A method for evaluating ultra-high cycle fatigue properties of carburized steel

A technology of fatigue performance and evaluation method, which is applied in the direction of strength characteristics, instruments, and the use of repeated force/pulsation force to test the strength of materials, etc., can solve the problems of low core strength and inability to accurately evaluate the fatigue performance of carburized steel, and achieve shortening Evaluate the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Taking 18CrNiMo7-6 carburized steel for high-speed iron gear as an example, the evaluation methods of other carburized steels are similar and can be implemented by reference.

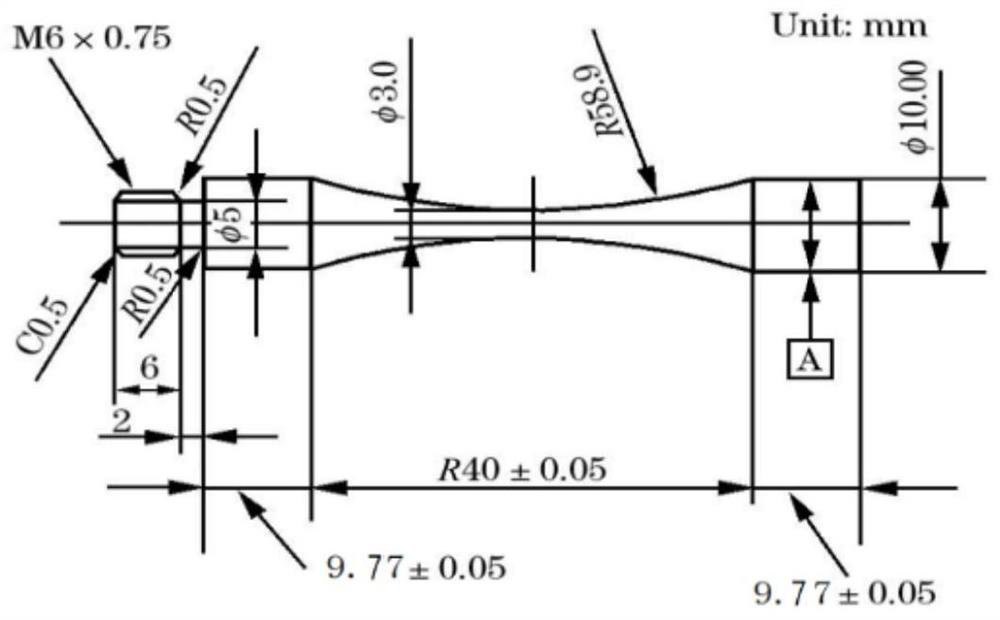

[0035] Material preparation: according to figure 1 The size of the sample shown is for processing the fatigue blank sample, leaving a machining allowance of 0.2mm on each side of the working section for subsequent finishing.

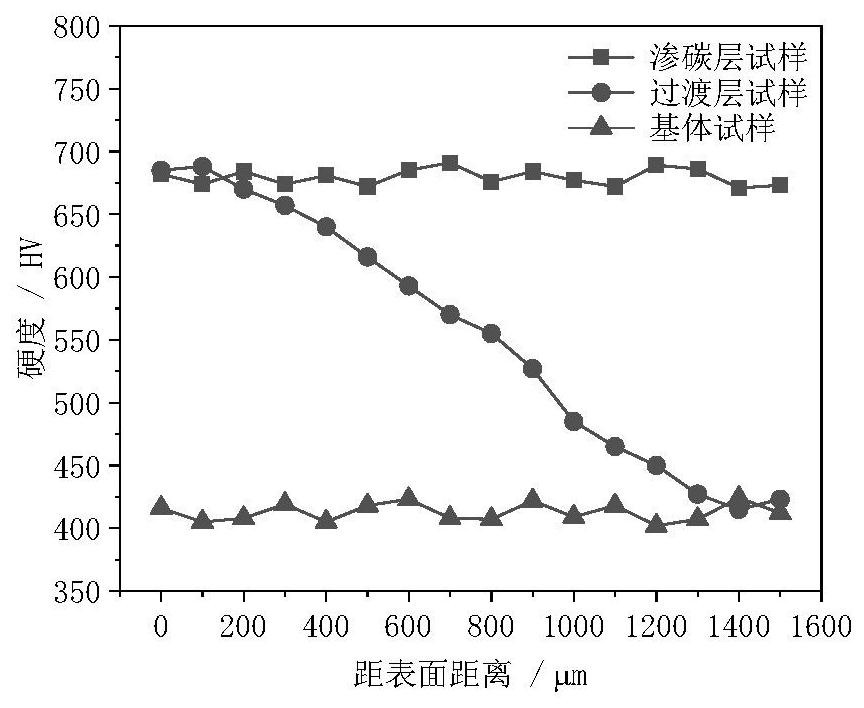

[0036] Carburizing treatment: The carburizing agent is propane and the diluent methanol, and the protective gas is nitrogen. The carburizing process includes strong infiltration, diffusion, quenching, tempering and other processes. The carburizing process of different samples is different, and the hardness distribution of the samples after carburizing is as follows: figure 2shown.

[0037] (1) Carburizing layer sample: The carburizing temperature of the sample is 930 ° C. First, it is intensively infiltrated under 1.1% carbon potential for 12 hours, and then diffusion ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com