Sweat-resistant and anti-wear colorful 3D glass panel and surface coating method thereof

A glass panel, 3D technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of poor acid or alkali resistance, affecting product coating quality, poor coating wear resistance, etc. , to achieve the effect of promoting the curing of the film layer, the curing effect is good, and the hydrophobicity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

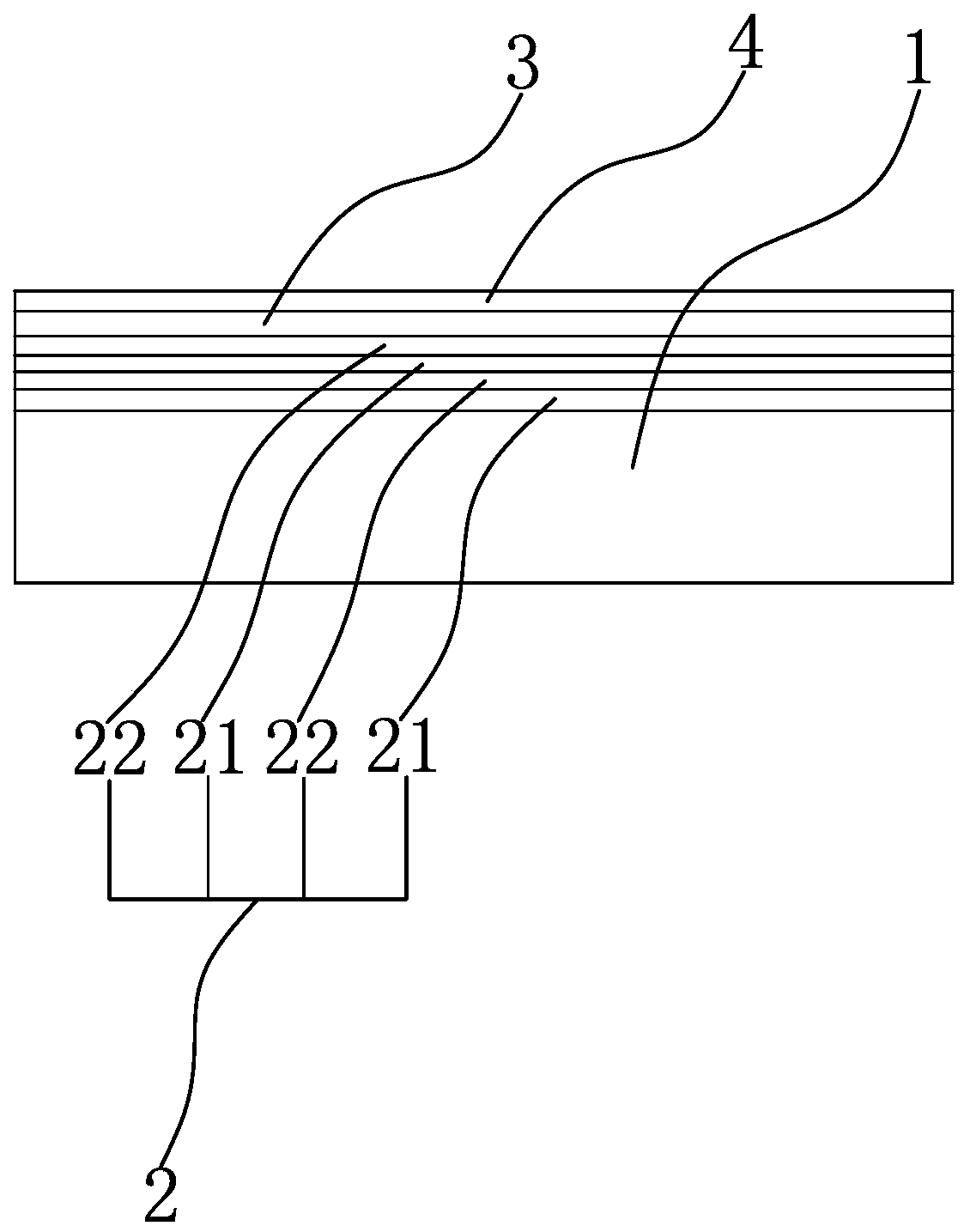

[0036] The sweat-resistant, wear-resistant and colorful 3D glass panel of this embodiment includes a 3D glass panel substrate 1, the surface of the 3D glass panel substrate 1 is coated with a colorful coating layer 2, and the surface of the colorful coating layer 2 is coated with nano-scale The DLC film layer 3 is coated with a sweat-resistant AF film layer 4 on the surface of the nano-scale DLC film layer 3, and the sweat-resistant AF film layer 4 is mainly deposited from a material containing fluorosilicon polymer and fluoroalkane. The content of the fluoroalkane material in the sweat-resistant AF film layer 4 is 10% to 12%, and the fluoroalkane material is selected from 1,1,1,2,3,3,3-heptafluoro-2-(B oxydifluoromethyl)-propane or 1,1,2,2,3,3,4,4,4-nonafluoro-1-ethoxy-hexane.

[0037] The processing of the above-mentioned sweat-resistant and wear-resistant colorful 3D glass panel can be generally carried out by vacuum coating (such as vapor deposition coating). Of course, i...

Embodiment 2

[0044] The sweat-resistant, wear-resistant and colorful 3D glass panel of this embodiment includes a 3D glass panel substrate 1, the surface of the 3D glass panel substrate 1 is coated with a colorful coating layer 2, and the surface of the colorful coating layer 2 is coated with nano-scale The DLC film layer 3 is coated with a sweat-resistant AF film layer 4 on the surface of the nano-scale DLC film layer 3, and the sweat-resistant AF film layer 4 is mainly deposited from a material containing fluorosilicon polymer and fluoroalkane. The sweat-resistant AF film layer 4 here is formed by evaporative deposition of a sweat-resistant AF liquid mainly comprising the following raw materials in mass percent:

[0045] Fluorosilicone polymer: 2.0%;

[0046] 1,1,1,2,3,3,3-Heptafluoro-2-(ethoxydifluoromethyl)-propane: 5.0%;

[0047] 1,1,2,2,3,3,4,4,4-nonafluoro-1-ethoxy-hexane: 6.0%;

[0048] All the other are solvents, here the solvent will adopt acetone or ethanol or their mixed solv...

Embodiment 3

[0057] The sweat-resistant, wear-resistant and colorful 3D glass panel of this embodiment includes a 3D glass panel substrate 1, the surface of the 3D glass panel substrate 1 is coated with a colorful coating layer 2, and the surface of the colorful coating layer 2 is coated with a thickness of 10nm nano-scale DLC film layer 3, the surface of the nano-scale DLC film layer 3 is plated with a sweat-resistant AF film layer 4 with a thickness of 15nm, and the sweat-resistant AF film layer 4 is mainly composed of fluorosilicon polymer and fluoroalkane material deposited. The sweat-resistant AF film layer 4 here is formed by evaporative deposition of a sweat-resistant AF liquid mainly comprising the following raw materials in mass percent:

[0058] Fluorosilicone polymer: 3.0%;

[0059] 1,1,1,2,3,3,3-Heptafluoro-2-(ethoxydifluoromethyl)-propane: 6.0%;

[0060] 1,1,2,2,3,3,4,4,4-nonafluoro-1-ethoxy-hexane: 6.0%;

[0061] All the other are solvents, here the solvent will adopt acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com