Patents

Literature

91results about How to "Human factors are small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

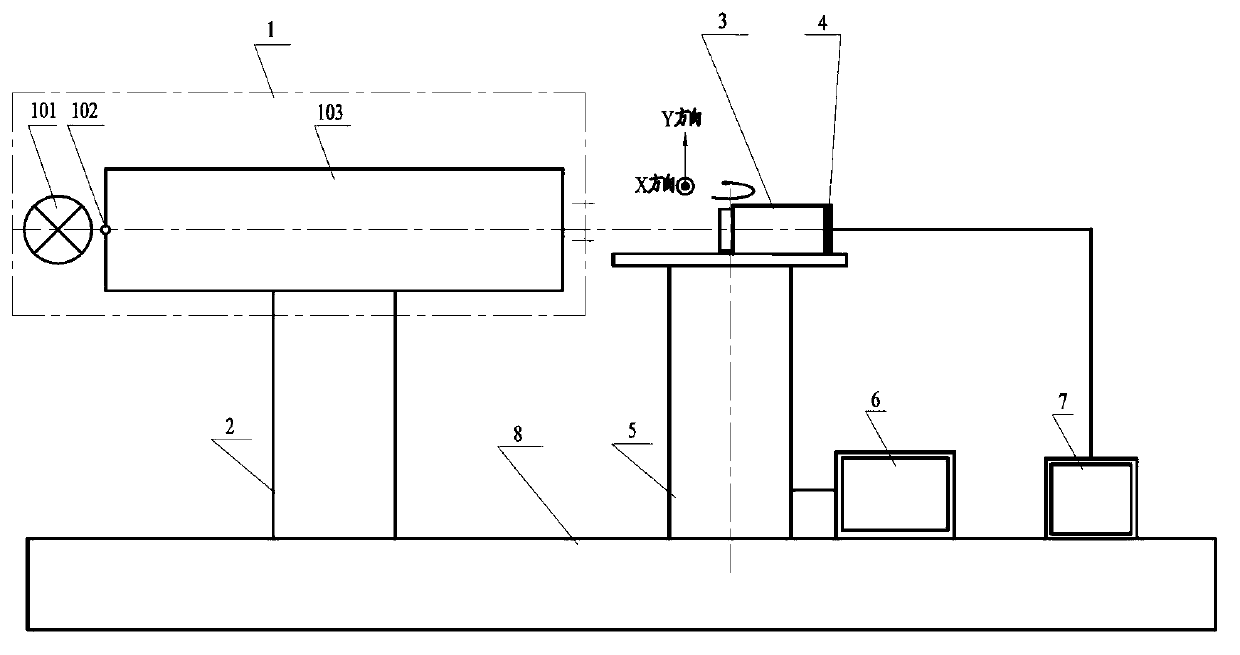

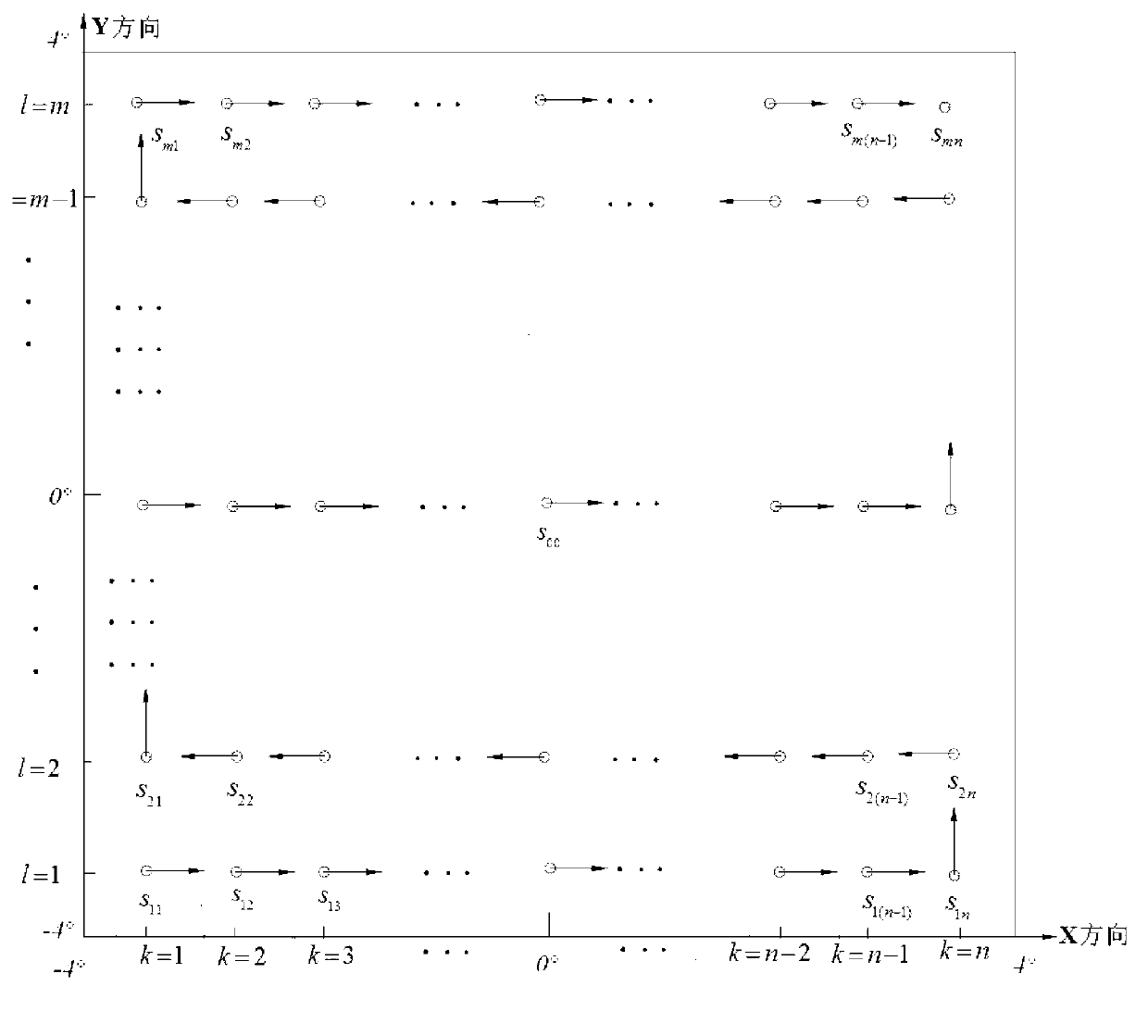

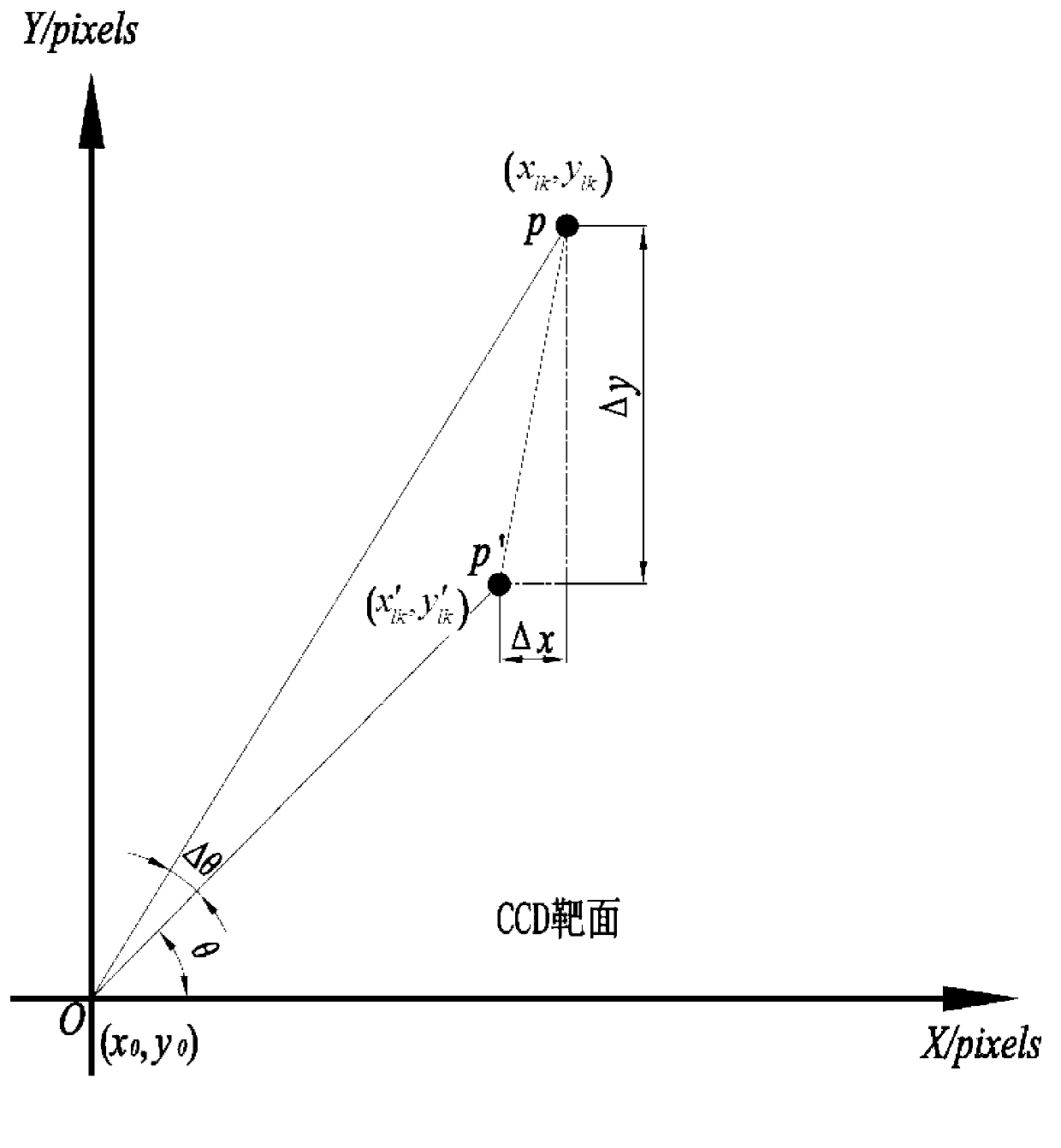

Measuring device and calibration method for optical lens distortion

InactiveCN103292981ANo complex alignment process requiredHuman factors are smallTesting optical propertiesCamera lensSingle star

Provided is a measuring device and a calibration method for optical lens distortion. The measuring device comprises a single star light simulator, an adjusting rack, a to-be-tested lens, a CCD (charge coupled device) camera, a one-dimensional air flotation turntable, an angle encoder, a computer and an optical platform. The calibration method includes the steps of using a centroid localization algorithm to determine centroid position coordinates of a star point image when the to-be-tested lens is under different fields of view, establishing a calibration model for the to-be-tested lens distortion based on the distribution of the centroid position coordinates of the star point image under the entire field of view, and realizing the calibration of the distorted to-be-tested lens. The measuring device and the calibration method for the optical lens distortion has the advantages that the device is simple; the method is convenient; measurement accuracy is high; and the optical lens distortion can be easily measured and calibrated.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Quantitative determination RBP4 kit by chemiluminescence magnetic enzymoimmune method

ActiveCN101452001AExtended storage timeStable LuminescenceChemiluminescene/bioluminescenceBiological testingImmunocompetenceMagnetic bead

The invention relates to a medical testing kit for performing quantitative detection on human serum RBP4 using chemiluminescence magnetic-enzyme immunotherapy. The kit is composed of four reagent parts: specificity mouse anti-human RBP4 custodite immunomagnetic beads, enzyme labelling specificity mouse anti-human RBP4 antibody II, chemiluminescence substrate, corresponding titer and quality control liquid. The using method of the kit comprises: using bead particulates as solid phase carrier, combining specificity mouse anti-human RBP4 antibody I on the surface, forming RBP4 specificity immunocompetence beads, capturing antigen RBP4 to be detected in the enzyme labelling specificity mouse anti-human RBP4 antibody II, forming double antibody sandwich composite on the surface of the beads, wherein enzyme marked on the composite reacts with corresponding irradiance substrate in the reaction system to form stable luminous signals, thereby reaching quantitative detection and analysis on RBP4 through strength of the detection light signals. The invention has the advantages of high sensitivity, high specificity, simple and fast operation.

Owner:WUHAN EASYDIAGNOSIS BIOMEDICINE

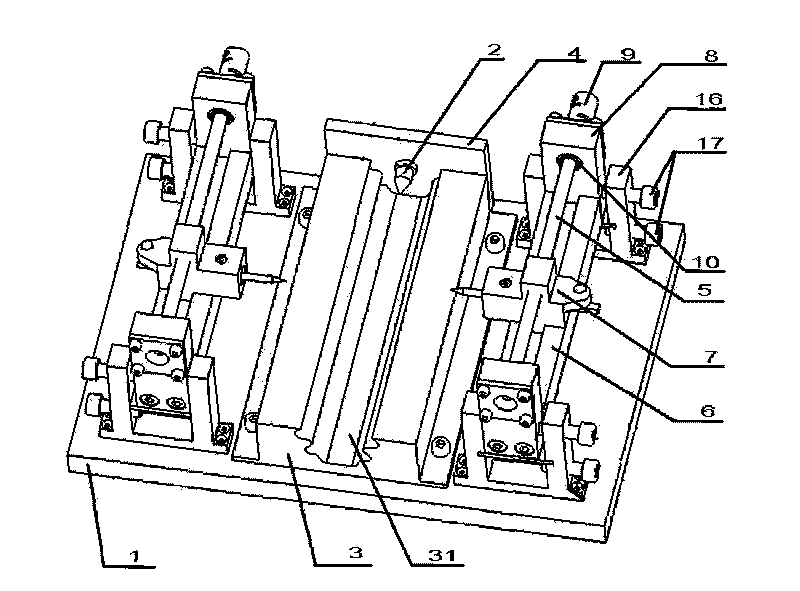

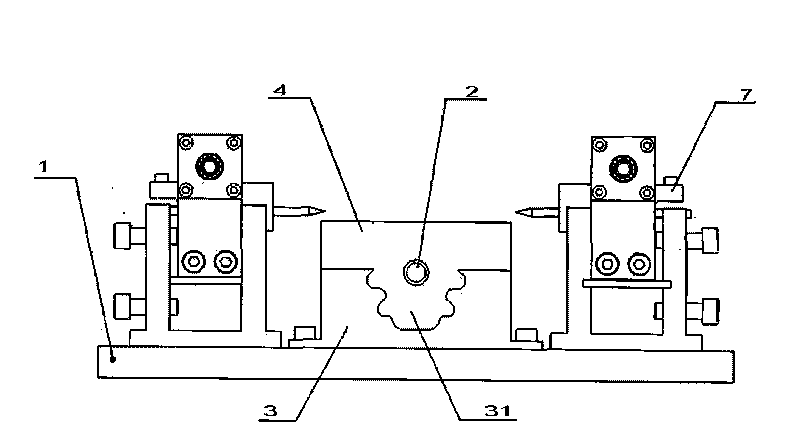

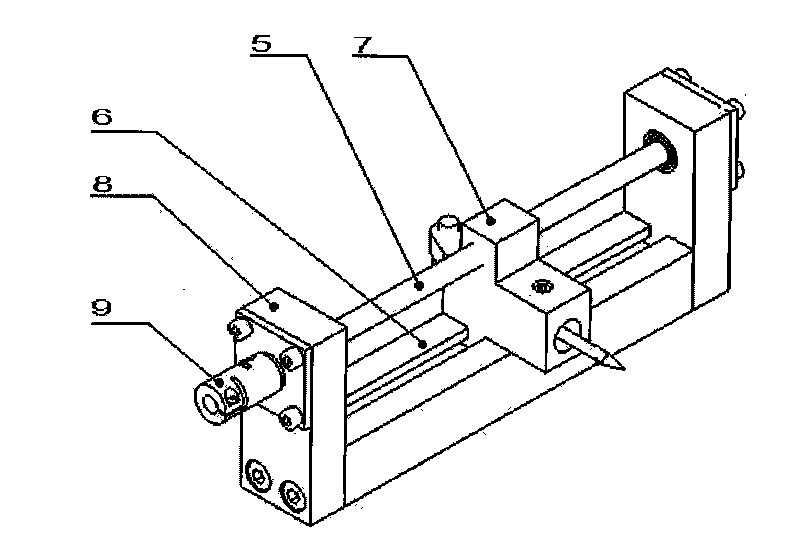

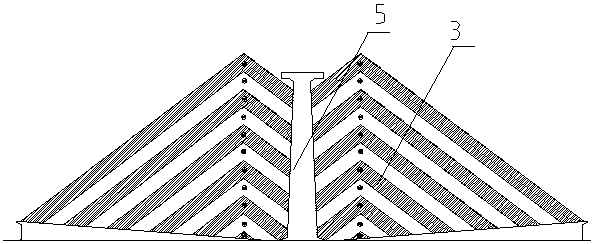

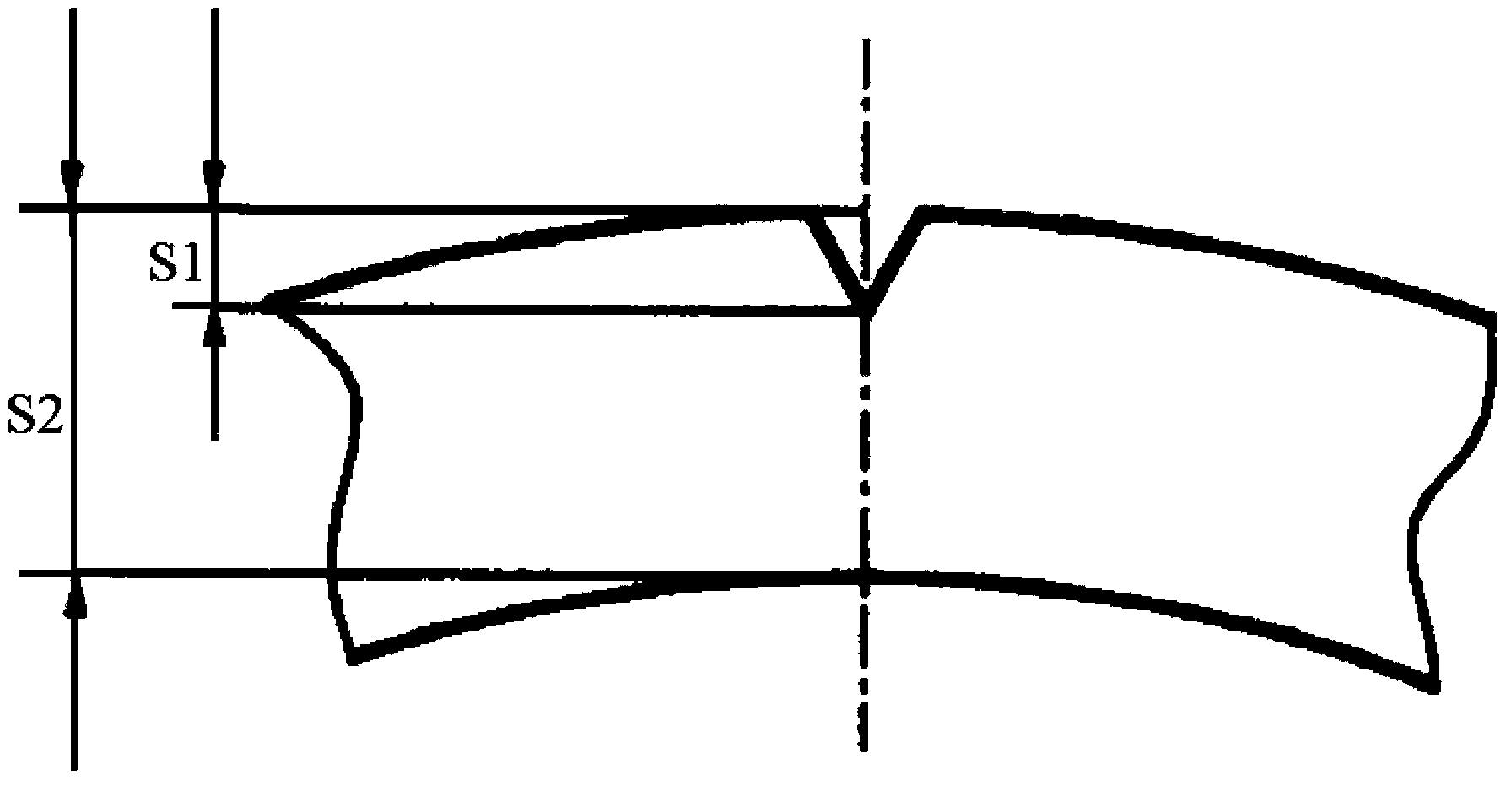

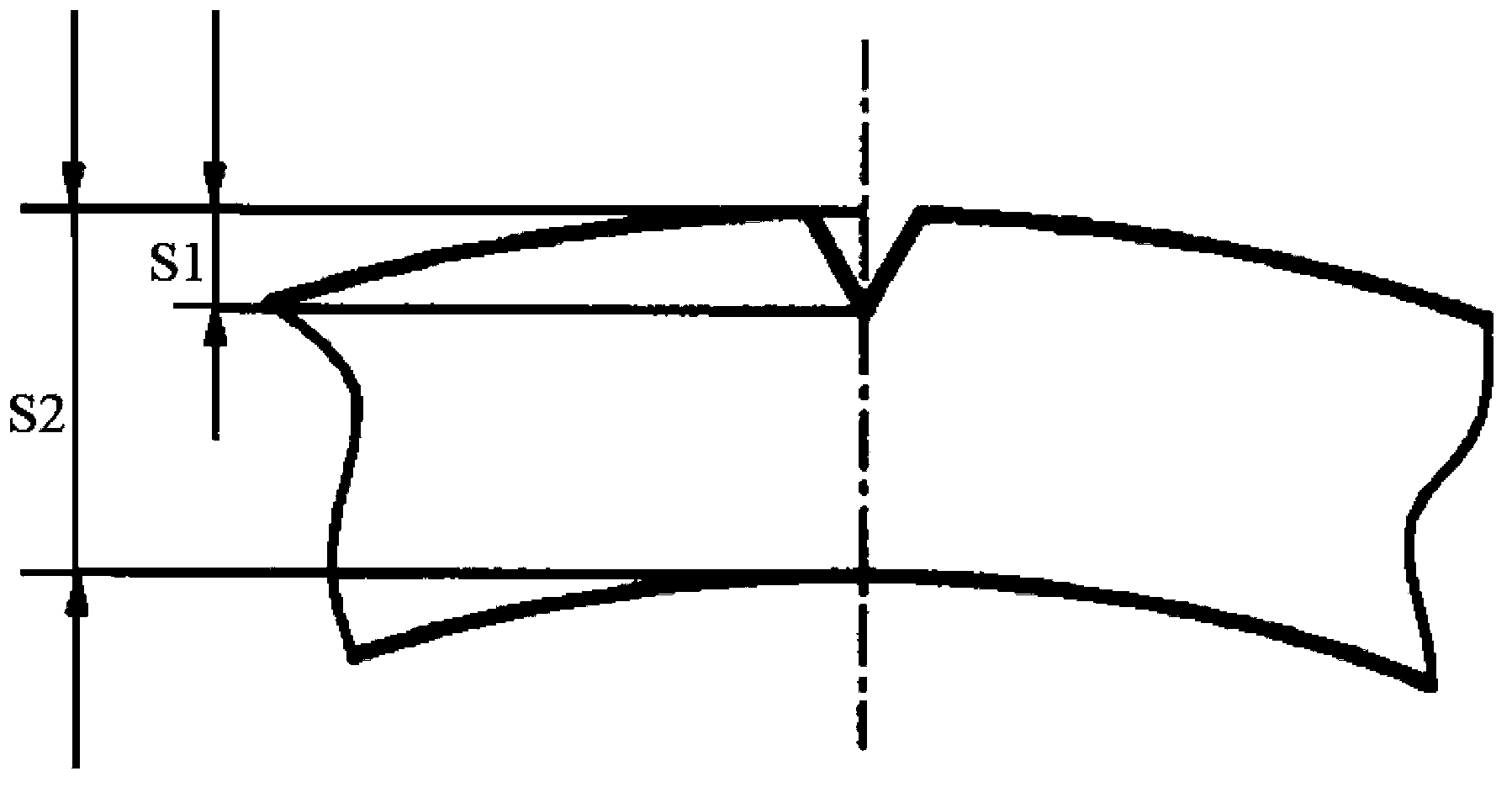

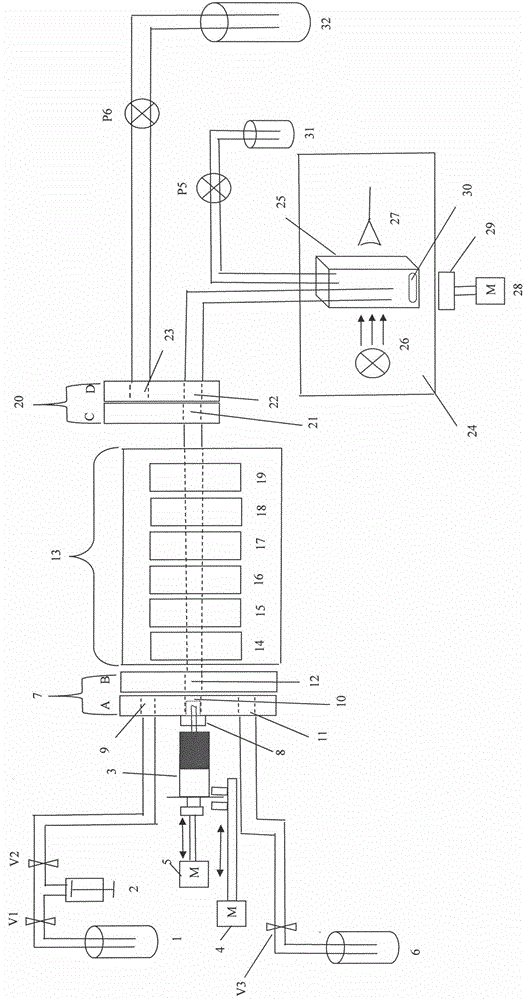

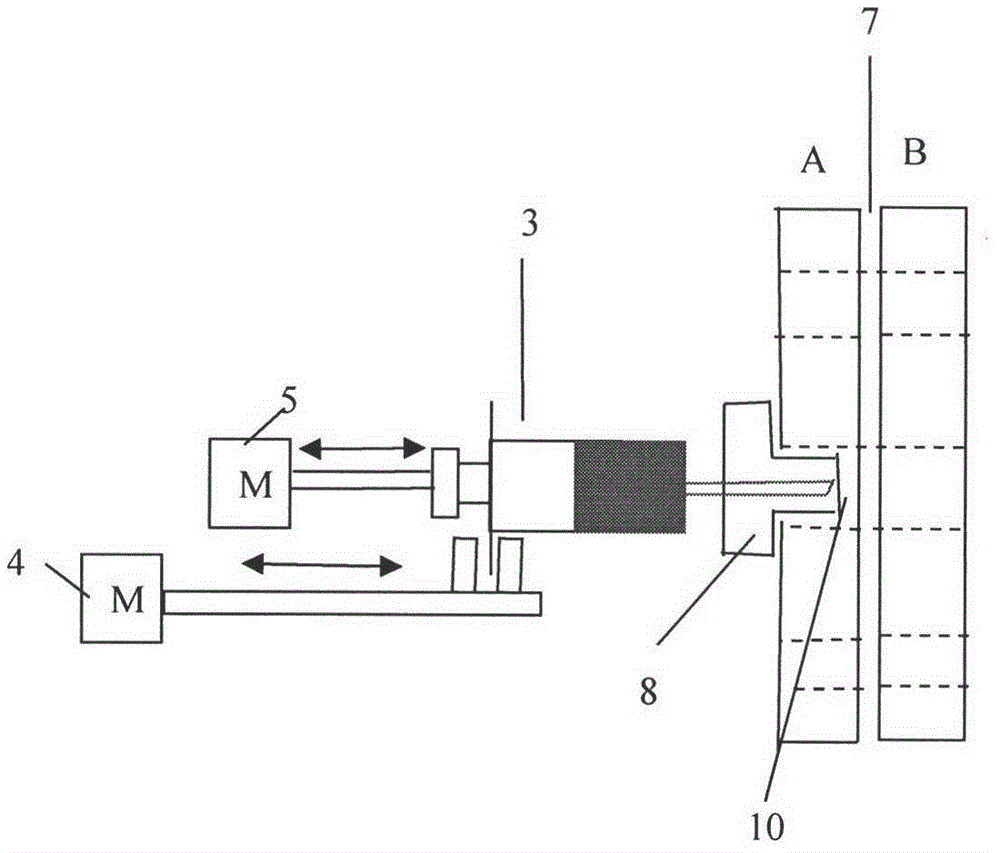

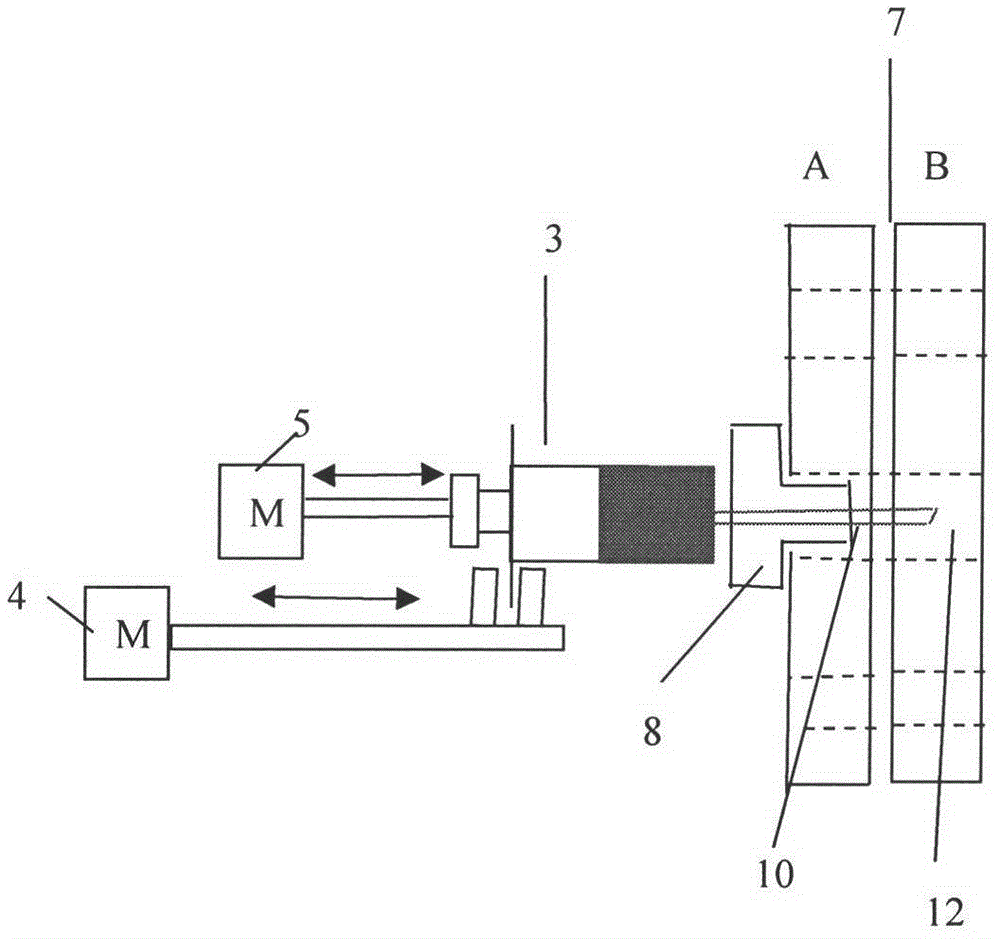

Rapid detecting device and detecting method of precision of blades of gas turbine

The invention discloses a rapid detecting device and a detecting method of the precision of blades of a gas turbine. A detected blade is positioned by a blade positioning device; and profile measuring devices are symmetrically arranged at two sides of the blade positioning device and used for acquiring profile data of the section of the blade. By adopting the rapid detecting device and the detecting method, the workload for acquiring blade conic data is greatly reduced; influence from personal factors is little and the data acquiring speed is high; contact type measurement by a measuring pen is adopted with high measurement precision; the arithmetic of the profile data of a discrete section is simple and mature, is high in precision and is easy for subsequent error analysis calculation; the height and the quantity of the profile data is selective and adjustable and has high flexibility; the mechanical structure is simple, the cost is relative low and the measurement precision is ensured.

Owner:XI AN JIAOTONG UNIV

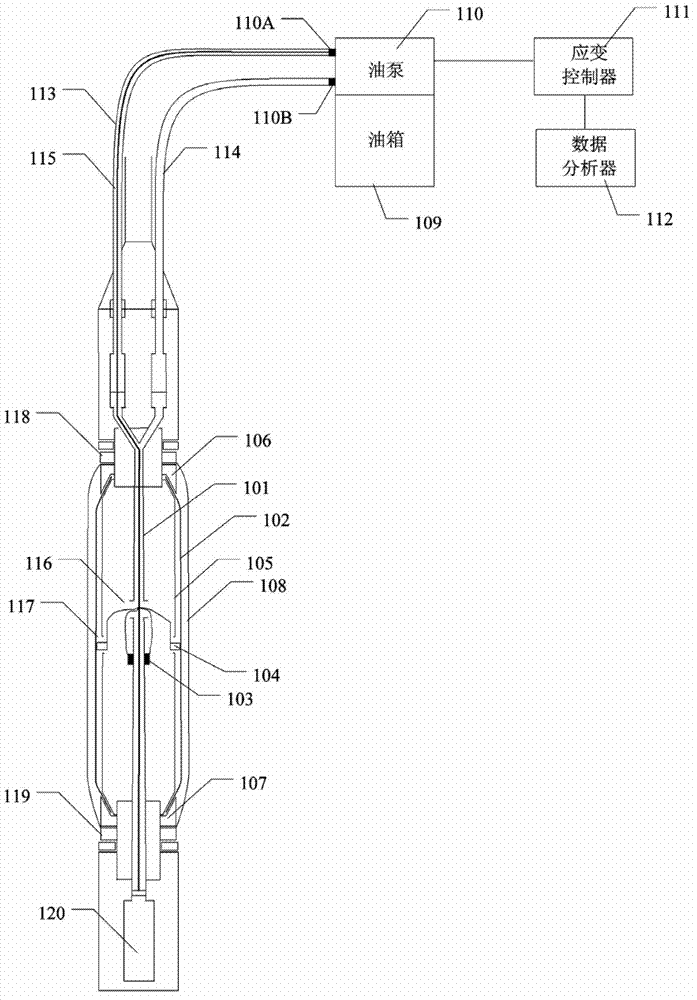

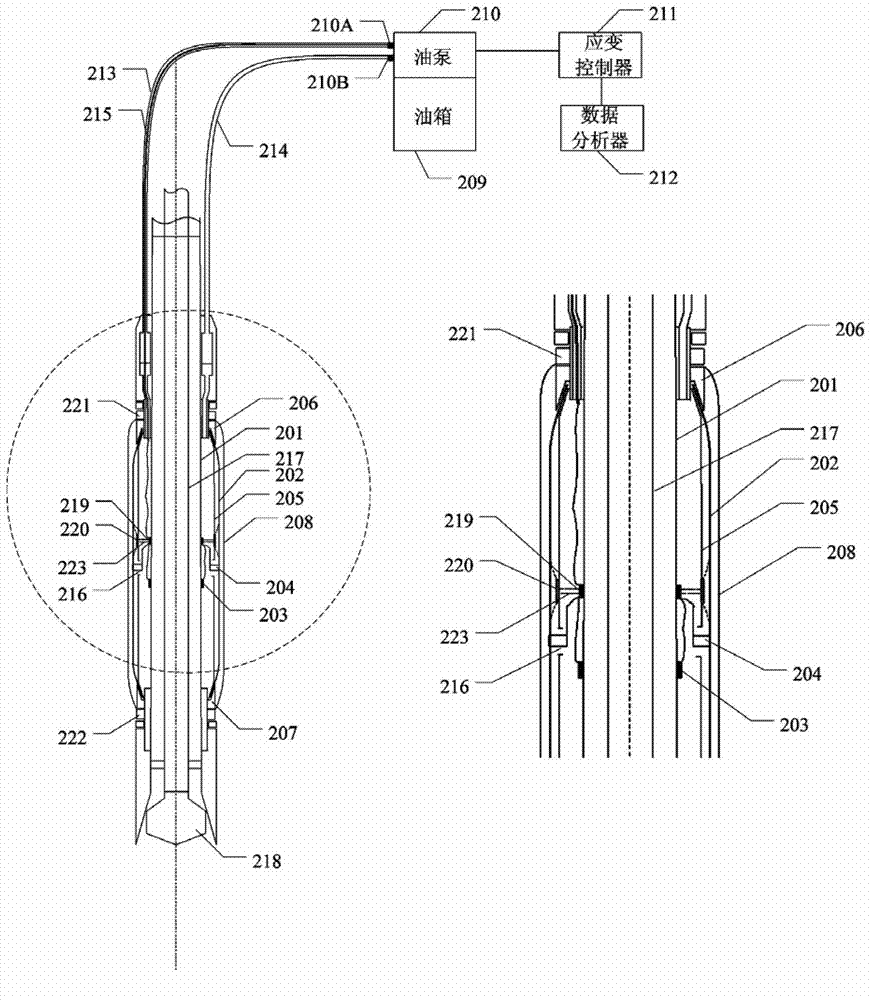

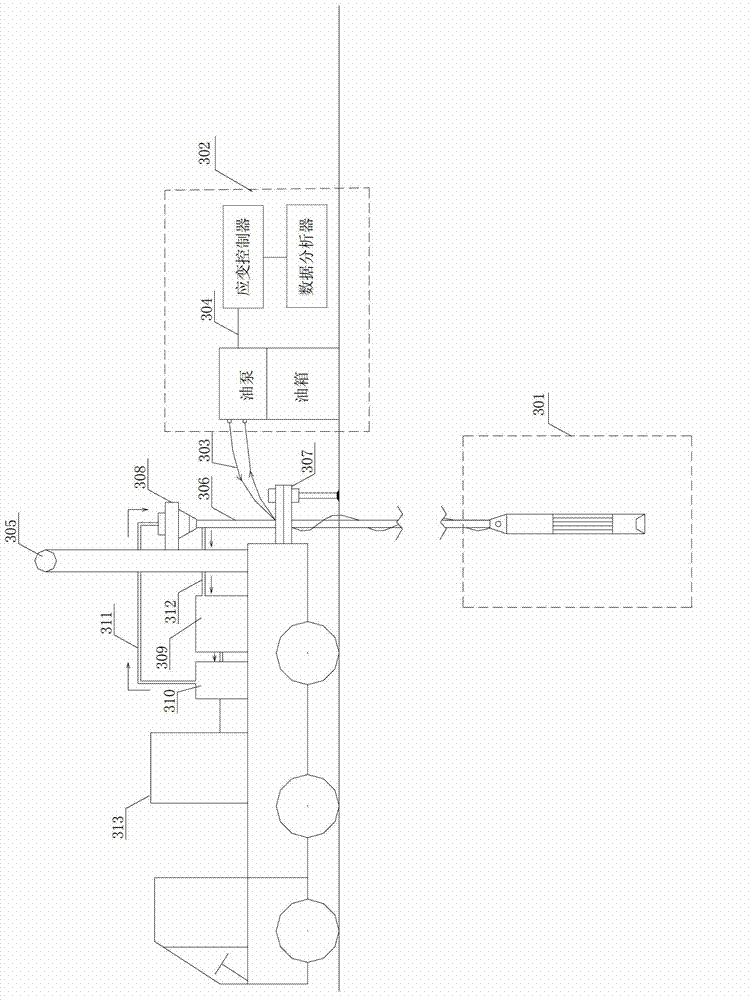

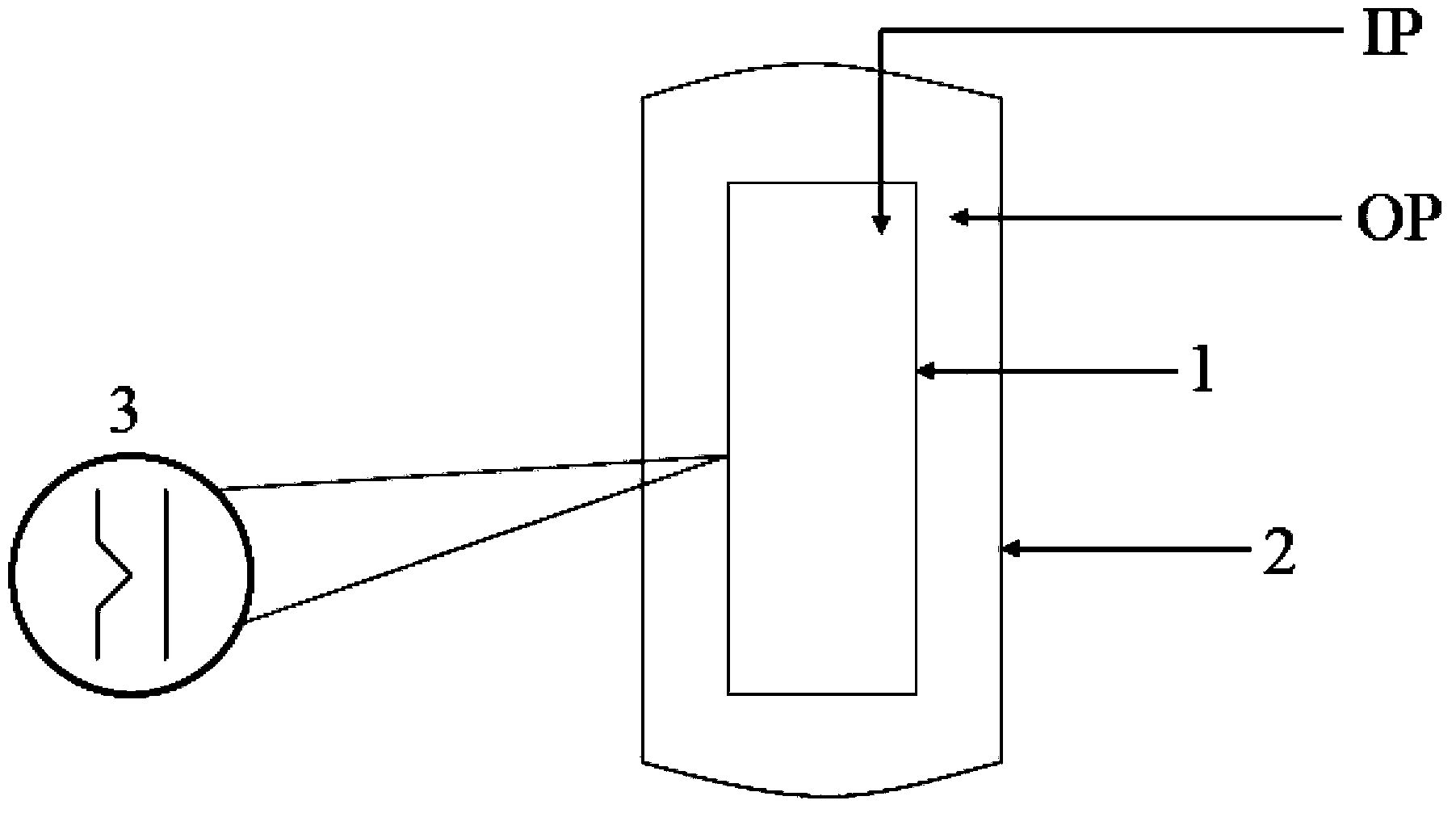

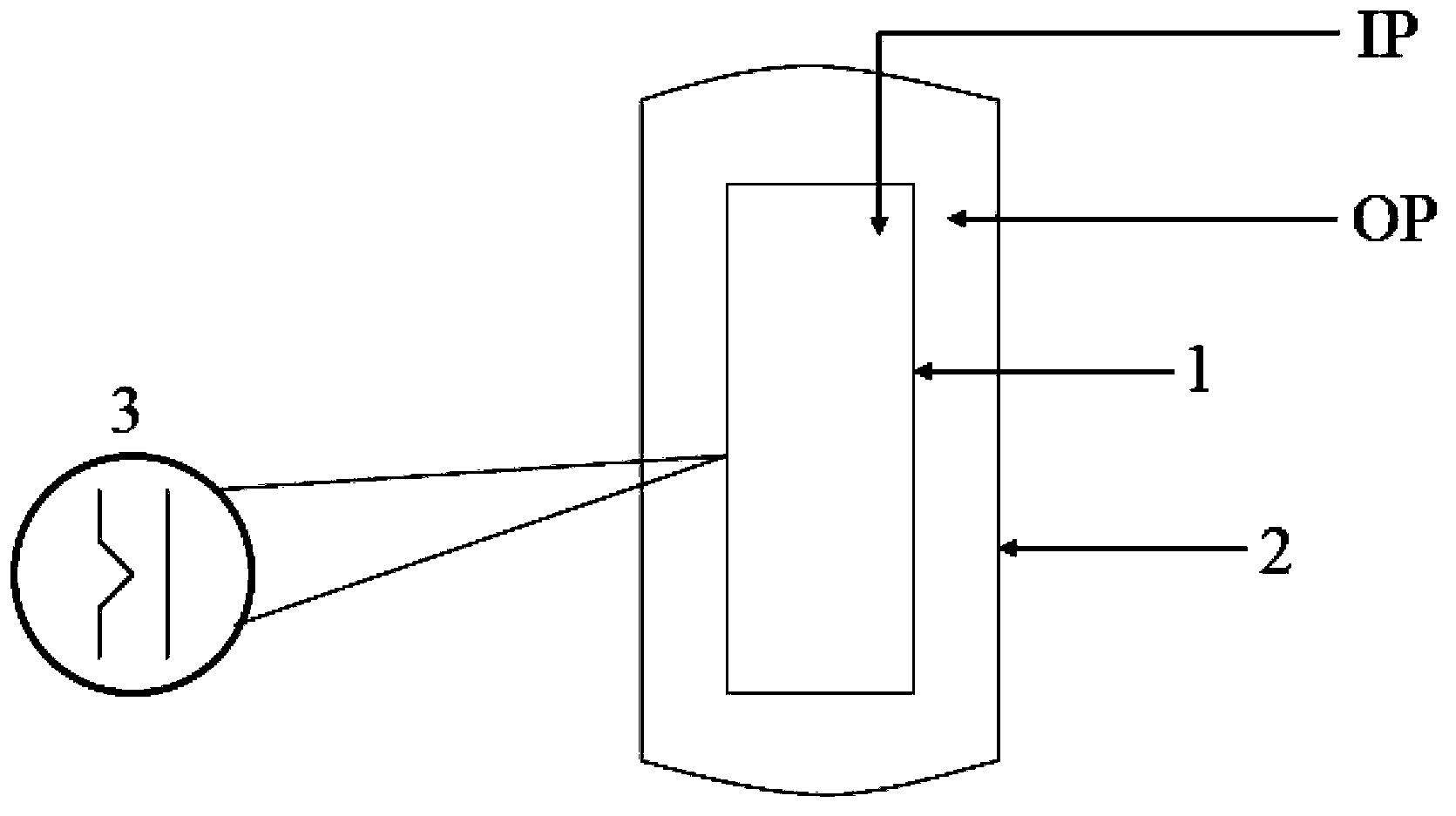

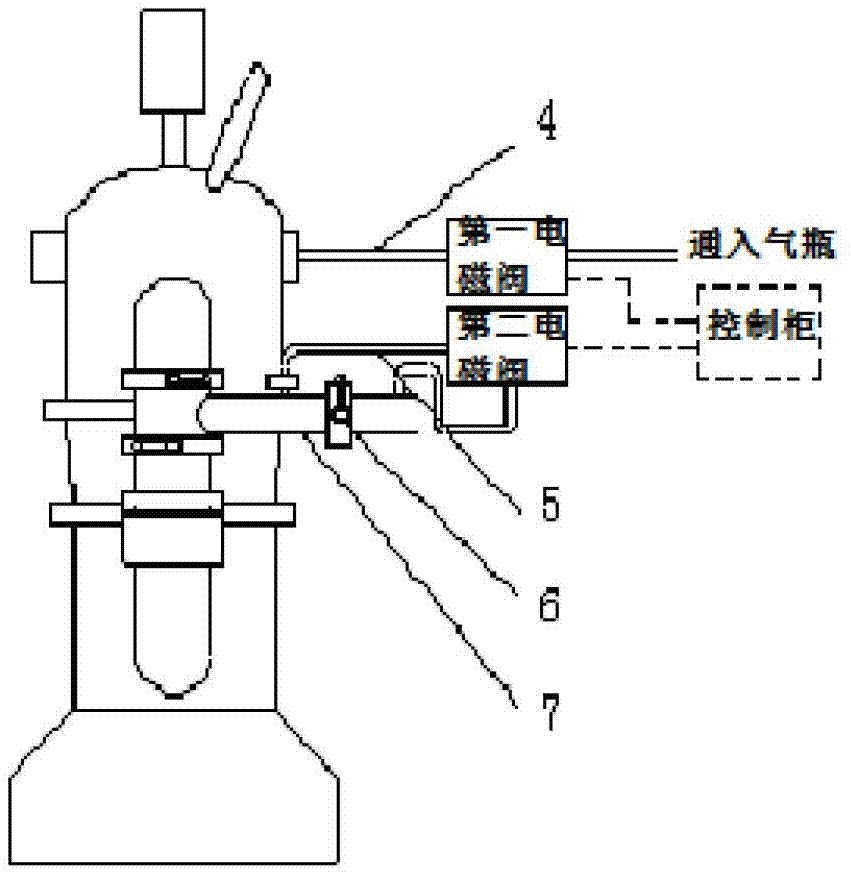

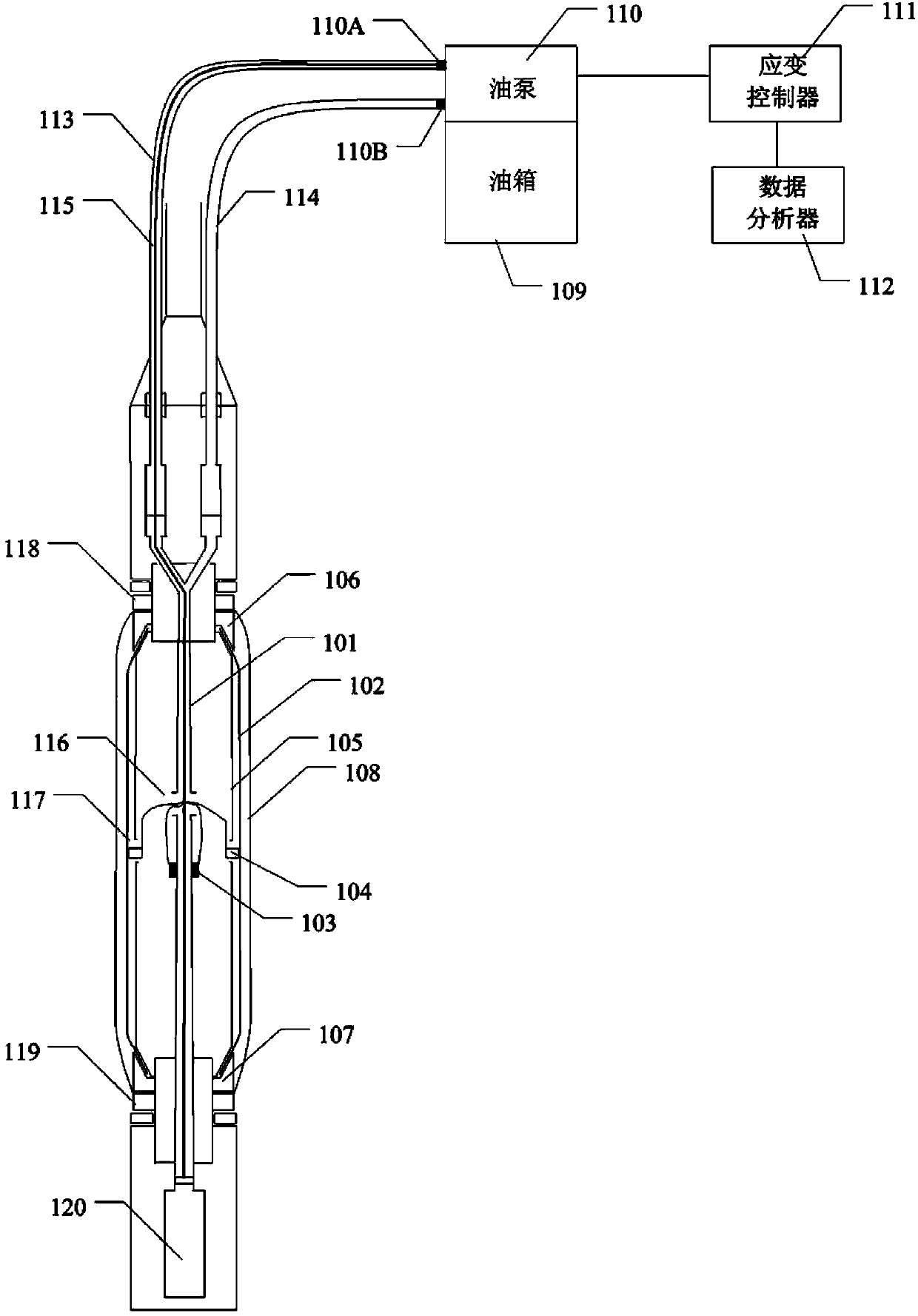

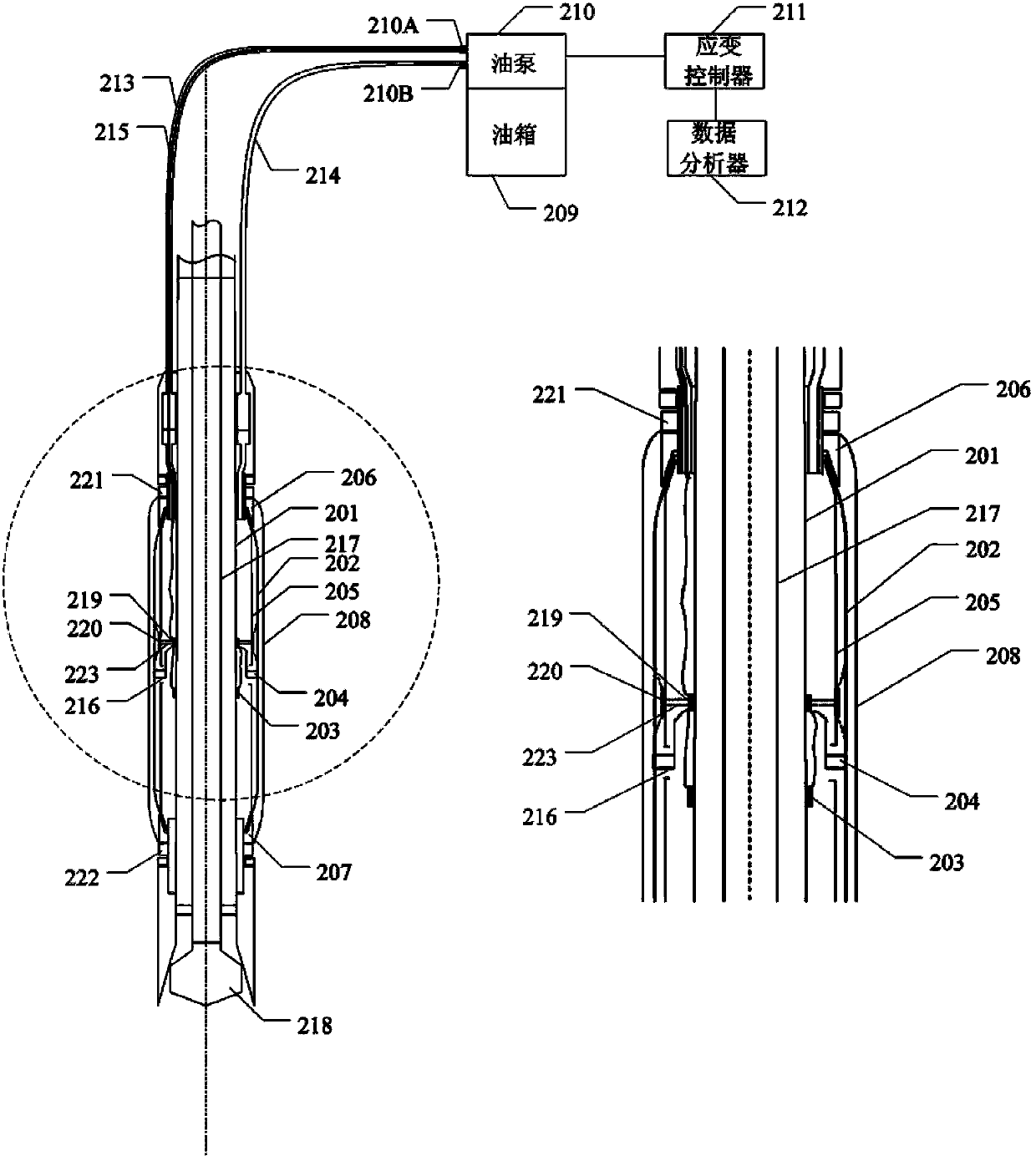

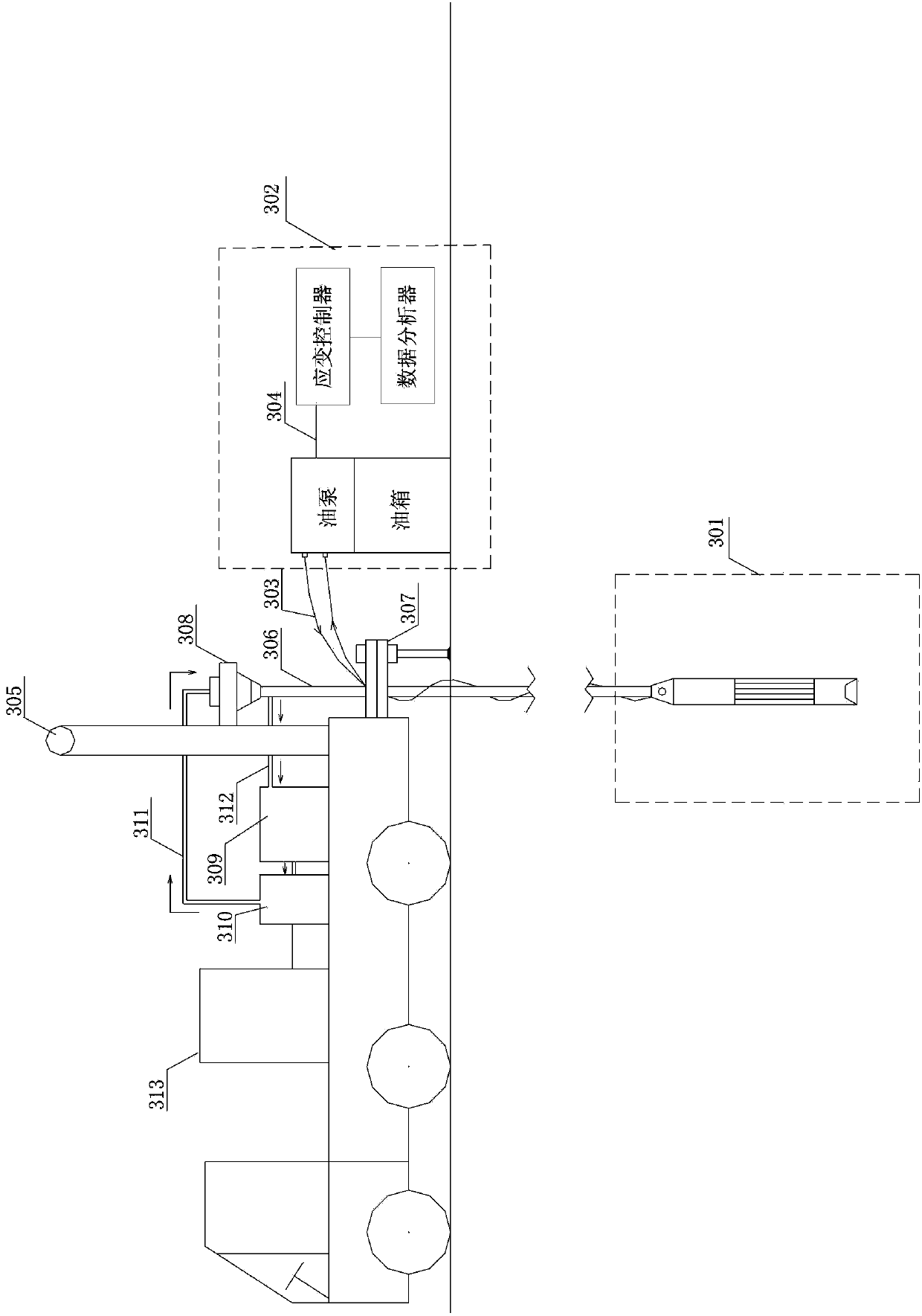

Pre-boring pressure meter, self-boring pressure meter and self-boring pressure metering equipment

ActiveCN102926369ASteady change in degree of expansionAvoid crackingIn situ soil foundationPore water pressureFuel tank

The invention provides a pre-boring pressure meter, a self-boring pressure meter and a self-boring pressure metering equipment. The pre-boring pressure meter comprises a test device, a control device and an oil conveying tube, wherein the test device comprises a main body barrel, an elastic film, a pressure sensor and a displacement sensor; and the control device comprises an oil tank, an oil pump, a strain controller and a data analyzer. The self-boring pressure meter comprises a test device, a control device and an oil conveying tube, wherein the test device comprises an outer layer sleeve, an inner layer sleeve, a drill bit, an elastic film, a pressure sensor, a displacement sensor, a porous stone and a pore water pressure sensor; and the control device comprises an oil tank, an oil pump, a strain controller and a data analyzer. The self-boring pressure metering equipment comprises a self-boring pressure meter, a boring device, a water circulating device and a power device. According to the invention, the elastic film is controlled to stably expand, so that fracture phenomena due to uneven expansion of the elastic film can be avoided, and test data can be ensured to be continuous and accurate; and moreover, hydraulic oil is used as an inflating medium to protect an inner circuit structure from corroding.

Owner:刘潋

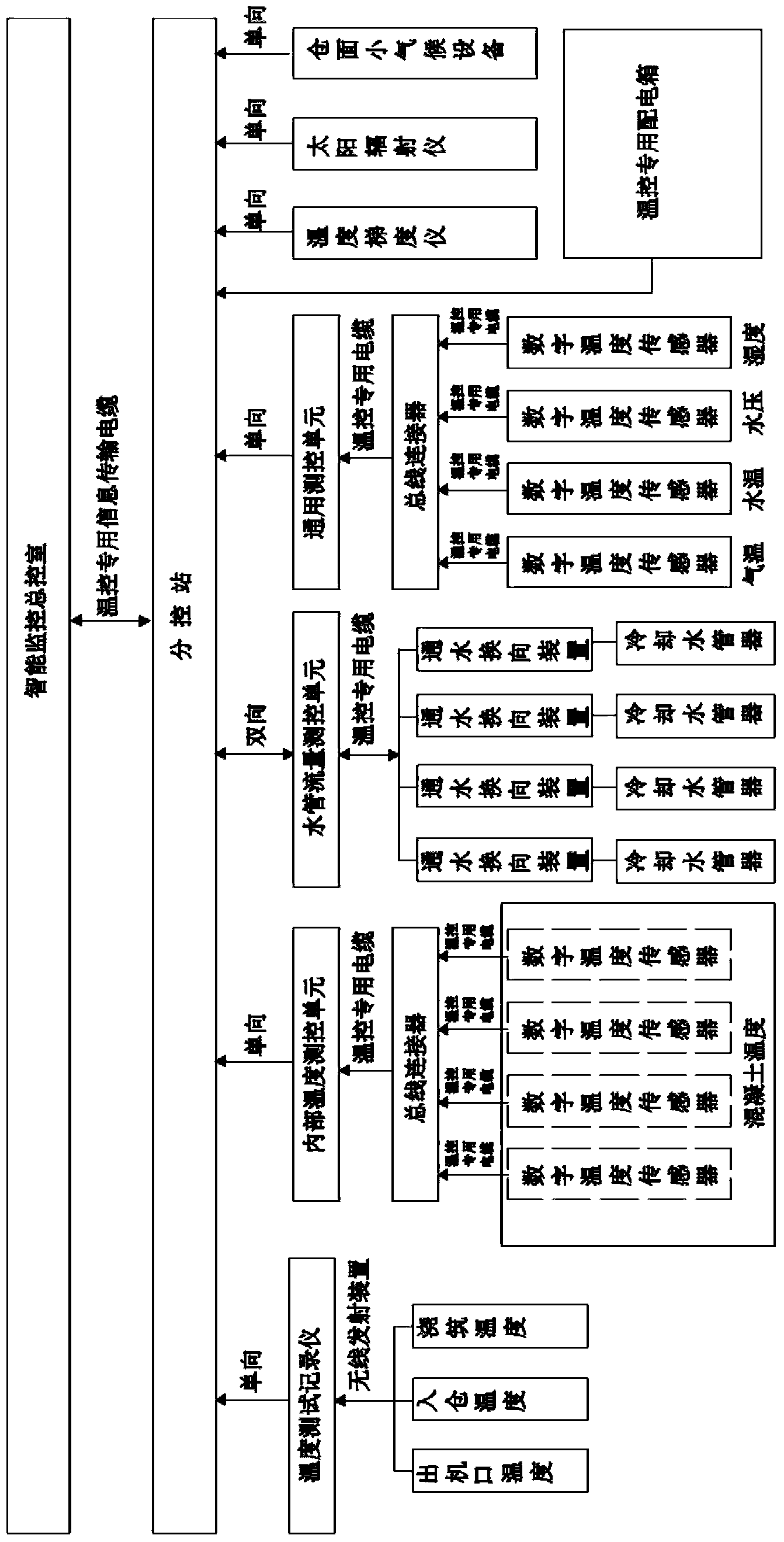

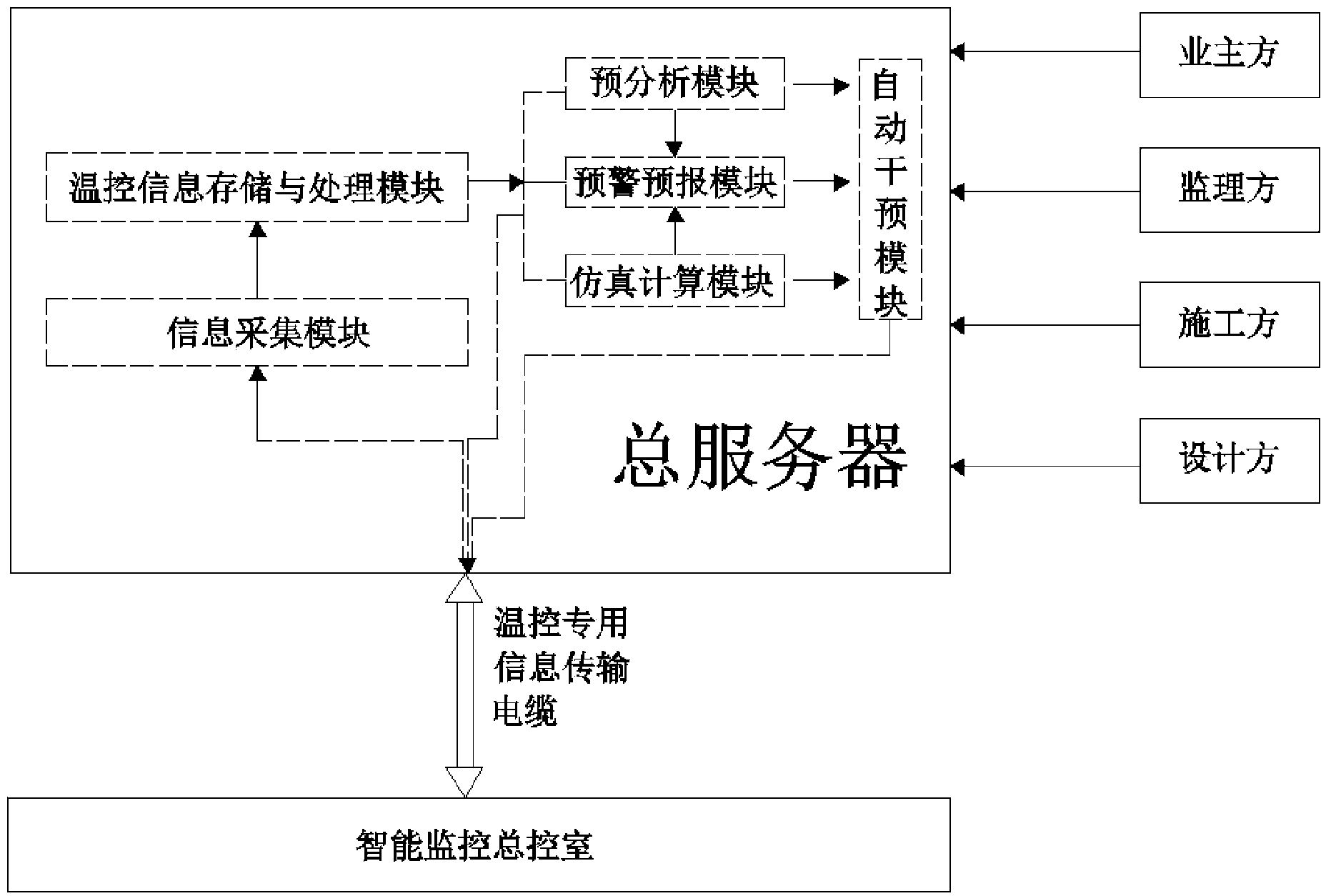

Novel concrete intelligent temperature control system and method

InactiveCN104298272AEasy to superviseEasy to manageTemperature control using electric meansBuilding constructionTemperature control

The invention discloses a novel concrete intelligent temperature control system and method. The system comprises a main server, an intelligent monitoring main control room and branch control stations. The main server of the system is responsible for data storage, management, calculation, analysis, pre-warning, forecasting and instruction transmission of the whole system and can dynamically and visually display all types of temperature control information in form of graphs, lists and lines, and related workers can conveniently conduct supervision and management. The intelligent monitoring main control room directly distributes instruction information of the main server to all the branch control stations and can send temperature control information of all the branch control stations to the main server in a concentrated mode. The branch control stations draw all monitoring devices to the system so that management and information transmission can be conveniently conducted. By means of the modularized, unitized and systemic design, the true temperature and stress, influenced by the true environment where various factors exist at the same time, of concrete are achieved, man-made influence factors are reduced through intelligent water injection, and rapid and high-quality construction of large-size concrete are ensured under the complex environment conditions.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

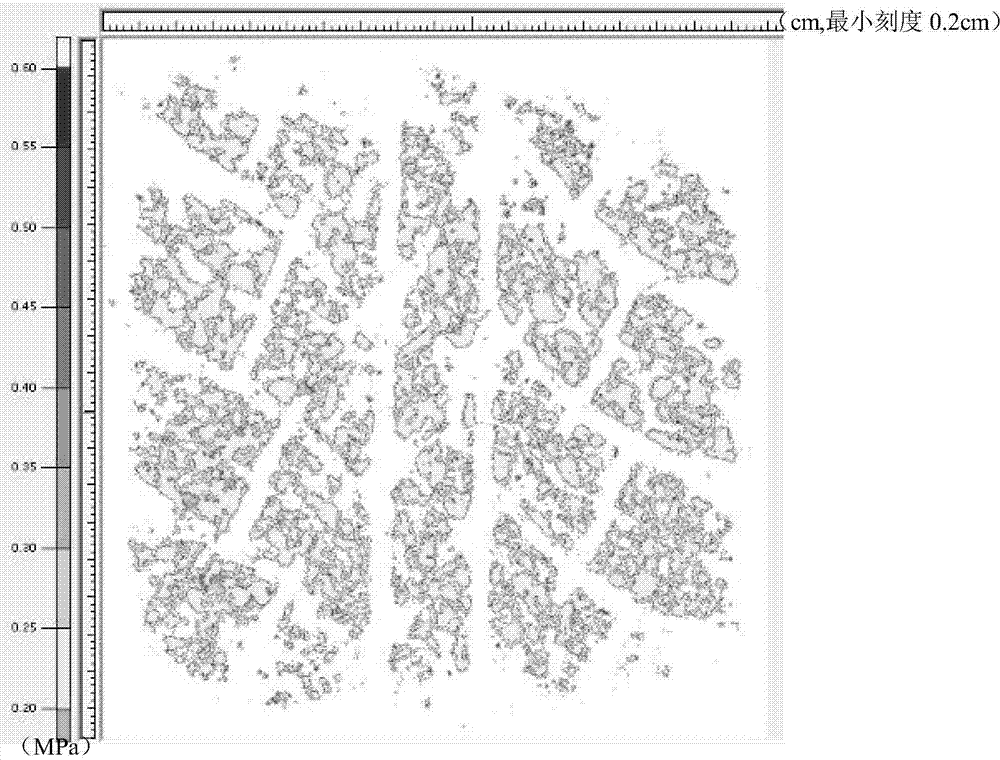

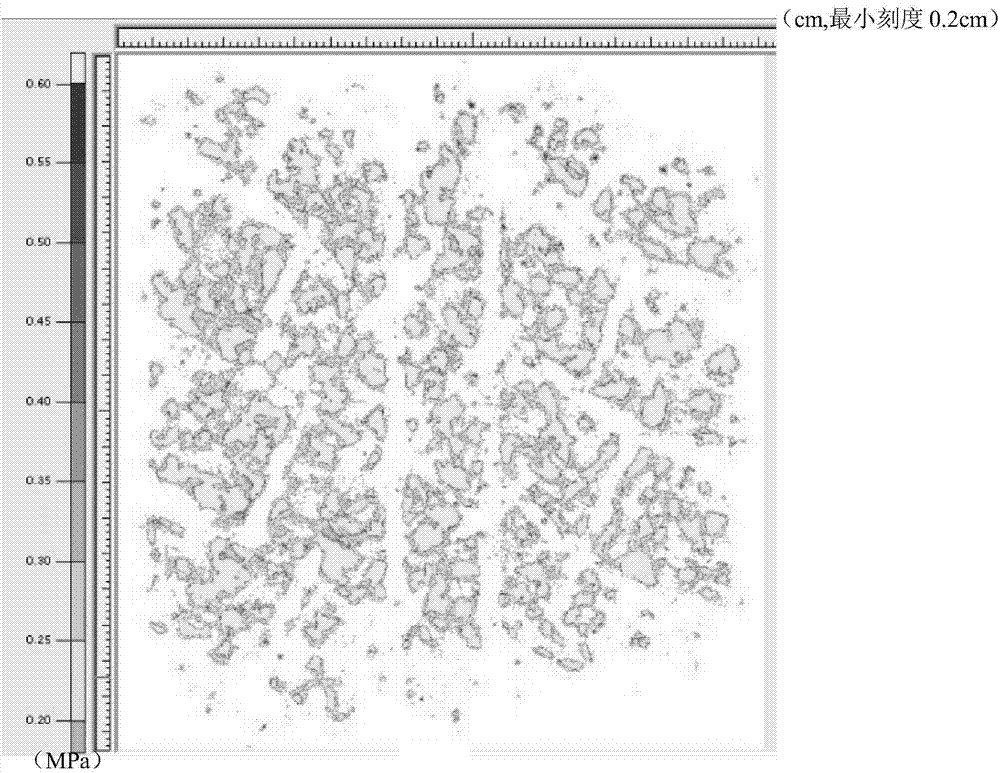

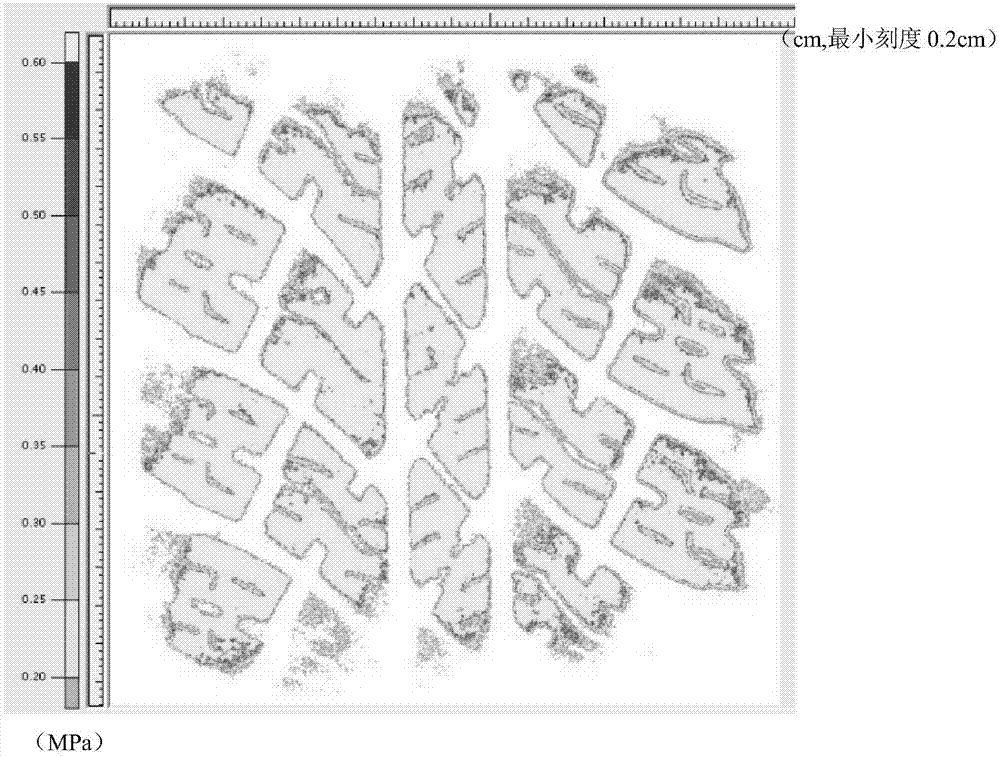

Tire and pavement contact pressure characteristic-based pavement skid resistance condition evaluation method

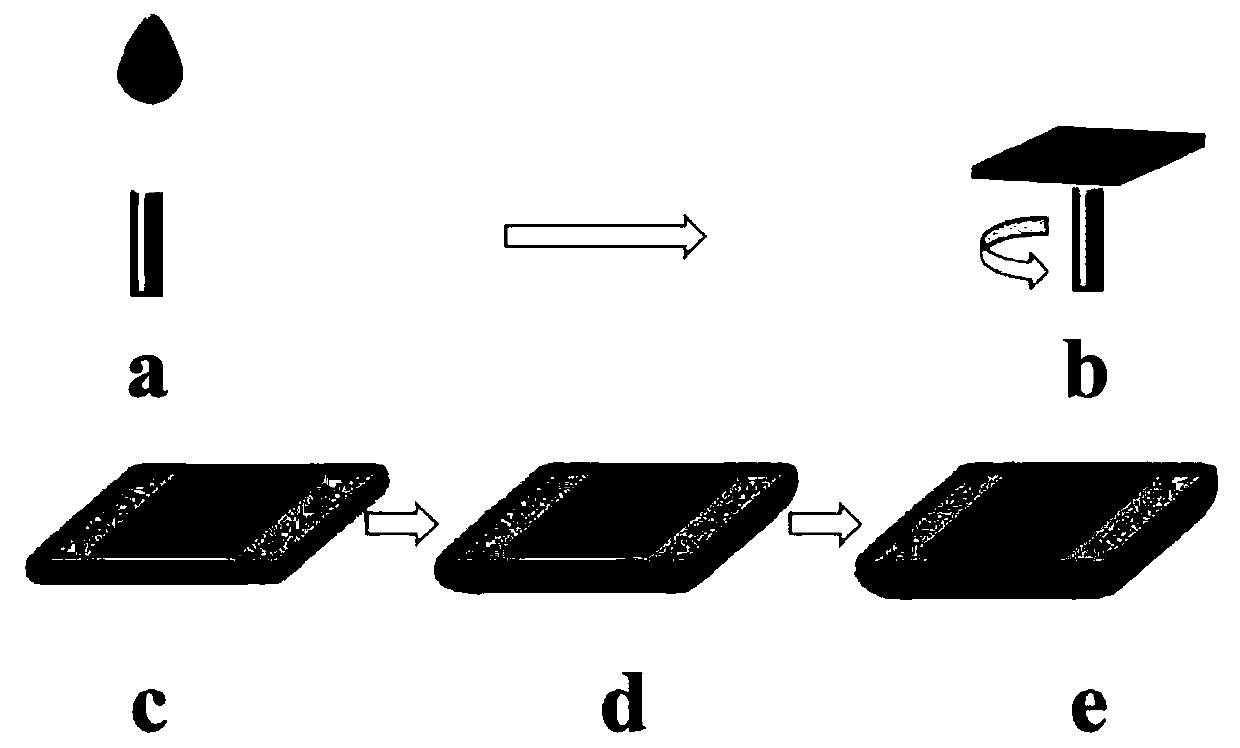

InactiveCN104749095AGood effectOvercome the problem of large influence of human factors and large deviation of resultsUsing mechanical meansMaterial analysisEvaluation resultContact pressure

The invention discloses a tire and pavement contact pressure characteristic-based pavement skid resistance condition evaluation method. The tire and pavement contact pressure characteristic-based pavement skid resistance condition evaluation method comprises the following steps: 1. adopting at least two pressure induction films, placing the pressure induction films on a bottom surface of a tested automobile tire and between the tire and different pavements to be tested; 2. contacting the tire of the tested automobile to the pressure induction film in a dead weight manner; 3. taking out the pressure induction film; (4) scanning the pressure induction film to acquire the pressure intensity value of each tested point of each pressure induction film; (5) determining the area M having the pressure intensity value of 0-0.2MPa of the contact surface of each pressure induction film and the tire; (6) calculating P which is equal to M / the area of the contact surface of the pressure induction film and the tire respectively; and (7) comparing all P values and evaluating the pavement skid resistance of all pavements to be tested. According to the method, the pressure induction film is utilized for measuring the pressure distribution of the tire and the pavement, the pavement skid resistance condition can be evaluated and the evaluation result is accurate; and besides, according to the tire and pavement contact pressure characteristic-based pavement skid resistance condition evaluation method, the cost is low, the use is convenient and the popularization is easy.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +2

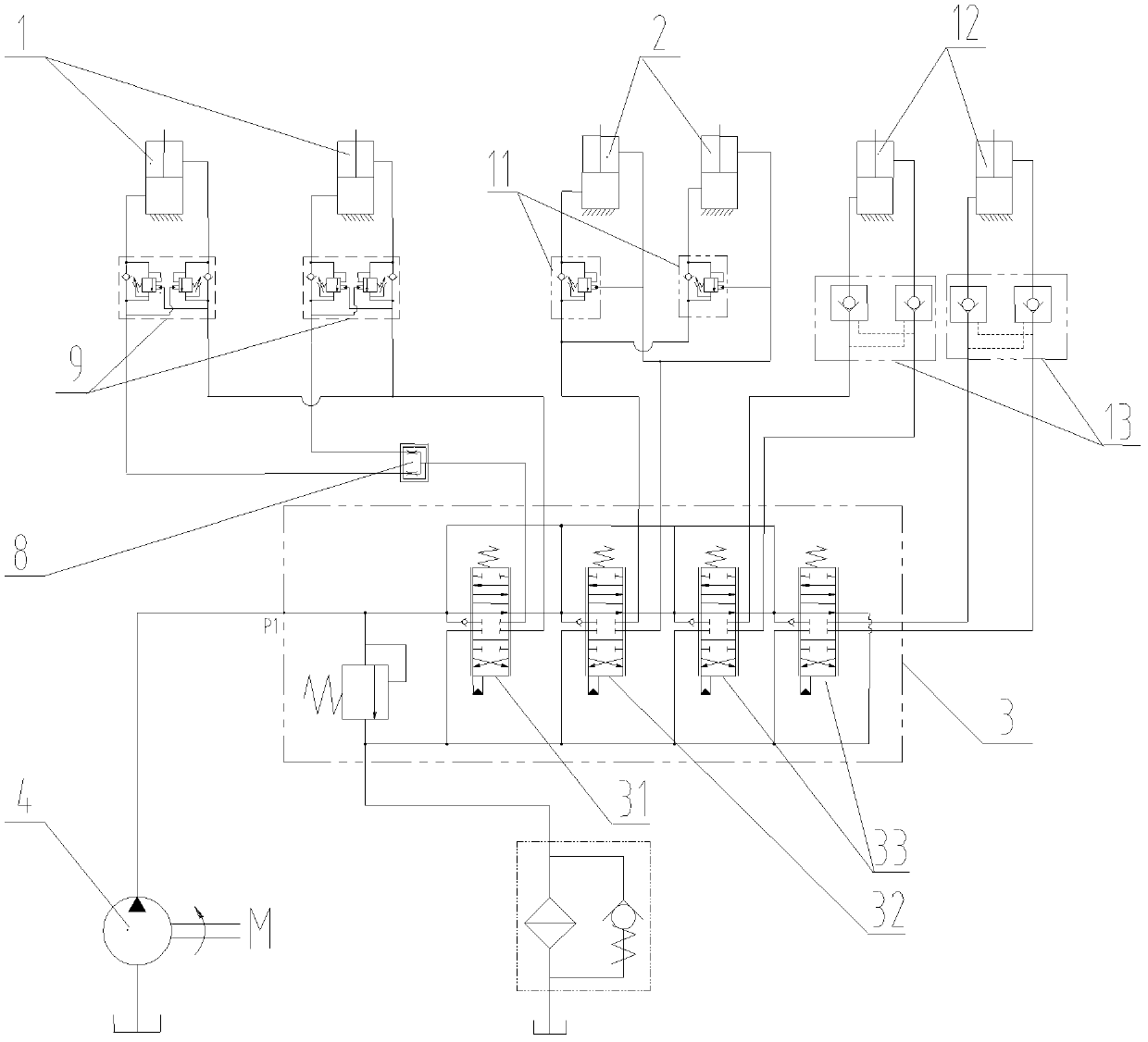

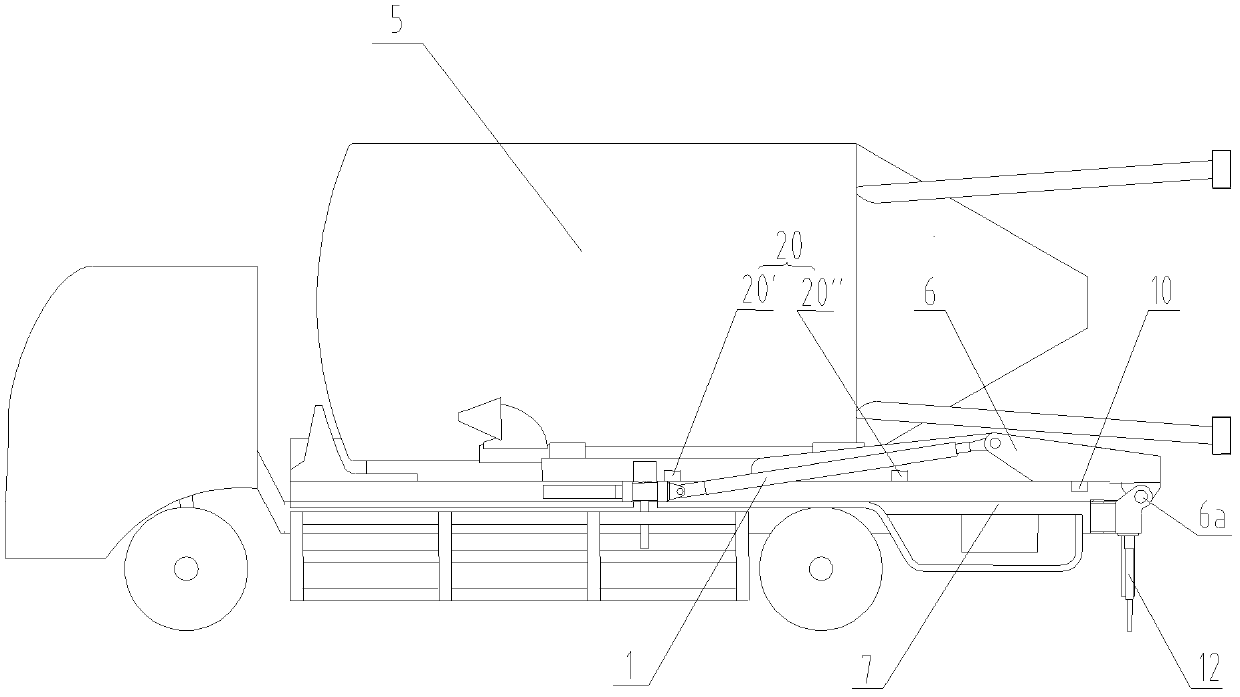

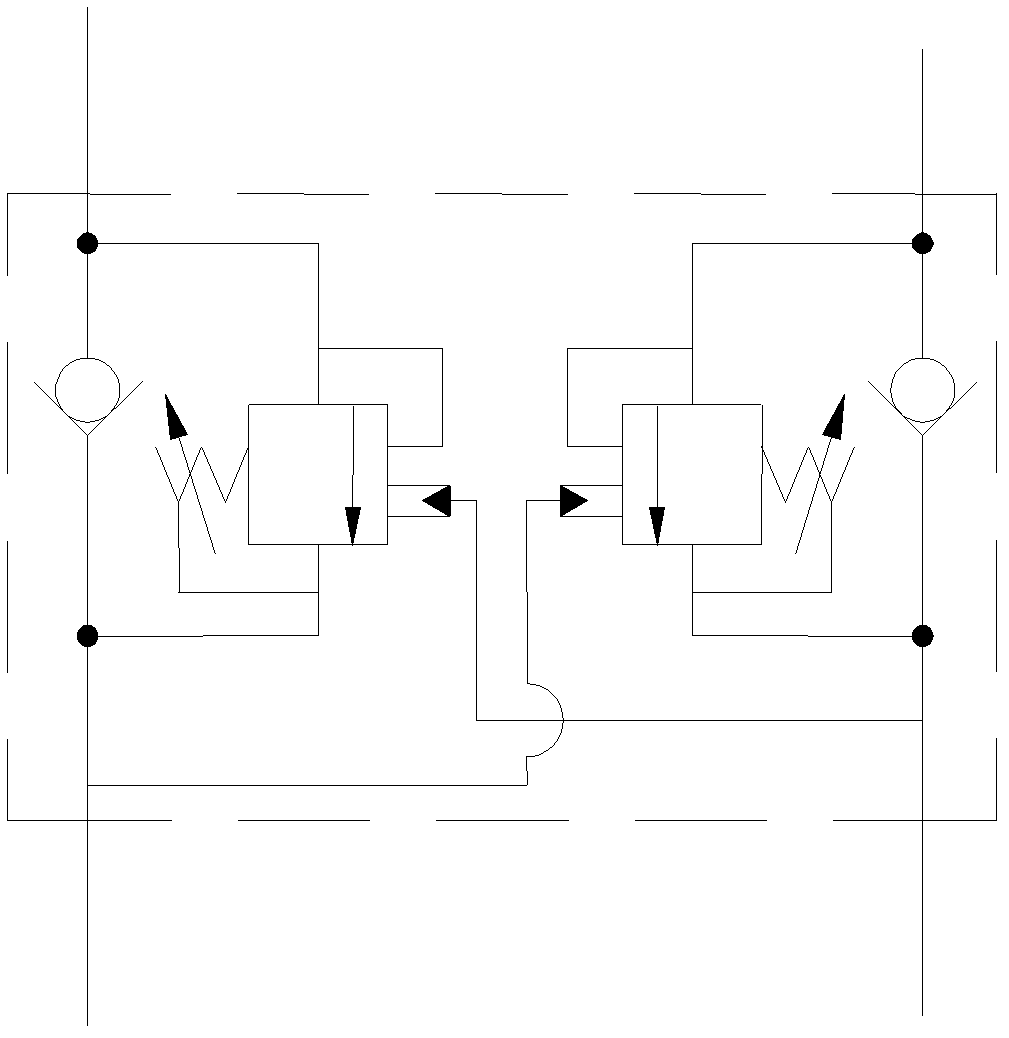

Demountable tanker truck and hydraulic system thereof

InactiveCN102381230AAnti-stall movementImproved speed stabilityTank vehiclesVehicle with tipping movementHydraulic pumpTruck

The invention provides a demountable tanker truck and a hydraulic system thereof. The hydraulic system comprises a hydraulic pump, wherein the hydraulic pump supplies oil to a main oil cylinder and a moving oil cylinder through a multi-way valve, the multi-way valve at least comprises a main oil cylinder reversing valve and a moving oil cylinder reversing valve, and the hydraulic system also comprises a first position detection device and / or a second position detection device. The moving state of the main oil cylinder can be controlled according to the first position detection device, and the moving state of the moving oil cylinder can be controlled according to the second position detection device. The synchronism of the operation process of the main oil cylinder can also be ensured, and in addition, the protection on a main oil path can also be realized. The demountable tanker truck and the hydraulic system thereof have the advantages that misoperation can be reduced, the synchronism is high, the anti-impact performance is good, and the like.

Owner:SANY HEAVY IND CO LTD (CN)

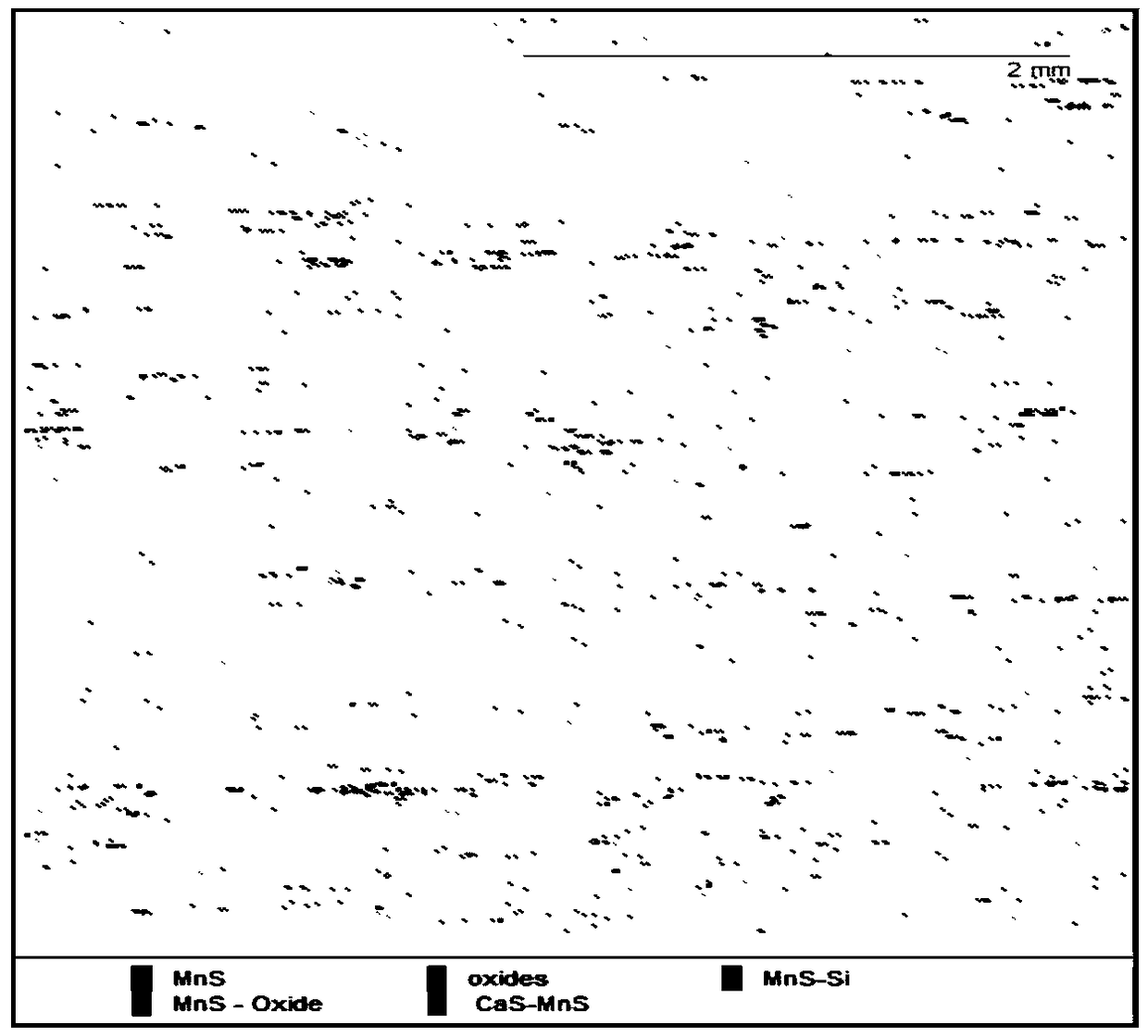

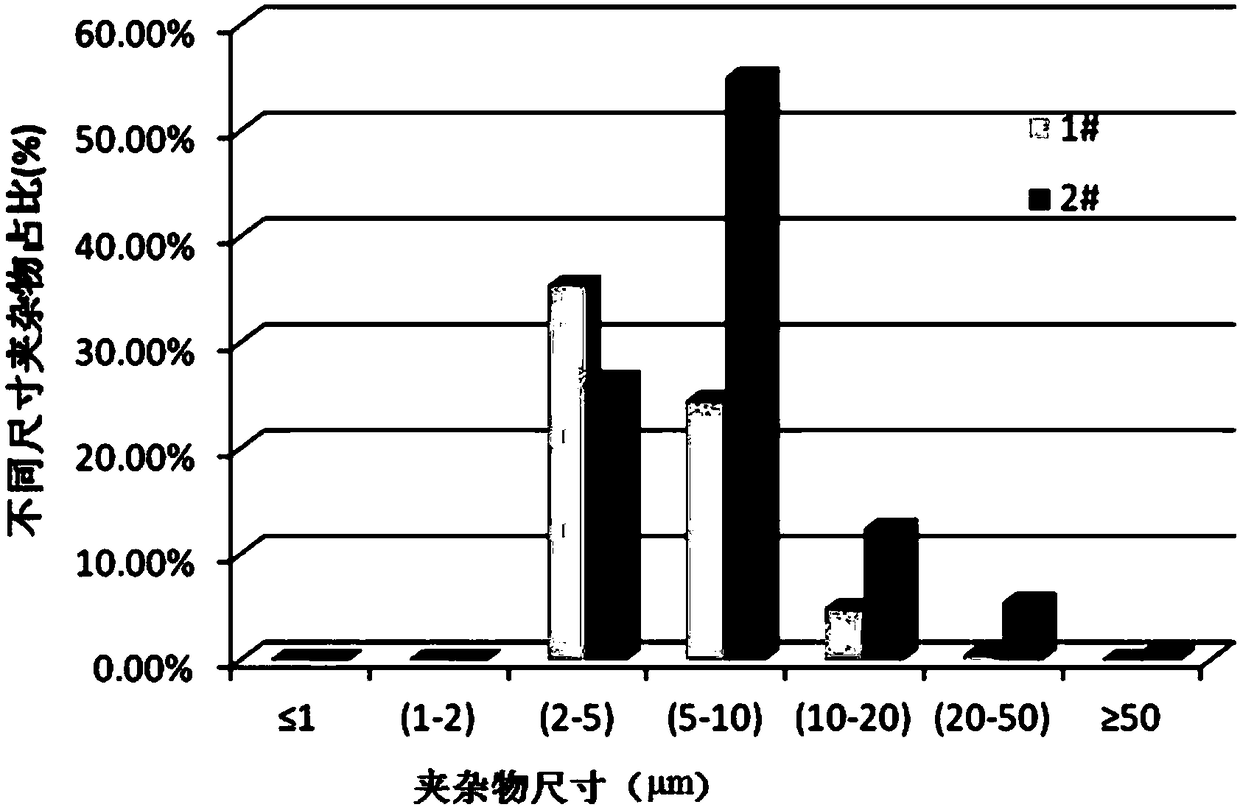

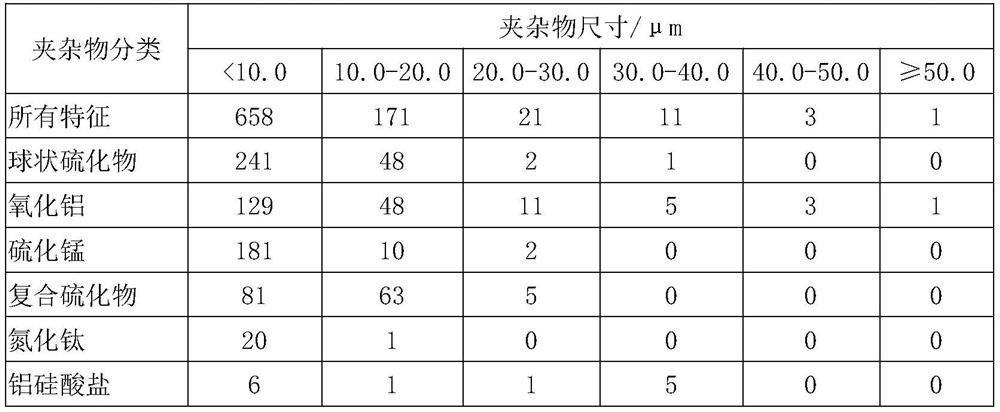

Method for qualitatively and quantitatively testing and analyzing impurities in steel

ActiveCN108593649AQualitatively accurateHuman factors are smallMaterial analysis by optical meansMaterial analysis by measuring secondary emissionEvaluation resultTest sample

The invention provides a method for qualitatively and quantitatively testing and analyzing impurities in steel. The method includes the following steps of firstly, preparing a to-be-tested sample, wherein the to-be-tested sample is ground and polished, and the surface is clean, smooth and free of peculiar objects; secondly, observing the to-be-tested sample in a metallographic microscope, and determining the size range of the impurities; thirdly, adjusting testing parameters of a scanning electron microscope according to the impurity size range determined in the second step, and conducting scanning electron microscope testing and EDS energy spectrum component analysis on the to-be-tested sample to obtain size, shape and component data of the impurities in steel. By setting the component content standard, size and length standard and shape standard of the impurities in steel in application software and related accessories of the scanning electron microscope and setting the proper testing parameters according to the size of the impurities in steel, the properties of the impurities in steel can be accurately, qualitatively and quantitatively analyzed, analyzing and testing are accurate and comprehensive, artificial influence factors are small, and the evaluation result is specific, precise and visual.

Owner:CENT IRON & STEEL RES INST

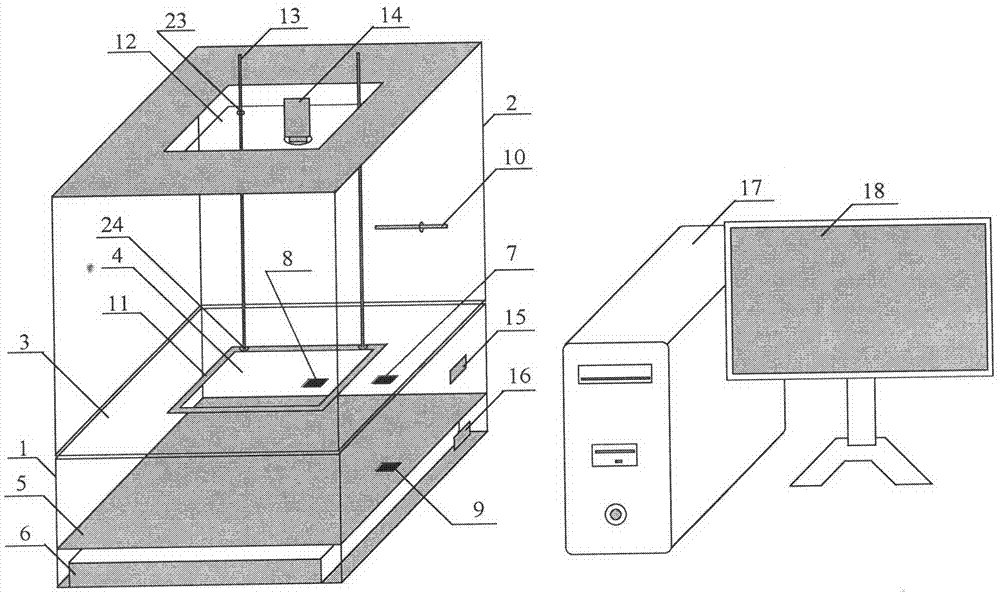

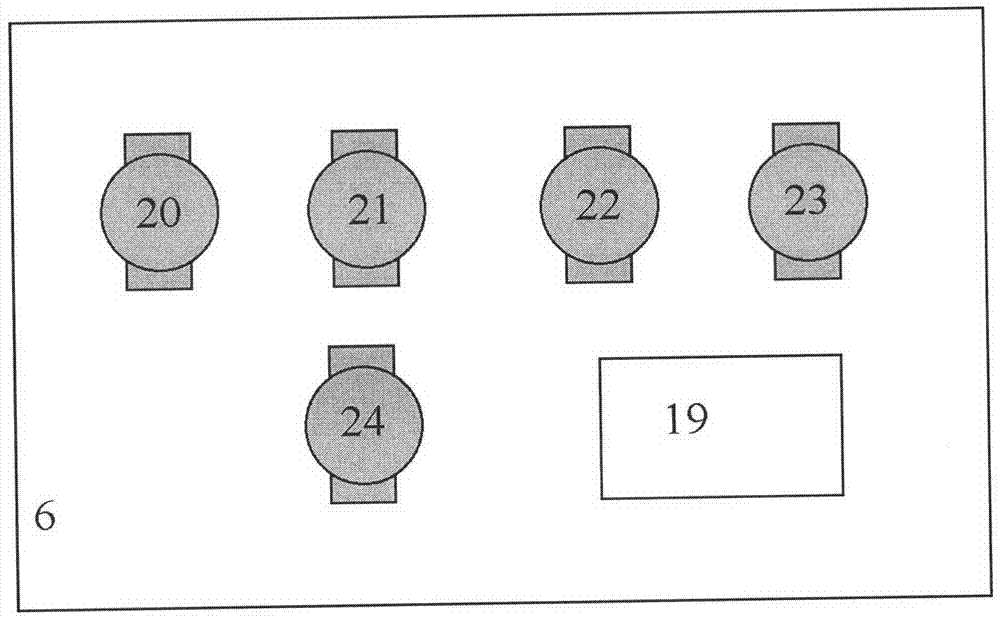

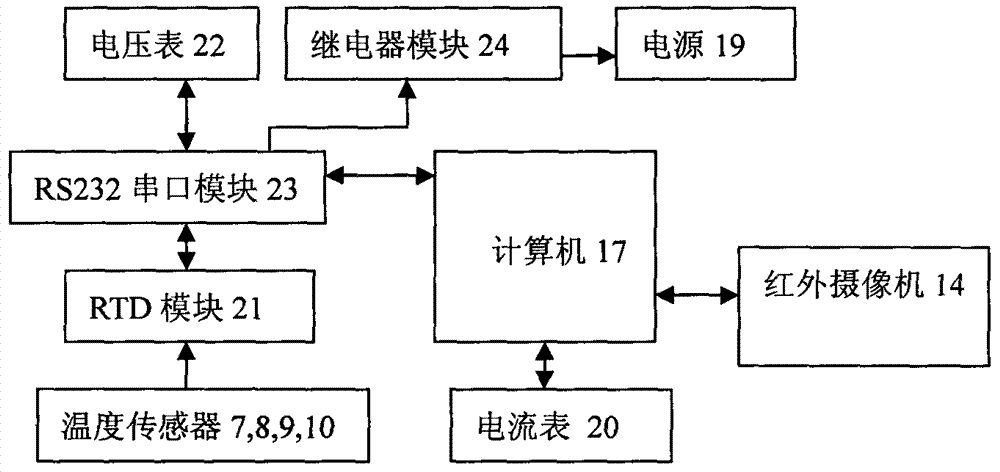

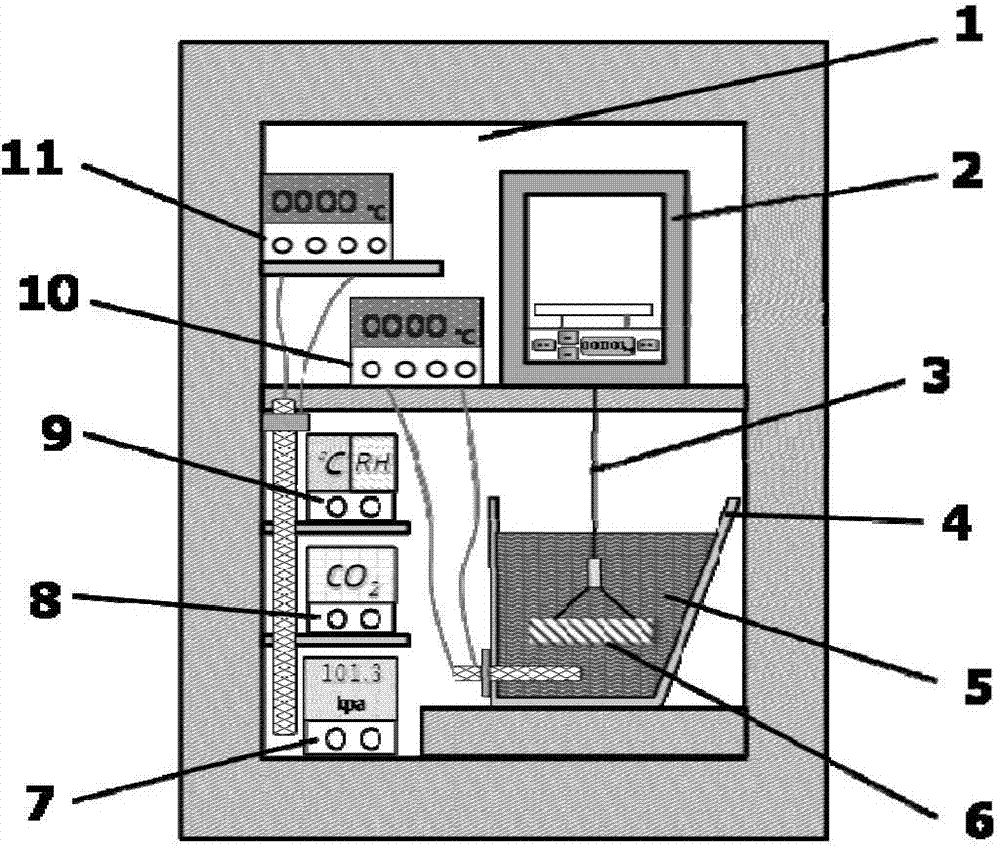

Fabric thermal property tester

InactiveCN103675018ASimple structureEasy to operateMaterial heat developmentTemperature controlPower switching

The invention relates to a fabric thermal property tester. The fabric thermal property tester comprises three parts including an infrared image acquisition part, a signal measurement and temperature control cabinet and a data analysis and processing module. An infrared camera is used for acquiring an infrared image and sending the infrared image to a computer; a solid-state relay can be in control connection with a power supply switch of a heated fabric; a voltage measurement module and a current measurement module can be used for acquiring voltages at the two ends of the heated fabric and current flowing through the fabric; a heating property of the heated fabric can be obtained by analysis and comparison of a temperature image and consumption power. According to the fabric thermal property tester, the dynamic real-time measurement on a fabric surface temperature field can be realized; the heating property of the heated textile and indexes including heat-conducting properties and the like of the fabric can be measured; the fabric thermal property tester has the advantages of high precision, high measurement speed, simplicity in operation, comprehensive data information and the like.

Owner:TIANJIN POLYTECHNIC UNIV

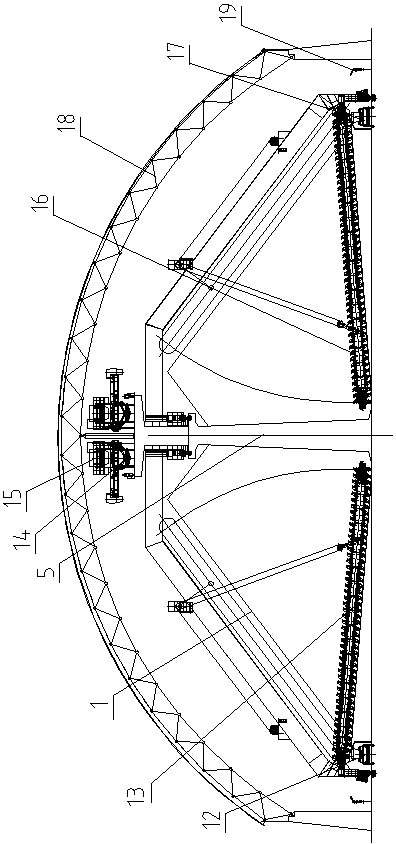

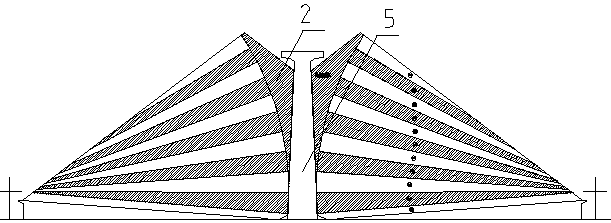

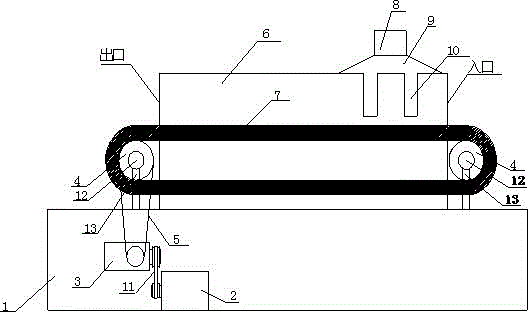

Closed stock yard intelligent control system and intelligent control method with pre-homogenization function

ActiveCN105173771ARealize automatic reclaimingRealize pre-homogenized productionLoading/unloadingWirelessInformation management

The invention relates to a closed stock yard intelligent control system and an intelligent control method with a pre-homogenization function. A closed stock yard comprises a closed material storage shed, a material input system and a material output system. The intelligent control system comprises a material input system control system, a material output system control system and a central control system. Material stacking logic control and collection of the states of all material stacking mechanisms and fault information are achieved through the material input system control system. Material taking logic control and collection of the states of all material taking mechanisms and fault information are achieved through the material output system control system. The central control system comprises a data processing server, an automatic operation device, a material information management device, a central control PLC, a network device and a remote operation table. The systems are connected through an industrial wireless Ethernet. Links of the Ethernet and an industrial control network are industrially established between a central control chamber and all devices to serve as a communication platform for exchange of various types of information, data exchange is conducted through the communication platform, automated layered material stacking is achieved in the material stacking process, multiple material layers are cut at the same time in the material taking process, and pre-homogenization is achieved.

Owner:TIDFORE INT ENG

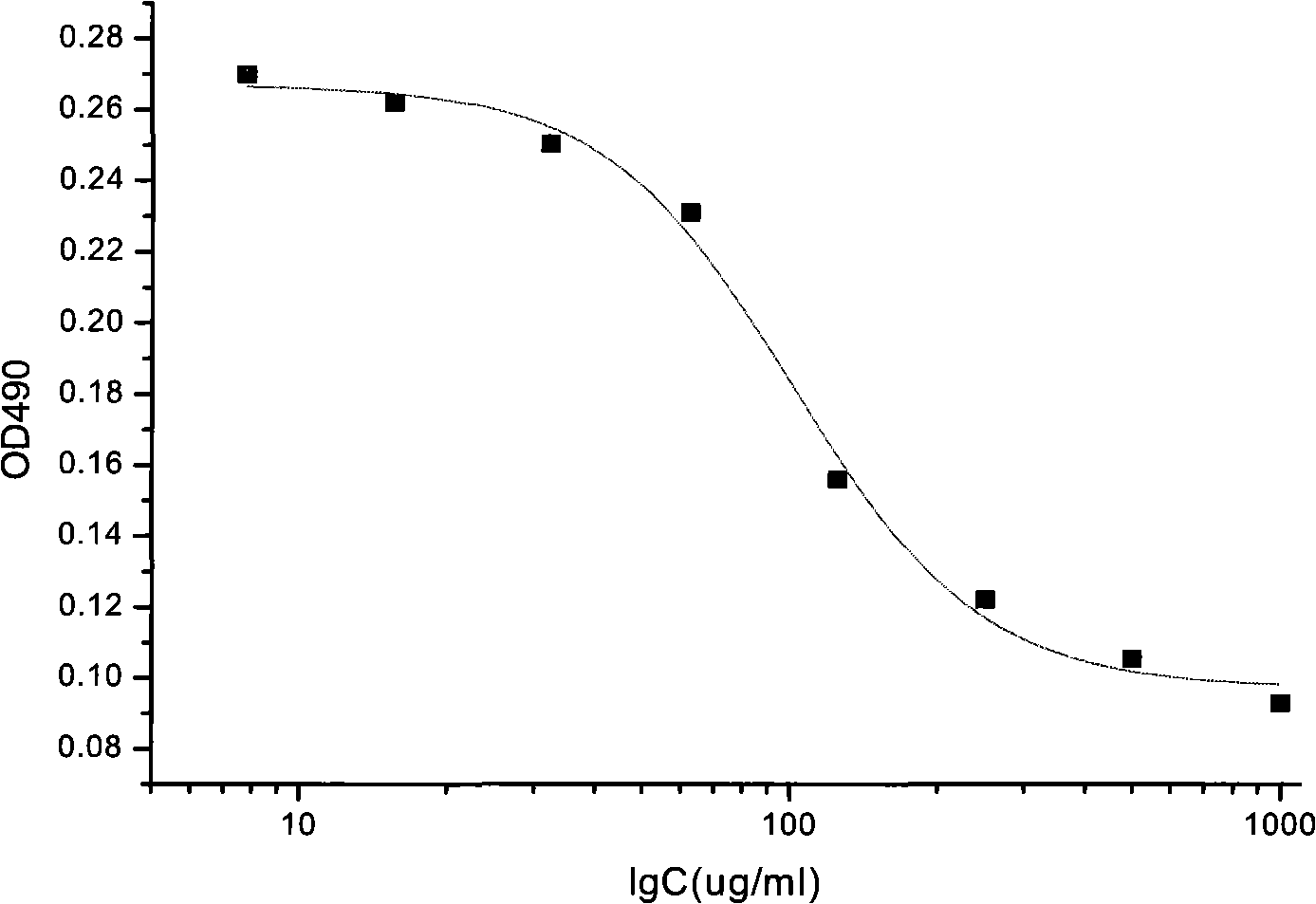

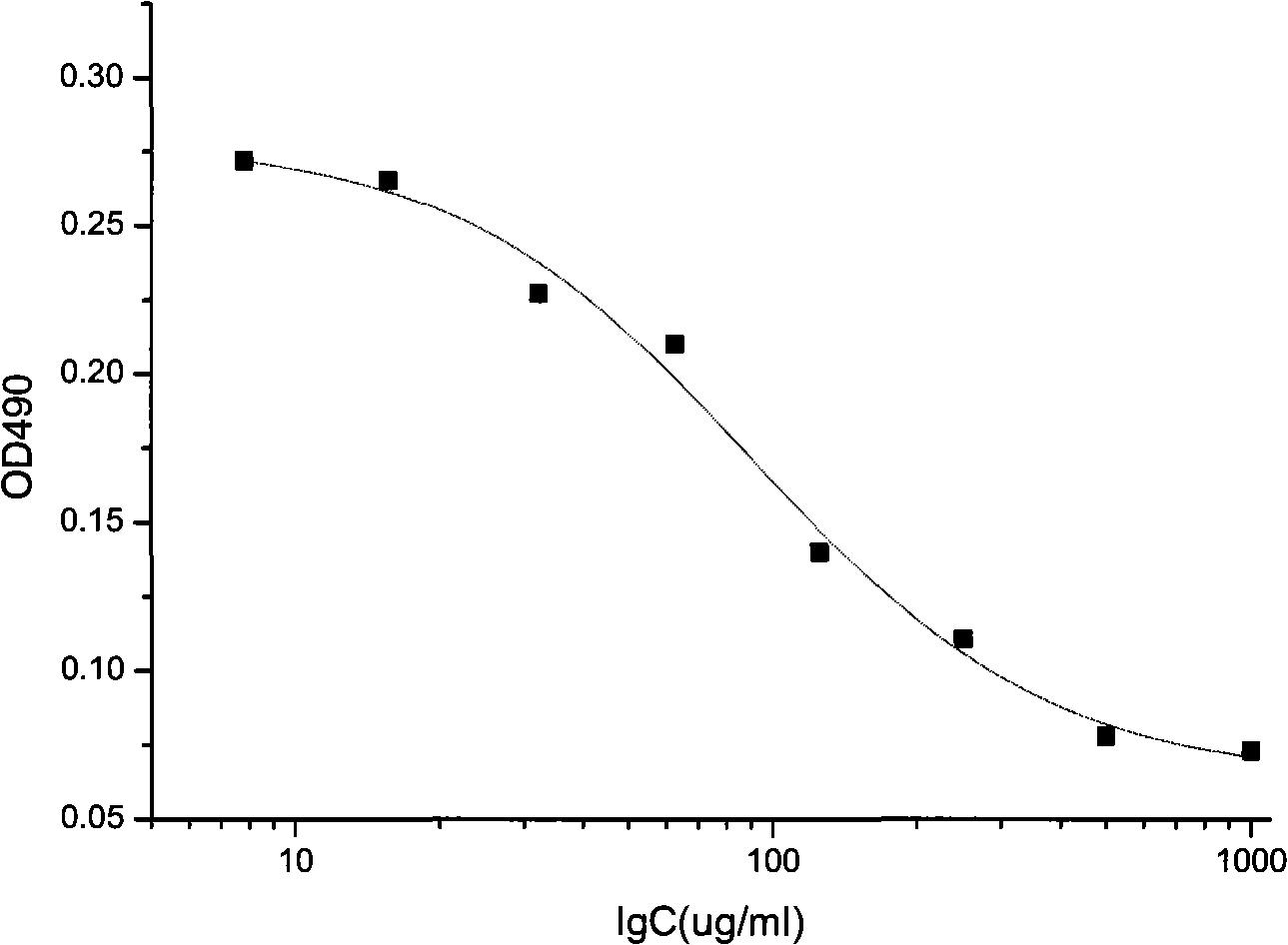

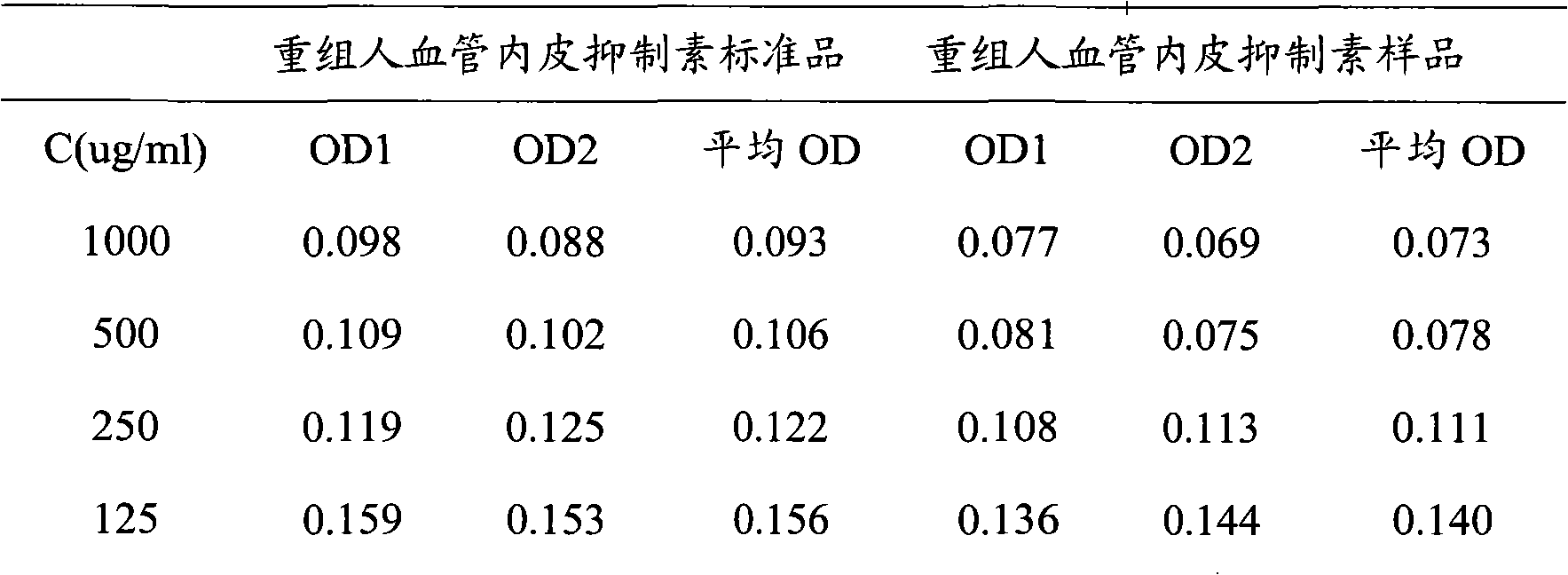

Method for testing vascellum esoderma inhibin bioactivity

InactiveCN101256139AWith characteristicsRepetitiveMicrobiological testing/measurementColor/spectral properties measurementsAngiogenesis InhibitionVascular endothelium

The invention discloses a method for testing vascular endothelial inhibitor biological activity, the method utilizes vascular endothelial inhibitor standard and sample with the same concentration gradient after dilution in multiple proportions to inhibit HUVEC cell proliferation, and detects the proliferate inhibition activity of vascular endothelial inhibitor to HUVEC cells with trace enzyme reaction colorimetry, and then analyzes biological activity of angiogenesis inhibition of vascular endothelial inhibitor. The method uses the vascular endothelial inhibitor standard to correct testing errors of vascular endothelial inhibitor samples in different batches, which causes the cell proliferation inhibition activity testing results of vascular endothelial inhibitor have specificity and repeatability, and overcomes the defects that existed in prior vascular endothelial inhibitor activity testing method that the repeatability is bad, the method can not be unified, and the method can not meet the needs of large scale production and multiple-batch quality control.

Owner:SHANDONG SIMCERE BIO PHARMA CO LTD

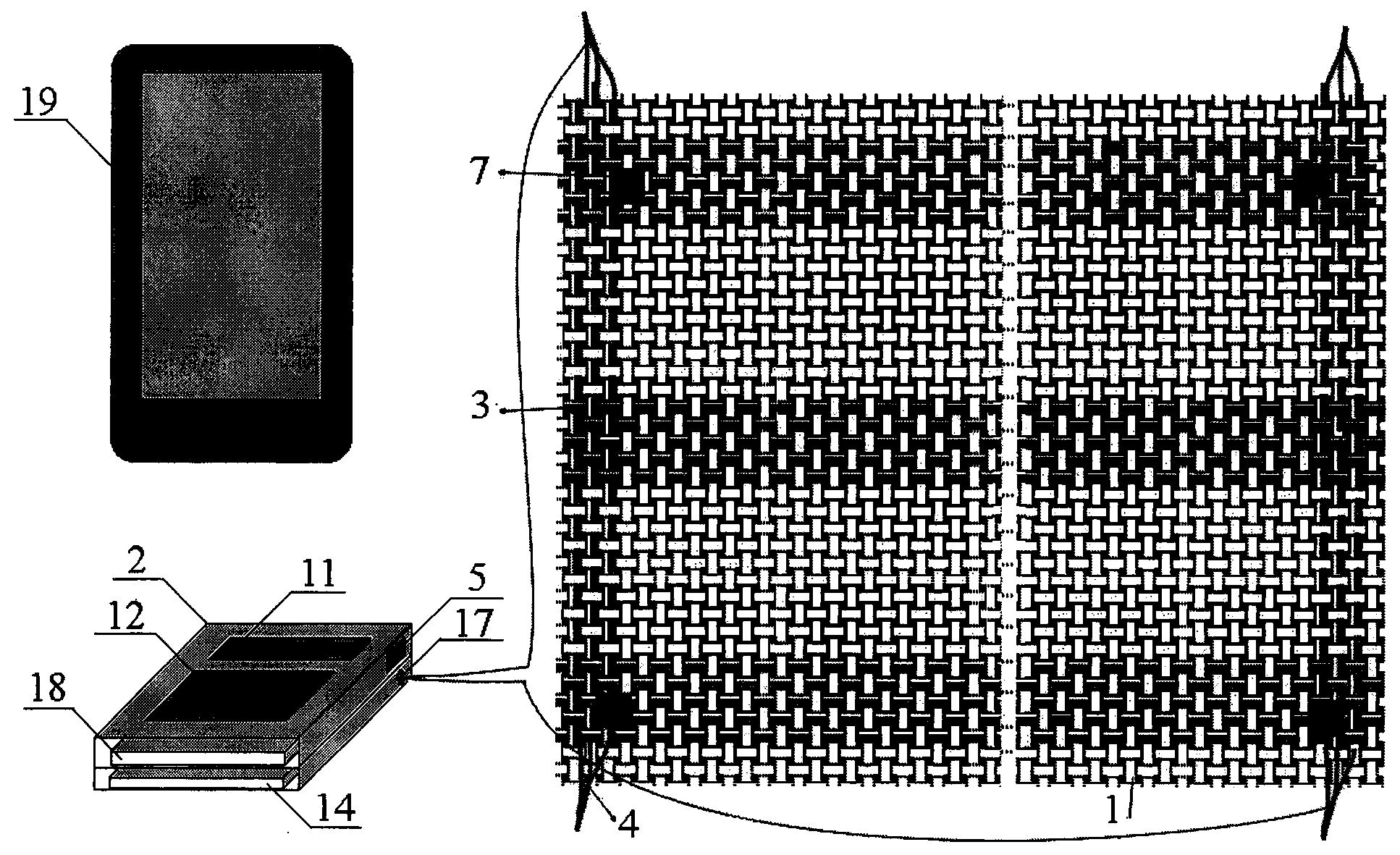

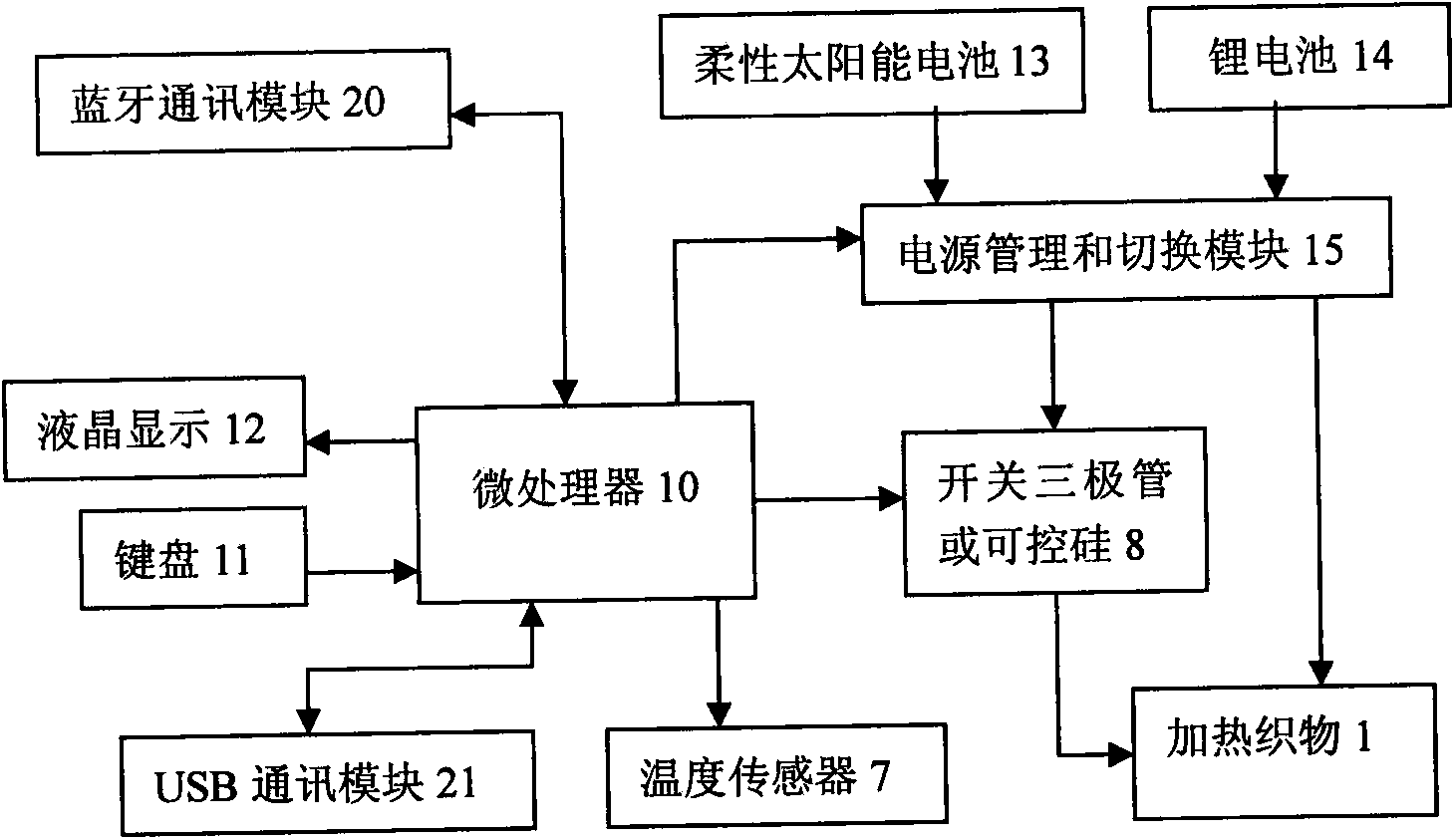

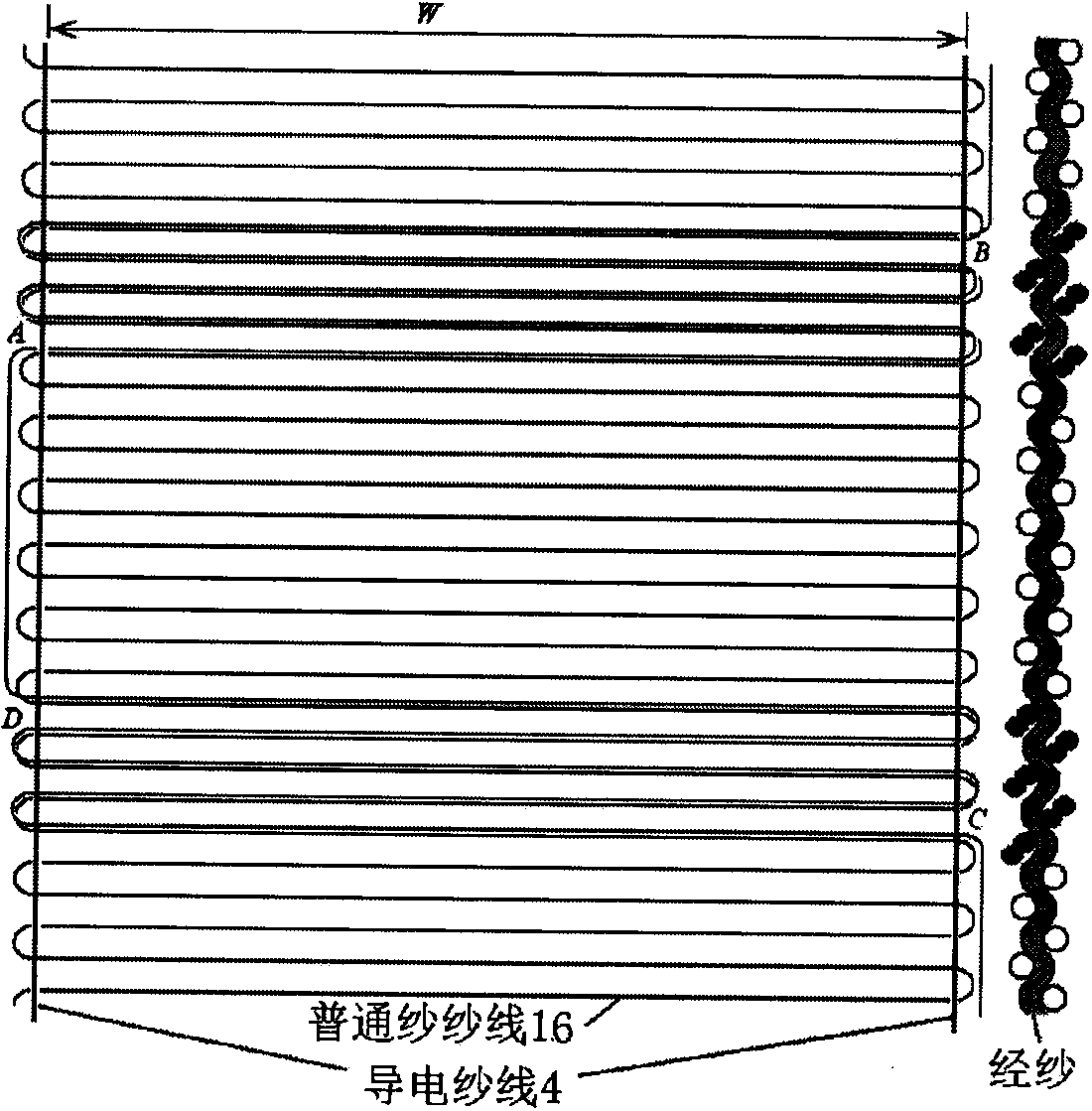

Flexible heating fabric system

ActiveCN103533683AEvenly distributedAdjustable resistanceOhmic-resistance heatingMicrocontrollerMicrocomputer system

The invention relates to a flexible heating fabric system. The flexible heating fabric system comprises flexible heating fabric and a temperature control system. The flexible heating fabric has a heating function by weaving metal wires in the fabric. The heating fabric is characterized in that the conductive metal wires or metal-coated yarns are distributed in the fabric in a warp and weft manner; the length of each weft conductive yarn can be controlled through a cycle count, and the interweaved point number of the warp and weft conductive yarns can be controlled by the number of parallel warp yarns. The temperature control system comprises a smartphone, a single-chip microcomputer system, a temperature sensor, an electronic microswitch and a bluetooth communication module, and is characterized in that the temperature data of the digital temperature sensor is directly read by a single-chip microcomputer but not by a temperature signal conditioning module; the electronic microswitch consists of a triode or silicon controlled. The heating fabric system can be used for realizing resistance adjustment, and has the advantages that the flexibility and the serviceability are good, the temperature is controllable, manufacturing is simple, and the like.

Owner:TIANJIN POLYTECHNIC UNIV

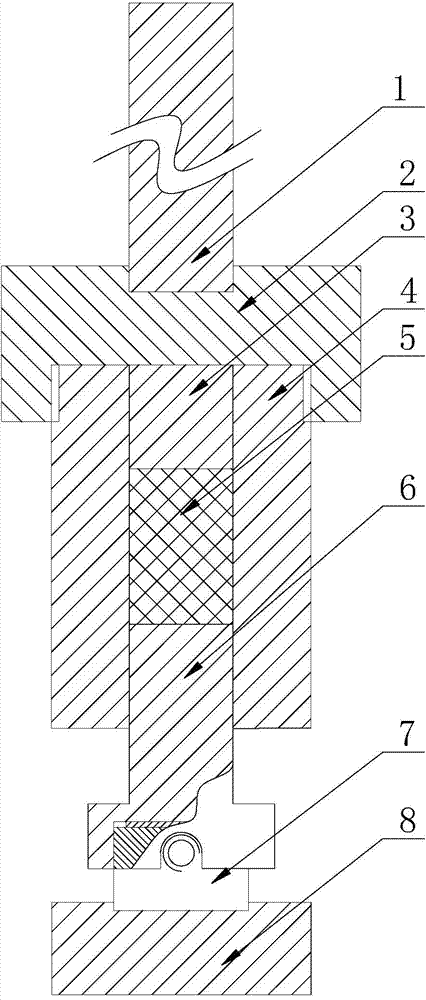

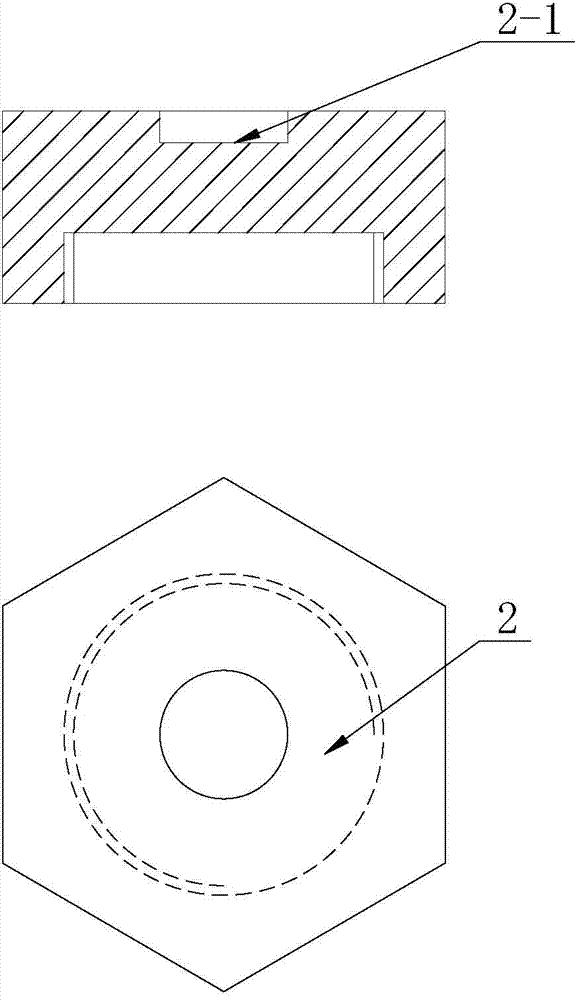

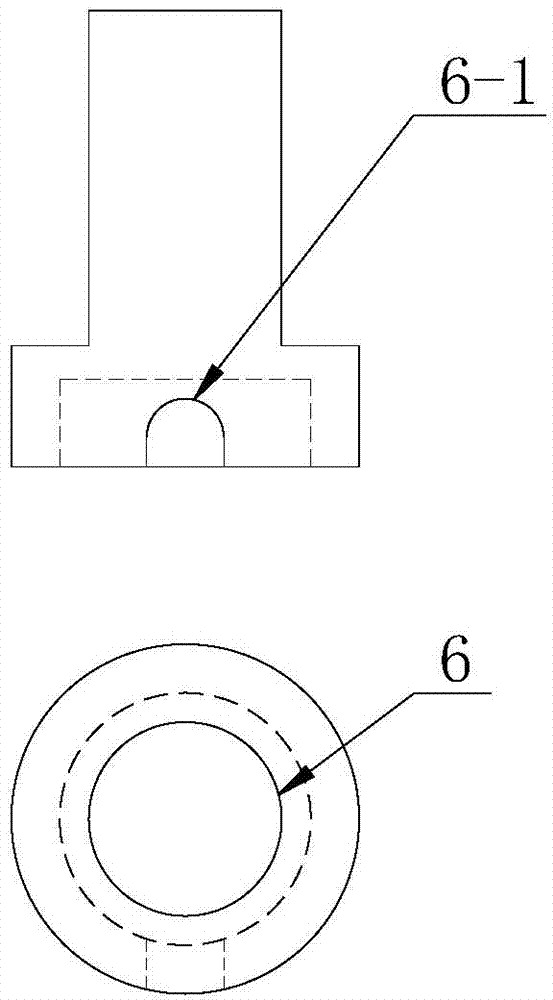

Explosive column stress measurement device under low-speed hammer-dropping impact loading

The invention discloses an explosive column stress measurement device under low-speed hammer-dropping impact loading, aiming at solving the problems that the current measurement device measures force indirectly, a sensor cannot be calibrated secondarily after measurement and the operation in the testing process is complex. The explosive column stress measurement device is composed of a strike rod, a stressed cap, an upper striking column, a sample pipe, a sample, a lower striking column, a pressure sensor and a striking anvil. The explosive column stress measurement device can directly measure the sample stress and has a simple operation process, and the sensor can be calibrated after measurement. The explosive column stress measurement device can measure the stress of the explosive column under low-speed hammer-dropping impact loading, and is both suitable for fragile explosive columns and viscoelastic fragile explosive columns.

Owner:XIAN MODERN CHEM RES INST

Method for evaluating point load performance of plastic tube

ActiveCN103575595AShorten evaluation timeHuman factors are smallMaterial strength using tensile/compressive forcesEvaluation resultEngineering

The invention relates to a method for evaluating the point load performance of a plastic tube. The method comprises the following steps: 1, forming a notch on the outer wall of the plastic tube, wherein the depth of the notch is lower than the wall thickness of the plastic tube; 2, allowing the formed notched plastic tube to be full of a first liquid, and sealing two ends of the plastic tube to obtain a plastic tube sample for detection; and 3, putting the plastic tube sample for detection in a sealable container, allowing the sealable container to be full of a second liquid, sealing the sealable container, and carrying out hydrostatic test. The method for evaluating the point load performance of the plastic tube substantially shortens the evaluation time, and the dispersivity of evaluation results is small.

Owner:CHINA PETROLEUM & CHEM CORP +1

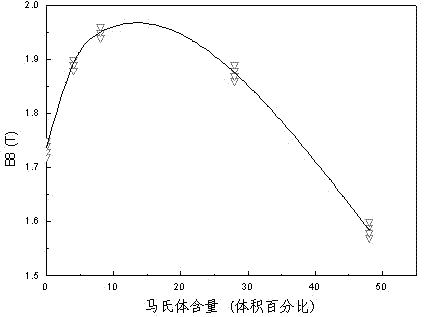

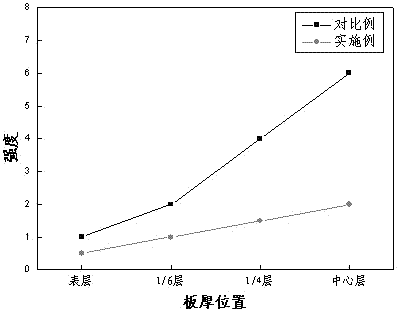

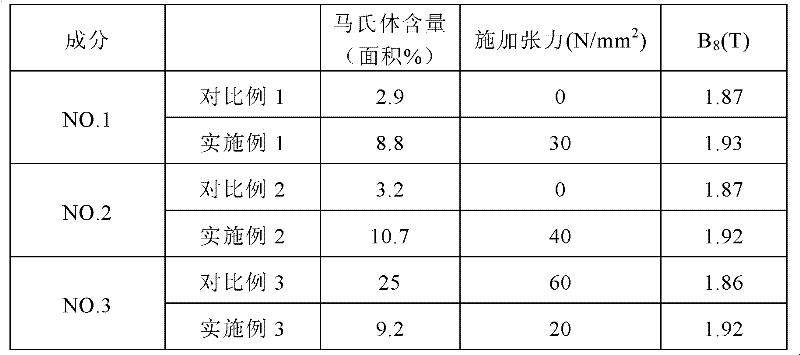

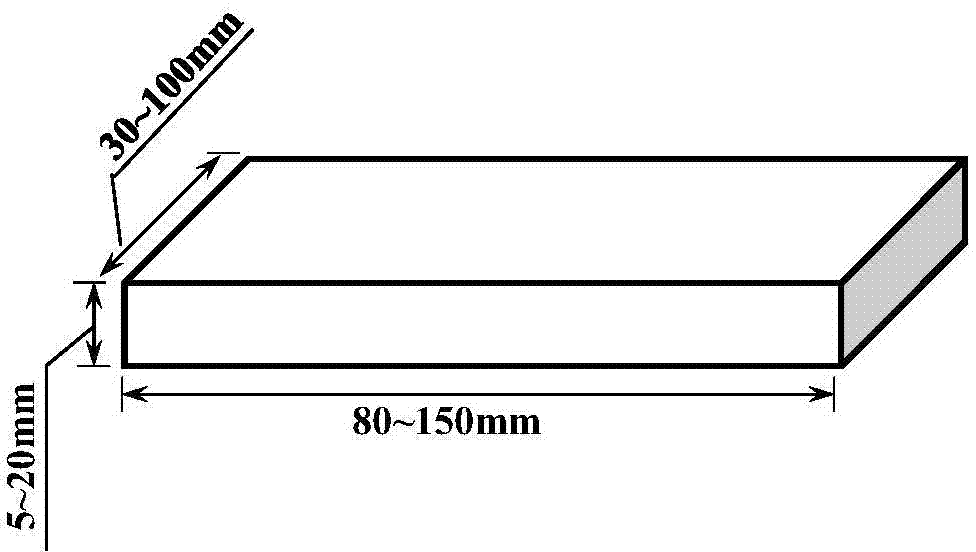

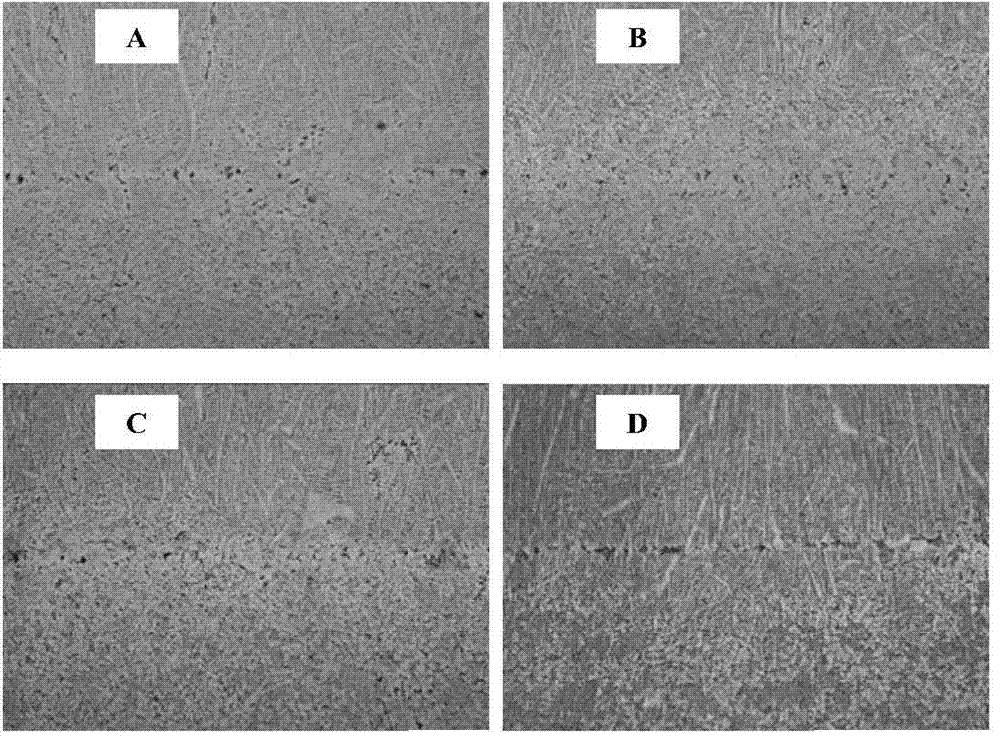

Method for producing oriented silicon steel with excellent magnetic property

ActiveCN102477483AImprove magnetismGet stableTension/compression control deviceStrip steelMartensite

The invention relates to a method for producing an oriented silicon steel with excellent magnetic property, which comprises the following steps: 1) smelting in a routine mode, heating a slab; 2) heating the slab, hot rolling to form a strip steel; 3) normalization processing in two phases firstly heating to the temperature of 1100-1200 DEG C, then cooling to the temperature of 900-1000 DEG C in 50-200 seconds, then quenching in water with the temperature of 10-100 DEG C; applying tension on the strip steel, wherein the magnitude of the stress on the strip steel in the temperature range of 900-500 DEG C is 1-200 N / mm<2>; 4) cold rolling: carrying out primary a cold rolling, or a secondary cold rolling with intermediate annealing; 5) performing primary recrystallization annealing, then coating an annealing isolation agent which takes MgO as a main part, carrying out finished product annealing composed of secondary recrystallization annealing and purification annealing. According to the invention, martensite content and its distribution in normalized steel plate can be optimized by adjusting the stress on steel plate during normalized phase transition, the martensite content is in the scope within which the better finished product magnetic property can be acquired, and the finished product magnetic property optimization can be realized.

Owner:BAOSHAN IRON & STEEL CO LTD

Measuring method for quantification of central looseness of casting blank

InactiveCN103575618ALow costHuman factors are smallSpecific gravity measurementArchimedes' principleAcid corrosion

The invention relates to a measuring method for quantification of central looseness of a casting blank. The method utilizes a principle that the density of a loose part is different from the density of a compact part, so that the central looseness can be described quantitatively. Moreover, the method utilizes the Archimedes principle to autonomously design a casting blank density measuring device. The density measuring device is utilized to measure the densities of a compact part specimen and a loose part specimen of the casting blank, respectively measure the mass of the specimens in water and air, and compute the densities of the specimens so as to quantitatively describe the central looseness of the specimens. Compared with the traditional method that after hot acid corrosion, naked eyes observe to quantitatively grade the central looseness of the casting blank, the measuring method has the advantages of no corrosion, accurate evaluation, small human error, superior measurement environment, visual and clear result and the like, therefore the measuring result of the quantification of central looseness of the measuring method has a more realistic and workable important guiding significance on field production, such as continuous casting, rolling and the like.

Owner:UNIV OF SCI & TECH BEIJING

Surfactant composition, its application and point load performance evaluating method

ActiveCN103792132AShorten evaluation timeHuman factors are smallMaterial strength using tensile/compressive forcesLow speedPhenyl Ethers

The invention relates to a surfactant composition and its application. The application contains polyoxyethylene nonyl phenyl ether and an anionic surfactant. The invention also relates to a method for evaluating the point load performance of a plastic tube by using the surfactant composition. The use of the surfactant composition in environmental stress crack resistance evaluating test and low speed crack increase resistance evaluating test substantially shortens the evaluating time.

Owner:CHINA PETROLEUM & CHEM CORP +1

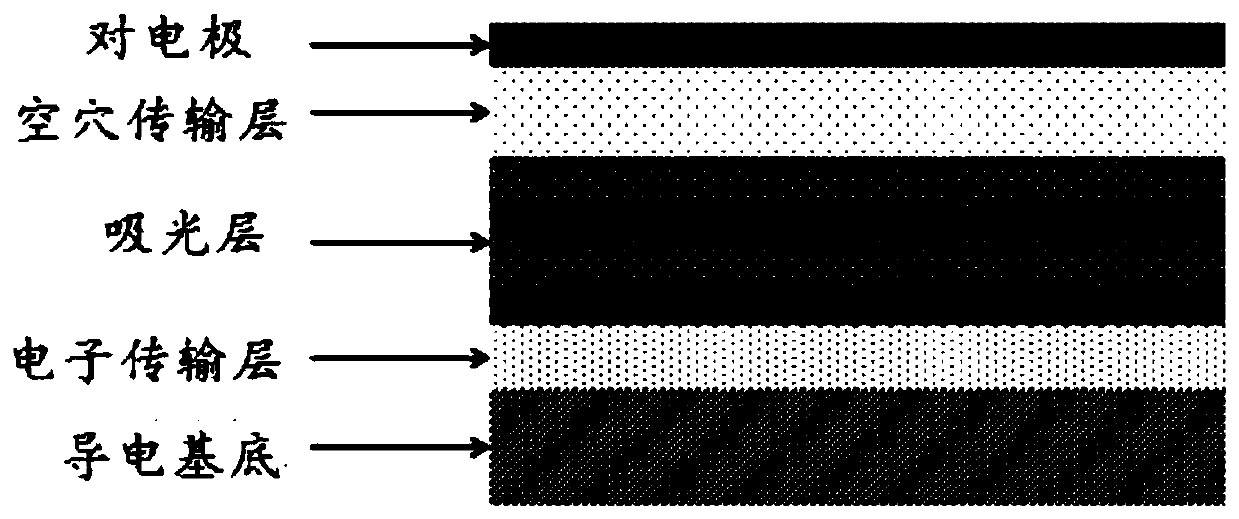

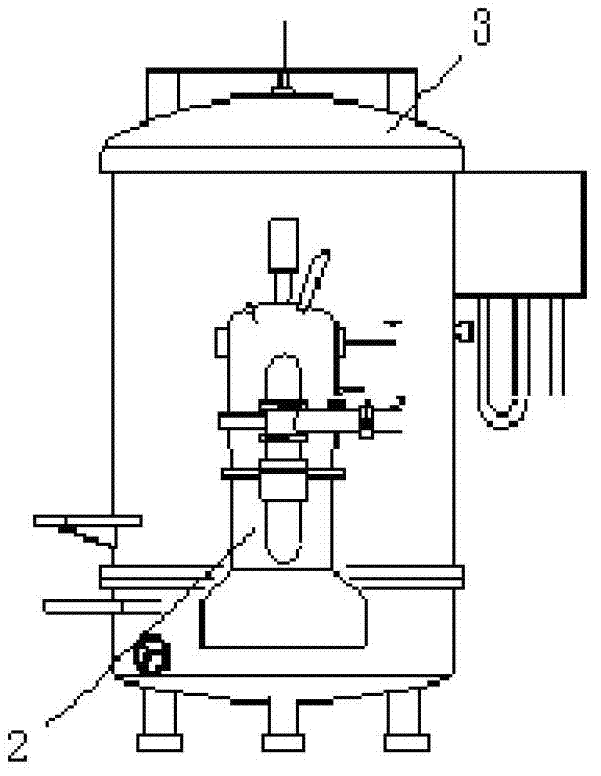

Preparation method for efficient CsPbI2Br inorganic perovskite solar cell

InactiveCN110767813AReduced growth rateReduce porositySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellPhysical chemistry

The invention discloses a preparation method for an efficient CsPbI2Br inorganic perovskite solar cell, which belongs to the technical field of solar cells and comprises the following steps of: preparing an electron transport layer on a conductive substrate, dropwise adding a CsPbI2Br light absorption layer solution on the surface of the electron transport layer, conducting standing in a glove boxat 20-28 DEG C for 10-40 minutes after spin coating, conducting annealing at 30-60 DEG C for 1-6 minutes, and conducting annealing at 155-165 DEG C for 8-12 minutes to obtain a light absorption layerfilm, and sequentially preparing a hole transport layer and a counter electrode on the light absorption layer film to prepare the efficient CsPbI2Br inorganic perovskite solar cell. According to themethod, after spin coating of the CsPbI2Br light absorption layer solution is completed, a gradient temperature annealing mode is adopted, the crystal nucleation and crystallization rate is reduced, the pinhole-free and high-quality CsPbI2Br perovskite film is prepared, and the performance of the perovskite solar cell is improved.

Owner:SOUTHWEST PETROLEUM UNIV

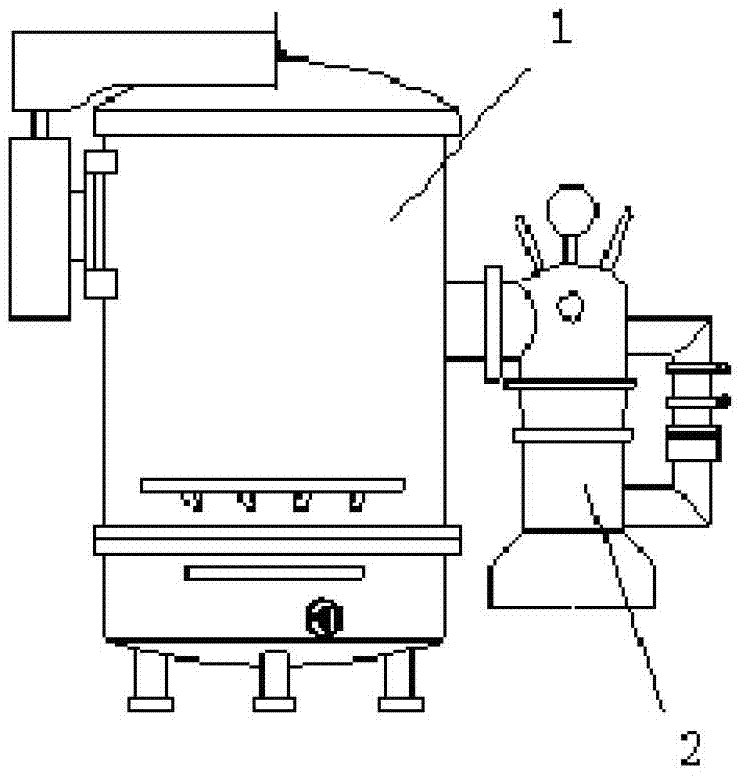

Vacuum pulse hydrogen annealing apparatus and method for electric pure iron

Owner:NANJING CHENGUANG GRP

Blood-gas analyzer and detection method thereof

InactiveCN106290493AReduce medical costsShorten the timeColor/spectral properties measurementsMaterial electrochemical variablesBlood gas analyzerReduced hemoglobin

The invention discloses a blood-gas analyzer and a detection method thereof. The blood-gas analyzer comprises a blood sample introduction device, a reagent blank introduction device, a cleaning reagent introduction device, a waste liquid recovery device, an electrochemical detection device, an optical detection device, a three-way rotary valve and a double-way rotary valve. Through the three-way rotary valve and the double-way rotary valve, electrochemical detection and optical detection are skillfully combined. A whole blood sample to be detected is subjected to pH and ion determination and simultaneously, the optical detection method determines oxidized hemoglobin and reduced hemoglobin. The blood-gas analyzer saves time, simplifies operation and reduces a patient seek treatment cost. The apparatus detection process is completely automatic so that the detection is convenient and fast and human influence is small.

Owner:SINNOWA MEDICAL SCI & TECH

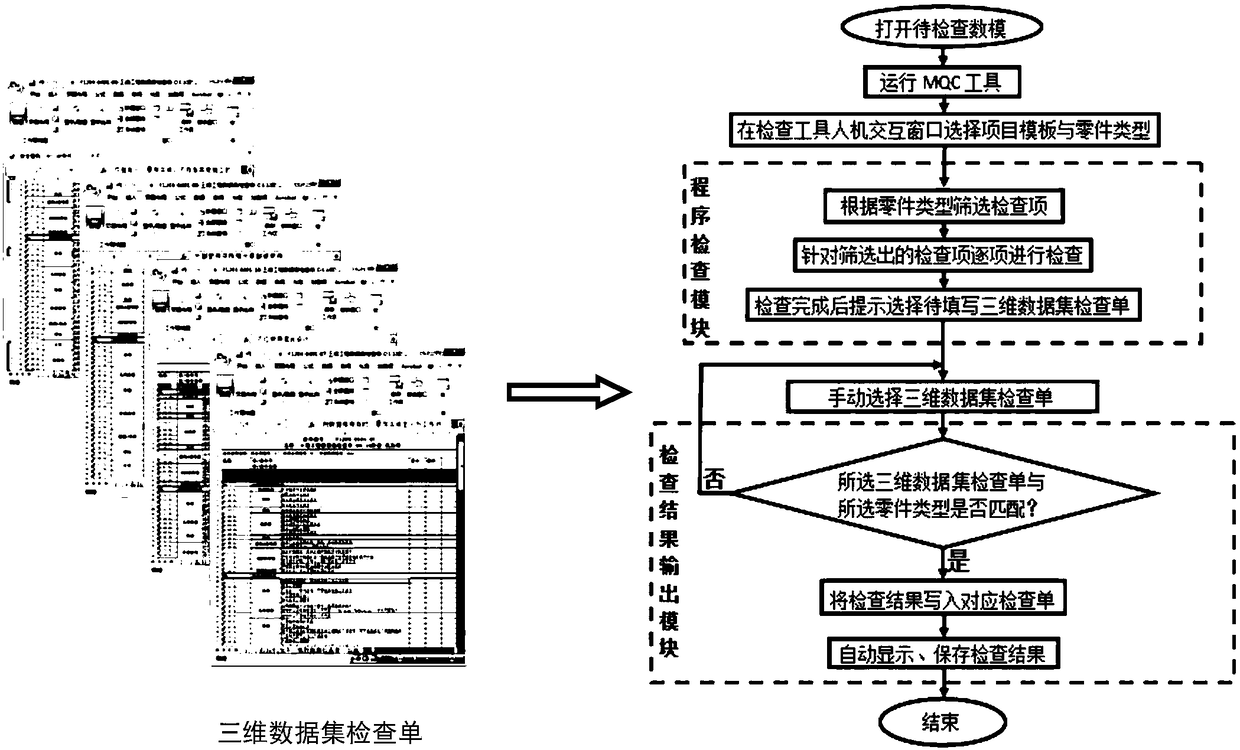

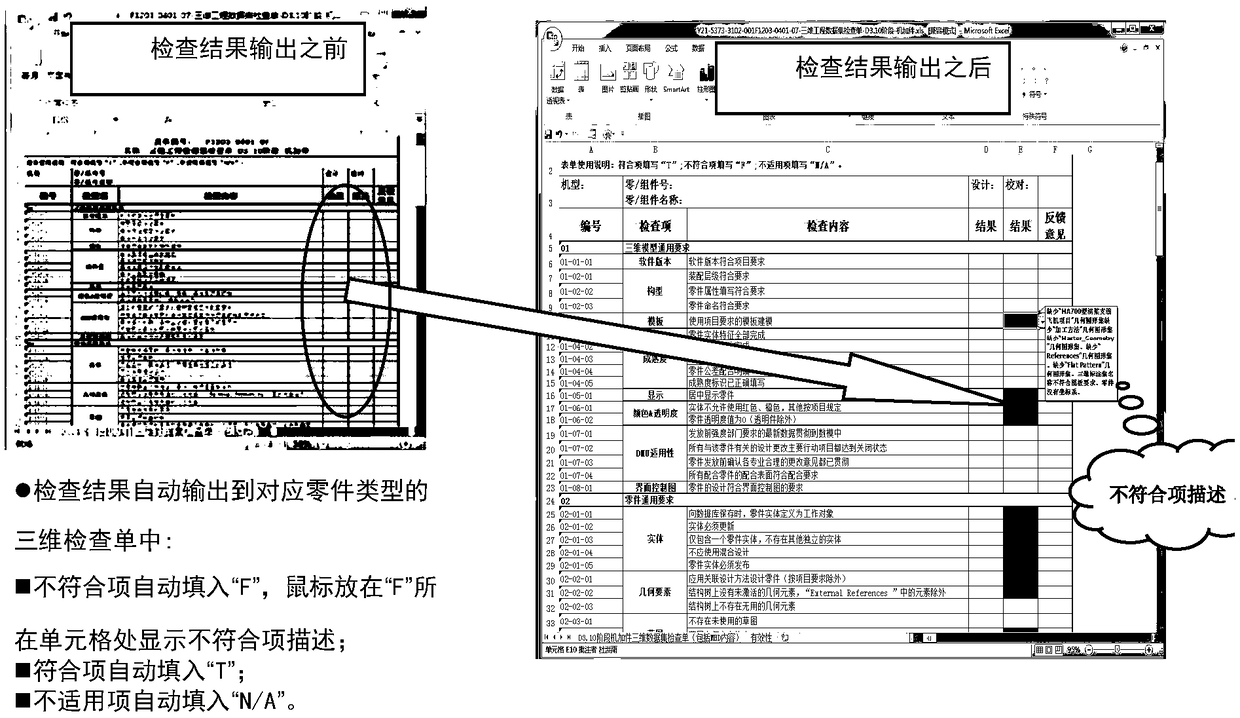

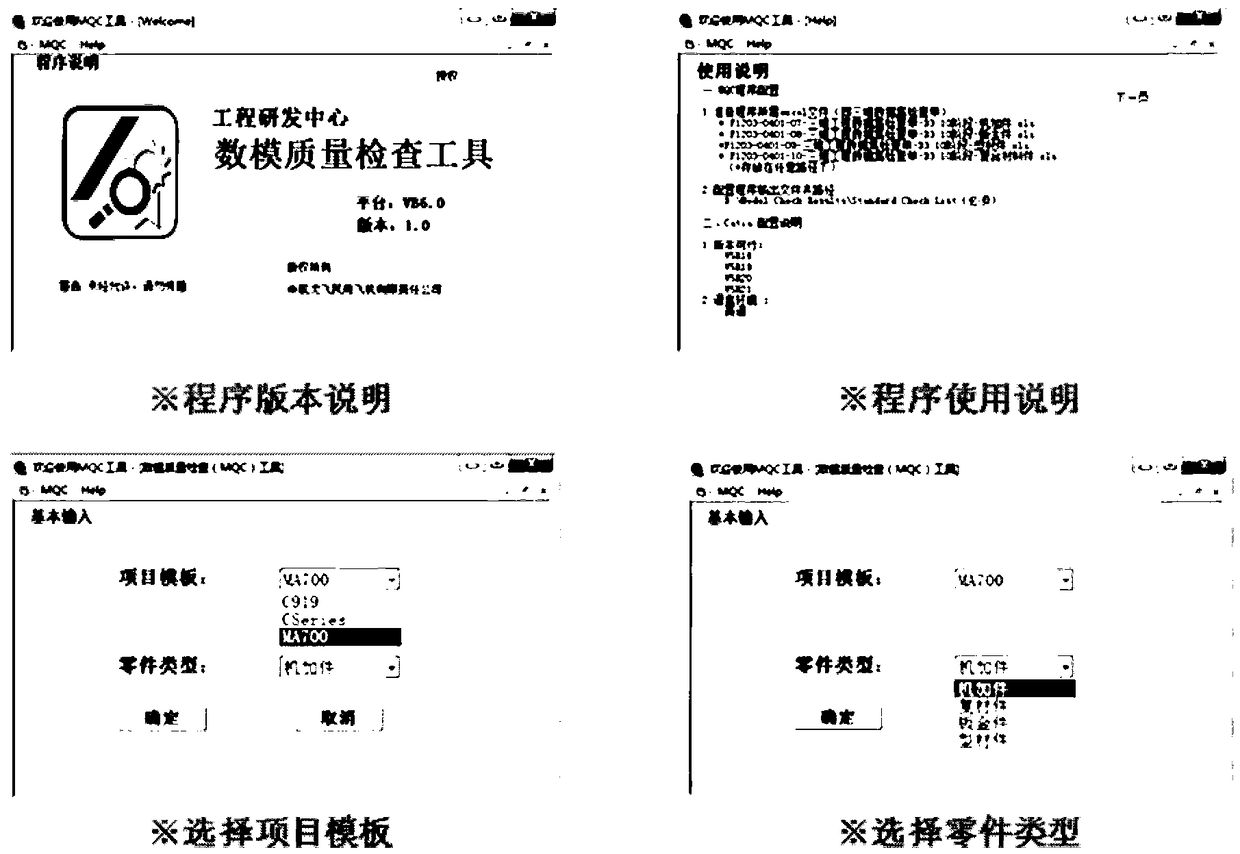

Implementation method of automatic checking for apparent quality of digital and analog signals

InactiveCN109064128AImprove developmentEasy maintenanceGeometric CADOffice automationModularityProject management

The invention relates to a method for automatically checking the apparent quality of a digital model, belonging to the field related to the design of aircraft parts. According to the industry standardin aircraft field, Enterprise standards or user-defined project management regulations, the selection of apparent quality inspection items, the use of CATIA open secondary development interface to form a part of the surface quality automatic inspection tools, aircraft parts CATIA surface quality of the rapid inspection and inspection results output management. The method realizes modular management and has the advantages of wide application range, simple maintenance and high inspection efficiency.

Owner:AVIC SAC COMML AIRCRAFT

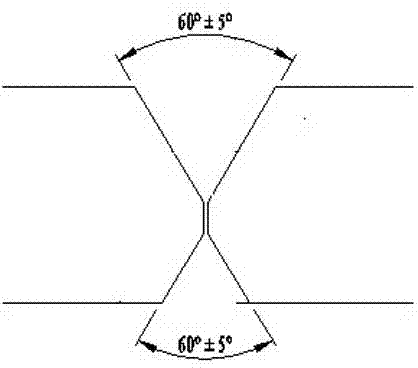

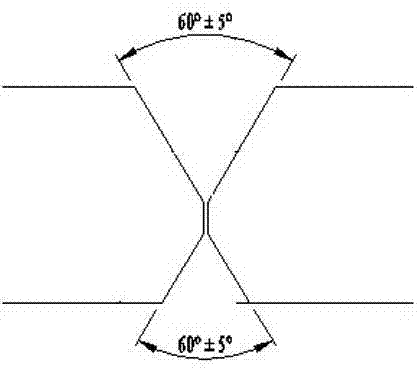

A kind of anti-icing riser welding method

InactiveCN102294552AReduce fillingQuality improvementArc welding apparatusWorkpiece edge portionsEngineeringStructural engineering

The invention provides a welding method for ice-resistant water riser, which changes the original V-shaped groove into a symmetrical X-shaped groove; the longitudinal seam and the circular seam welded with the joint are welded by internal and external submerged arc welding; the joint and the pipe body weld the ring The inner seam is first welded by the submerged arc welding manipulator, and the outer groove is filled after the outer root is cleaned and polished; it has the advantages of high speed and high efficiency.

Owner:SHANDONG QILONG OFFSHORE PETROLEUM STEEL PIPE

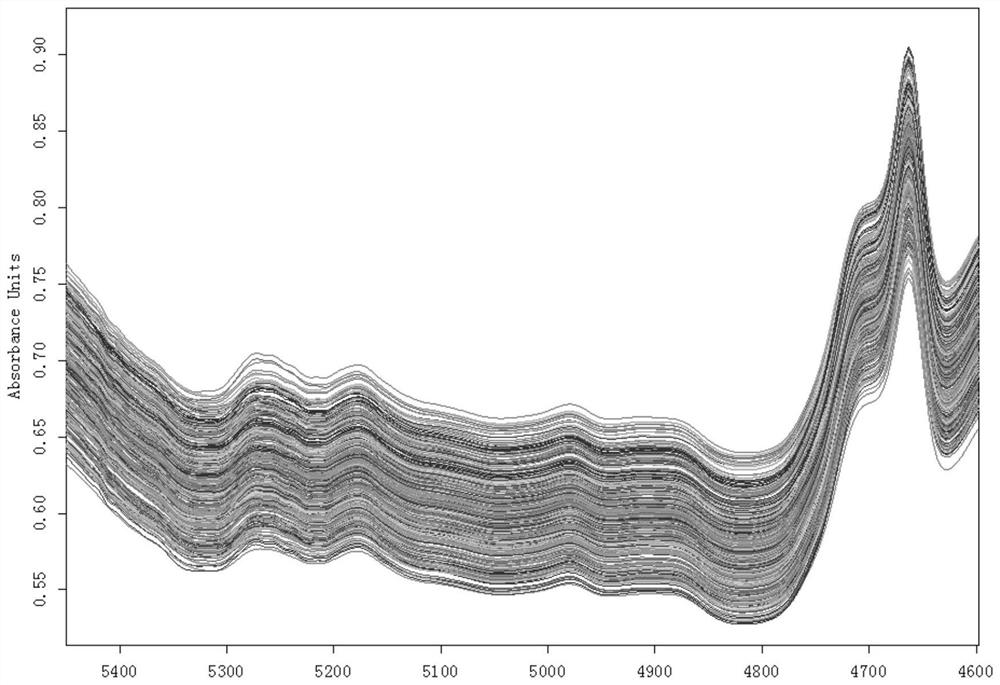

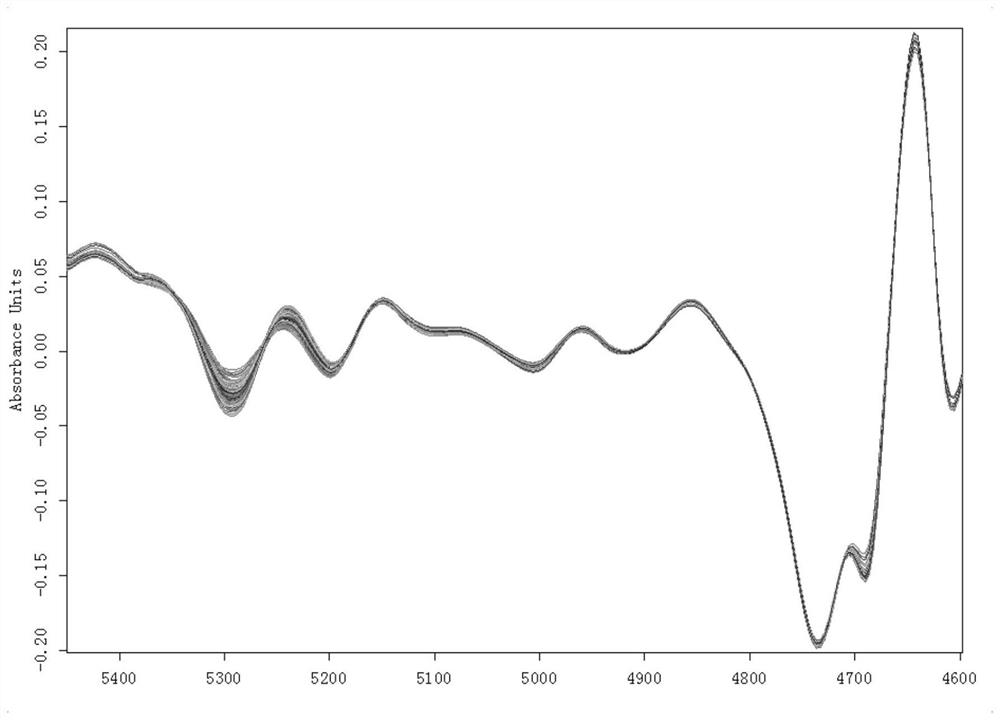

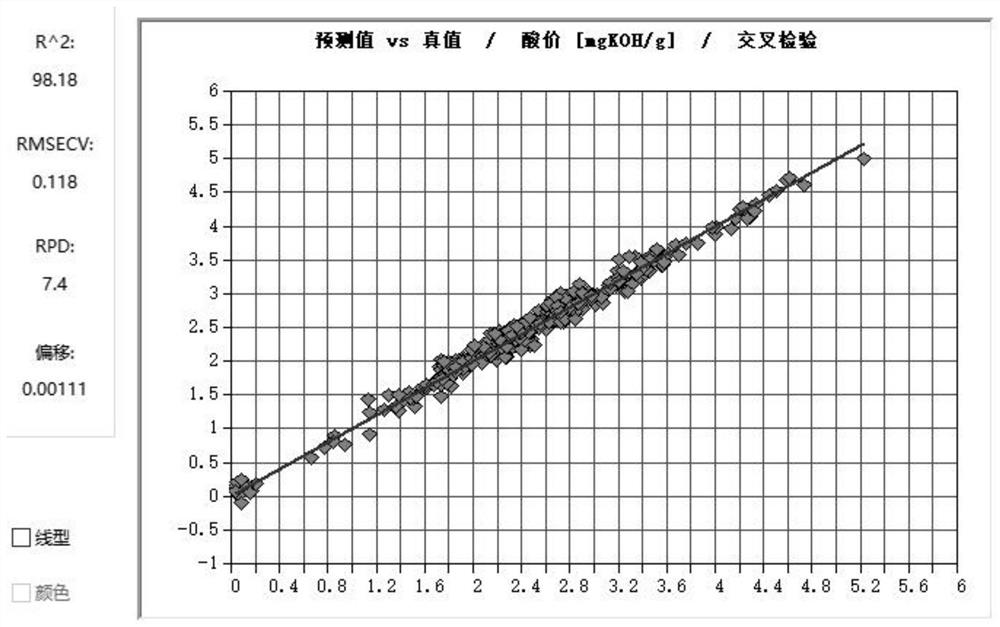

Grease quantitative analysis method based on near-infrared transmission and reflection spectrum technology

InactiveCN111650154ASimple and fast operationImprove detection accuracyMaterial analysis by optical meansOil and greaseMahalanobis distance

The invention discloses a grease quantitative analysis method based on a near-infrared transmission and reflection spectrum technology, which comprises the following steps: S1, collecting a pluralityof grease samples, and carrying out calibration wet chemical detection; s2, formulating a grease fatty acid reference standard of each grease index; s3, synchronously carrying out near infrared spectrum scanning on the collected grease sample; s4, through calibration software OPUS8.1, according to the wet chemical detection value calibrated by the grease sample in the S1 and the near infrared spectrum in the S3, carrying out spectrogram preprocessing; according to a spectral residual error, a Mahalanobis distance and a component density value, rejecting an abnormal spectrum and a wet chemicalvalue, establishing a grease quantitative model by applying a partial least squares method; s5, performing algorithm verification on the established quantitative model, and determining an optimal quantitative model; s6, performing blind verification on the quantitative model; s7, performing near infrared spectrum scanning on the grease sample to be detected to obtain a prediction result; and S8, analyzing the fatty acid result of the to-be-detected grease sample obtained by the quantitative model according to the grease fatty acid reference standard formulated in the S2, and identifying the adulteration condition.

Owner:WENS FOOD GRP CO LTD

Air cooling machine for quenching

InactiveCN105695693AQuality assuranceNo pollution in the processQuenching agentsQuenching devicesEngineeringSprocket

The invention relates to an air cooler for quenching, which is equipped with a bracket, a speed-regulating motor, a gearbox, a tooth plate, a chain, an iron cabinet box, a transmission belt, an axial fan, a bellows, an air outlet, a triangle belt, a fixed shaft, The fixed bracket is characterized in that: the base is equipped with a rectangular iron box, and the two ends of the iron box are connected, the axial flow fan is installed on the rectangular iron box, the lower end of the axial flow fan is equipped with a bellows, and two front and rear outlets are installed on the bellows. The air hole and the fixed shaft are installed on the base with a fixed bracket. The speed-adjusting motor and the gearbox are installed on the base. To cooperate, the transmission belt is installed on the two cranksets. The invention adopts air cooling for quenching, the wind speed fluctuation range is small, the surface state of the workpiece is not sensitive, the quality of the quenched workpiece is guaranteed, and it has the advantages of simple structure, economical and practical, low workpiece reject rate, no environmental pollution, and safe use.

Owner:孙德春

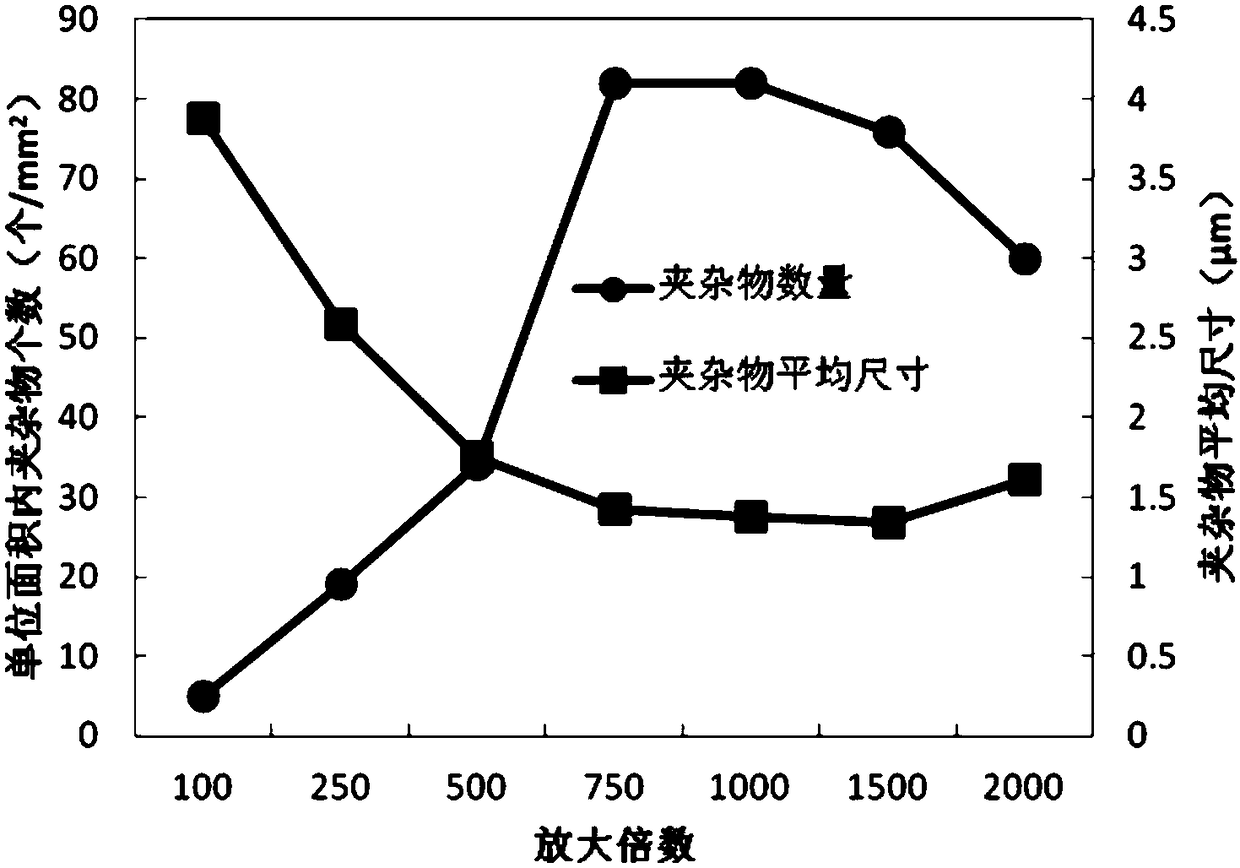

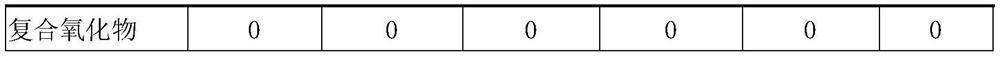

Method for detecting and analyzing small-size non-metallic inclusions in steel by using scanning electron microscope

PendingCN113899763AQuick statisticsAutomatic statisticsPreparing sample for investigationMaterial analysis by transmitting radiationScanning electron microscopeMaterials science

The invention discloses a method for detecting and analyzing small-size non-metallic inclusions in steel by using a scanning electron microscope, and mainly solves the technical problems of low quantitative analysis precision and poor stability of the small-size non-metallic inclusions in the steel in the prior art. According to the technical scheme, the method for detecting and analyzing the small-size non-metallic inclusions in the steel by using the scanning electron microscope comprises the following steps: (1) preparing a metallographic sample, and embedding the surface of the sample to be detected by using a hot embedding machine; grinding, polishing and cleaning the embedded sample and pasting aluminum-foil paper on a non-analysis area on the edge of the sample to obtain a metallographic sample; 2) regulating and controlling scanning electron microscope and energy spectrum detection parameters; (3) detecting inclusions; and 4) analyzing the inclusions, setting a classification standard of the inclusions, and analyzing a detection result by utilizing a computer inclusion analysis program to obtain the quantity, size, shape and component information of the inclusions. The method is easy and convenient to operate, high in efficiency and high in precision of qualitative and quantitative analysis of the small-size non-metallic inclusions in the steel.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

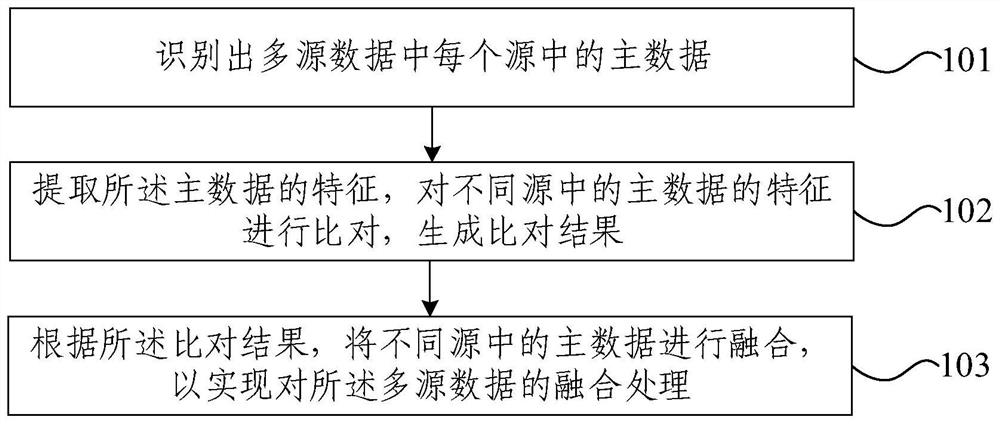

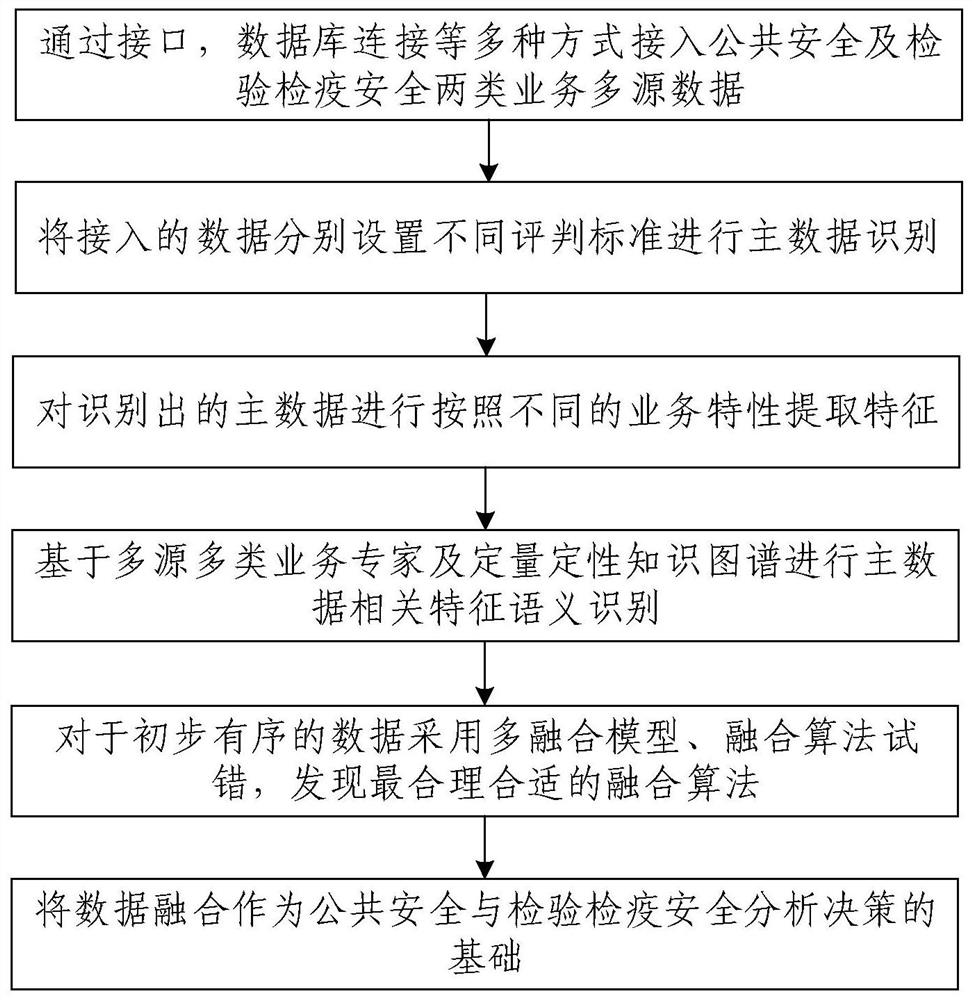

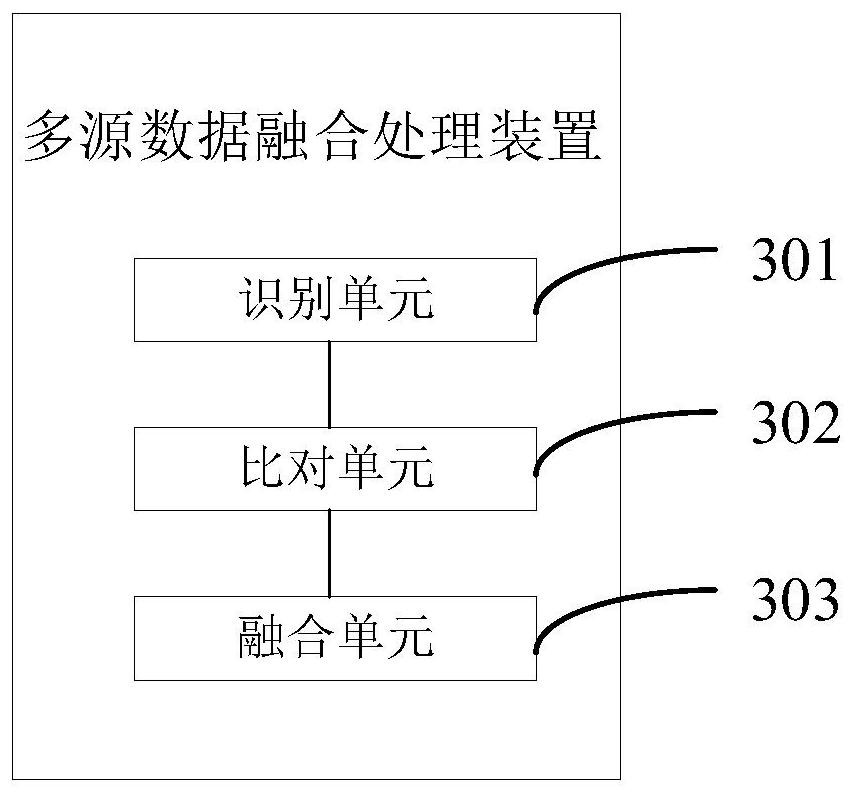

Multi-source data fusion processing method and device, electronic equipment and storage medium

PendingCN112949745AAchieve integrationEliminate the effects ofSemantic analysisCharacter and pattern recognitionEngineeringMulti source data

The invention provides a multi-source data fusion processing method and device, electronic equipment and a storage medium. The method comprises the following steps: identifying main data in each source in multi-source data; extracting features of the main data, comparing the features of the main data in different sources, and generating a comparison result; according to the comparison result, fusing the main data in the different sources so as to realize fusion processing of the multi-source data. By extracting the main data of the multi-source data, the influence of useless data in the multi-source data on a multi-source data fusion result is eliminated, and the fusion accuracy is improved; the data are fused by extracting the characteristics of the main data, so that the limitation on communication thinking of personnel in different fields in a multi-source data fusion process can be reduced, finally, human influence factors are reduced for data fusion, and the credibility of a data fusion processing result is improved.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Pre-boring pressure meter, self-boring pressure meter and self-boring pressure metering equipment

ActiveCN102926369BSteady change in degree of expansionAvoid crackingIn situ soil foundationPore water pressureEngineering

The invention provides a pre-boring pressure meter, a self-boring pressure meter and a self-boring pressure metering equipment. The pre-boring pressure meter comprises a test device, a control device and an oil conveying tube, wherein the test device comprises a main body barrel, an elastic film, a pressure sensor and a displacement sensor; and the control device comprises an oil tank, an oil pump, a strain controller and a data analyzer. The self-boring pressure meter comprises a test device, a control device and an oil conveying tube, wherein the test device comprises an outer layer sleeve, an inner layer sleeve, a drill bit, an elastic film, a pressure sensor, a displacement sensor, a porous stone and a pore water pressure sensor; and the control device comprises an oil tank, an oil pump, a strain controller and a data analyzer. The self-boring pressure metering equipment comprises a self-boring pressure meter, a boring device, a water circulating device and a power device. According to the invention, the elastic film is controlled to stably expand, so that fracture phenomena due to uneven expansion of the elastic film can be avoided, and test data can be ensured to be continuous and accurate; and moreover, hydraulic oil is used as an inflating medium to protect an inner circuit structure from corroding.

Owner:刘潋

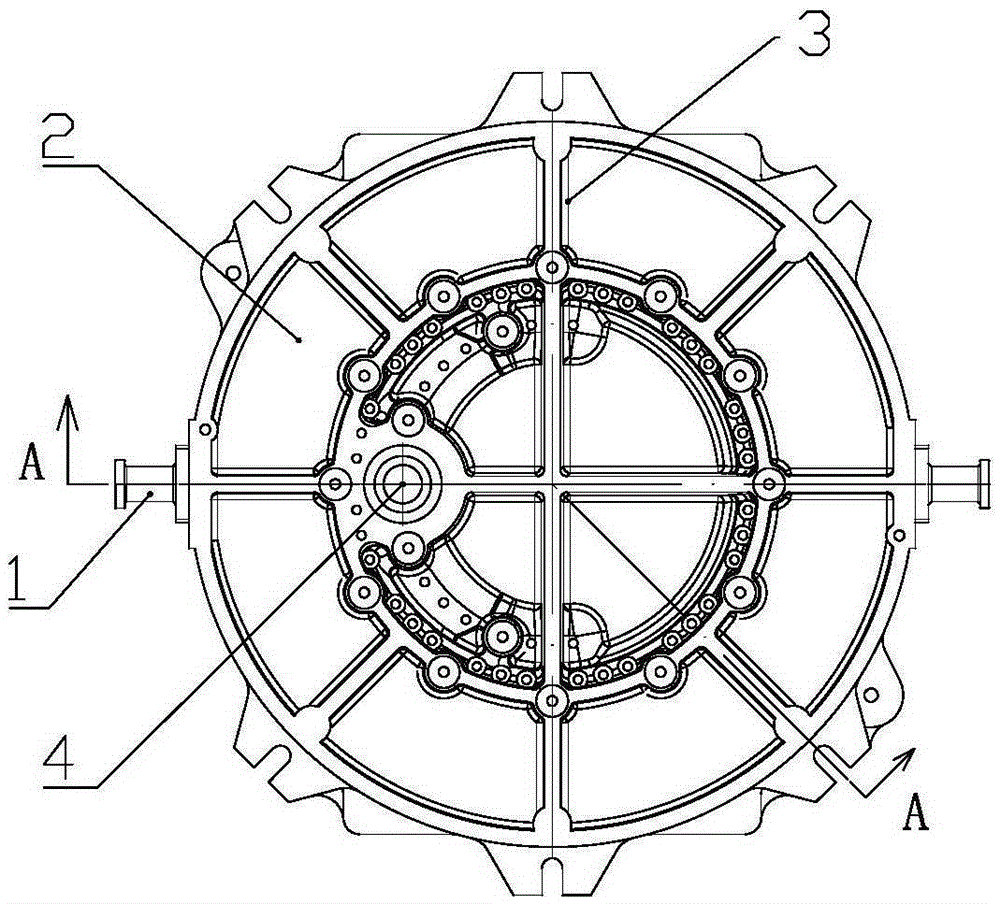

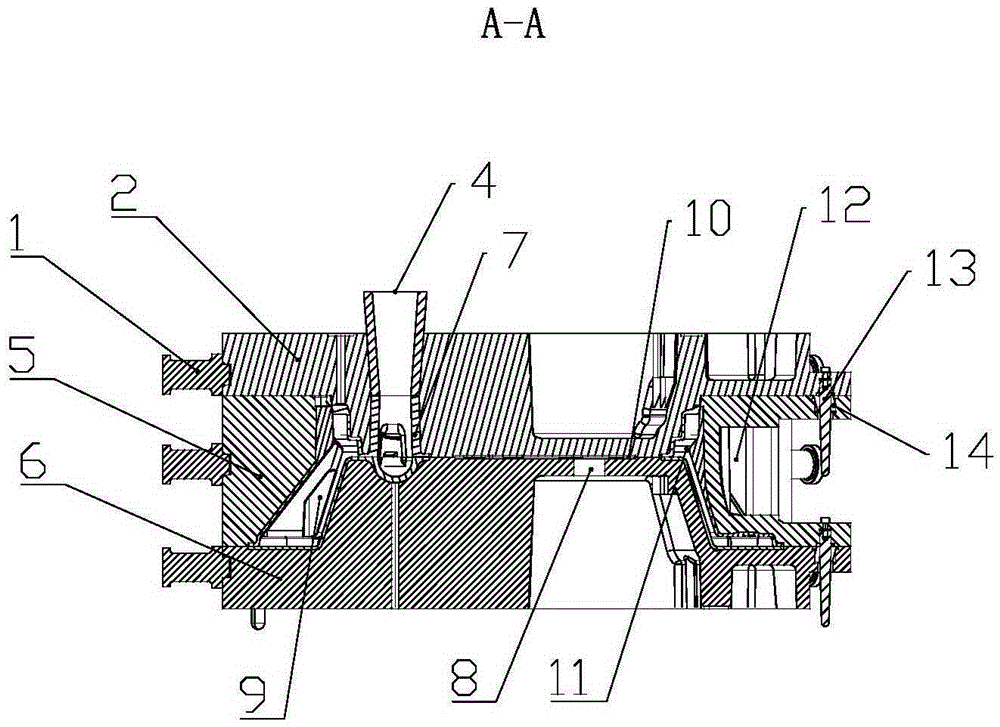

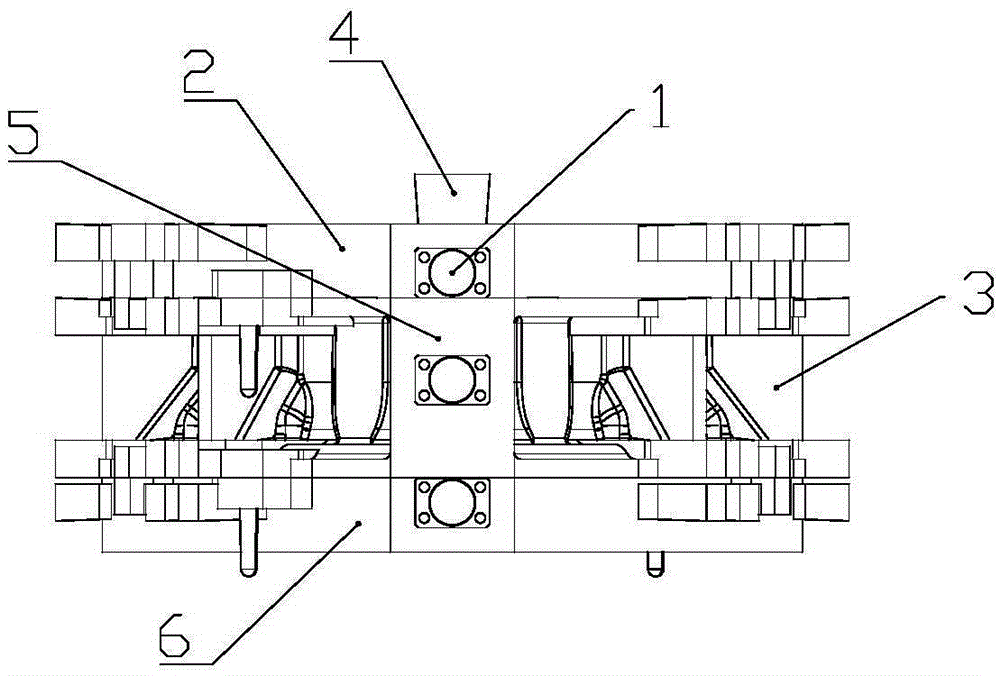

Sand coated iron mould casting device and casting technology of three-part-box ring type casting

ActiveCN105290322ABig spaceImprove appearance qualityFoundry mouldsFoundry coresProduction rateMaterials science

The invention discloses a sand coated iron mould casting device and casting technology of a three-part-box ring type casting, and belongs to the field of sand coated iron mould casting. The casting device comprises an upper sand box, an upper mould, a lower sand box and a lower mould. A casting system is arranged on the upper mould, and the device further comprises a middle sand box and a middle mould, wherein the middle sand box is located between the upper sand box and the lower sand box; a columnar middle mould movable block is arranged on the middle mould, and a middle mould inserting block is arranged on the back face of the middle mould movable block; and positioning devices are arranged between the middle sand box and the upper sand box and between the middle sand box and the lower sand box respectively in a matched manner. The casting technology comprises the steps of heating the moulds and the sand boxes, conducting modeling, conducting box assembling, conducting casting, and finally obtaining a casting product. The ring type three-part-box casting is produced through the sand coated iron mould casting technology, the product quality is reliable and stable, the production rate is high, and the size precision is high.

Owner:JINAN FOUNDRY PATTERN +1

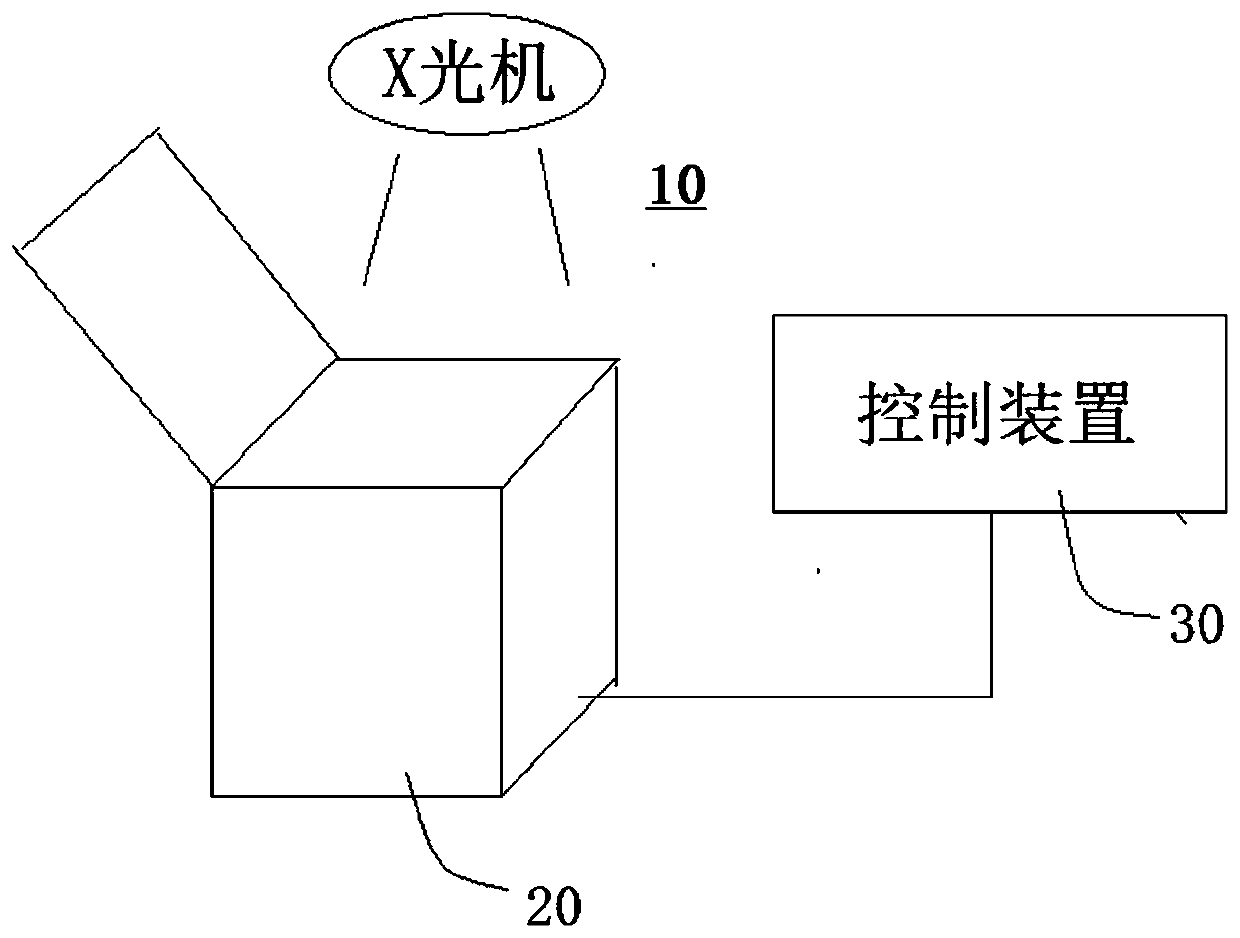

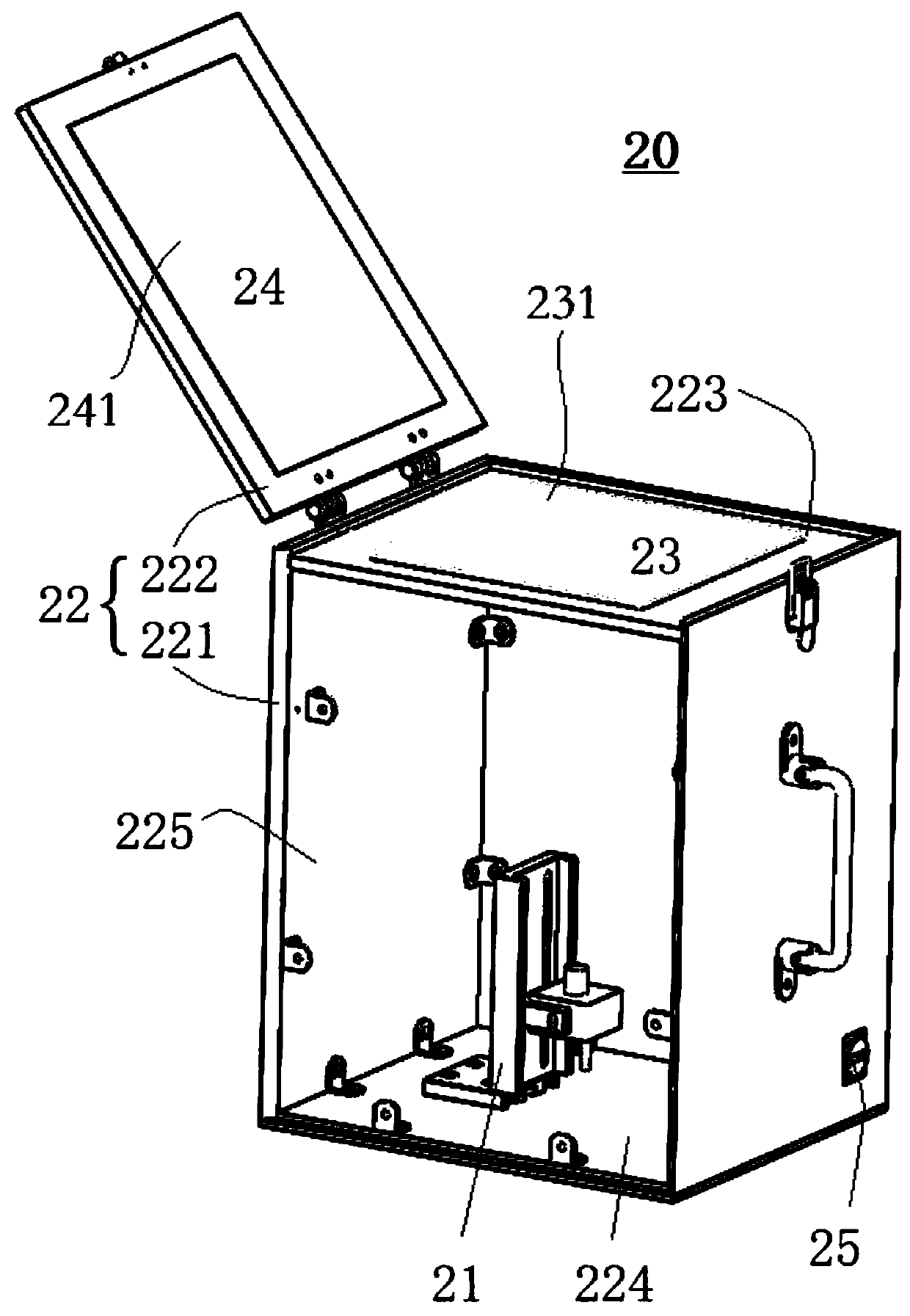

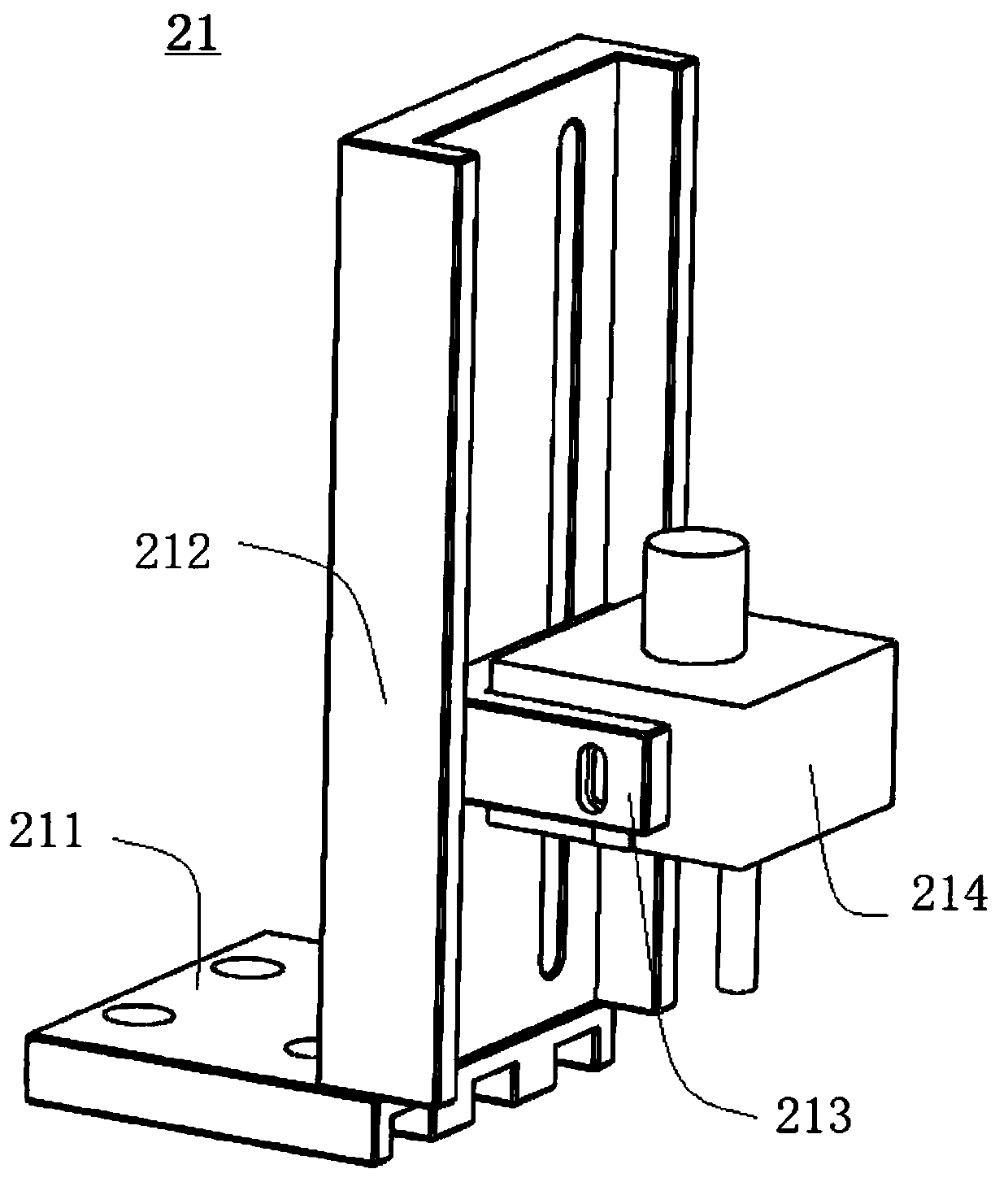

Light radiation field visual detection method and light radiation field visual detection equipment

PendingCN110859641ACan saveShort timeRadiation diagnostics testing/calibrationCamera moduleRadiation field

The invention relates to a light radiation field visual detection method and light radiation field visual detection equipment, and the method comprises the following steps: obtaining a light field image which is formed by visible light emitted by an X-ray machine radiation field indication lamp and shot by a camera module, wherein the light field image comprises an illuminated light field region;acquiring a radiation field image of X-rays emitted by an X-ray machine and shot by the camera module on a radiation field detection plate, wherein the radiation field image comprises a radiation field area; analyzing the light field image to obtain image attributes of the light field area; analyzing the radiation field image to obtain image attributes of the radiation field area; and calculatinga light field consistency parameter of the X-ray machine according to the light field area and the image attributes of the light field area, wherein the light field consistency parameter of the X-raymachine comprises an offset parameter of the light field area relative to the light field area.

Owner:深圳市博视科技有限公司

Diagnostic control method and device for air conditioner engineering installation

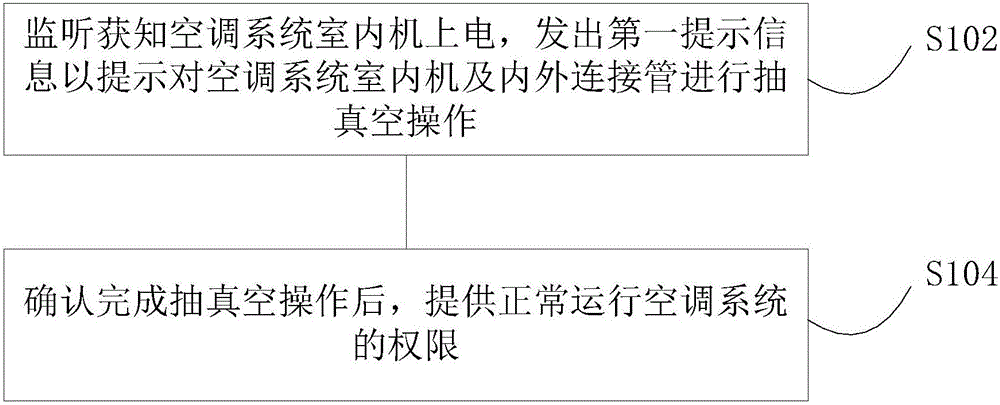

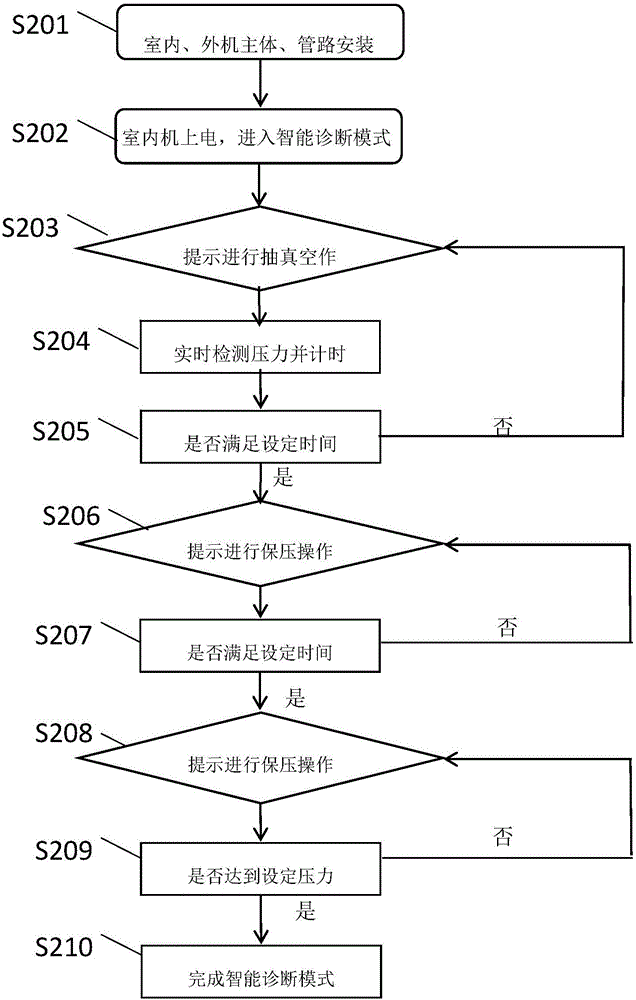

InactiveCN106052017AGuaranteed uptimeAddressing quality degradationMechanical apparatusSpace heating and ventilation safety systemsControl engineering

The invention discloses a diagnostic control method and device for air conditioner engineering installation. The method comprises the steps that electrifying of an indoor unit of an air conditioner system is known through monitoring, a first prompt message is sent to prompt conducting of vacuumizing operation on the indoor unit of the air conditioner system, an inner connection pipe and an outer connection pipe; and after completing of vacuumizing operation is affirmed, jurisdiction of normal operation of the air conditioner system is provided. Through the diagnostic control method and device for air conditioner engineering installation, the problems that in the prior art, in the air conditioner installation process, the quality of the air conditioner system is possibly lowered due to the fact that an installation worker does not do vacuumizing operation are solved, the precise degree of the air conditioner installation is improved, operation quality after installation of an air conditioner is ensured, and the experience degree of a user to an air conditioner brand is further improved.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com