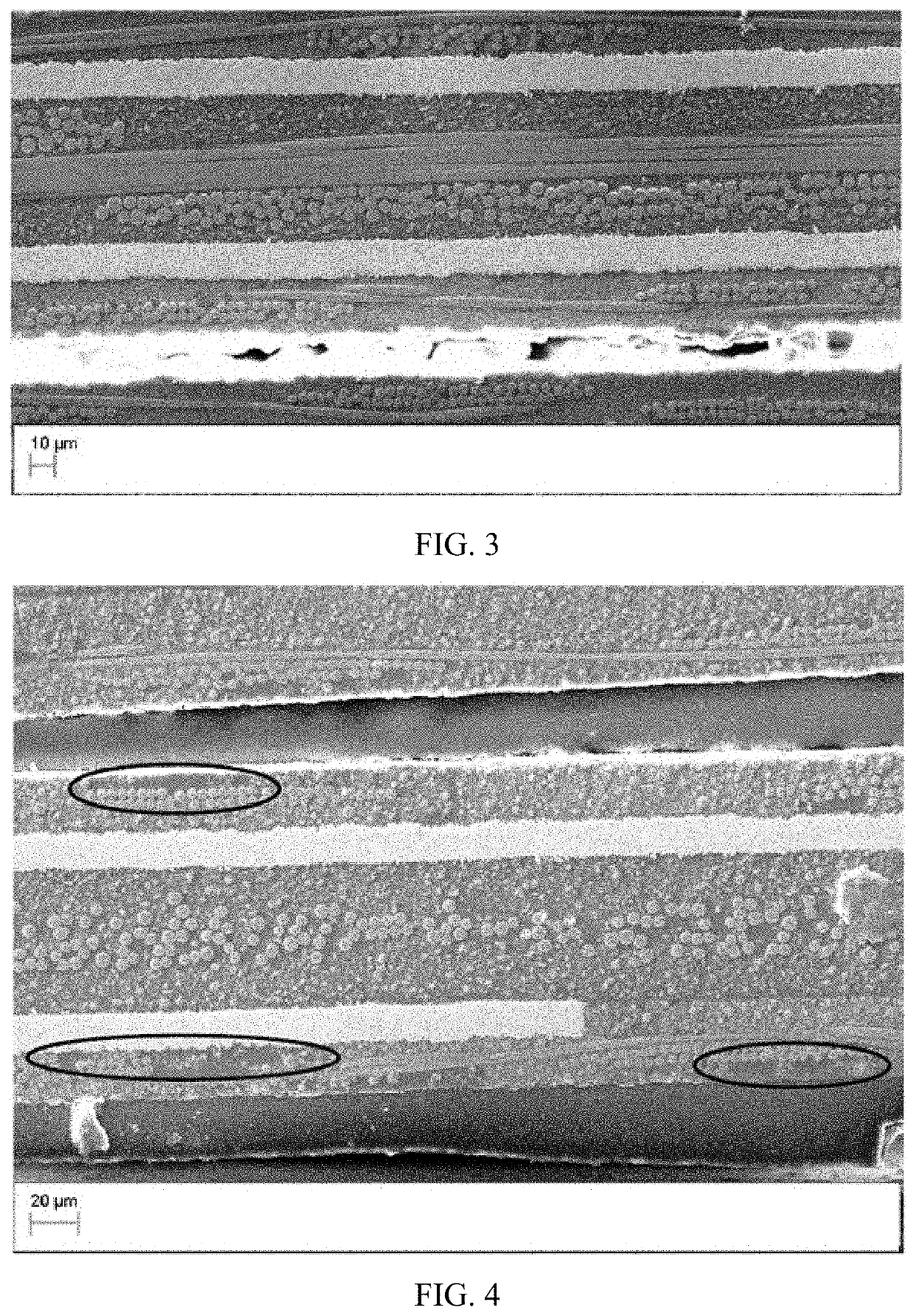

Drug sustained-release material and application thereof in sustained-release material for treating proctitis

The invention provides a drug sustained-release material and an application of the drug sustained-release material for treating proctitis. An outer layer of a composition is prepared by tannic acid, 3, 4, 5-trihydroxybenzoic acid, deoxyadenylic acid modified gelatin, polyethylene glycol, polyvinyl alcohol and the like; a middle layer is a drug sustained-release layer taking poly epsilon-caprolactone and polylactic acid as chain segments, and an inner layer is condensed silica gel modified by 1H, 1H, 2H, 2H-perfluoroheptadecane trimethoxysilane and N-2-(aminoethyl)-3-aminopropyltrimethoxysilane. The drug sustained-release composition has good adhesion performance for treating pathological organs such as intracavitary mucosas such as proctitis and the like which are difficult to administrate. The rectal drug sustained-release material composition provided by the invention has good elasticity and interface bonding strength, good biocompatibility, and no toxicity or harm to human body. Thecomposition is capable of improving the interface bonding force between different layers is wide in application range and can be applied to a series of multi-layer materials to improve the interfacebonding force.

Owner:CHINA THREE GORGES UNIV

Powdery coating applied to wood finishing and production method thereof

InactiveCN108219625AGood weather resistanceImprove heat resistancePowdery paintsGrain treatmentsEpoxyAntioxidant

The invention provides a powdery coating applied to wood finishing. The powdery coating is prepared from the following raw materials in parts by weight: 25 to 40 parts of modified epoxy resin, 1 to 3parts of a curing agent, 0.5 to 1 part of a pigment, 0.5 to 1 part of a degassing agent, 0.2 to 0.5 part of a dispersant, 0.5 to 1 part of a toughening agent, 0.2 to 0.5 part of a luster enhancing agent, 0.1 to 0.5 part of a wetting agent, 0.1 to 0.3 part of a preservative, 0.1 to 0.3 part of an antioxidant and 0.2 to 0.5 part of a light stabilizer, wherein an electricity enhancing agent is beta-hydroxyalkylamide; the degassing agent is stearic acid; the dispersant is zinc thionate; the toughening agent is a pvc (polyvinyl chloride) toughening agent; the wetting agent is heptadecylimidazoline;the preservative is 5-chloro-2-methyl-4isothiazoline-3-one. The raw materials are mixed and crushed and then are extruded; then a mixture is subjected to sheet preparation, shearing, crushing and sieving to obtain the powdery coating. According to the powdery coating provided by the invention, the modified epoxy resin is added and the antioxidant and the light stabilizer are introduced, so that the problems that the storage stability is poor, the leveling property is not good and the curing temperature is too high are remarkably solved.

Owner:广西福宝信科技有限公司

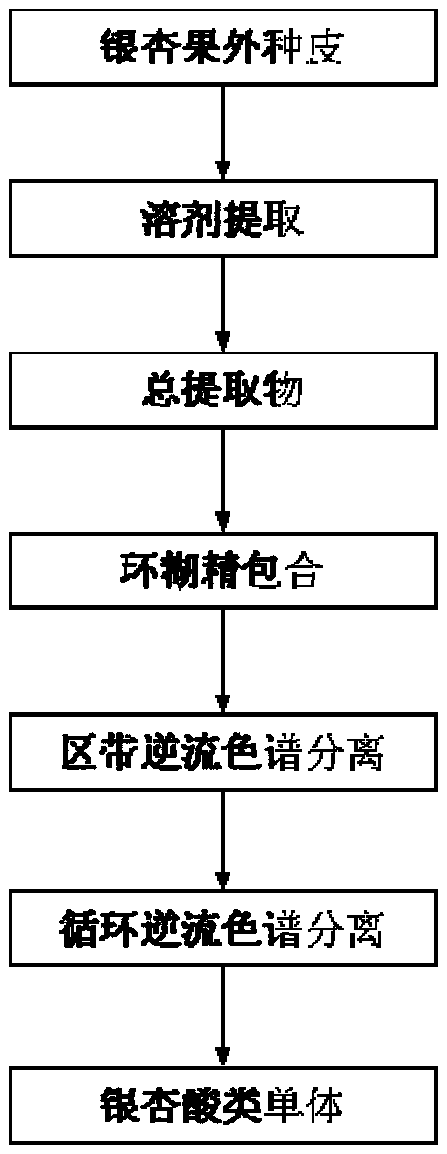

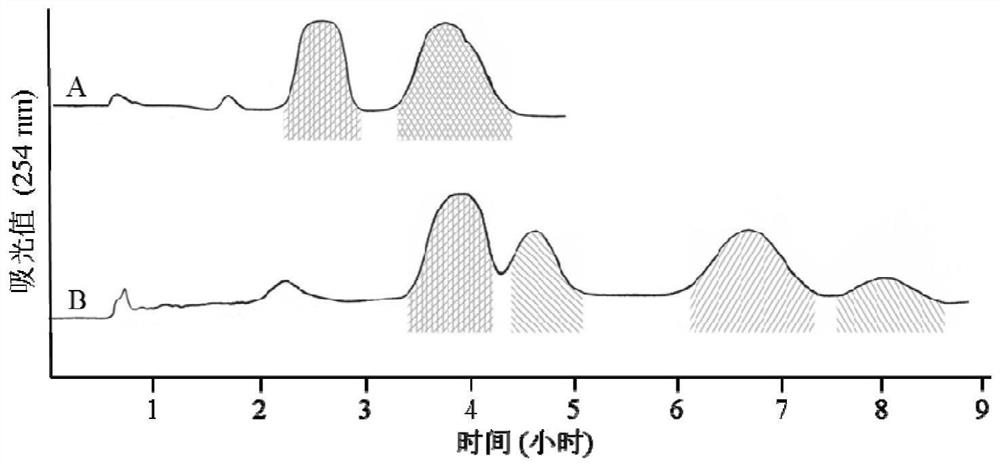

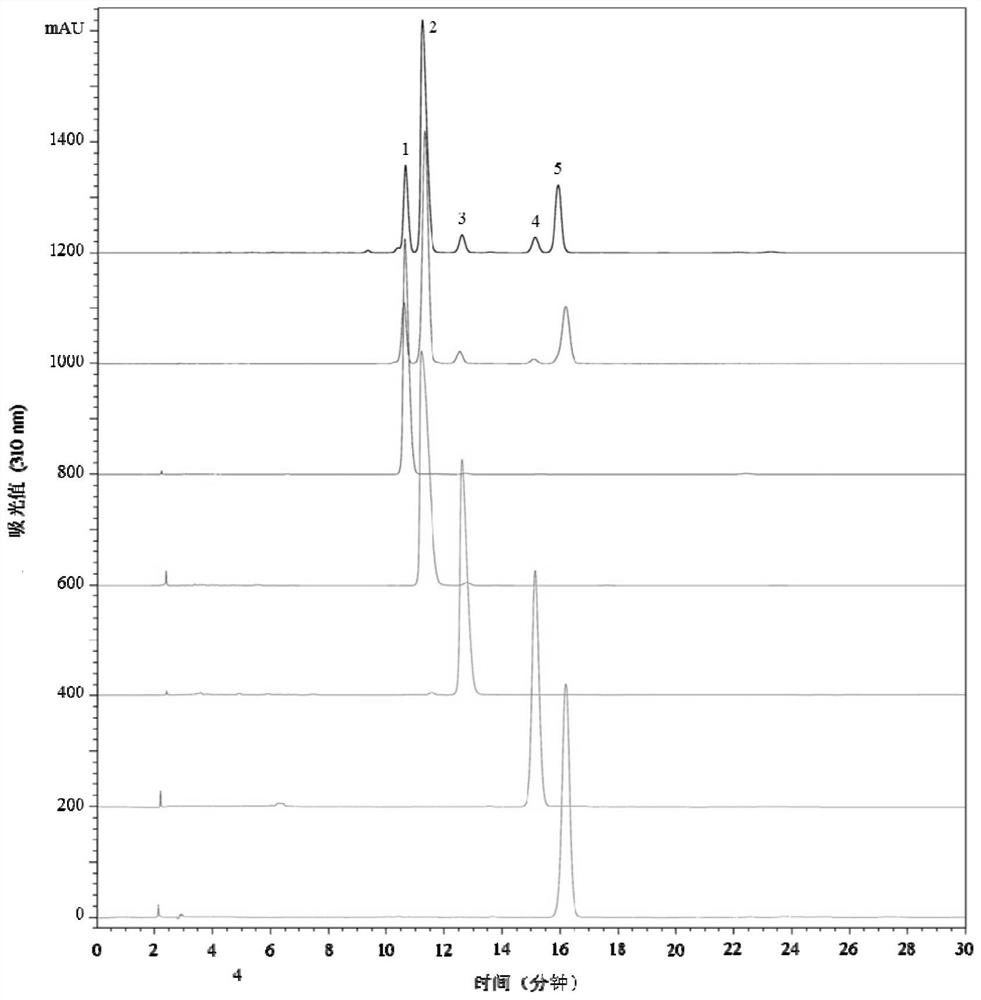

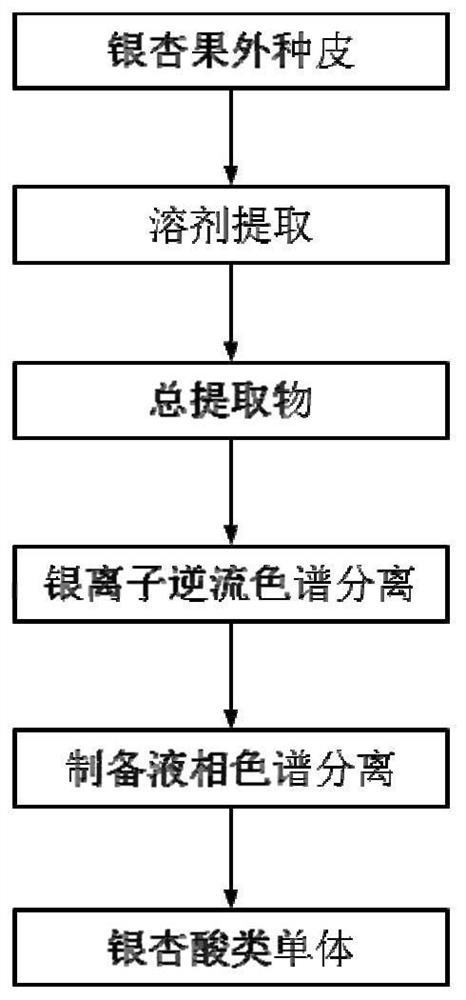

Combined preparation method of ginkgolic acid

ActiveCN109053433AIncrease the difficulty of separationImprove efficiencyCarboxylic compound separation/purificationHydrogenCountercurrent chromatography

The invention relates to a method for separating ginkgolic acid monomer from total ginkgolic acid extract by a pH (potential of hydrogen)-zone countercurrent chromatography method. The method has theadvantages that the hydrophilicity is improved by the type of using beta-cyclodextrin to coat the ginkgolic acid, so as to improve the distribution ratio of extracts in two phases; a two-phase solventsystem is n-heptane / ethyl acetate / methanol / water (2:1:1.5:1, v / v); the five types of high-purity ginkgolic acid monomer compounds, such as ginkgoneolic acid, ginkgolic acid, heptadecane diene ginkgolic acid, hydrogenated ginkgolic acid, and heptadecane monomer ginkgolic acid, can be separated out at one time; the preparation method is simple, the efficiency is high, the cost is economic, the preparation method is suitable for industrialized production, and the important economic meaning is realized.

Owner:SHANDONG ANALYSIS & TEST CENT

Method for preparing n-tetradecane, n-heptadecane and n-eicosane at one time

InactiveCN101891574AHigh purityHigh yieldHydrocarbon from halogen organic compoundsChemical modification purification/separationAlkaneDistillation

The invention relates to a method for preparing n-tetradecane, n-heptadecane and n-eicosane at one time, which comprises the following steps of: preparing raw materials comprising bromoalkane and sodium metal for later use; adding bromoalkane mixed liquid and the sodium metal into a reaction kettle, stirring the solution and heating the solution to 80 DEG C, maintaining the temperature between 120 and 140 DEG C, controlling the temperature to be 140 to 160 DEG C after the rest material is completely added, and keeping constant temperature for 2 hours; and adding ethanol and water into the solution in turn, separating out organic substances and washing the organic substances to be neutral by using water, drying the organic substances by using anhydrous magnesium sulfate, collecting fractions by distillation, and collecting n-tetradecane, n-heptadecane and n-eicosane finished products through water distillation columns according to different boiling points. A strong oxidant such as concentrated sulfuric acid or acid potassium permanganate used in the preparation method has oxidation effect on unsaturated organic substances and alcoholic impurities in the reactants and removes unsaturated hydrocarbons to achieve the effect of eliminating the impurities, the content of the normal alkanes reaches 96 to 98 percent, and the purity of the finished products is improved.

Owner:TIANJIN CHEM REAGENT RES INST

Dual interior labels gas chromatography test method for determining contents of various organic ingredients in cellulose acetate fiber filter stick

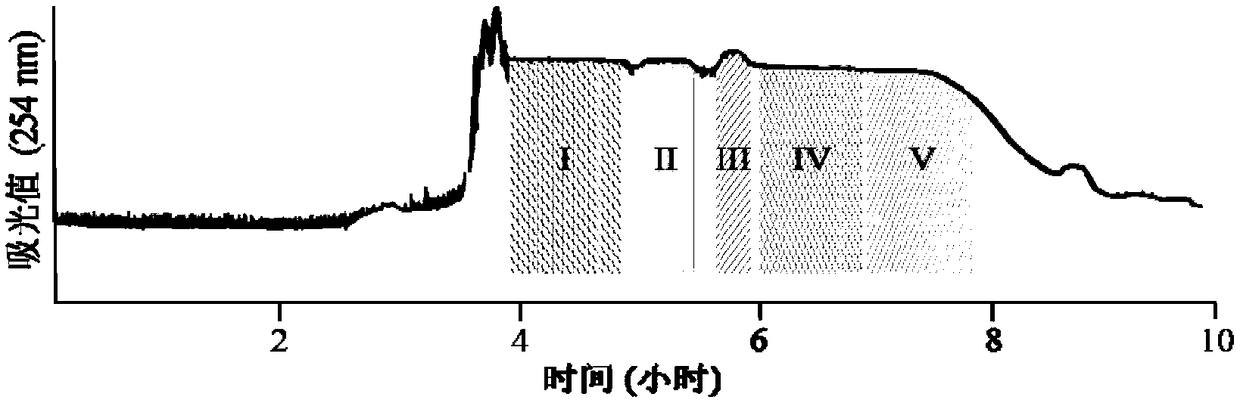

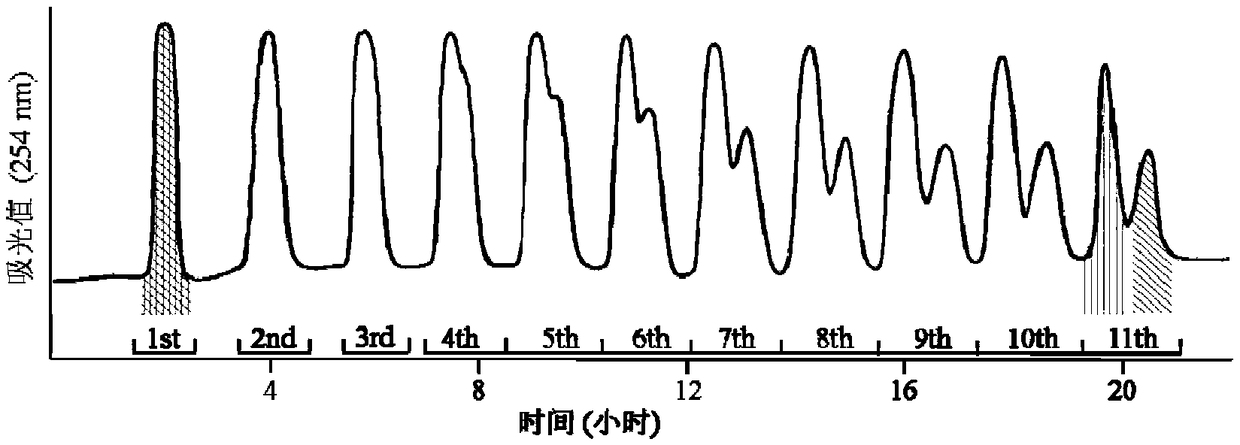

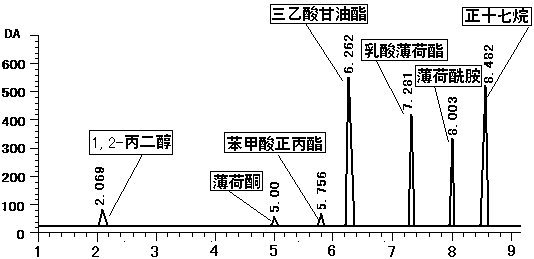

The invention discloses a dual interior labels gas chromatography test method for determining contents of various organic ingredients in a cellulose acetate fiber filter stick. Interior labels adoptedcomprise n-heptadecane and n-propyl benzoate and are respectively used for determining contents of triacetin, menthyl lactate and menthol carboxamide with higher contents and contents of 1, 2-propylene glycol and menthone with lower contents. According to the method, the additive amounts of the selected interior labels differ widely, the interior labels can be respectively used for measuring contents of five organic substances with different contents, different structures or different natures, and the method has the advantages of being less in mutual interference, high in measurement accuracy, small in error and short in time.

Owner:NANTONG CIGARETTE FILTER

Temperature-resistant and salt-resistant zwitterionic oil displacement agent, preparation method and application thereof

InactiveCN111303852AStrong salt resistanceImprove high temperature resistanceOrganic compound preparationAmino-carboxyl compound preparationBetaineEthylene oxide

The invention discloses a temperature-resistant and salt-resistant zwitterionic oil displacement agent, a preparation method and application thereof, wherein the structure of the temperature-resistantand salt-resistant zwitterionic oil displacement agent is represented by a formula (I). According to the method, under an acidic condition, ethylene oxide and heptadecyl imidazoline are subjected toa reaction; the reaction product reacts with alkyl dimethyl betaine, wherein the structure of the alkyl dimethyl betaine is represented by a formula (II); and after the reaction is finished, sodium hydroxide is used for adjusting the pH value of the reaction solution to be neutral to obtain the zwitterionic oil displacement agent. The oil displacement agent provided by the invention is suitable for high-temperature and high-salinity oil fields, and has the characteristics of strong salt resistance, excellent high-temperature resistance and outstanding oil-displacing effect.

Owner:NANJING NORMAL UNIVERSITY

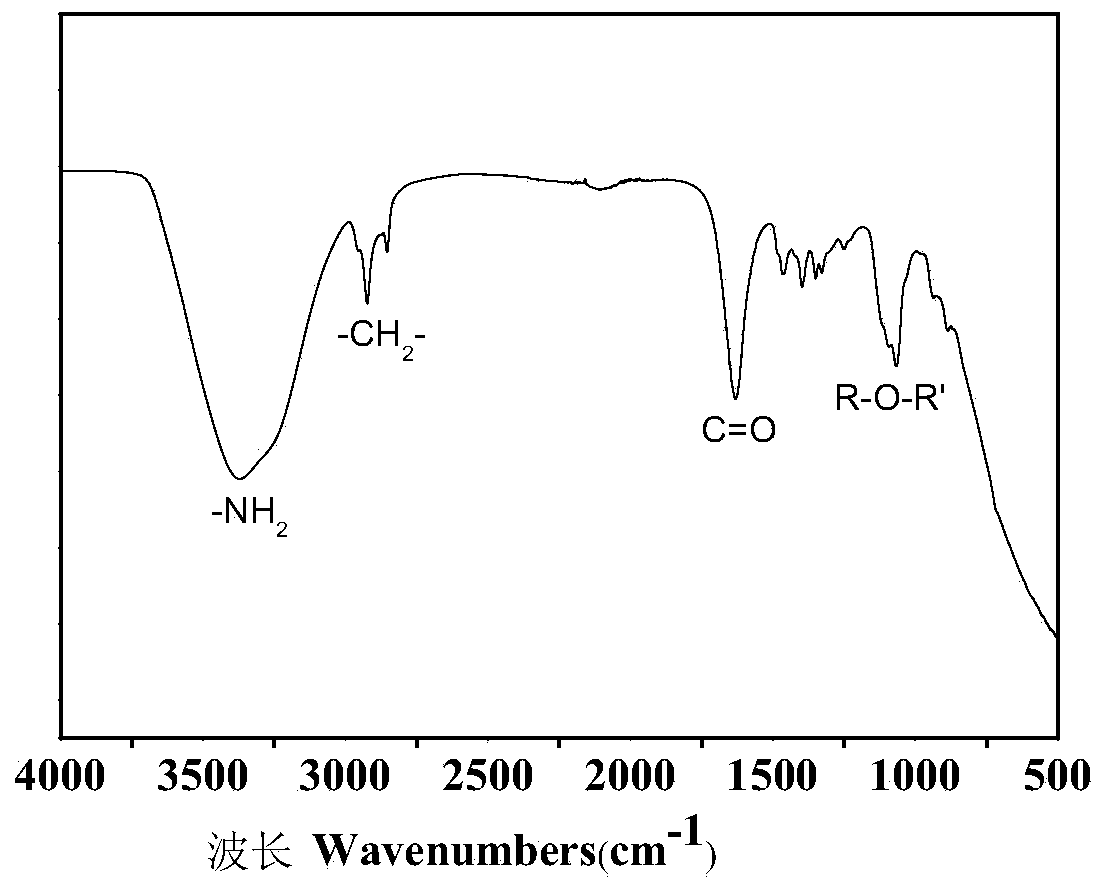

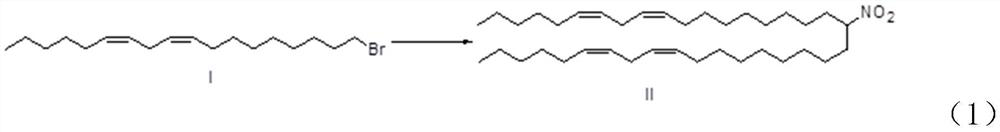

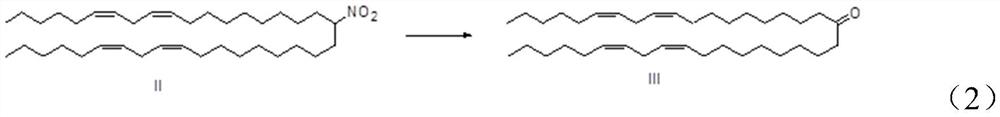

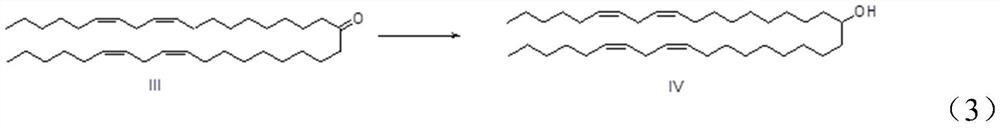

Synthesis method of DLin-MC3-DMA intermediate

InactiveCN112299951ASimple process conditionsSimple and fast operationOrganic compound preparationHydroxy compound preparationPotassium borohydrideKetone

The invention provides a synthesis method of a DLin-MC3-DMA intermediate, the DLin-MC3-DMA intermediate is (6Z, 9Z, 28Z, 31Z)-triheptane-6, 9, 28, 31-tetraen-19-alcohol, and the synthesis method comprises the following steps: S1, carrying out substitution reaction on (6Z, 9Z)-18-bromooctadecane-6, 9-diene and nitromethane to obtain (6Z, 9Z, 28Z, 31Z), step S2, carrying out hydrolysis reaction on (6Z, 9Z, 28Z, 31Z)-19-nitrotriheptane-6, 9, 28, 31-tetraene to obtain (6Z, 9Z, 28Z, 31Z)-triheptane 6, 9, 28, 31-tetraen-19-ketone, and S3, the (6Z, 9Z, 28Z, 31Z)-triheptane-6, 9, 28, 31-tetraen-19-oneand a reducing agent are subjected to a reduction reaction, (6Z, 9Z, 28Z, 31Z)-triheptan-6, 9, 28, 31-tetraen-19-alcohol is obtained, and the reducing agent comprises sodium borohydride, potassium borohydride, lithium aluminum hydride or a mixture of sodium borohydride, potassium borohydride and lithium aluminum hydride. The synthesis method disclosed by the invention has the characteristics of simple process conditions, simplicity and convenience in operation, short route, high repeatability, higher total yield and contribution to industrial production.

Owner:SUZHOU HIGHFINE BIOTECH

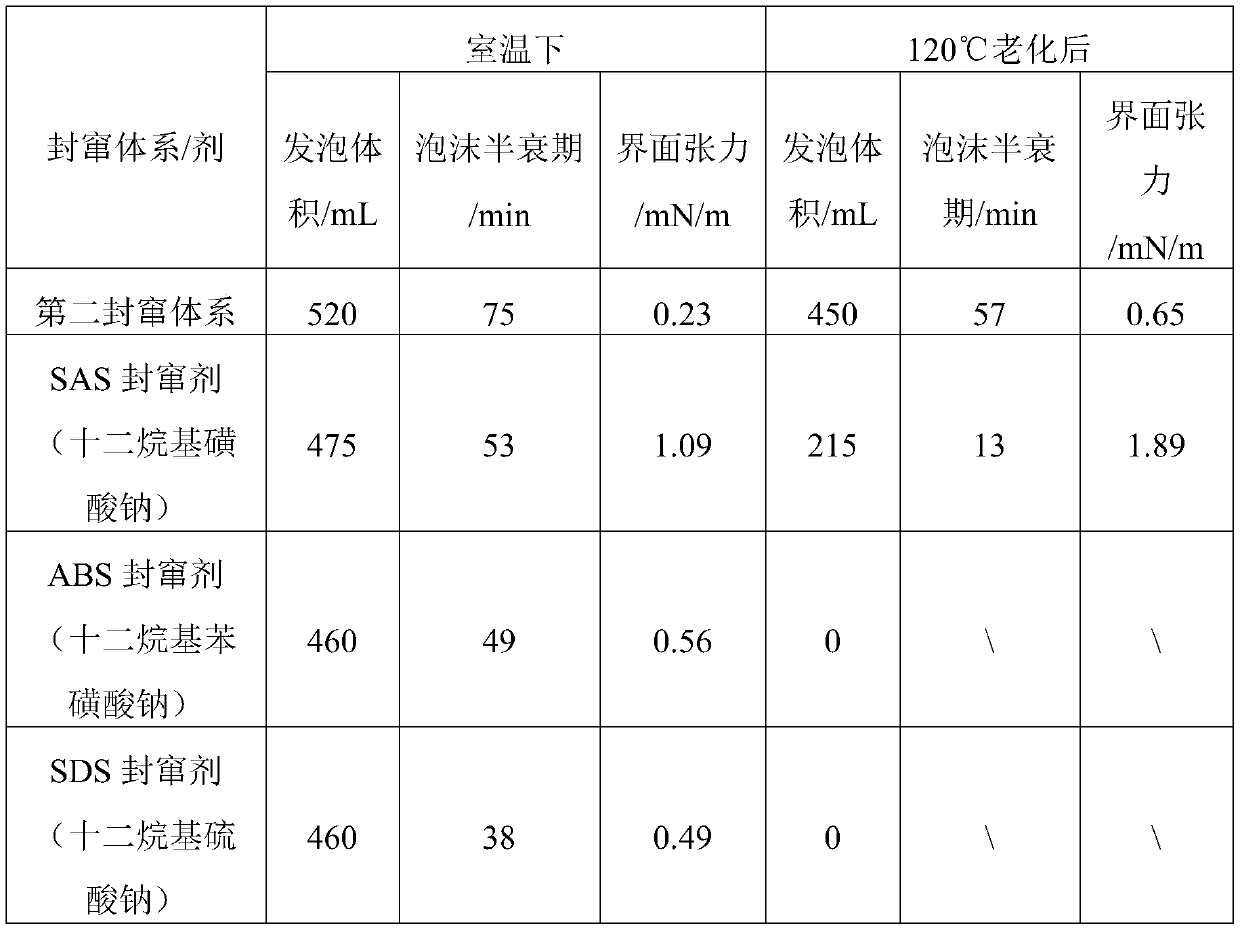

A channel sealing system and its preparation method and application

ActiveCN108048056BRealize deep sealingImprove the blocking effectFluid removalDrilling compositionBetaineCross linker

The invention provides a channelling sealing system, a preparation method and application thereof. The channelling sealing system comprises a first sub-channelling sealing system and a second sub-channelling sealing system. By weight, the first sub-channelling sealing system comprises the following raw materials: 0.05-0.35 part of Na2SO3, 0.2-0.5 part of cationic polyacrylamide, 0.1-0.5 part of polyoxyethylene ether, 0.2-1.0 part of oil sludge, 0.05-0.3 part of a phenolic resin crosslinking agent, 0.05-0.1 part of C6H4(NH2)2 and 100 parts of water; by weight, the second sub-channelling sealingsystem comprises the following raw materials: 1.0-3.0 parts of heptadecyl dimethyl betaine, 0.01-0.1 part of fatty acid diethanol amide, 0.5-1.5 parts of polyoxyethylene fatty acid amide and 100 parts of water. The channelling sealing system provided by the invention has a series of advantages of high viscosity, good temperature resistance, excellent bubble performance and the like, and can effectively realize deep plugging of volcanic rock stratum.

Owner:PETROCHINA CO LTD

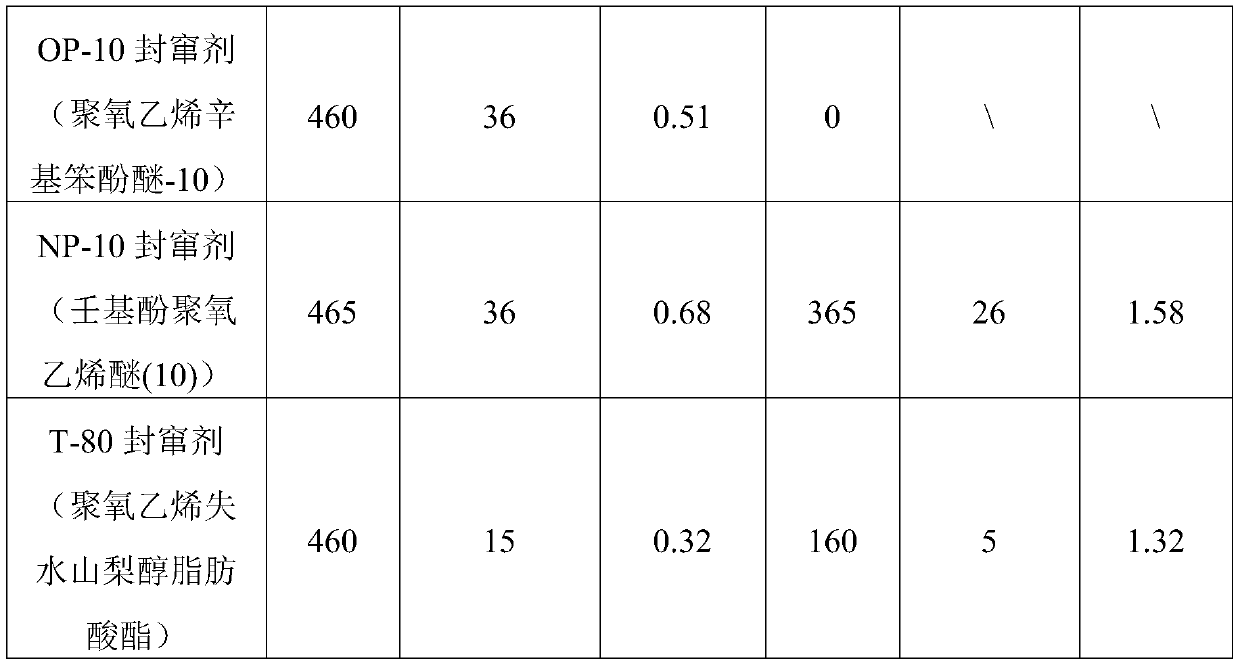

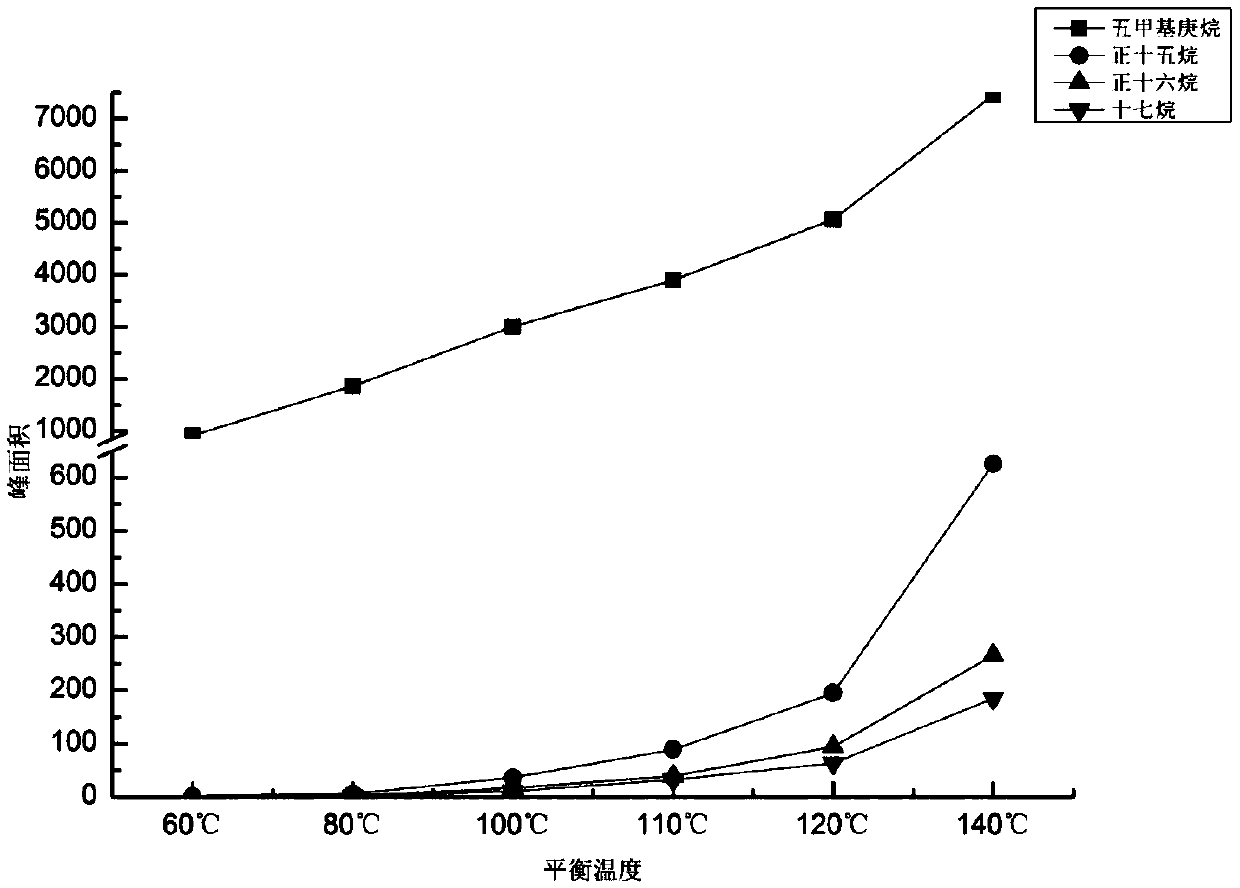

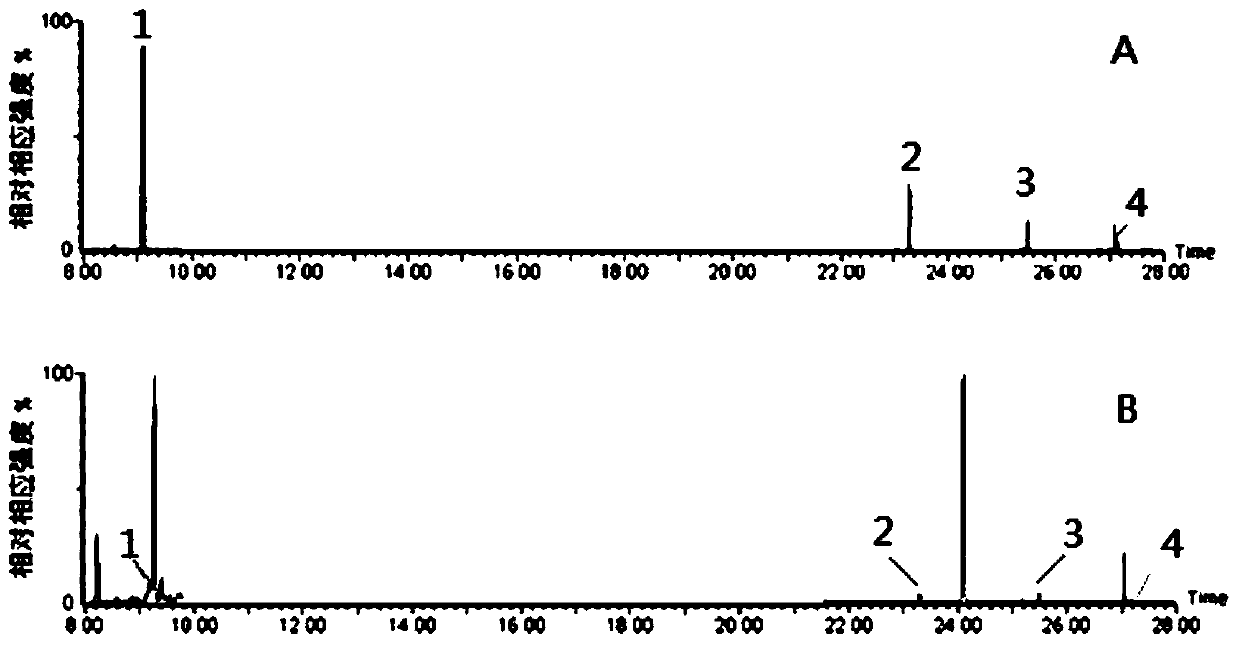

Method for detecting organic matters in packaging material

The invention belongs to the technical field of analysis and detection and in particular relates to a method for detecting organic matters in a packaging material. The method provided by the inventionand used for detecting the organic matters in the packaging material comprises the following steps: detecting a packaging material sample by adopting static headspace balance and gas chromatography-mass spectroscopy, thus obtaining gas chromatography data and mass spectroscopy data; and according to a standard curve of gas chromatography data as well as mass spectroscopy data of organic matter standard solution, obtaining contents of the organic matters in the packaging material, wherein the organic matters comprise one or more of 5-methyl heptane, n-pentadecane, n-hexadecane and n-heptadecane. The method provided by the invention can detect the contents of 5-methyl heptane, n-pentadecane, n-hexadecane and n-heptadecane in the packaging material sample at the same time, and the method issimple, rapid, accurate, good in repeatability and high in accuracy.

Owner:CHINA TOBACCO GUIZHOU IND

Resin composition and article made therefrom

ActiveUS20220204746A1Overcome problemsPrinted circuit detailsPrinted circuit aspectsEpoxyThermal dilatation

A resin composition includes 100 parts by weight of a maleimide resin; 20 parts by weight to 60 parts by weight of a benzoxazine resin; 5 parts by weight to 40 parts by weight of an epoxy resin; 120 parts by weight to 240 parts by weight of silica including spherical silica having a sediment volume of less than or equal to 0.4 mL / g and a particle size distribution D50 of less than or equal to 1.0 μm; and 0.5 part by weight to 1.6 parts by weight of an imidazole compound having a long-chain alkyl group, wherein the imidazole compound having a long-chain alkyl group includes octylimidazole, undecylimidazole, heptadecylimidazole or a combination thereof. The resin composition may be used to make a prepreg, a resin film, a laminate or a printed circuit board, and at least one of the following improvements can be achieved, including glass transition temperature, ratio of thermal expansion, copper foil peeling strength, thermal resistance after moisture absorption, dissipation factor, amount of resin cluster and appearance of cooper-free circuit board.

Owner:ELITE ELECTRONICS MATERIAL ZHONGSHAN

Aromatic composition extracted from Cymbidium goeringii Rchb. f. and extracting method thereof

The invention discloses an aroma composition extracted from spring orchids and an extraction method thereof. The composition includes octadecatrienal, nerolidol, dibutyl phthalate, heptacosanol , Pentadecanoic acid, hexadecanoic acid (palmitic acid), oleic acid, linoleic acid and cyclohexadecane were extracted by leaching and filtering, reflux leaching, filtering, merging and separation, volatile separation, concentration and drying steps, and successfully The aroma substance has been extracted from the flowers of Chunlan, the most important thing is that the main aroma substance octadecatrienal has been found, and the extraction rate of the aroma substance of the present invention is also relatively high. Octatrienal and nerolidol are the main components of the fragrance, and their content is almost 30%. The composition of the present invention has met the basic requirements of natural fragrances, and can be used in fragrances, perfumes, fragrances, etc. according to existing methods. In fragrance body and bath products, this natural "orchid fragrance" can be applied in industry.

Owner:魏平飞 +3

A kind of preparation method of ginkgolic acid

ActiveCN109020804BLow costSimple and fast operationCarboxylic compound separation/purificationAcetic acidCountercurrent chromatography

The invention relates to a method for separating ginkgolic acid monomers in total ginkgolic acid extracts by high-speed countercurrent chromatography. In the technical solution, silver nitrate is added to a two-phase solvent, and silver ion complexation is introduced. The two-phase solvent system For n-heptane / ethyl acetate / methanol / acetic acid. The method of the invention can separate ginkgolic acid, ginkgolic acid, heptadecanadiene ginkgolic acid, hydrogenated gingkoic acid, heptadecanone ginkgolic acid, five high-purity ginkgolic acid monomer compounds at one time, and the preparation method is simple and convenient High efficiency, cost-effective, suitable for industrial production, has important economic significance.

Owner:SHANDONG ANALYSIS & TEST CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com