Fiber force value inspection tool

A force value and fiber technology, applied in the direction of tension measurement, can solve the problems of changing the spring compression, inability to accurately measure the fiber tension force value, etc., and achieve the effect of reducing friction, ensuring service life and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

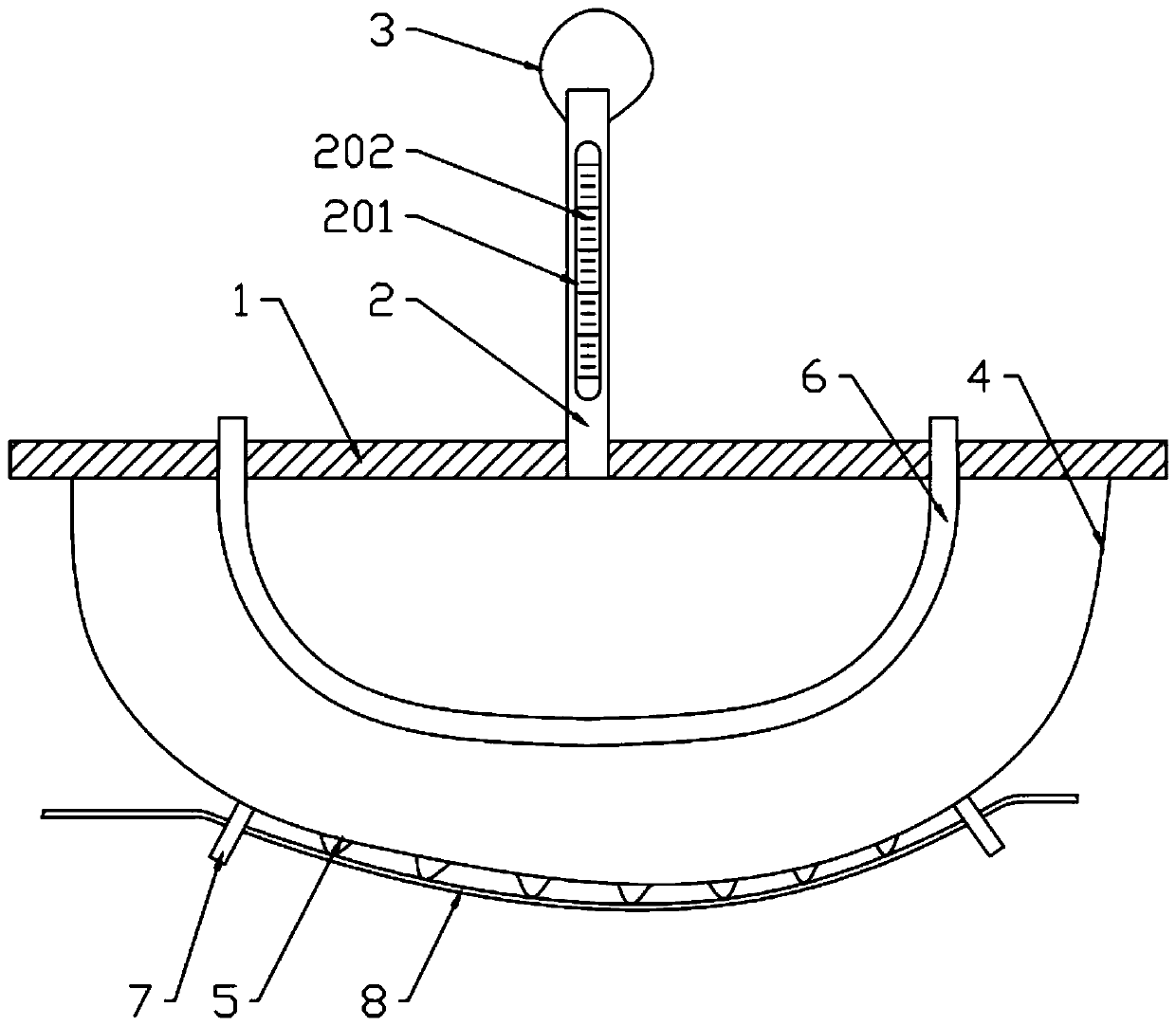

[0017] The reference signs in the accompanying drawings of the description include: mounting plate 1, air pipe 2, visible section 201, scale line 202, expansion air bag 3, compressed air bag 4, ice beads 5, cooling pipe 6, guide plate 7, and fiber 8.

[0018] The embodiment of the fiber force value checker is basically as attached figure 1 Shown: including mounting plate 1, air pipe 2, cooling pipe 6, expansion air bag 3 made of latex and compressed air bag 4 made of plastic film, the outer surface of compressed air bag 4 is coated with a layer of rapeseed oil film, air pipe 2 and The compressed airbags 4 are respectively installed on both sides of the mounting plate 1, and the compressed airbags 4 are filled with gas that keeps the compressed airbags 4 fully bulging. It is a transparent visible section 201, and the visible section 201 is provided with a scale line 202. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com