Method for evaluating point load performance of plastic tube

A plastic pipe and point load technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of difficulty in simulating the real situation and long time, and achieve small human influence factors, small dispersion, and shorten evaluation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This example is used to illustrate the method for evaluating the point load performance of plastic pipes provided by the present invention.

[0038] Sample: PE100 pipe, outer diameter 110mm, minimum wall thickness 10.48mm, SDR 11, length 700mm;

[0039] Reagent: 2% by weight Arkopal N100 surfactant solution, purchased from Sigma-Aldrich Company.

[0040] Evaluation process:

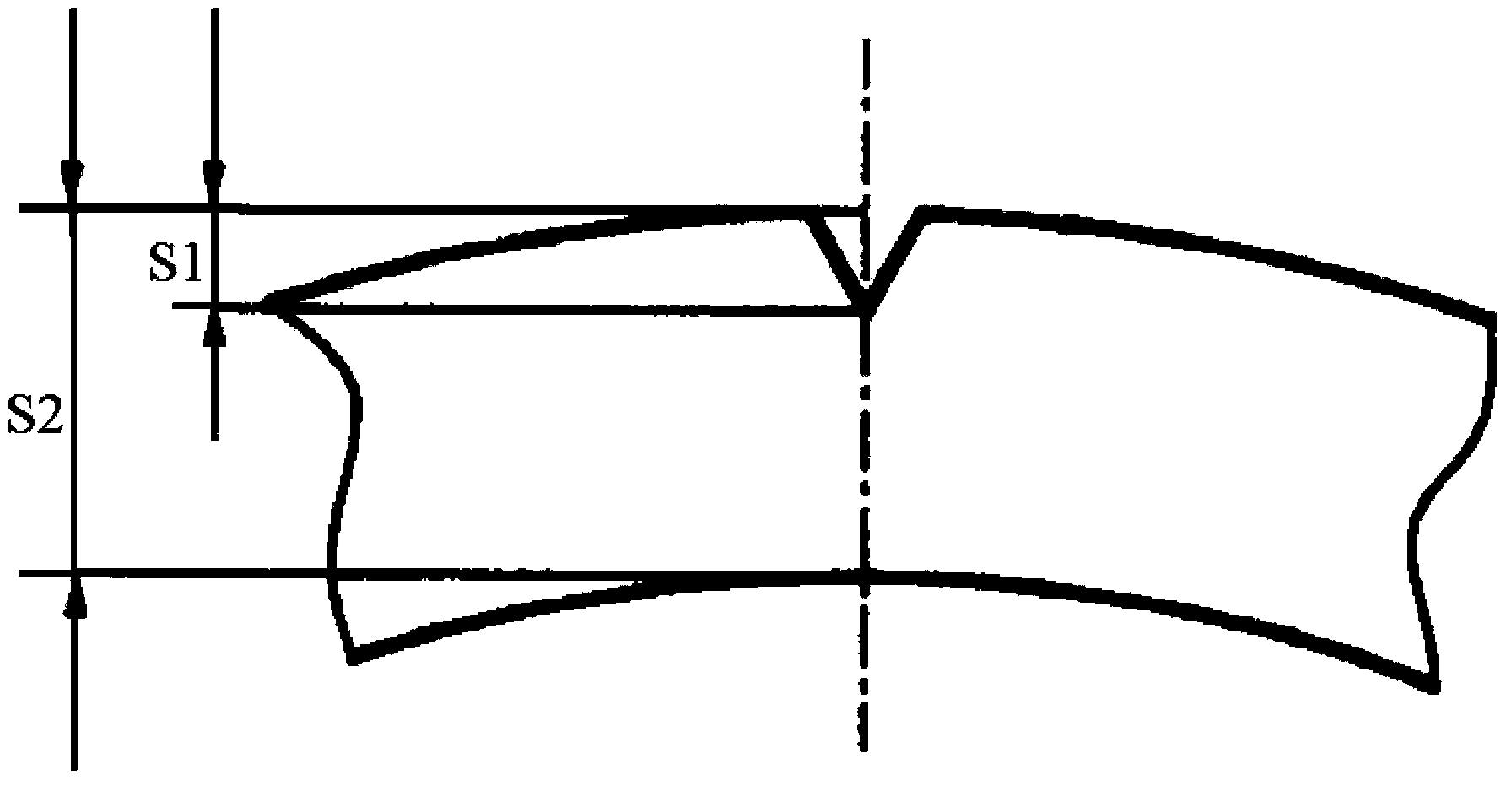

[0041] (1) Place the PE100 pipe at ambient temperature for 24 hours, then use a twist drill with a 90° cone angle and an outer diameter of 12mm to drill holes at the minimum wall thickness to form a conical shape with a depth of 5.24mm and a cone angle of 90° Notch, then leave for 24 hours.

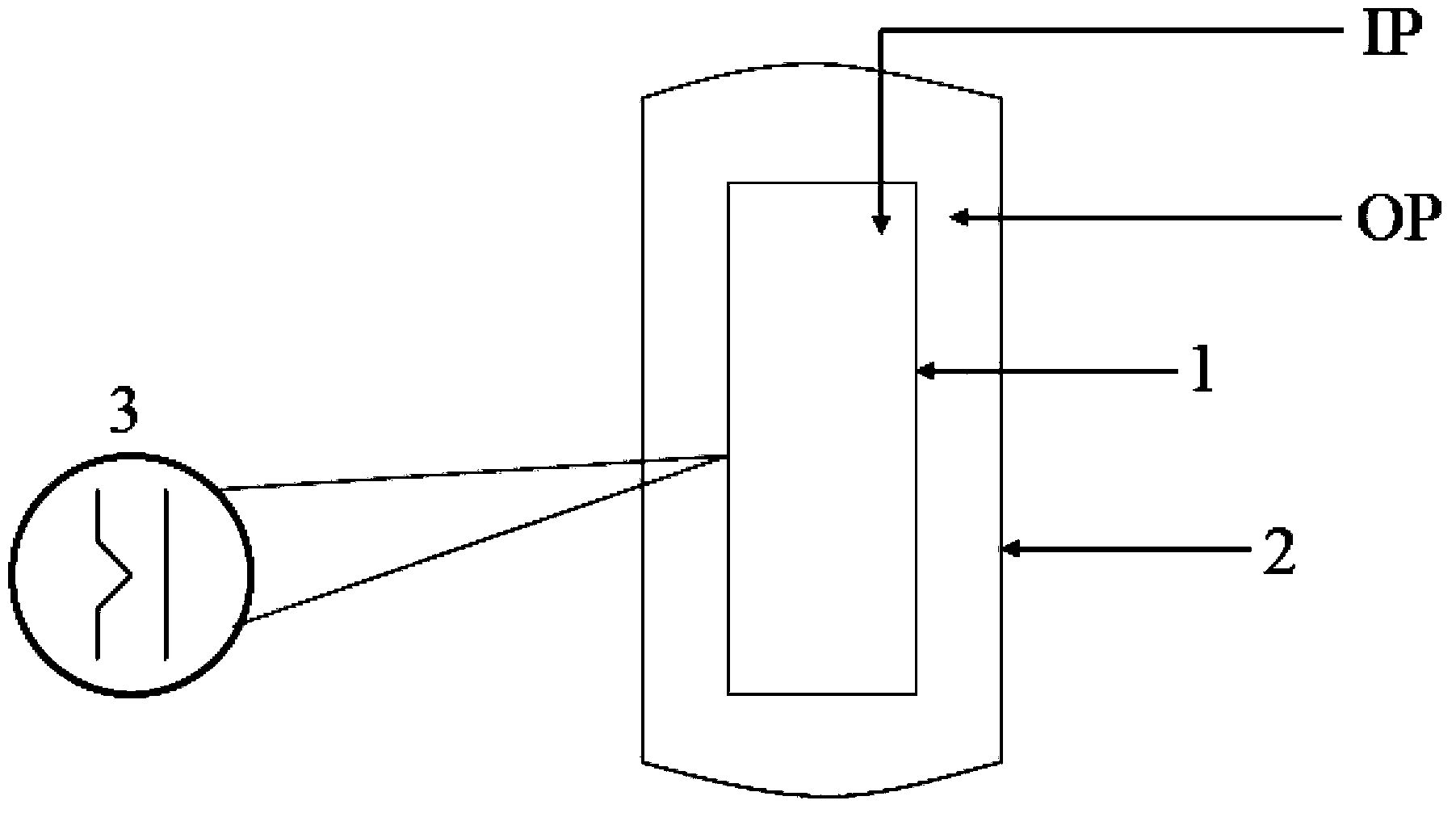

[0042] (2) Install a head on one end of the pipe formed with a gap, inject 2% by weight of Arkopal N 100 surfactant solution, and then install a head on the other end of the pipe (the head has a hydraulic interface and an exhaust port). Then continue to add the surfactant solution through the vent until th...

Embodiment 2

[0047] This example is used to illustrate the method for evaluating the point load performance of plastic pipes provided by the present invention.

[0048] The point load performance of the PE100 pipe was evaluated according to the method of Example 1, except that in step (3), the container was also filled with 2% by weight of Arkopal N100 surfactant solution.

[0049] As a result, the tubing samples failed after 206 hours.

Embodiment 3

[0051] This example is used to illustrate the method for evaluating the point load performance of plastic pipes provided by the present invention.

[0052] Evaluate the point load performance of PE100 pipe according to the method of Example 1, the difference is that in step (4), the pressure inside the pipe sample is adjusted to 17.8bar, and the pressure outside the pipe sample is adjusted to 6.0bar .

[0053] As a result, the tubing samples failed after 217 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com