Patents

Literature

115results about How to "Not to be worn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

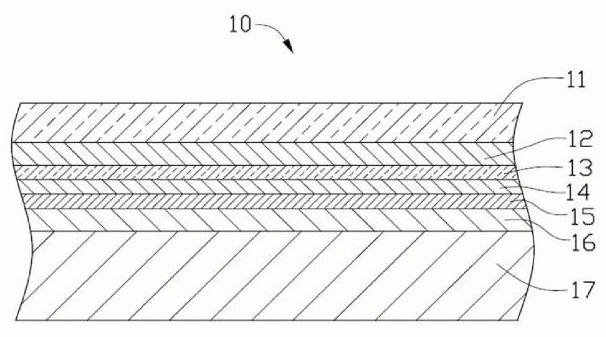

Print technology for cigarette cases

ActiveCN106585144AHigh recovery rateNot to be wornLaminationLamination apparatusHot stampingSilver paste

The invention discloses a print technology for cigarette cases. The print technology is characterized by including the steps of 1, cutting print base materials according to packaging requirements of objects to be packaged; 2, compressing the surfaces of the print base materials cut in the step 1 through dot-shaped optical grating molds to form groove patterns in the surfaces of the print base materials; 3, transferring silver paste mixtures into grooves of the groove patterns formed through compression in the step 2 through intaglio printing; 4, carrying out hot stamping treatment on the grooves in the surfaces of semi-finished print products obtained in the step 3 in a hot stamping manner through a hot stamping mold machine; 5, coating the print base materials on the surfaces of the semi-finished print products treated in the step 4 with cured resin in a silk-screen printing manner; and 6, cutting polyethylene heat shrinkage films according to sizes of the print base materials cut in the step 1. According to the print technology for the cigarette cases, the abrasive resistance of silver-coated parts on the surfaces of the finished cigarette cases is high, and print layers are smooth and have a fine and smooth hand feeling.

Owner:至远彩色印刷工业(惠州)有限公司

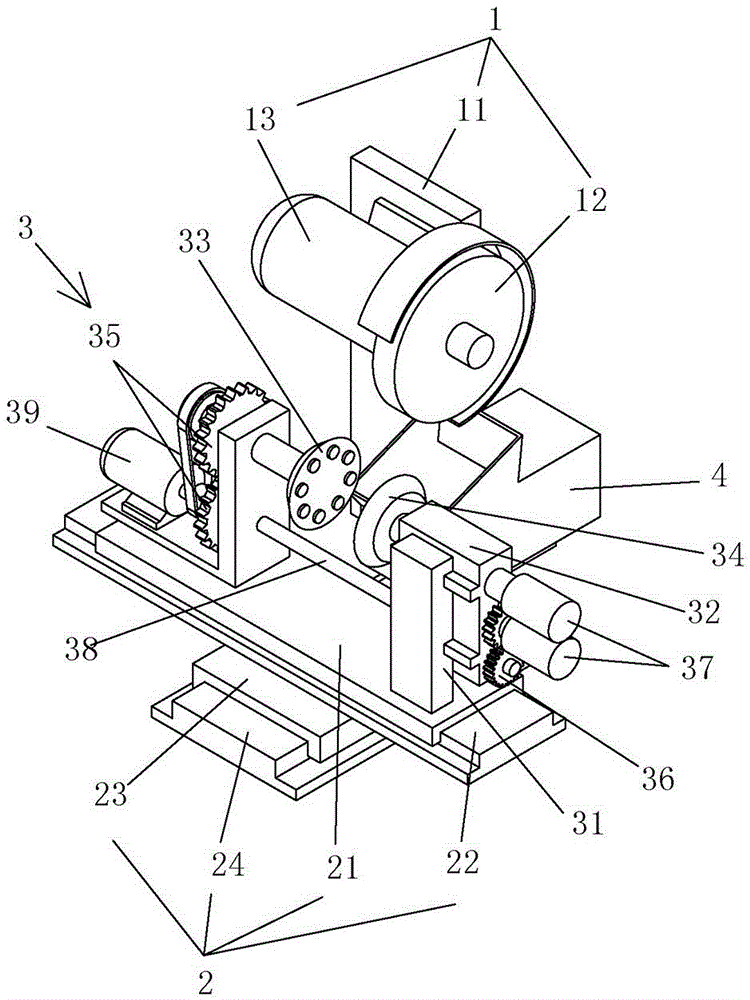

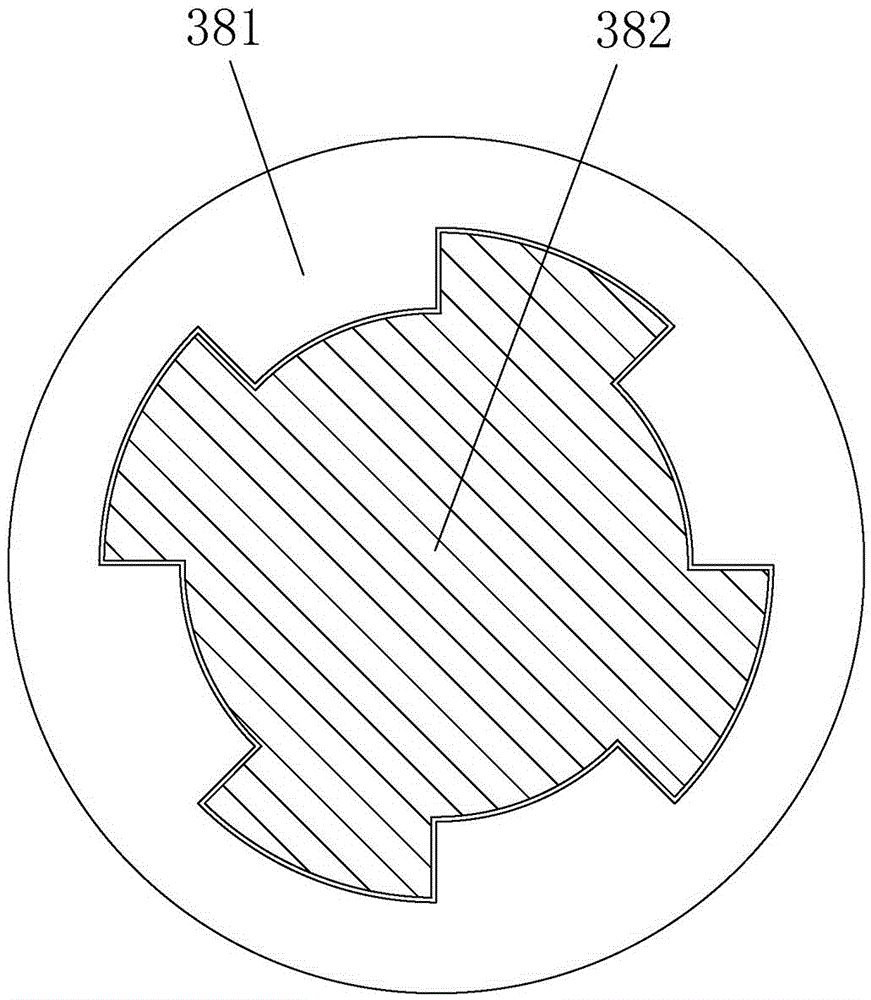

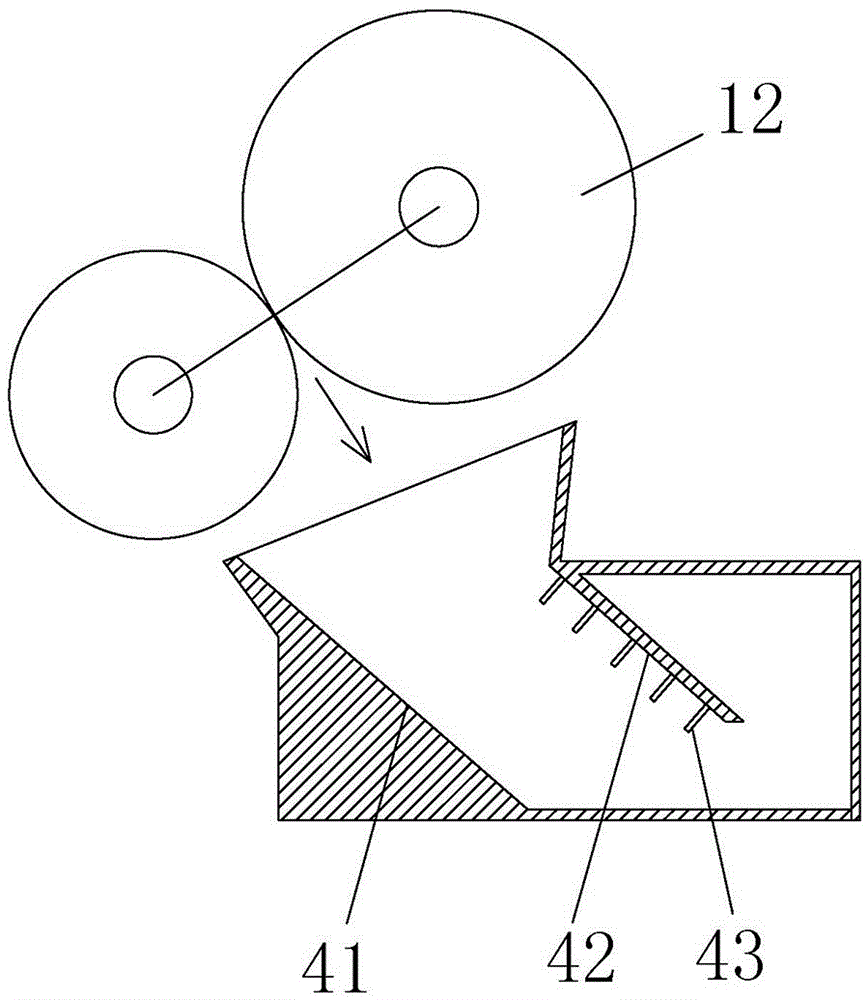

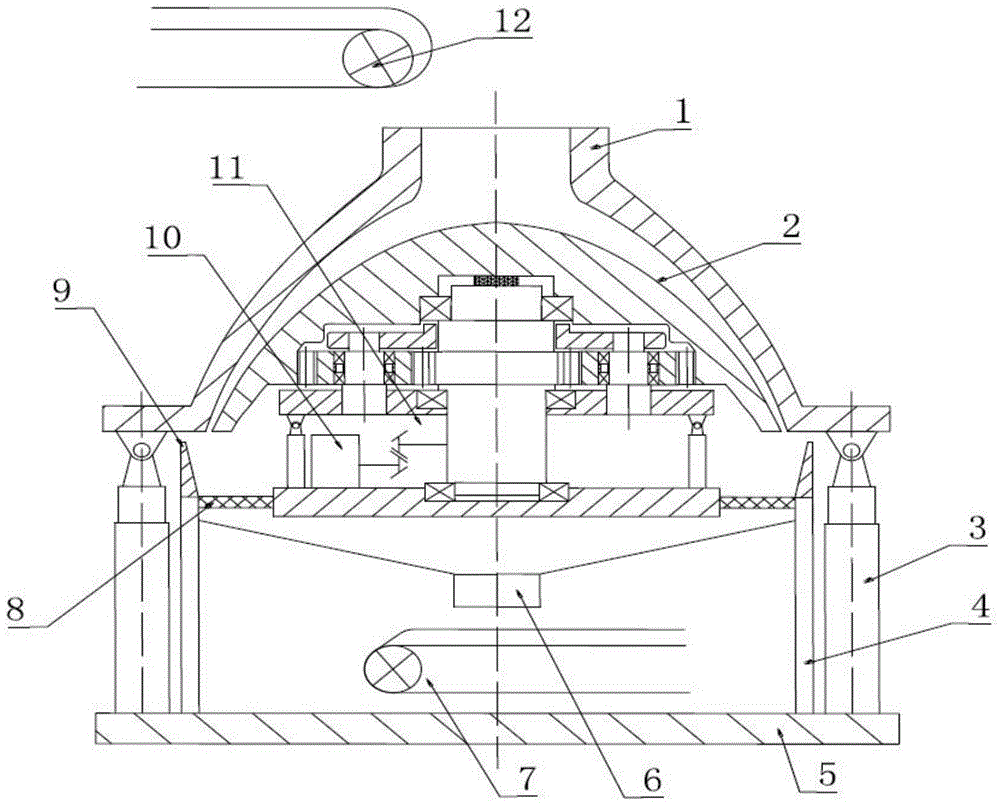

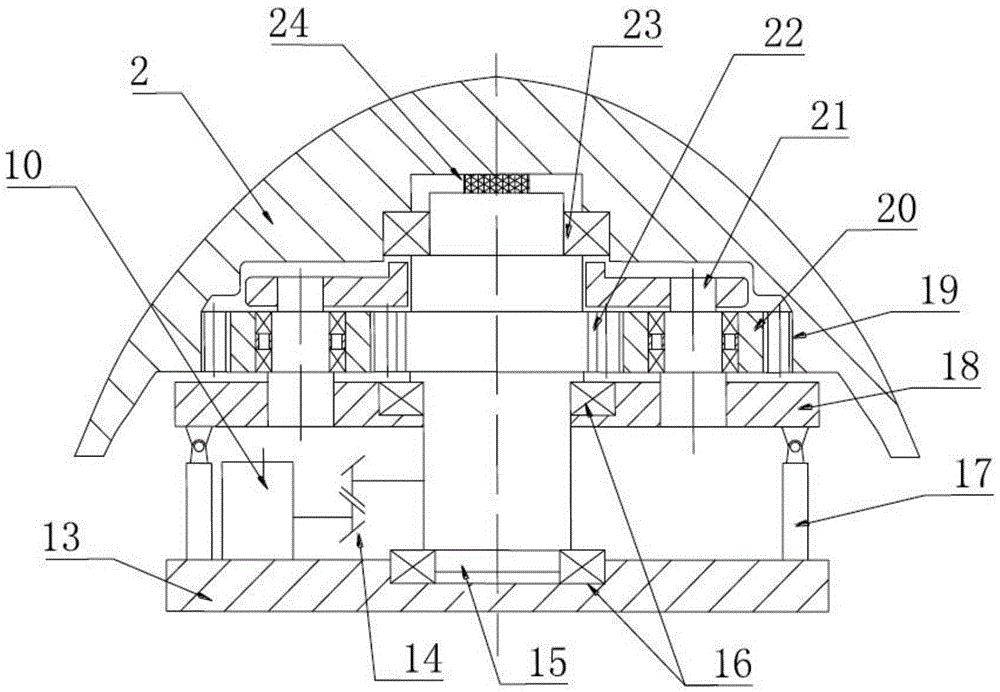

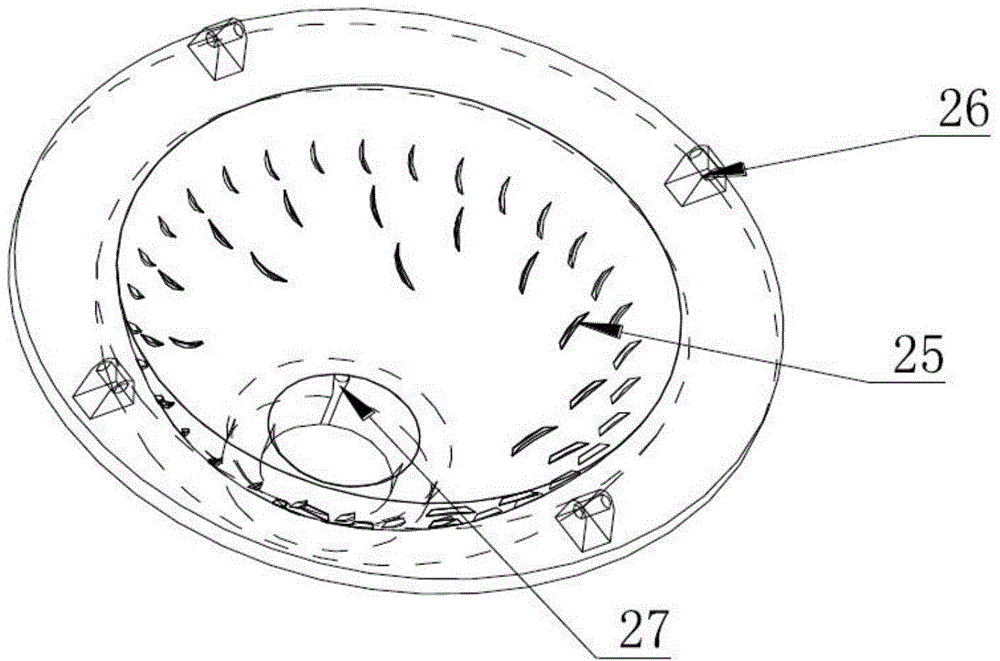

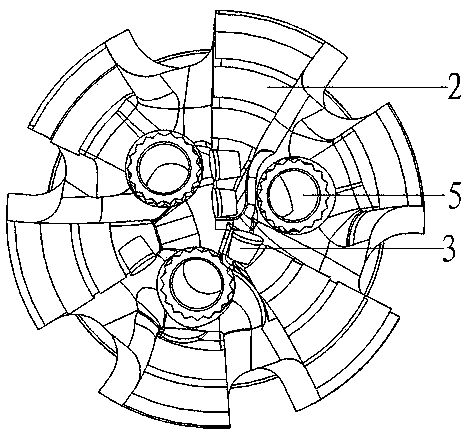

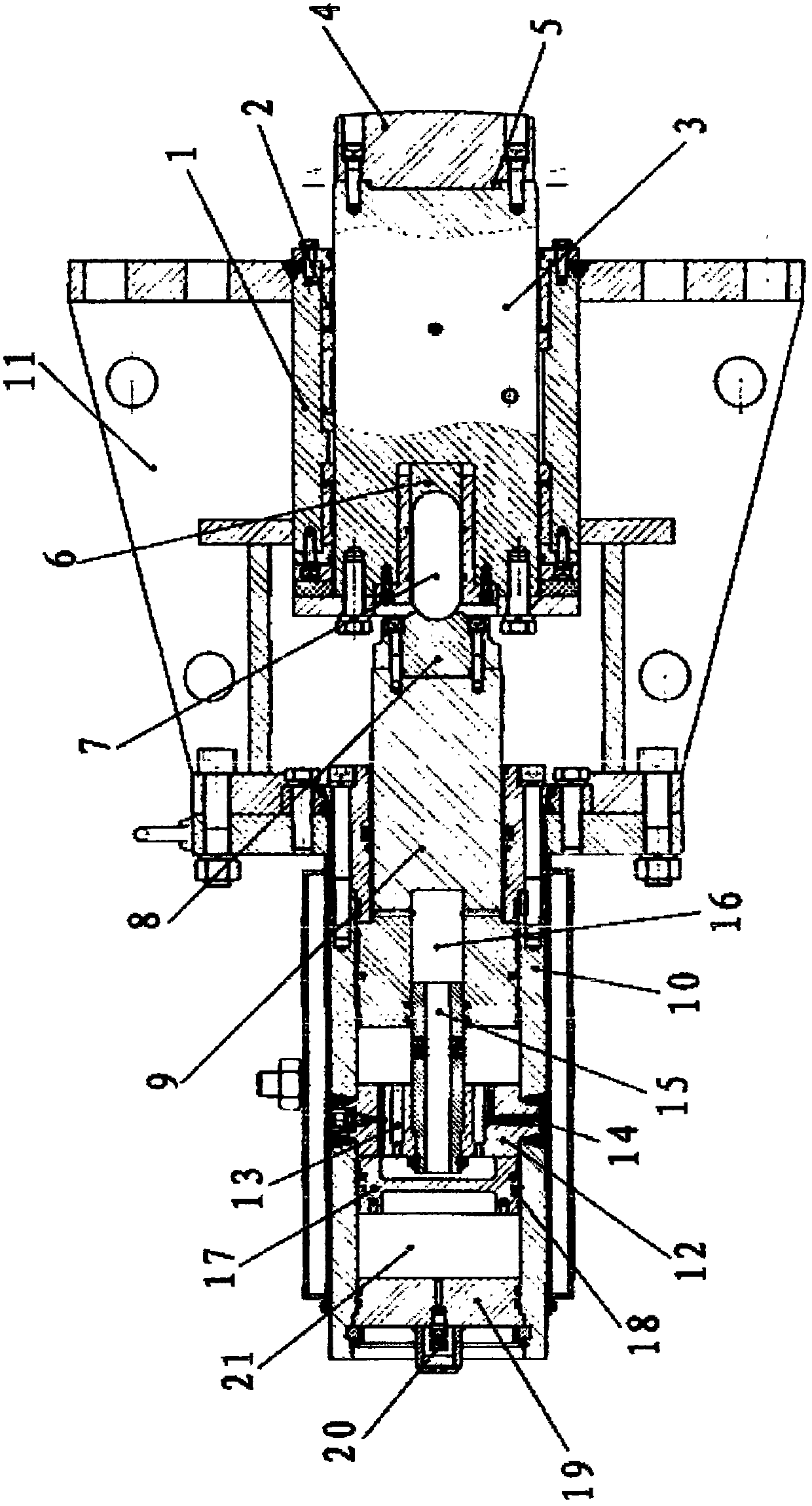

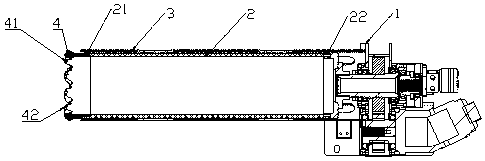

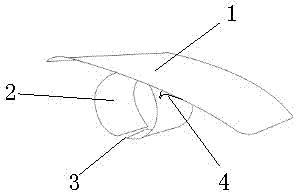

Quartz plate outer circle polishing machine

ActiveCN106166694AAvoid destructionLower bounce heightGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

The invention relates to the technical field of outer circle polishing equipment, in particular to a quartz plate outer circle polishing machine. The quartz plate outer circle polishing machine comprises a clamping device, a polishing device and a positioning device; the clamping device comprises clamping discs and a clamping base, the clamping base is arranged on the positioning device, and the clamping discs are rotationally mounted on the clamping base; the clamping discs comprise the driving clamping disc and the driven clamping disc, the driven clamping disc and the driving clamping disc synchronously rotate through a synchronizer, the rotating direction of the clamping discs is identical to that of a grinding wheel, and the clamping discs carry out intermittent rotation. An inclined angle of 45 degrees to 60 degrees is formed between the connecting line between the rotating centers of the clamping discs and the rotating center of the grinding wheel and the horizontal plane. According to the quartz plate outer circle polishing machine, the rebounding height of grindings entering a collecting box relative to the bottom of the collecting box can be effectively reduced, the sputtering preventing effect is good, the clamping discs carry out intermittent rotation, sufficient polishing time can be provided, the polishing effect is good, a quartz plate is firmly clamped, and the surface of the quartz plate is protected against abrasion.

Owner:HUZHOU OPAL QUARTZ TECH

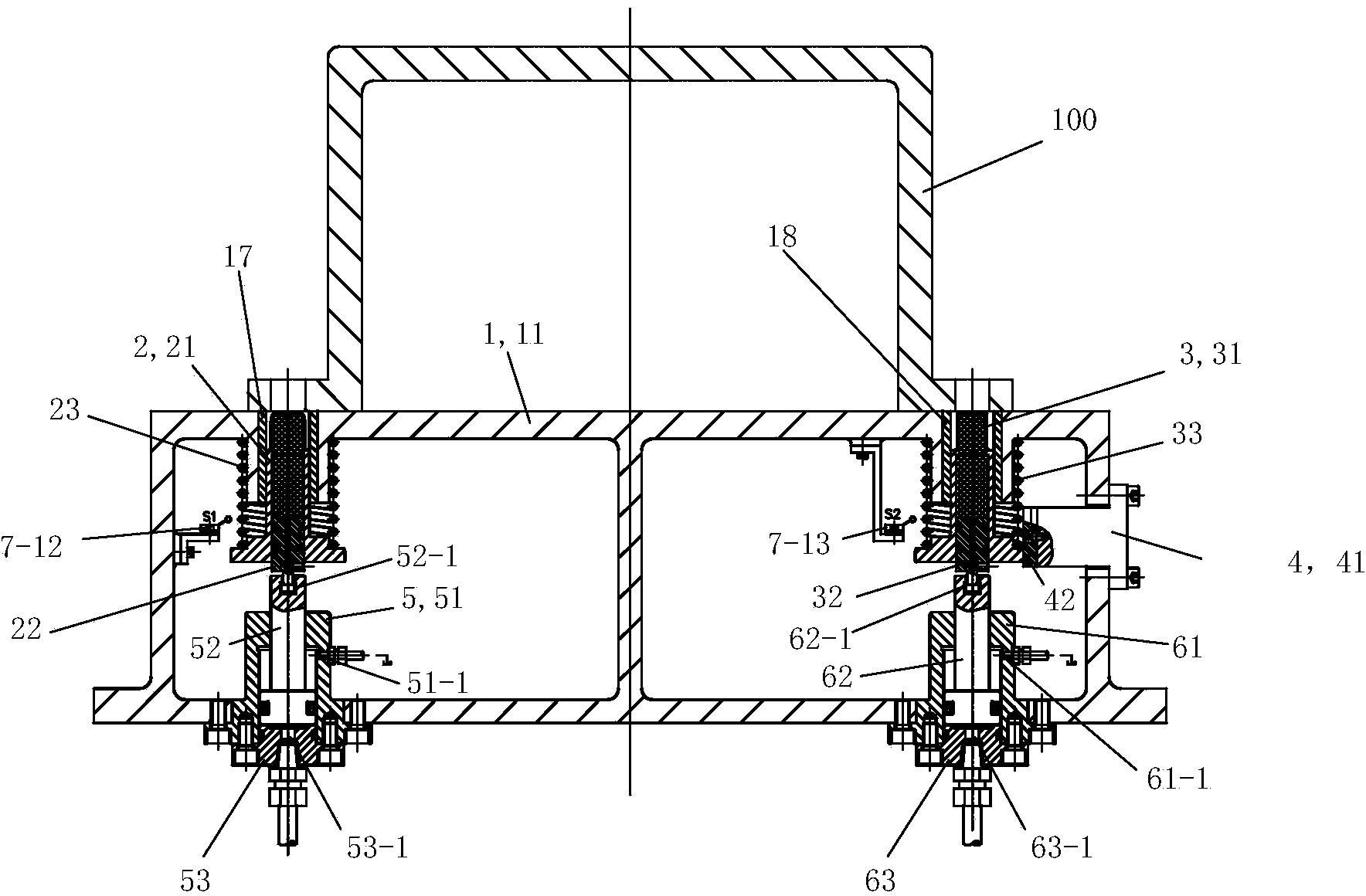

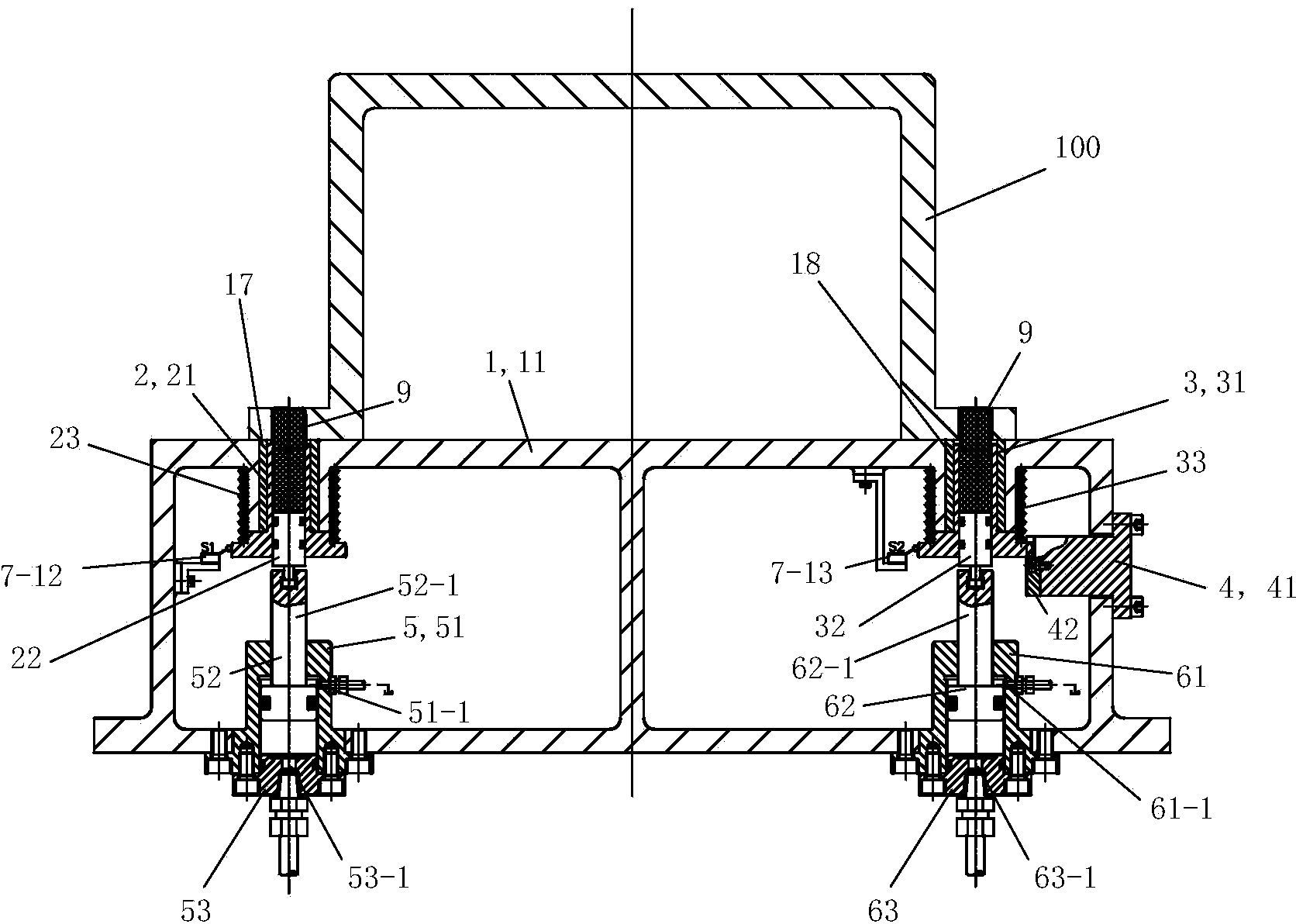

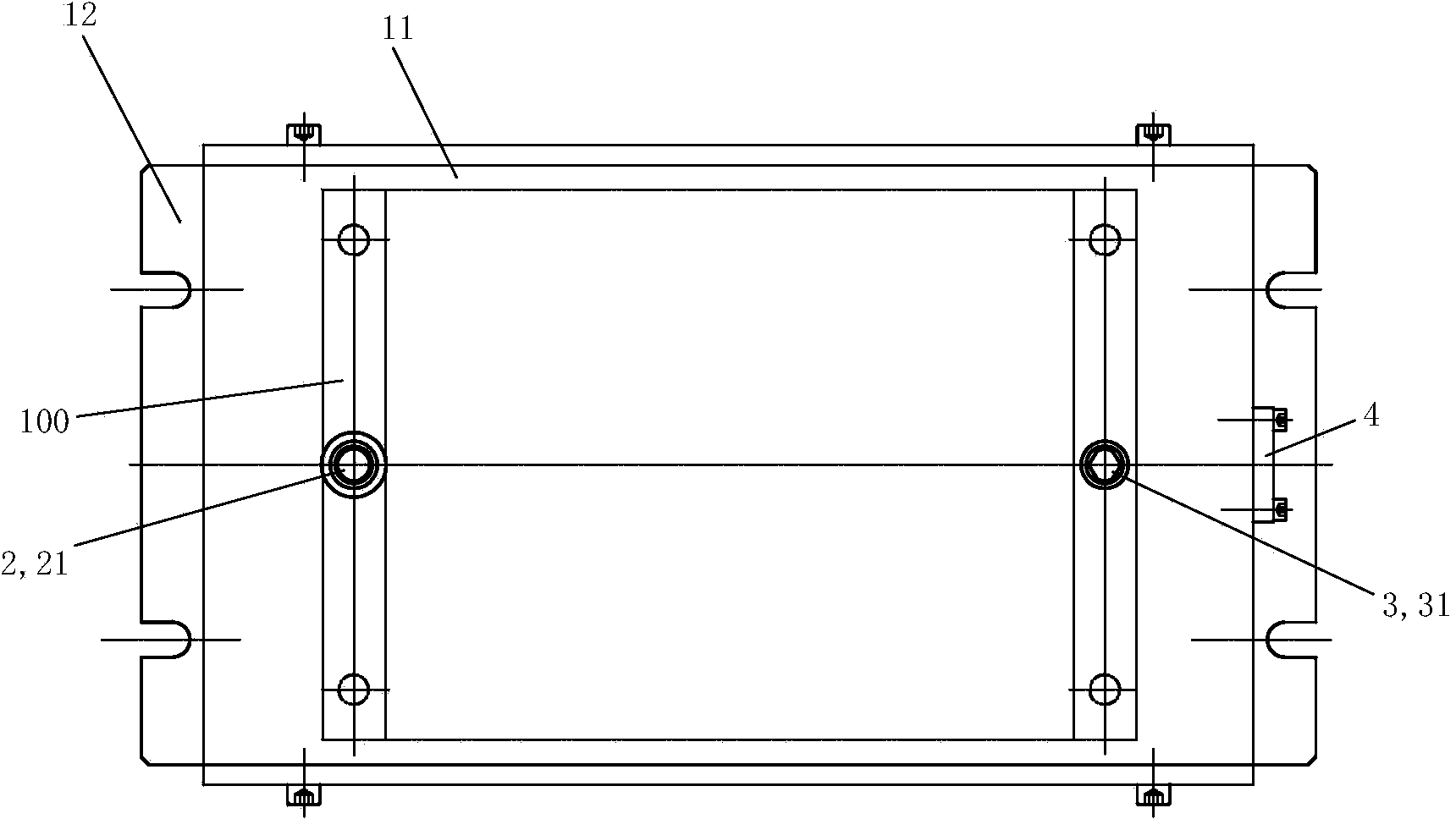

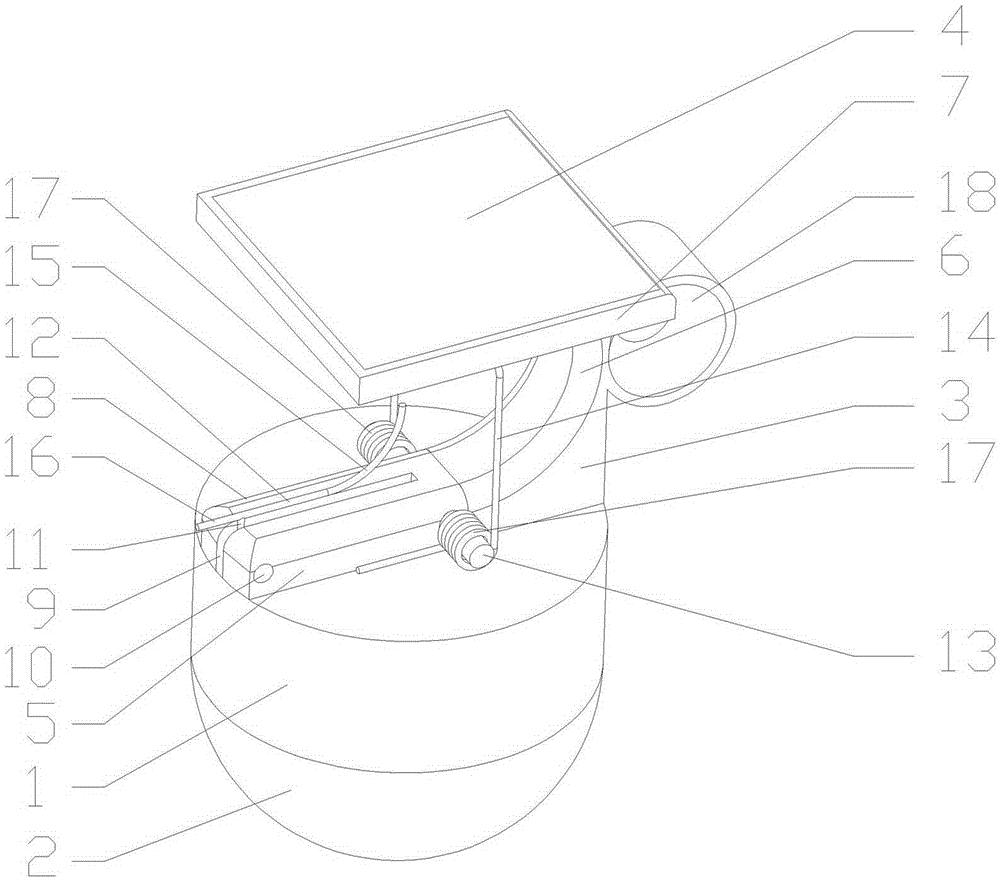

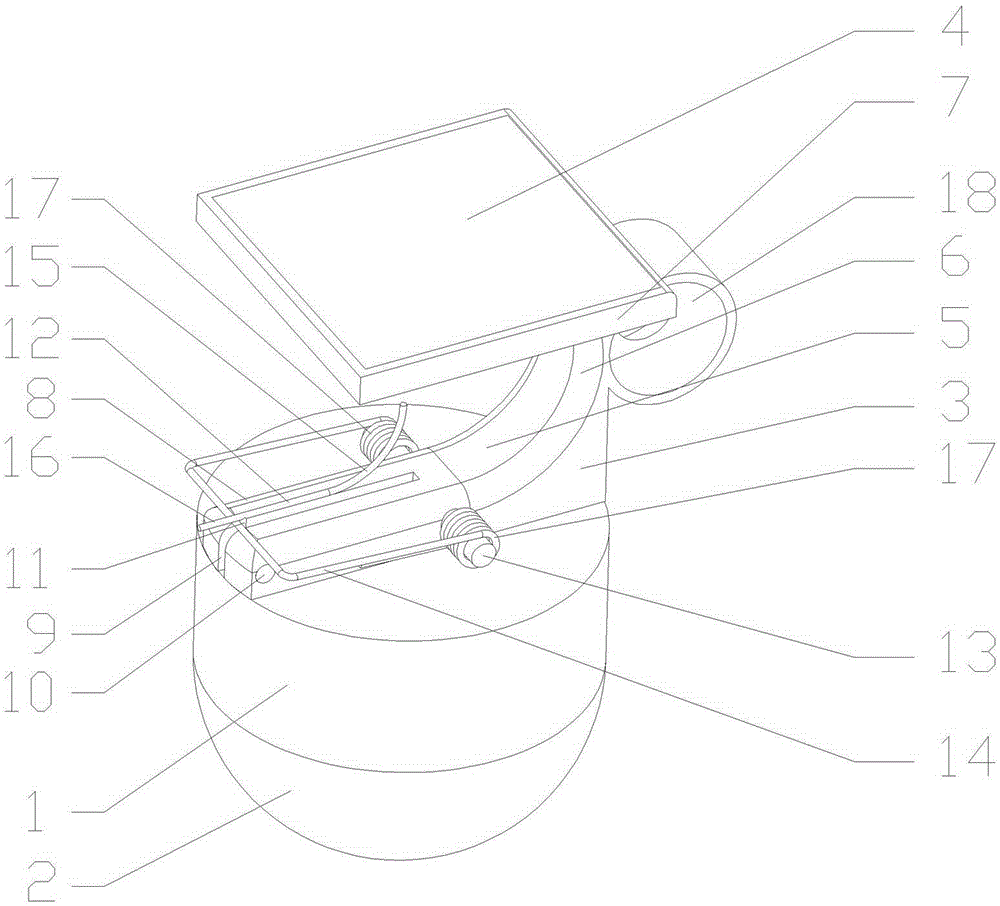

One-face two-pin precise positioning system and control method thereof

InactiveCN103962868AHigh positioning accuracySimple structureWork clamping meansPositioning apparatusControl systemEngineering

The invention discloses a one-face two-pin precise positioning system. The one-face two-pin precise positioning system is characterized by comprising a worktable, a round pin positioning device, a diamond pin positioning device and a control system; the control system comprises a first power device and a second power device, the first power drive drives a first plunger to move in a plunger hole of a round pin, the round pin is driven to move upwards by upwards extruding hydraulic plastics, the positioning portion of the round pin is inserted into a corresponding positioning hole of a workpiece, the positioning portion of the round pin generates corresponding plastic deformation and expands, and the gap between the round pin and the corresponding positioning hole in the workpiece is reduced. The second power device drives a second plunger to move in a plunger hole of a diamond pin, the diamond pin is driven to move upwards by upwards extruding the hydraulic plastics, the positioning portion of the diamond pin is inserted into a corresponding positioning hole of the workpiece, the positioning portion of the diamond pin generates corresponding plastic deformation and expands, and the gap between the diamond pin and the corresponding positioning hole in the workpiece is reduced.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

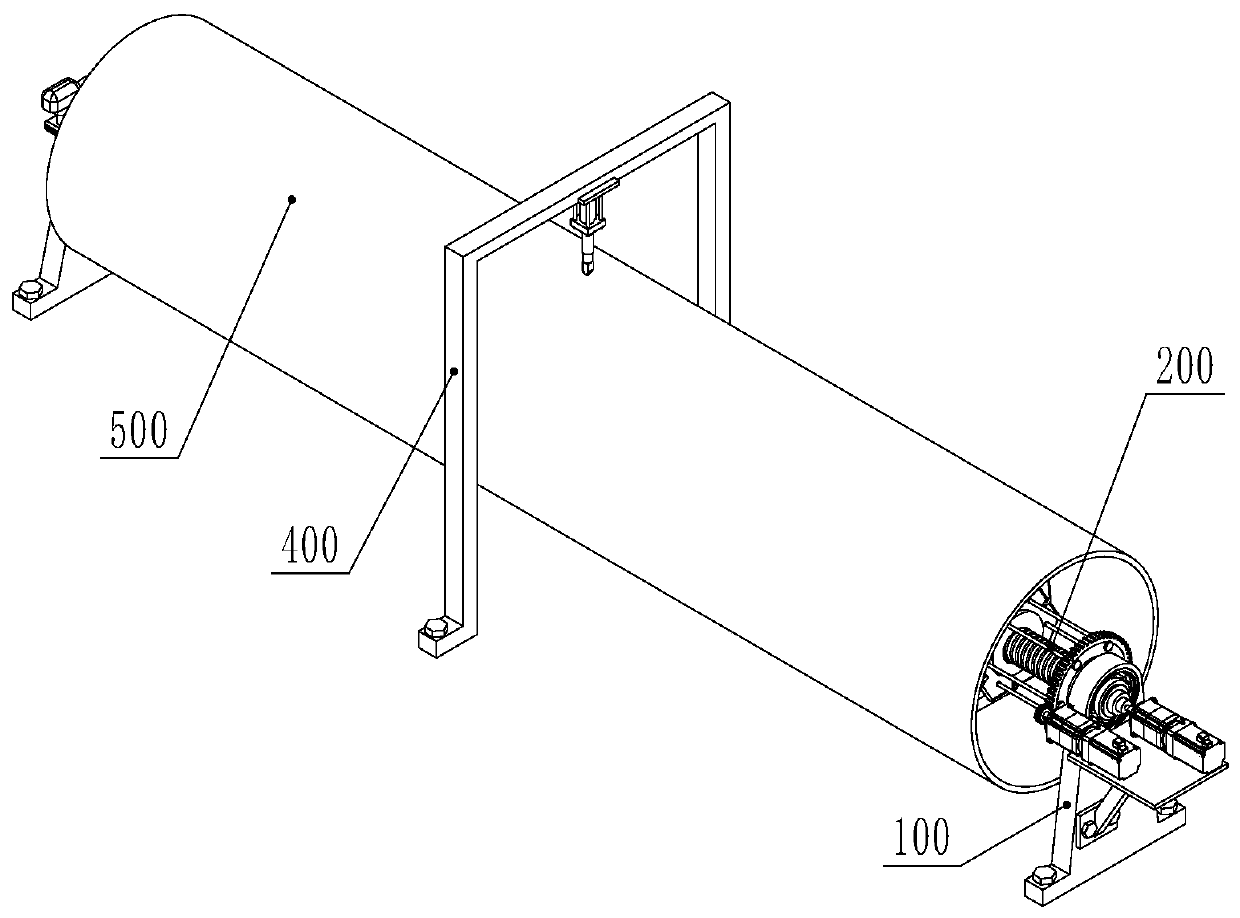

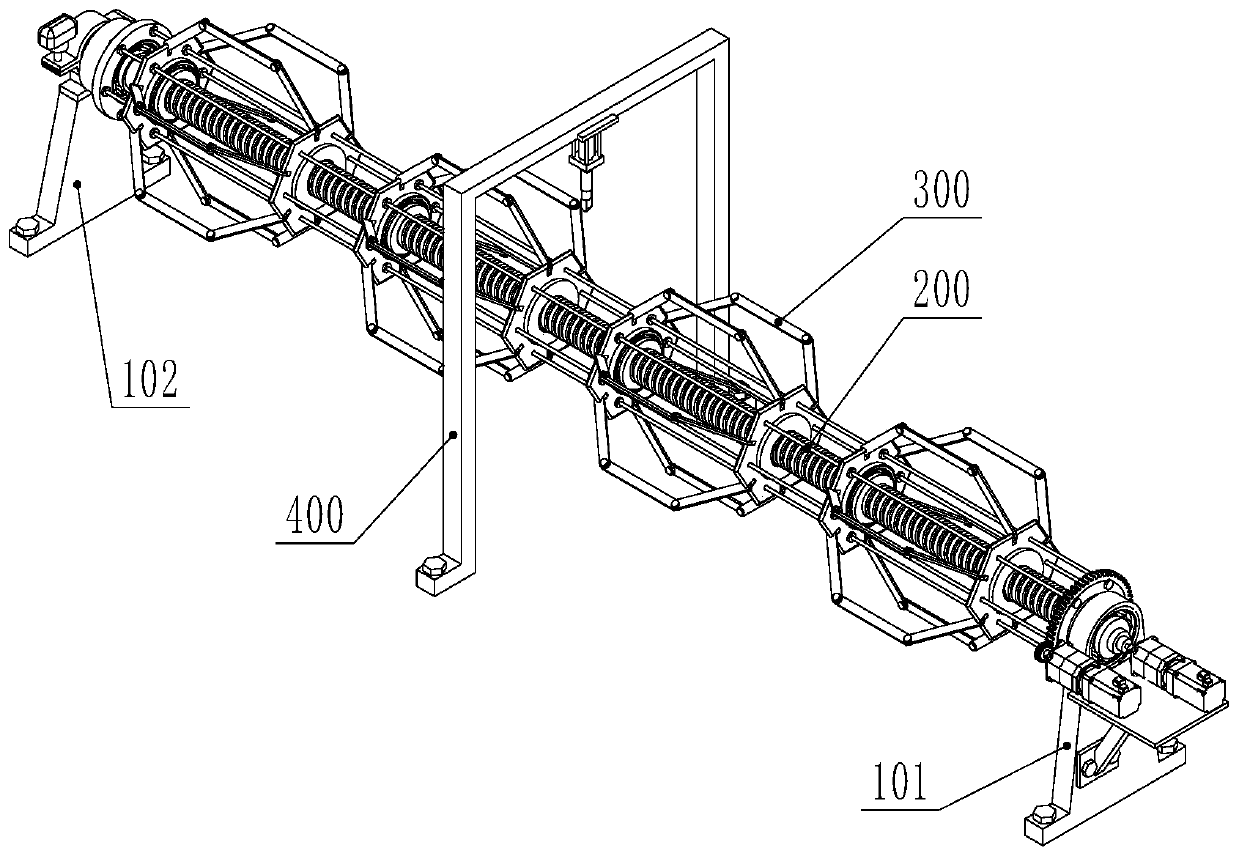

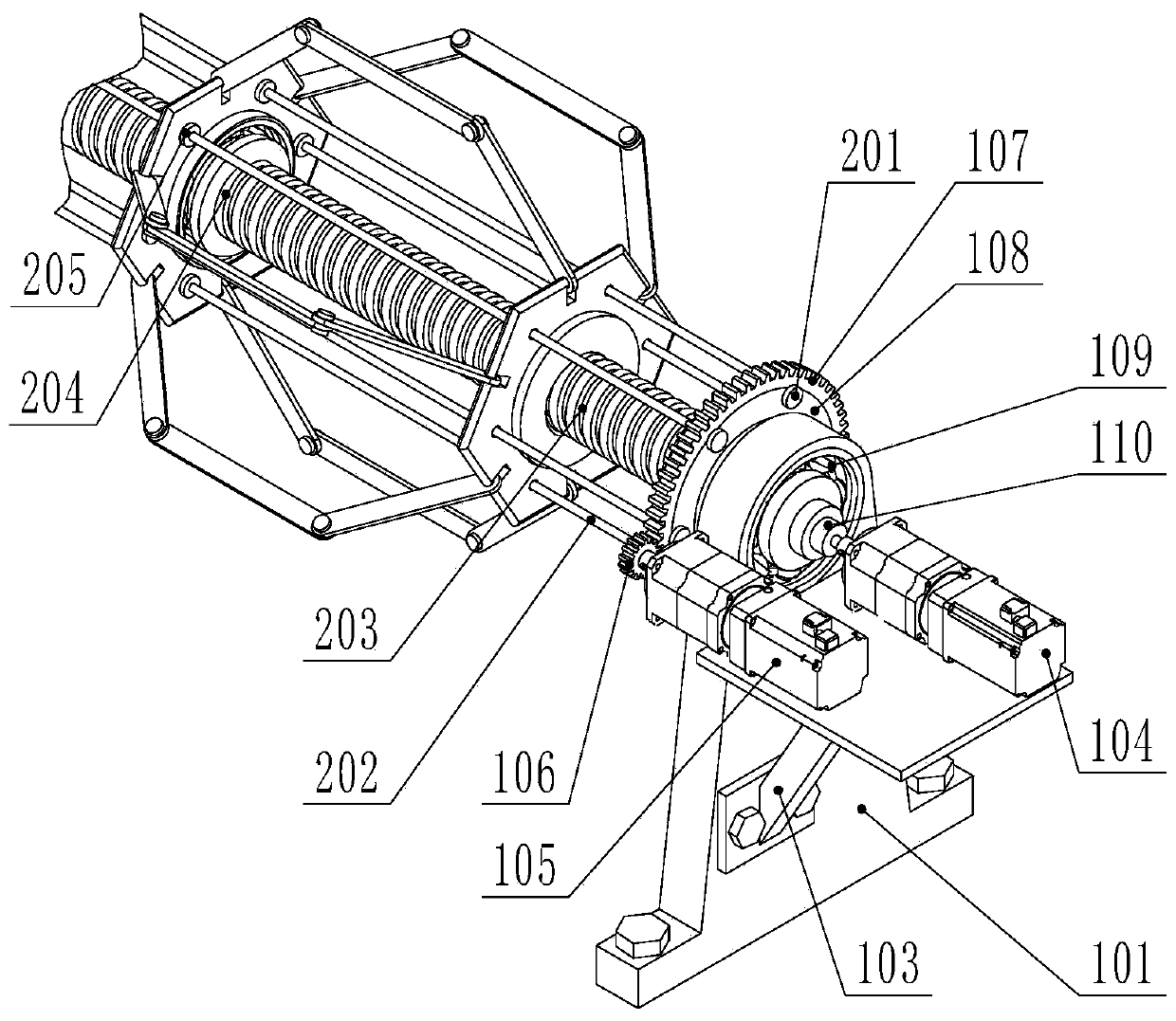

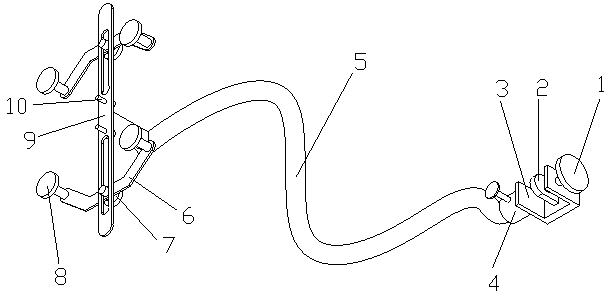

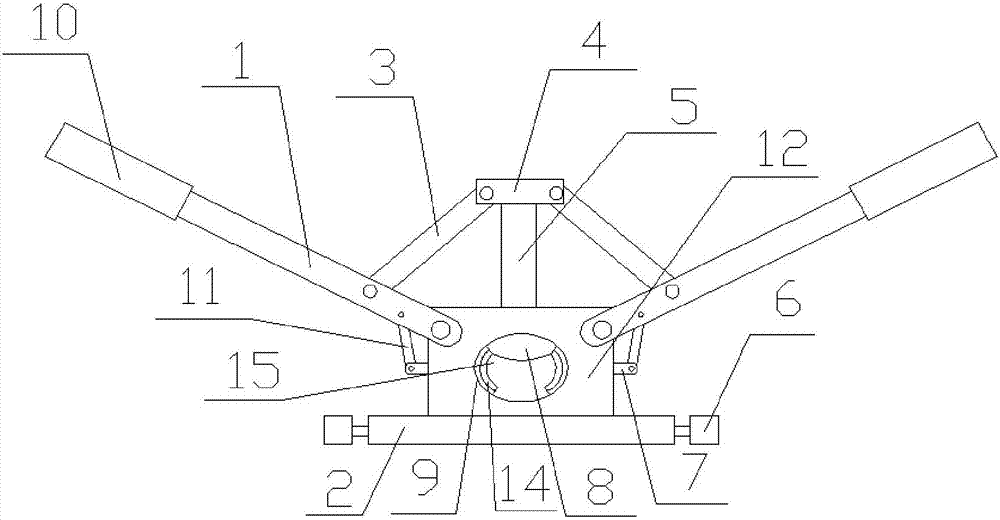

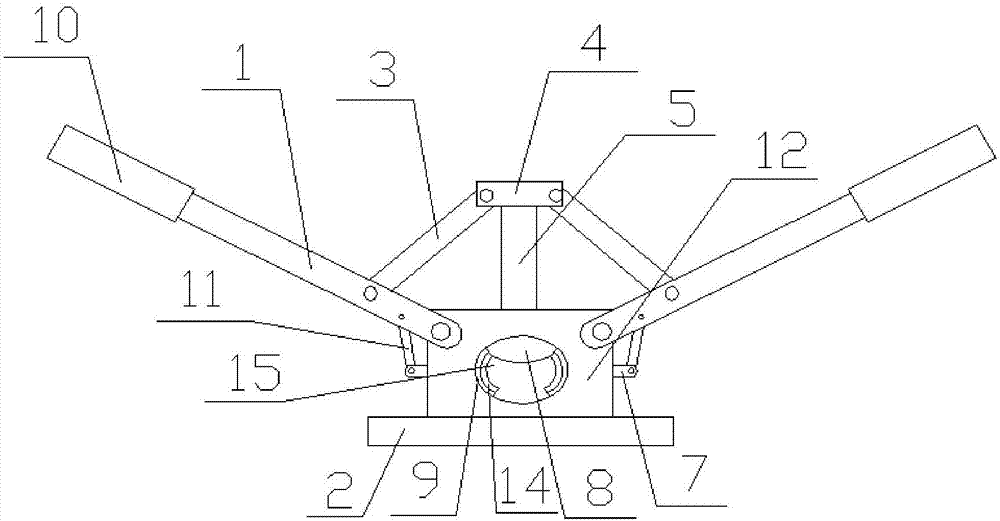

Lead screw clamping type metal hard tube rotary cutter

The invention provides a lead screw clamping type metal hard tube rotary cutter comprising a supporting device, a lead screw device, at least two expanding devices and a cutting device. The supportingdevice is located at the front and back ends of the whole cutter and fixedly connected with the ground. The front and back ends of the lead screw device are erected on the supporting device and can rotate relative to the supporting device. The expanding devices are both arranged on the lead screw device in a sleeving manner and connected with the lead screw device through threads. The expanding devices are sleeved with a to-be-cut metal hard tube. The cutting device is arranged between the two adjacent expanding devices. The supporting device is provided with an early operation motor and a later operation motor. The two motors can control the lead screw and the expanding devices to rotate correspondingly. The cutter is provided with multiple connection rod structures adopting expanding connection rods and front and back rockers to clamp the metal hard tube, a longer contact area is obtained in the length direction of the metal hard tube, and therefore the lead screw clamping type metal hard tube rotary cutter is suitable for to-be-cut metal hard tubes of different lengths, guarantees reliable clamping and avoids deformation.

Owner:HEBEI UNIV OF TECH

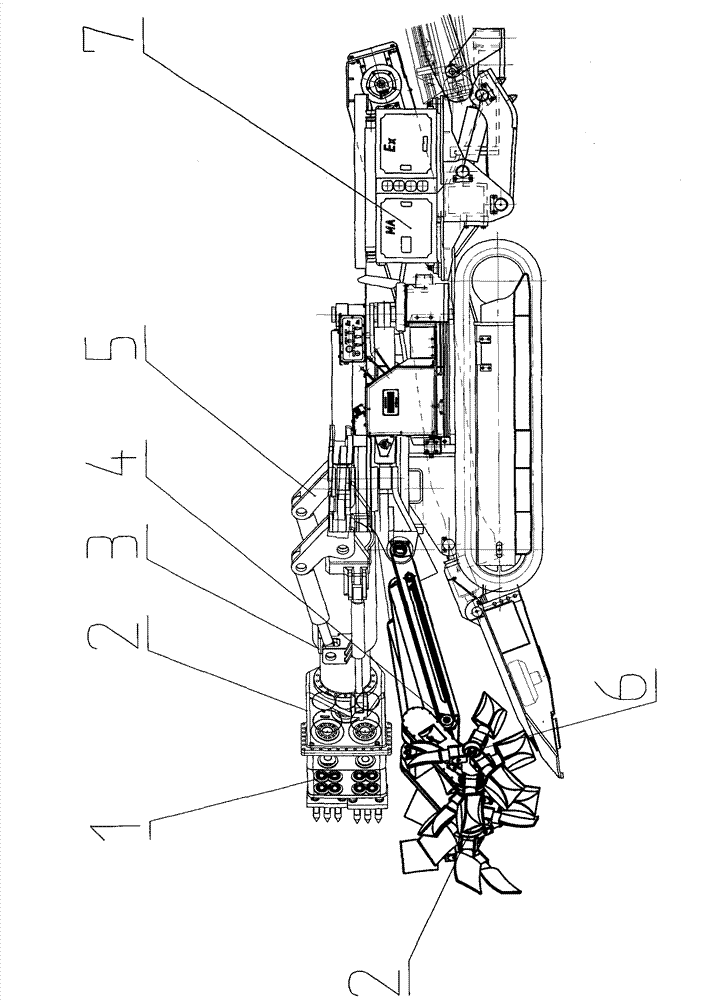

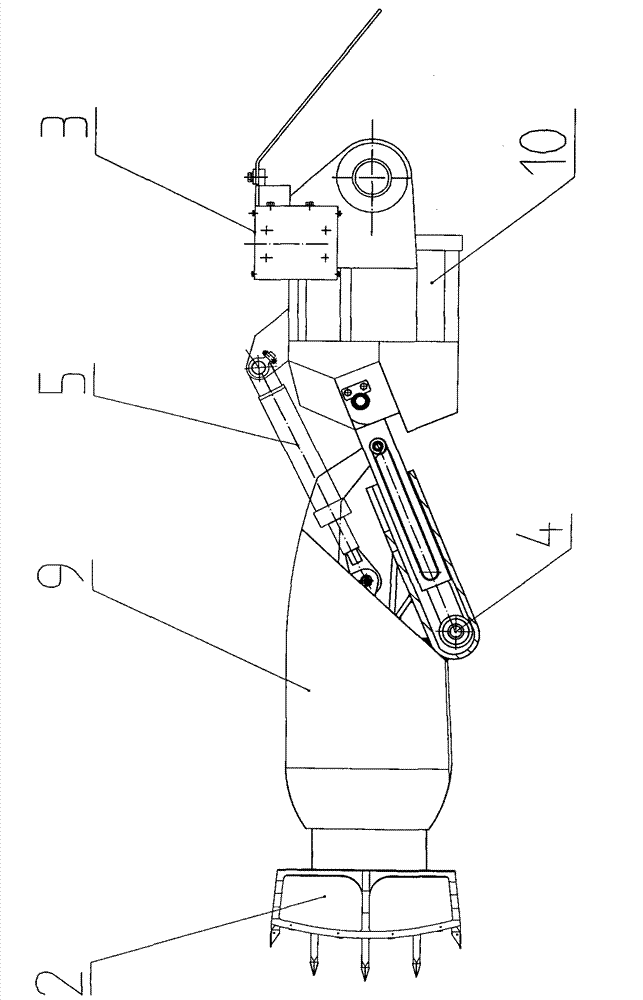

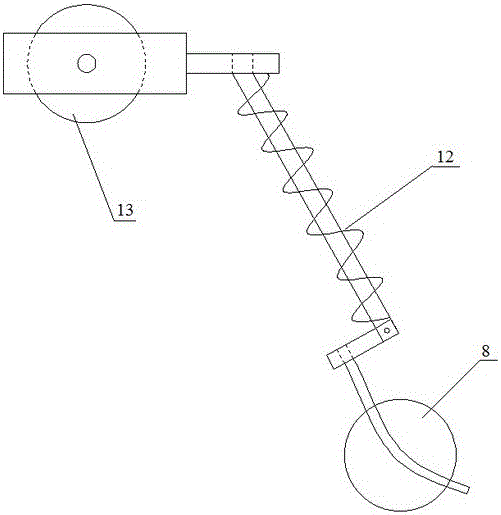

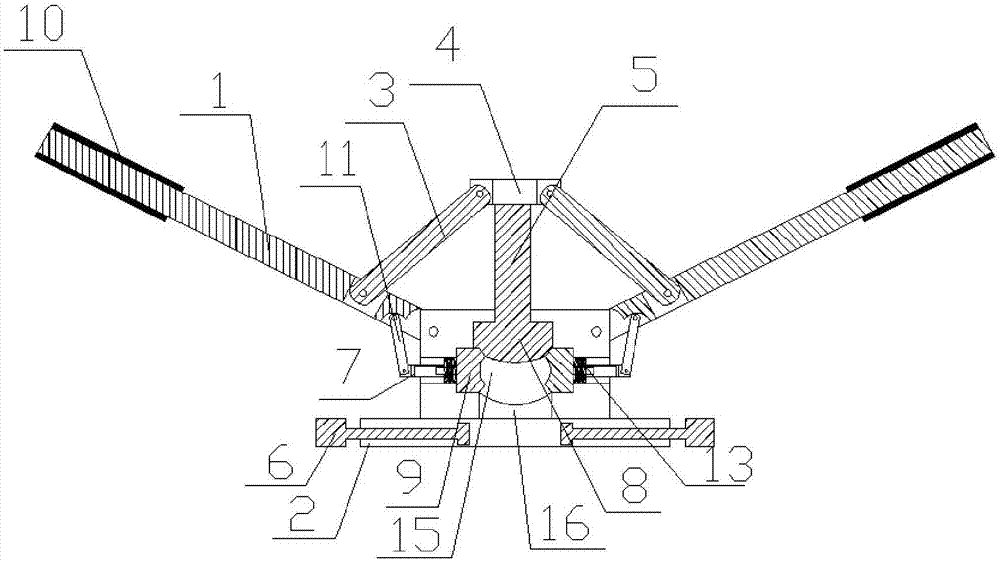

Method for rolling friction stretching and retracting of rocker and rolling friction stretching and retracting digger or loader of rocker

ActiveCN103835325AIncrease flexibilityReduce frictional resistanceMechanical machines/dredgersDriving meansRolling resistanceEngineering

The invention belongs to the field of digging, loading and the like, and particularly relates to a method for rolling friction stretching and retracting of a rocker and a rolling friction stretching and retracting digger or loader of the rocker. The rolling friction stretching and retracting digger or loader of the rocker comprises the rocker, a machine body, a rolling body, a stretching and retracting control part, a working head, a driving mechanism of the working head and the like, wherein the rocker comprises a stretching and retracting arm, a supporting arm for stretching and retracting and the like, the rolling body is arranged between the stretching and retracting arm and the supporting arm for stretching and retracting, one end of the stretching and retracting control part is connected with the machine body, the other end of the stretching and retracting control part is connected with the stretching and retracting arm, the rocker is connected with the machine body, the stretching and retracting control part controls the stretching and retracting arm to stretch and retract, the stretching and retracting arm moves in a rolling friction mode through the rolling body, the working head is arranged on the stretching and retracting arm, the driving mechanism of the working head drives the working head to perform digging or loading, the machine body comprises a walking mechanism, and the walking machine drives the whole machine to walk.

Owner:刘素华

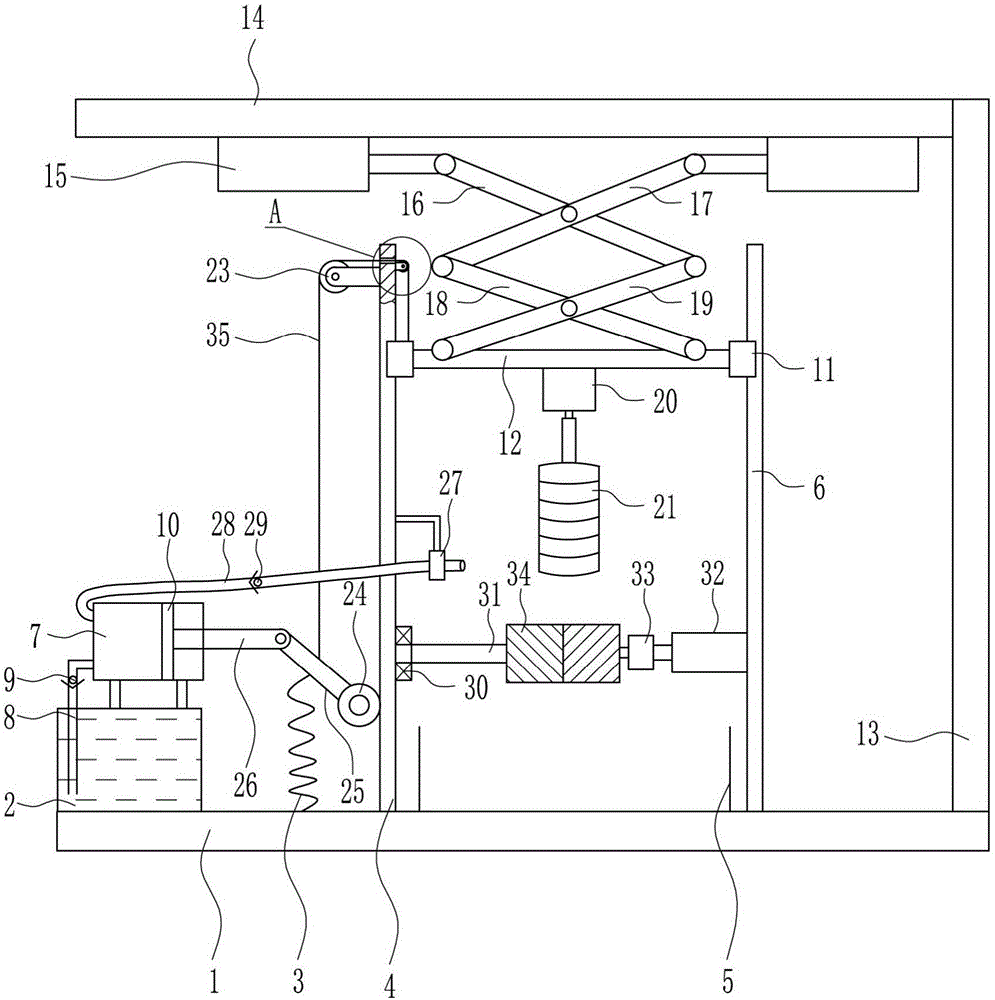

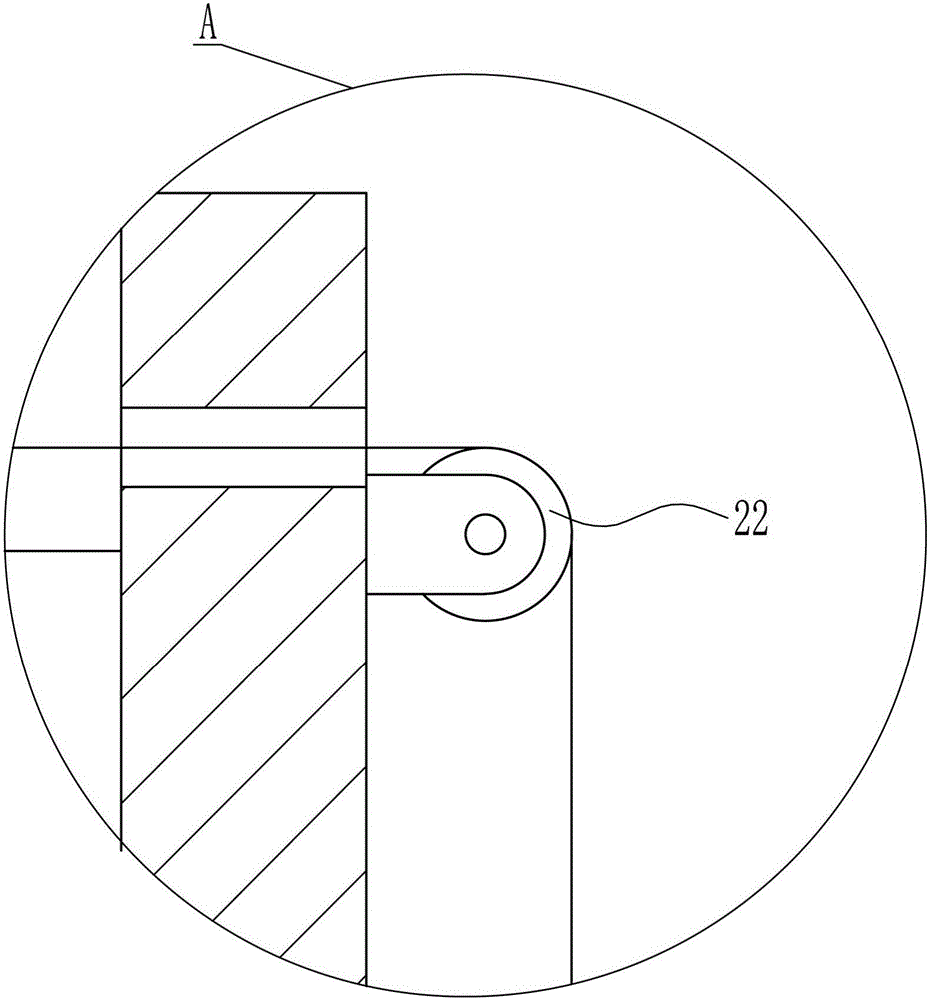

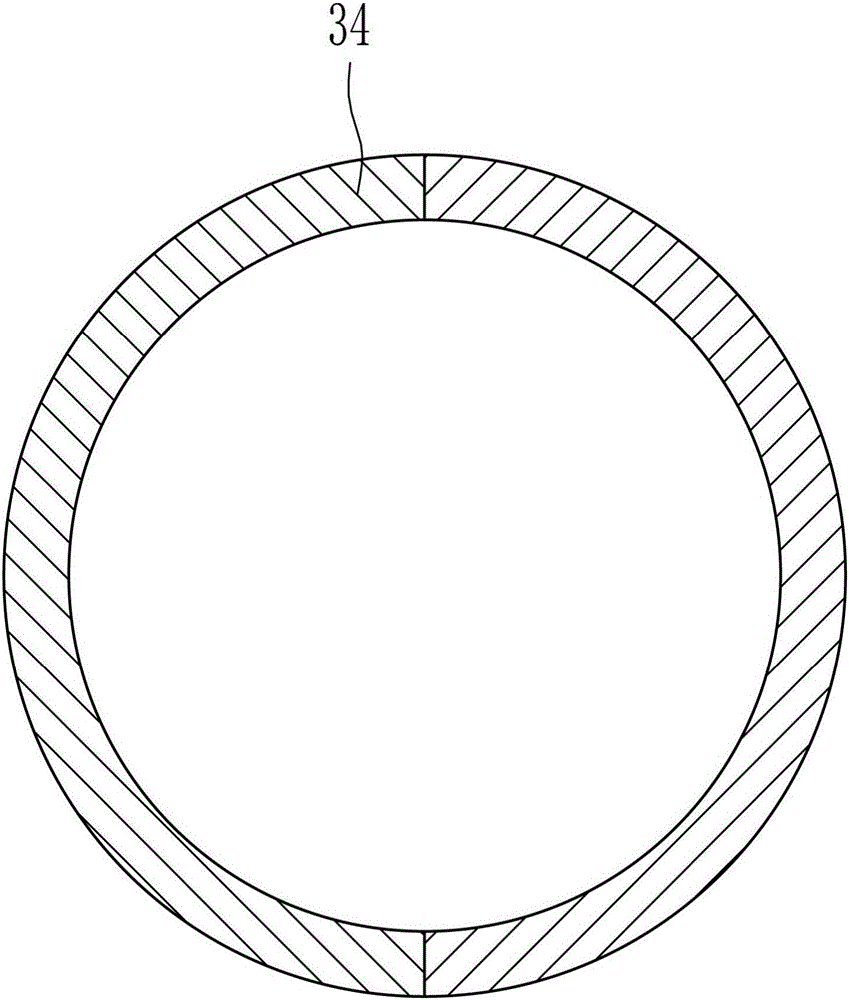

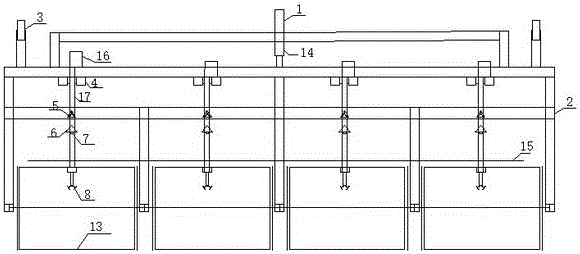

Cleaning device for chemical experiment container of senior middle school

ActiveCN106311695ASoft textureIncrease coefficient of frictionHollow article cleaningWater dischargeEngineering

The invention relates to a stationary cleaning device, in particular to a cleaning device for a chemical experiment container of a senior middle school and aims at solving the technical problems and providing a cleaning device for a chemical experiment container of a senior middle school. The cleaning device saves time and labor, is low in labor intensity, good in cleaning effect, simple to operate, can conduct unified cleaning water discharge and protects the environment. For solving the technical problems, the cleaning device for the chemical experiment container of the senior middle school comprises a base plate, a water tank, an elastic part, a first sliding rail, a water collecting basket, a second sliding rail, a compression cylinder, a first water pipe, a first one-way valve, a piston, a sliding block, a transverse plate and the like. The water tank, the elastic part, the first sliding rail, the water collecting basket, the second sliding rail and the support are sequentially arranged at the top of the base plate from left to right, and the water tank, the first sliding rail, the second sliding rail and the support are connected with the base plate in a welded mode. The cleaning device is used for the chemical experiment container of the senior middle school.

Owner:江苏易歌德科技有限公司

Method and equipment for simultaneously crushing and grinding ores

The invention discloses a method and equipment for simultaneously crushing and grinding ores. The method includes overlaying an upper arc-shaped grinding face on a lower arc-shaped grinding face, forming spatial regions which are gradually diminished from top to bottom between the inner surface of the upper arc-shaped grinding face and the outer surface of the lower arc-shaped grinding face, dividing the spatial regions into crushing regions and grinding regions from top to bottom, respectively arranging cutting teeth and fixing teeth on the inner surface of the upper arc-shaped grinding face and the outer surface of the lower arc-shaped grinding face in the crushing regions and arranging smooth arc faces on the outer surfaces of the upper arc-shaped grinding face and the lower arc-shaped grinding face in the grinding regions; enabling the upper arc-shaped grinding face and the lower arc-shaped grinding face to rotate relatively, feeding the ores into the crushing regions from a feed inlet in the top of the upper arc-shaped grinding face, fixing the ores by the aid of the fixing teeth, crushing the ores by the cutting teeth, enabling the crushed ores to fall into the grinding regions, grinding the ores by the smooth arc faces and enabling grains of the ores to fall via gaps at the lower ends of the upper arc-shaped grinding face and the lower arc-shaped grinding face. The method and the equipment have the advantages that the traditional crushers and ore grinding machines can be replaced, the ores can be crushed at first and then can be ground and integrally manufactured, and the equipment is high in crushing ratio.

Owner:CHINA UNIV OF MINING & TECH

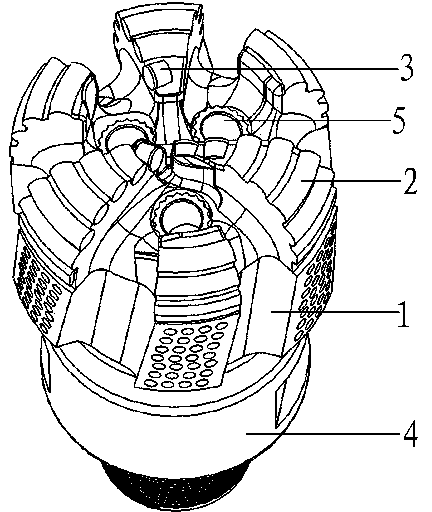

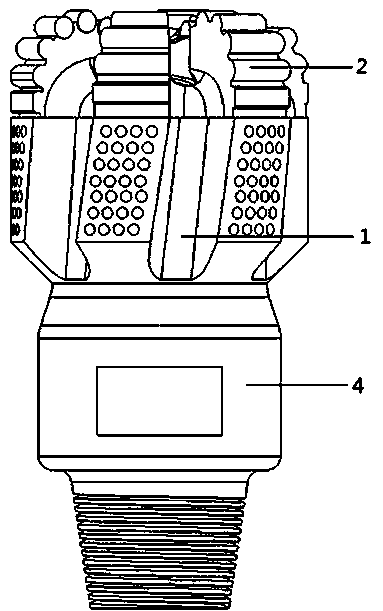

Diamond-impregnated bit of arc tooth

InactiveCN103758463AIncrease contact areaIncrease ROPDrill bitsConstructionsChemistryComposite material

The invention discloses a diamond-impregnated bit of an arc tooth and belongs to the technical field of bits for drilling. The diamond-impregnated bit of the arc tooth comprises a connector and a bit body connected to the connector. The arc diamond-impregnated tooth is horizontally arranged in a crown zone on the bit body, the arc diamond-impregnated tooth covers a crown contour line of the bit body, and a PDC composite piece is arranged in a heart zone on the bit body. According to the diamond-impregnated bit of the arc tooth, the arc diamond-impregnated tooth is used, the bit and the tooth carry out rotating drilling to form circular well bottom matching, the contact area between the impregnated tooth and a well bottom rock is increased, accordingly, the mechanical drilling speed of well drilling is improved, the diamond-impregnated tooth is arranged on the surface of the bit body so that the bit body cannot be in contact with the well bottom rock, accordingly, the bit body cannot be abraded by the rock, rock breaking efficiency is improved, and the service life of the bit is prolonged.

Owner:SICHUAN WANJI DIAMOND DRILL

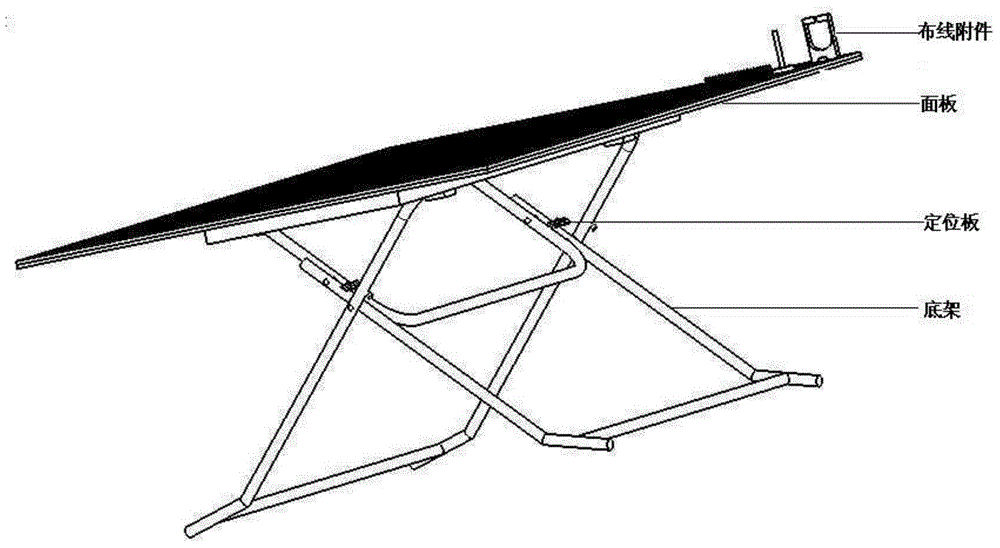

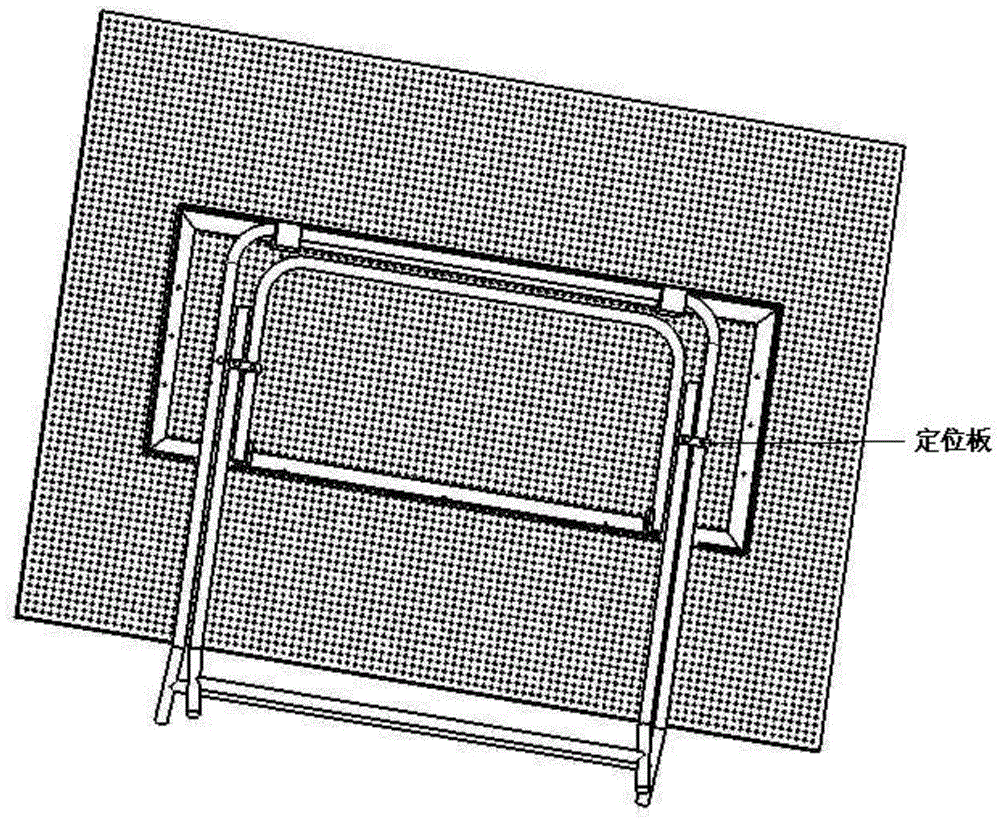

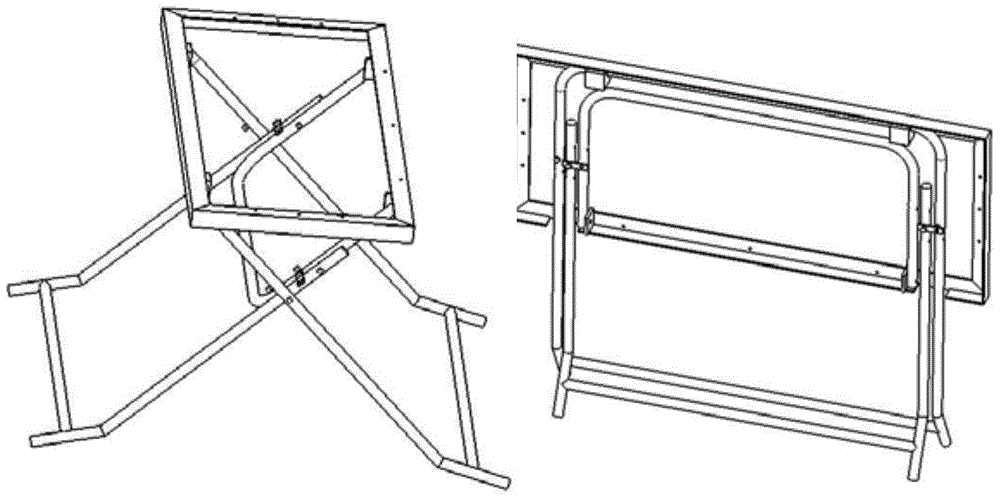

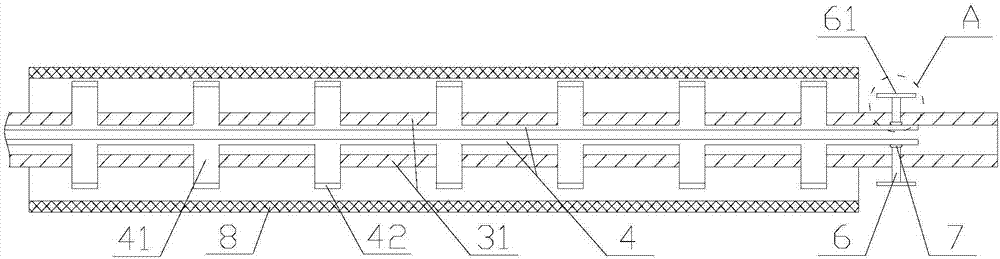

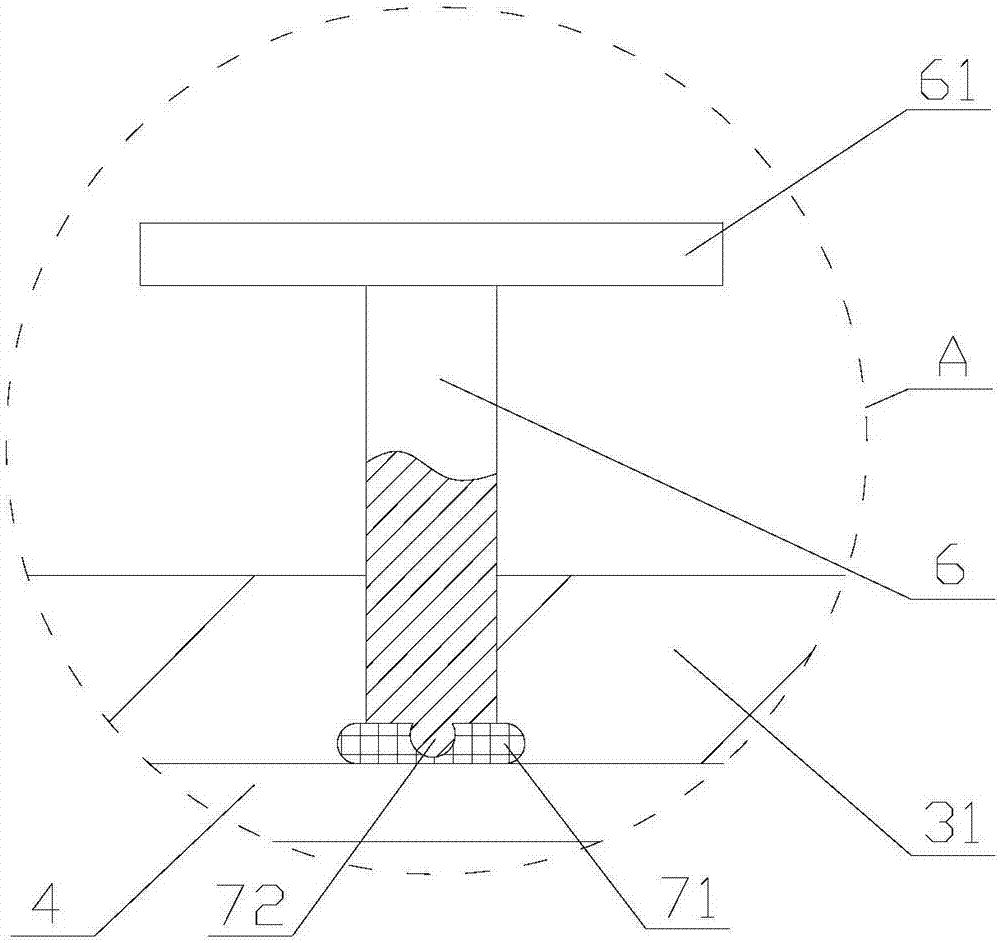

Pre-wiring template

InactiveCN104540367ANot to be wornEasy to installCircuit arrangements on support structuresEngineeringSmall hole

The invention relates to a pre-wiring template. According to the pre-wiring template, a four-connecting-shaft support is designed, and a panel of the template can freely erected or horizontally placed; the panel of the template is composed of two transparent glass steel plates, a plastic spraying drawing of the template can be clamped between the two transparent glass steel plates, it is ensured that the plastic spraying drawing is not abraded, even small holes are distributed in the glass steel plates, and therefore accessories can be conveniently mounted on the template. Three kinds of wiring accessories are selected, the wiring quality is improved, the pre-wiring working procedure is more flexible and convenient, the working efficiency is improved, waste is reduced, and the production cost is reduced.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Sealed ground beam

InactiveCN103114795ANot to be wornReduced tightnessConstruction fastening devicesSealing arrangementsJet aeroplaneEngineering

The invention provides a sealed ground beam. The sealed ground beam is composed of a protective door, a manual gear rotating table, a rotating table fixed shaft, a cross rod with rotating teeth, horizontal fixed riveting grooves, transverse movable linking bars, reversing connecting bars, vertical movable linking bars, vertical fixed riveting grooves, latching bolts, a linkage cross rod with positioning bolts, an amplitude reduction chute with radian, a movable linking piece and a sealed ground beam body. According to the sealed ground beam, influences of the sealed ground beam body to a channel can be avoided, meanwhile, the ground beam body can be protected from being worn, sealing effects can be improved, and the protective door with the sealed ground beam body can be used for occasions where requirements on protection levels are high, such as headquarters, funk holes and airplane shelters in wars.

Owner:苏州市江诚人防设备有限公司

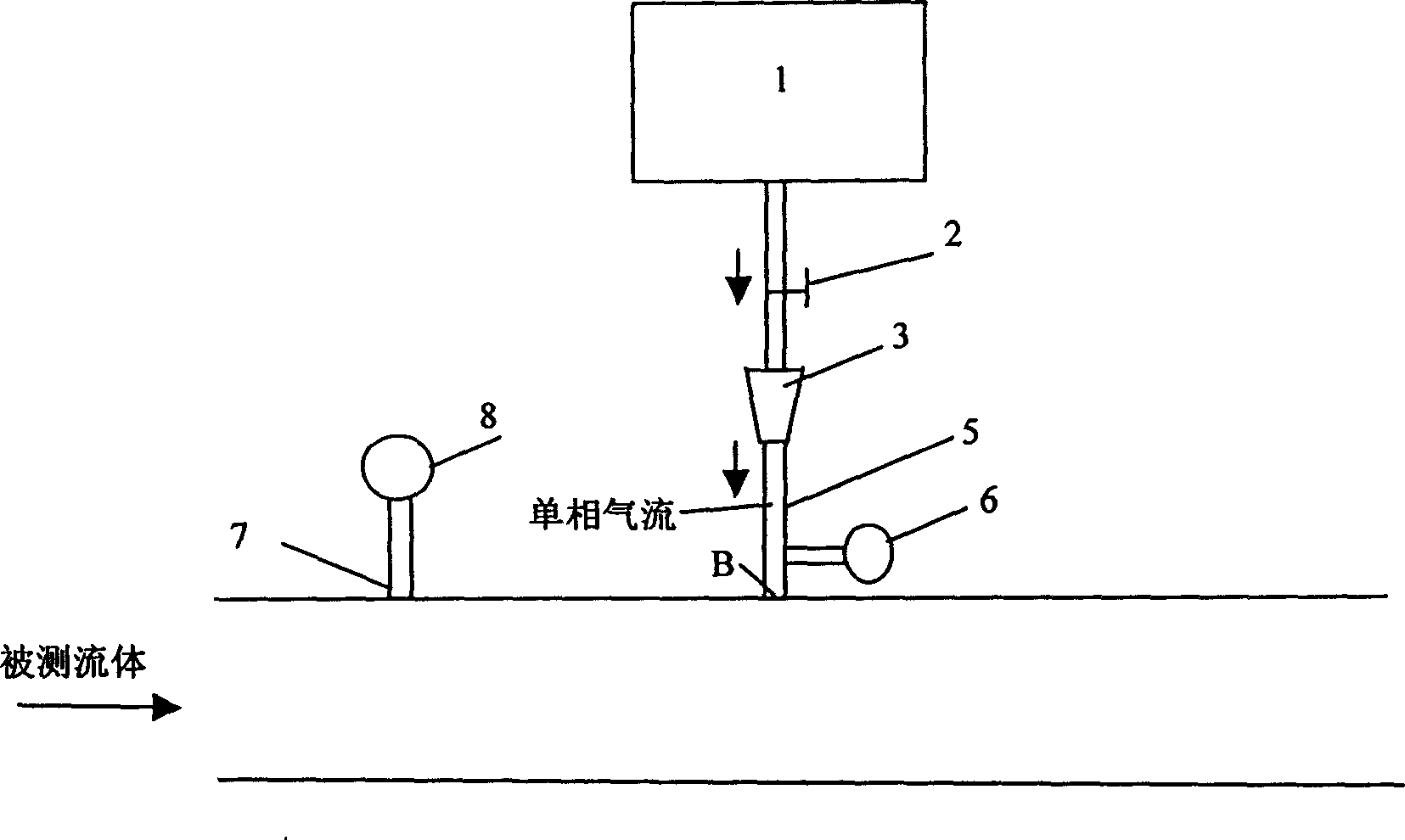

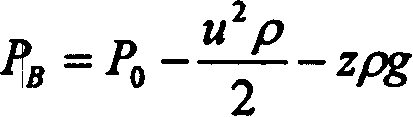

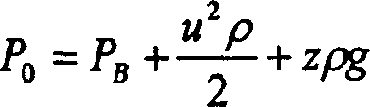

Method and device for measurnig multiple phase flow pressure

The invention which belongs to fluid measuring technical field, is concretely a method and device of measuring multi-phase fluid pressure. Its basic idea a strand single phase fluid(gas) is shot into fluid to be measured, whose pressure and flux are measured, then pressure of the fluid to be measured is acquired according to relationship of flux and pressure of liquid which is shot and pressure of the fluid to be successively connected and installed on pipeline of the fluid to be measured, it is also called gas sensor because of single phase gas used for delivering pressure, solving wear and blockage problem in surface - contact measurement and sensor needn't to have resistance to high and corrosion in measurement of high temperature medium or strong corrosive medium.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

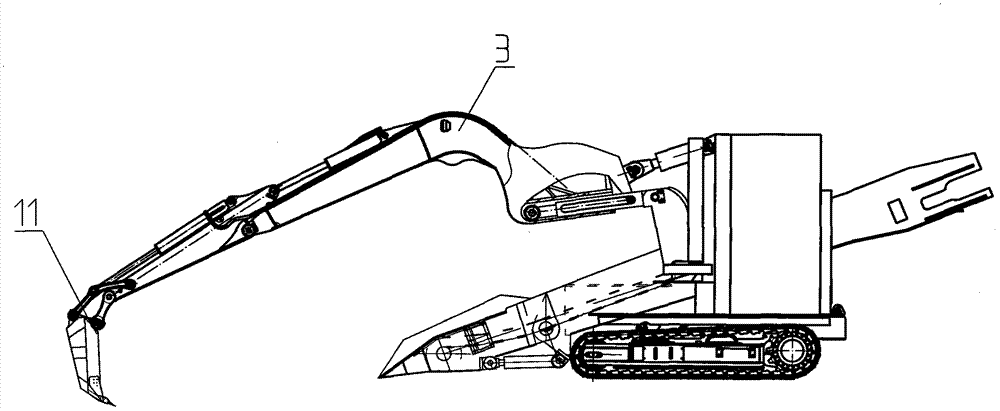

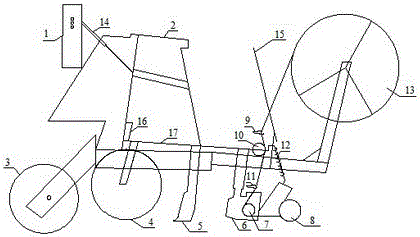

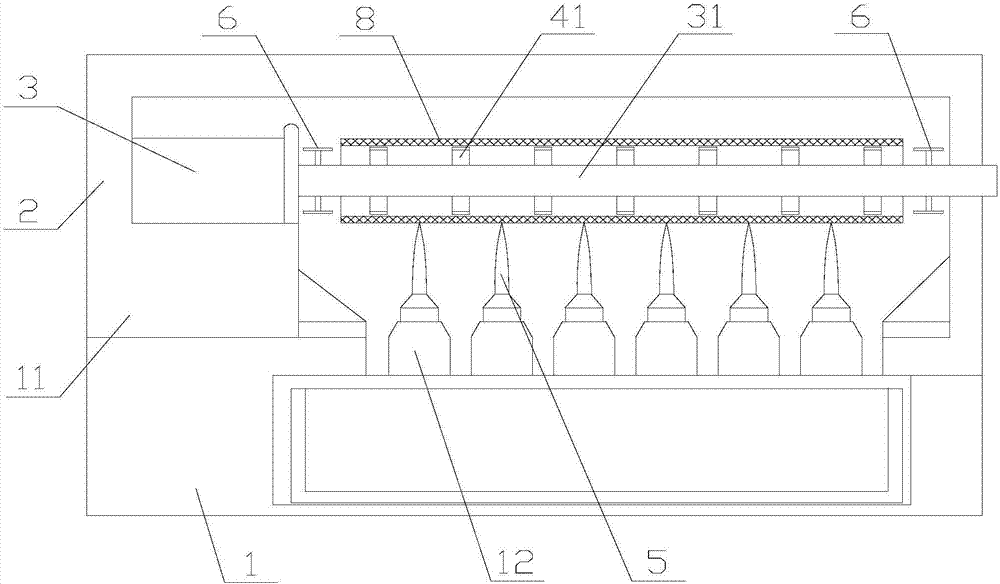

Hydraulic drip irrigation zone shallow-buried laying machinery

InactiveCN106069621AExtended duty cycleNot to be wornClimate change adaptationWatering devicesDrip irrigationAgricultural engineering

The invention belongs to agricultural mechanical equipment, and relates to hydraulic drip irrigation zone shallow-buried laying machinery. The hydraulic drip irrigation zone shallow-buried laying machinery comprises a furrowing device, a drip irrigation zone laying device, a covering device and a hydraulic device, wherein the furrowing device consists of a depth wheel, disc soil breaking wheels and a furrowing plough; the drip irrigation zone laying device consists of a drip irrigation zone suspension bracket, a positioning rod, a soil breaking plough, a guide wheel and a guide sleeve; the covering device consists of a control spring and a covering wheel; the hydraulic device consists of a hydraulic rod at a suspension connector and four hydraulic systems; each hydraulic system comprises a hydraulic tank, a hydraulic tube, a moving rack, a rotating shaft, a fixed shaft and the like; a main body structure of a structure rack comprises three cross beams; the first cross beam is provided with the suspension connector and the four hydraulic systems; the structure rack is connected with the suspension connector through the hydraulic rod; the second cross beam is successively provided with the four disc soil breaking wheels; and the third cross beam is provided with the furrowing plough and the drip irrigation zone laying device. The hydraulic drip irrigation zone shallow-buried laying machinery has the characteristics of simple structure, low manufacturing cost, high efficiency and the like.

Owner:新疆维吾尔自治区农牧区水利规划总站

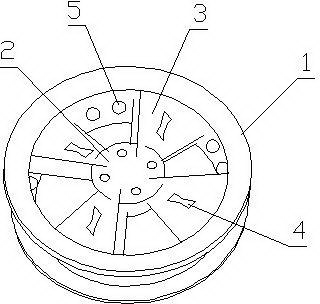

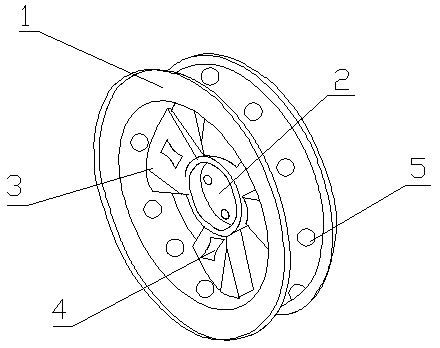

Novel automobile hub

InactiveCN104002611AImprove cooling effectExtended service lifeSpoked wheelsEngineeringMechanical engineering

The invention discloses a novel automobile hub which comprises a rim, an axle hub and spokes connected between the rim and the axle hub. Each spoke is in a fan shape, the width of the part, connected with the rim, of each spoke is larger than the width of the part, connected with the axle hub, of each spoke, the number of the spokes is 4 to 8, the spokes are evenly distributed in a radial shape in the outer circumference direction of the axle hub, the outer surface of each spoke inclines by 15-25 degrees relative to the side plane of the hub body, inwards-concave U-shaped blind grooves are formed in the middle portions of the outer surfaces of the spokes, and air holes penetrating through the rib are formed between every two spokes. The novel automobile hub is good in safety, simple in structure and high in heat dissipation.

Owner:CHONGQING HONGQI JIEXUN WHEEL

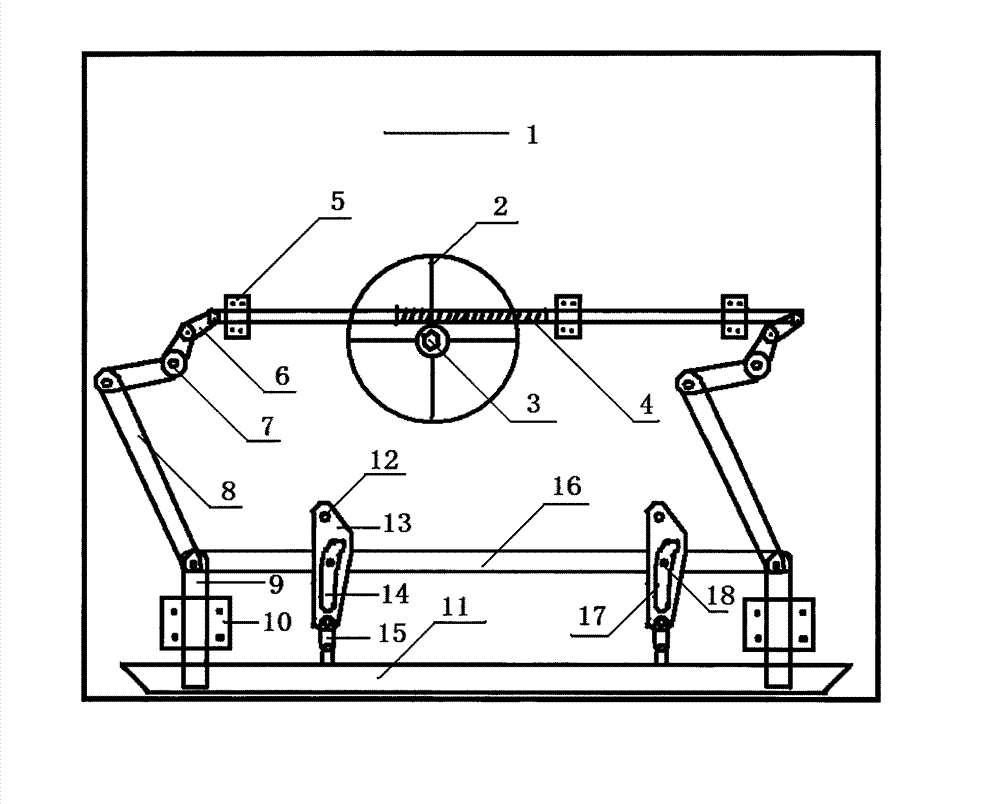

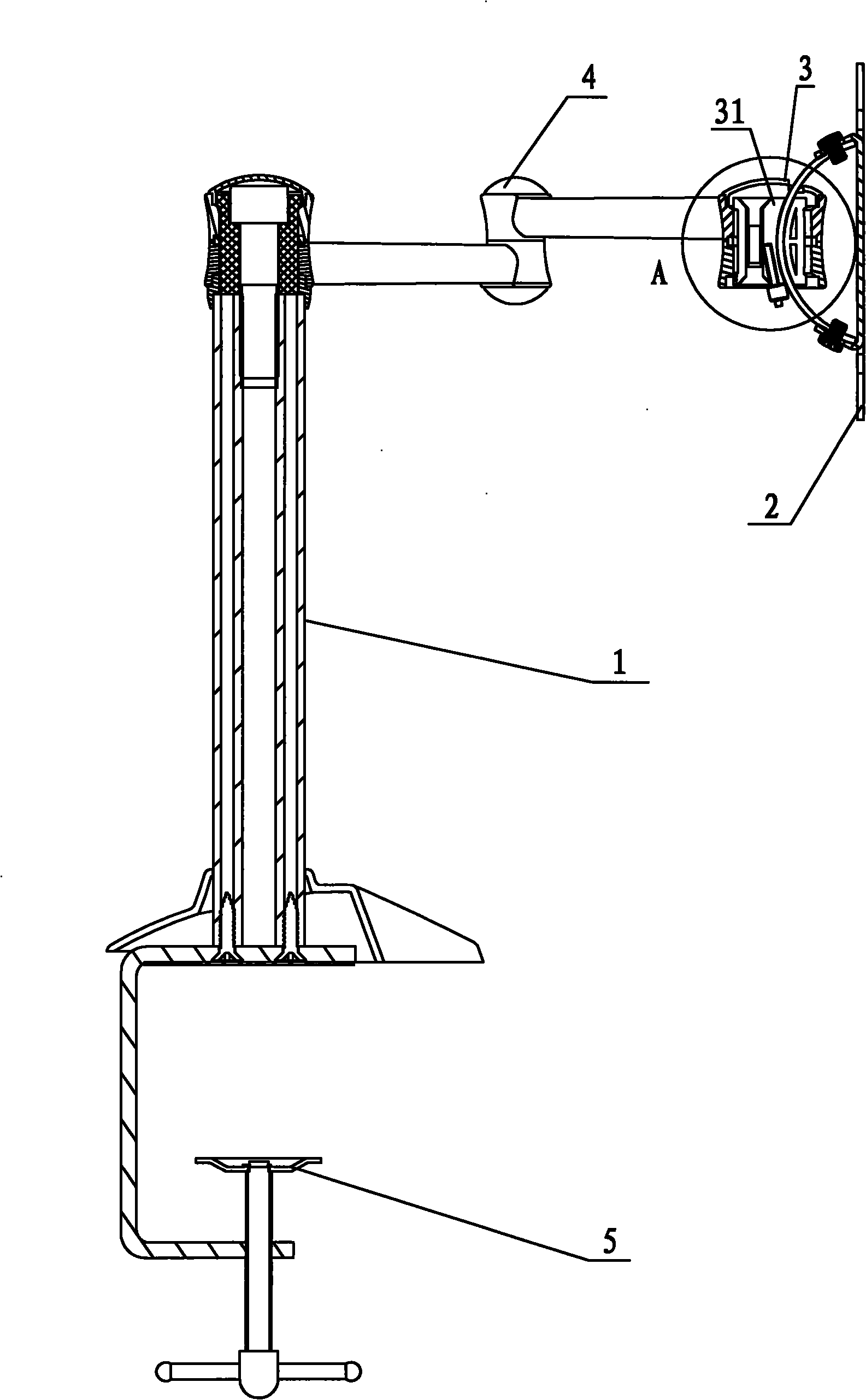

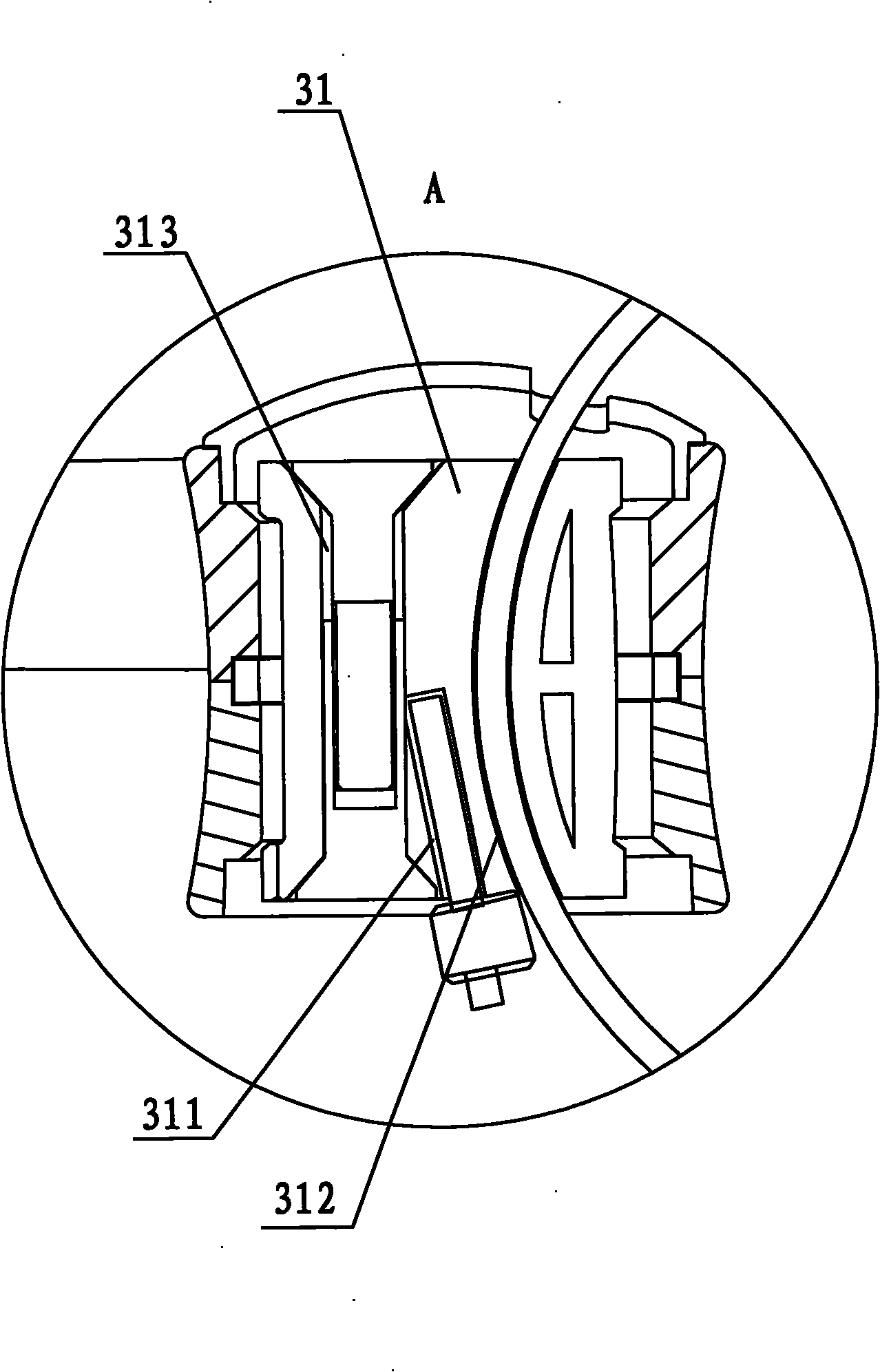

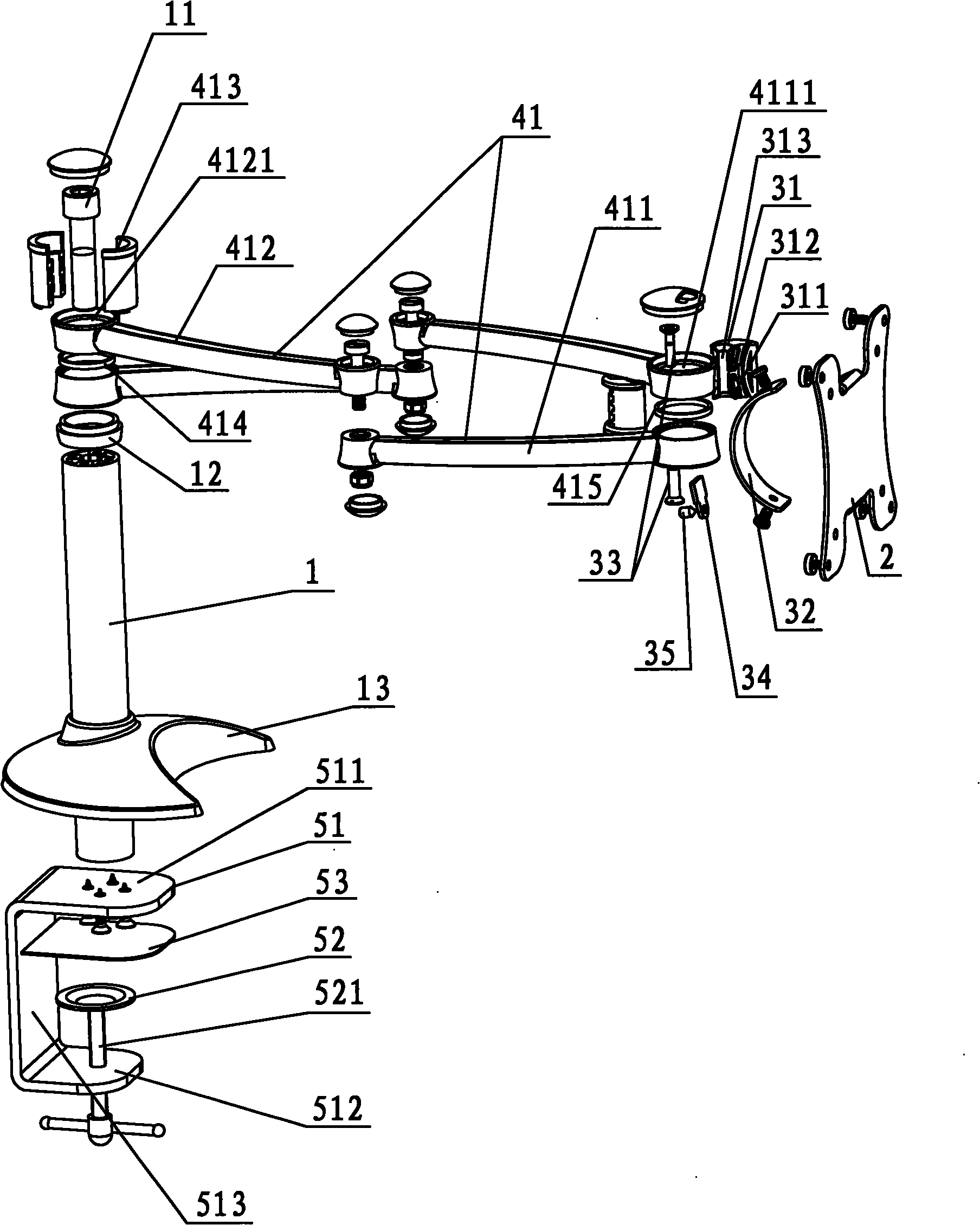

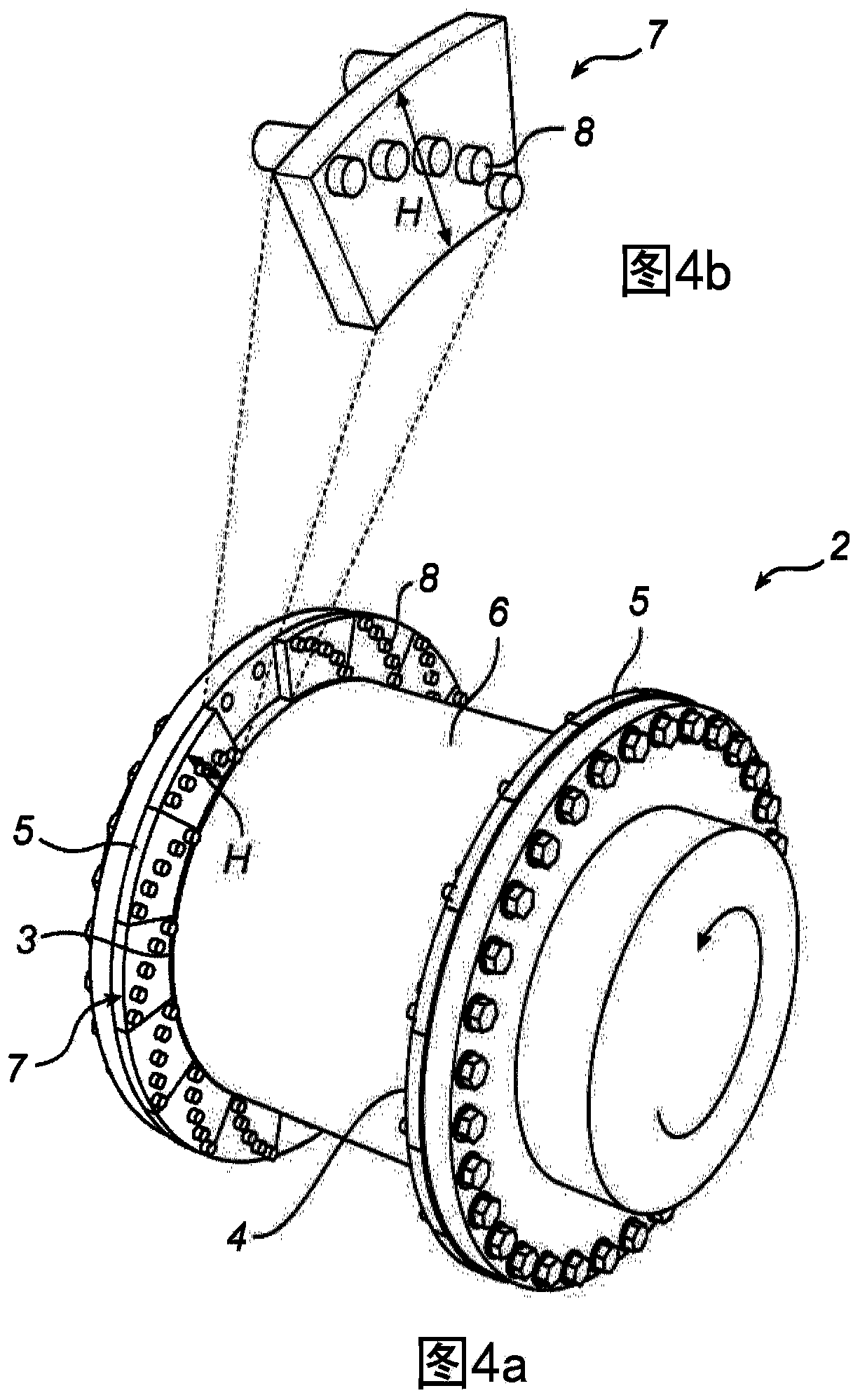

Liquid crystal display desktop installation device

InactiveCN101886734AAdjustable distanceReduce fatigueStands/trestlesLiquid-crystal displaySlant angle

The invention discloses a liquid crystal display desktop installation device which comprises a strut member (1), a mounting plate (2), a planar pivot angle and screen slant angle regulating device and an expansion hinge arm device, wherein the mounting plate (2) is fixed on the planar pivot angle and screen slant angle regulating device; the expansion hinge arm device comprises two hinge arms (41) with the same structure; each hinge arm (41) comprises a front arm (411) and a rear arm (412); one ends of the front arm (411) and the rear arm (412) of each hinge arm (41) are hinged with each other; and both the free ends of the rear arms (412)of the two hinge arms (41) are hinged on the strut member (1), and both the free ends of the front arms (412) of the two hinge arms (41) are hinged with each other and are provided with the planar pivot angle and screen slant angle regulating device. The liquid crystal display desktop installation device can regulate sight line distances, planar pivot angles, screen slant angles and 360-degree viewing angles.

Owner:宁波乐士洗涤科技有限公司

Sealing grease for main bearing of shield machine

InactiveCN106190443AGood stickinessExcellent anti-foam performanceLubricant compositionShield machineMain bearing

The invention belongs to the technical field of sealing grease, and particularly relates to sealing grease for a main bearing of a shield machine. The sealing grease is prepared from the following components in parts by weight: 14-20 parts of base oil, 6-12 parts of degradable fibers, 11-20 parts of a pasty adhesive, 4-15 parts of a structural stabilizing agent, 25-30 parts of an oiliness agent and a friction improver, 5-10 parts of a fire retardant and 3-8 parts of a rust inhibitor. The sealing grease disclosed by the invention has the beneficial effects of being favorable in stickiness and insoluble in water, so that the sealing grease has excellent flooding resistance, appropriate consistency and favorable lubricating properties; the lubricating and sealing properties of moving parts are guaranteed; a fibrous structure guarantees the head of the shield machine to be free from invasion of impurities, precision parts of bearings and the like are prevented from being abraded, and the sealing grease has favorable pumping performance and low-temperature performance.

Owner:天津盾构科技发展有限公司

Anti-fogging resin lens and preparation method thereof

InactiveCN107861259AImprove performanceImprove diffusion abilityOptical partsOptical elementsEpoxySodium dodecylbenzenesulfonate

The invention discloses an anti-fogging resin lens and a preparation method thereof. The anti-fogging resin lens includes a resin lens substrate, an anti-fogging layer and a rapid heat dissipation layer sequentially bonded to the upper surface of the resin lens substrate, and an anti-fogging layer and a rapid heat dissipation layer sequentially bonded to the lower surface of the resin lens substrate; Among them, the rapid heat dissipation layer is composed of the following raw materials: nano-carbon, epoxy resin, dibutyl phthalate, sodium dodecylbenzenesulfonate, citric acid; the anti-fogging layer is composed of the following raw materials: nano-silica , talcum powder, disodium edetate, alkanolamide, sodium benzoate; the anti-fogging resin lens of the present invention can quickly diffuse the temperature around the lens when the surrounding environment changes through the rapid heat dissipation layer, so as to avoid the lens from being heated, and at the same time The anti-fog layer prevents part of the undiffused heat from forming fog on the surface of the resin lens, so as to expand the application range of the resin lens.

Owner:永嘉姜君科技有限公司

Damping buffer device

The shock absorbing and buffering device relates to a device capable of playing the role of shock absorbing and buffering. The utility model is mainly designed to solve the problems of unsatisfactory damping and buffering effects of existing shock absorbing buffer devices. It includes a guide cylinder, the guide post is placed in the guide copper sleeve, the square boss of the collision head is placed in the square groove of the guide post, the ball head rod seat is placed in the ball head rod groove of the guide post, and the ball head rod The front end is in contact with the ball-end rod seat, the rear end of the ball-end rod is pushed against the groove of the bumper fixed on the piston rod, the cylinder and the guide cylinder are connected through the connecting frame, and the buffer rod fixing plate in the cylinder has a The oil chamber channel and exhaust nozzle, the buffer rod is placed in the groove of the piston rod, the buffer rod is fixed on the buffer rod fixing plate, the piston is placed in the cylinder and is in contact with the inner wall of the cylinder, and there is an inflatable valve plate at the rear end of the cylinder. There is an inflation nozzle on the inflation valve plate, and the space between the inflation valve plate and the piston is an air chamber. The advantage is that the shock absorption and cushioning effects are good.

Owner:朱丽辉

Efficient paper product cutting device

InactiveCN107953370ANot to be wornImprove processing efficiencyMetal working apparatusPulp and paper industry

The invention discloses a high-efficiency paper product cutting device, which includes a base and a frame. Fix the output shaft of the paper tube. The output shaft is a hollow tube. There are two coupling shafts inside the hollow tube. Several supporting blocks are evenly arranged on the coupling shafts. The bottom of the supporting blocks is vertically fixed on the coupling shafts. Two support blocks are arranged longitudinally along the connecting shaft, the output shaft is provided with a through hole matching the support block, the top of the support block passes through the through hole and is placed outside the output shaft, the top of the support block is also provided with a pad, and the center of the pad Point and the line connecting the center point of the pad of the support block on the other shaft intersects with the axis of the output shaft. Several tool mounting tables are arranged on the base below the output shaft, and cutting knives are arranged in the tool mounting table, and several The cutters are arranged axially along the output shaft. It has higher paper tube cutting efficiency, convenient and quick operation, and effectively improves paper tube processing efficiency.

Owner:成都鑫富汇纸业有限公司

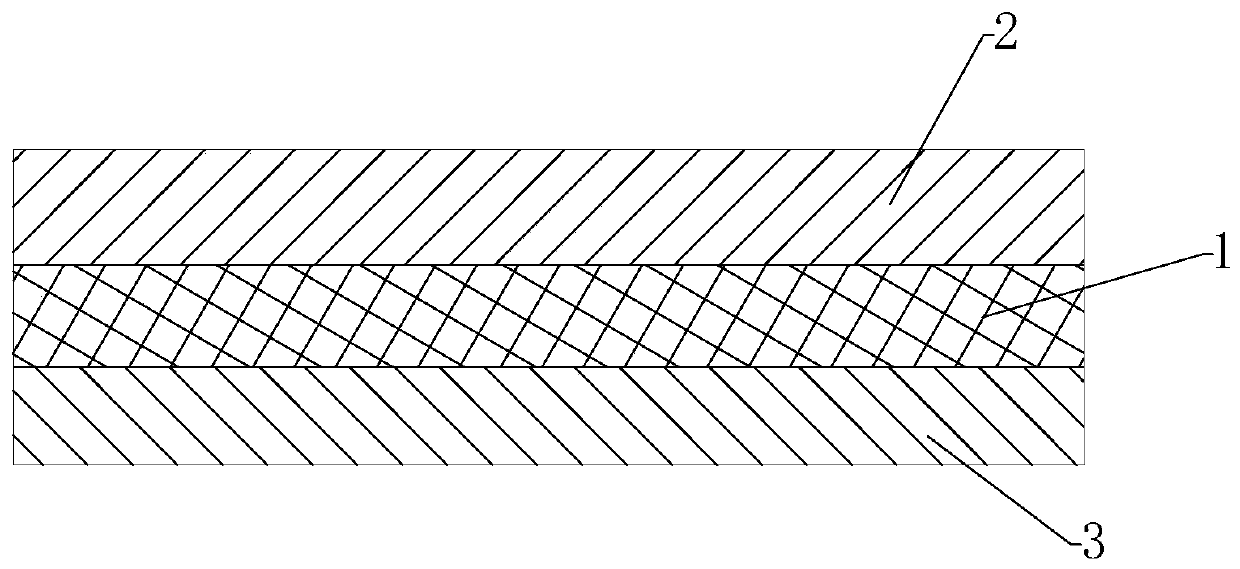

Finished biomass material product and preparation method thereof

InactiveCN110406196AIncrease profitHigh strengthLaminationLamination apparatusEcological environmentMicrowave

The present invention discloses a finished biomass material product and a preparation method thereof. The finished biomass material product comprises a first skin layer, an intermediate layer and a second skin layer which are sequentially arranged from top to bottom, the middle layer is a straw layer, and the material of the first skin layer is same to or different from the material of the secondskin layer. The preparation method of the finished biomass material product comprises the following steps: S1, crushing straws used as a raw material to obtain a fine straw material; S2, adding an adhesive to the fine straw material; S3, placing the obtained mixture in a pressing mold, and drying and curing the mixture by a microwave heating process to prepare the straw layer; and S4, respectivelyadhering the first skin layer and the second skin layer to two surfaces of the straw layer coated with the adhesive through the adhesive, and drying the obtained material by a microwave heating process to produce the finished biomass material product. The finished biomass material product and the preparation method thereof have the advantages of simple structure, low cost, effective utilization of agricultural wastes, and promotion of sustainable development of the ecological environment.

Owner:ZHEJIANG SAINON CHEM

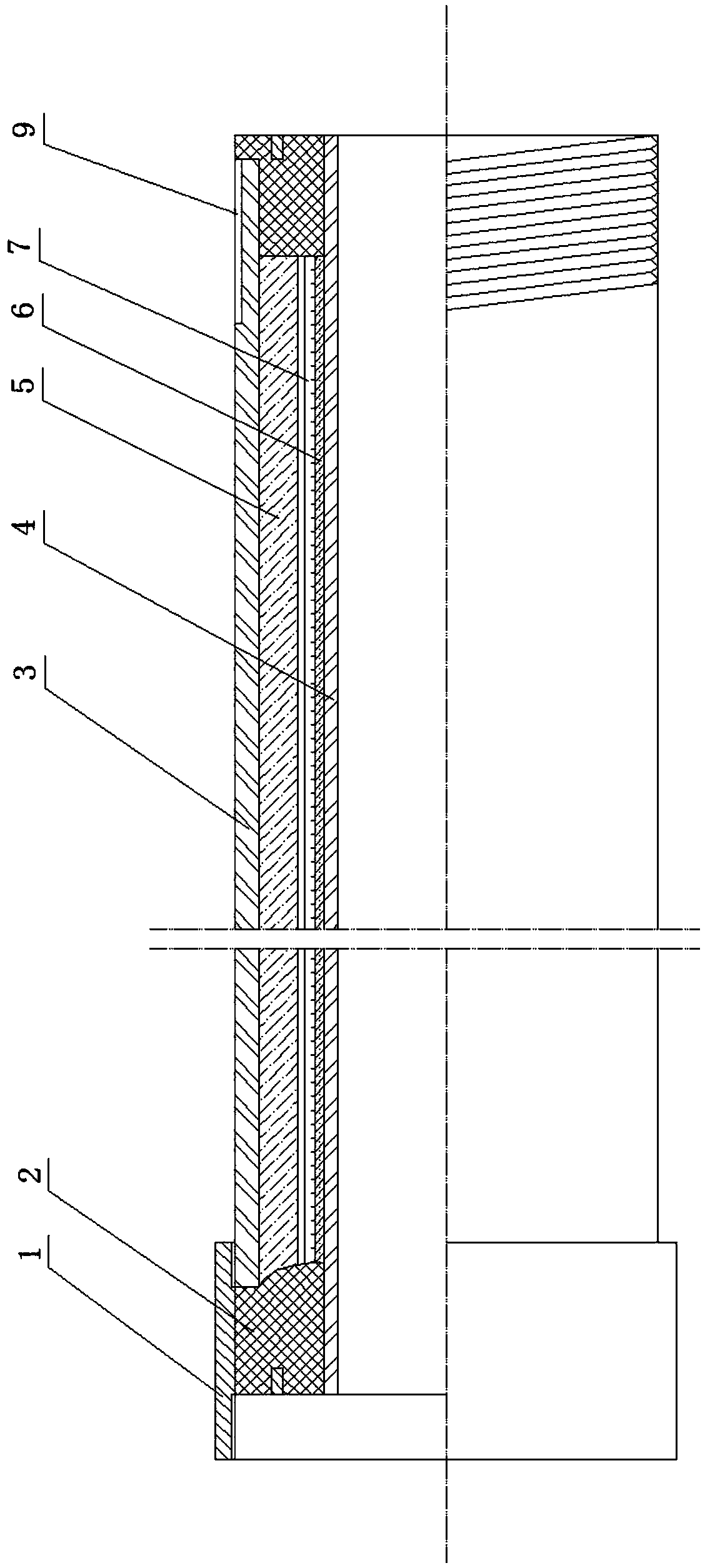

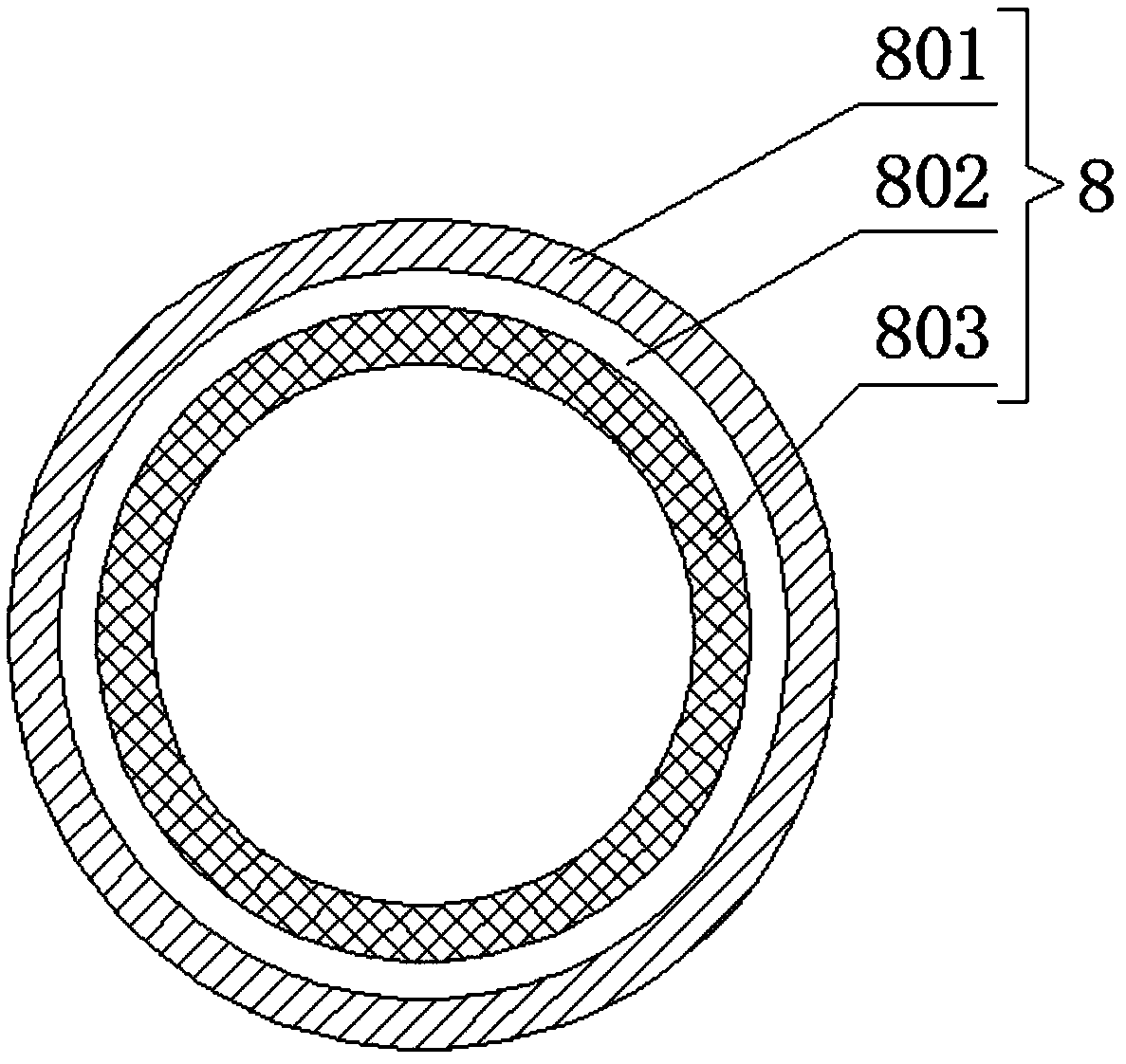

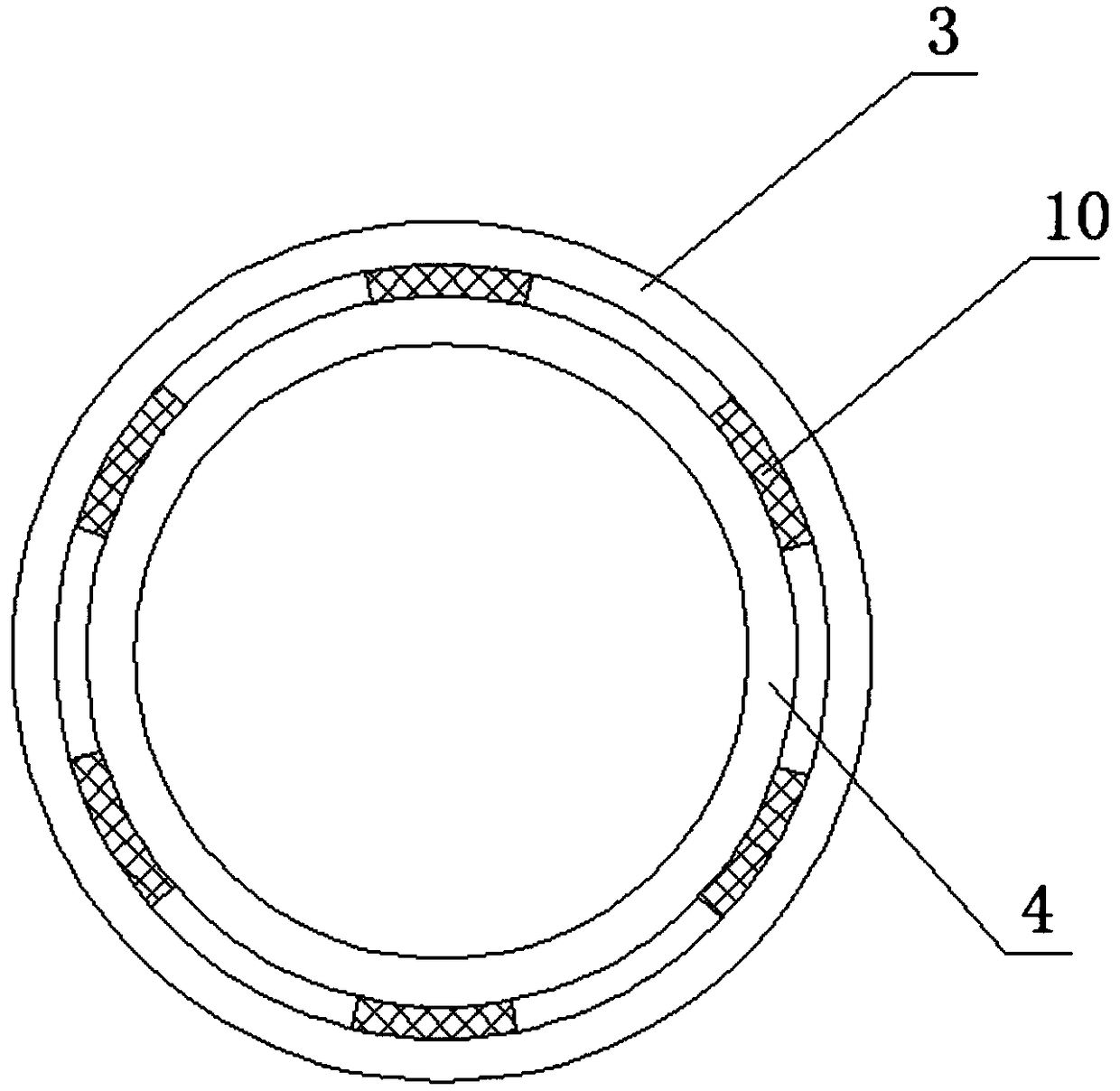

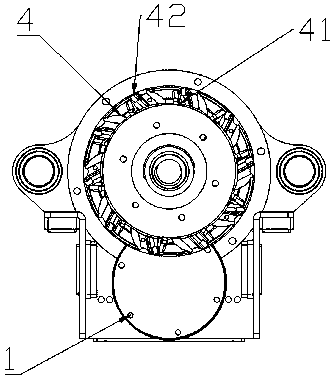

Efficient thermal insulation heating oil pipe suitable for heavy oil exploitation

PendingCN109138951ANot to be wornGuaranteed constant temperature liftDrilling rodsFluid removalSelf-healingHeating oil

The invention discloses an efficient thermal insulation heating oil pipe suitable for heavy oil exploitation. The efficient thermal insulation heating oil pipe comprises an oil pipe body. The oil pipebody is internally provided with a high wear-resistant inner lining, a polymer nano-thermal insulation layer is arranged between the oil pipe body and the high wear-resistant inner lining, and a self-healing type PTC self-limited temperature electrothermal film is arranged between the polymer nano-thermal insulation layer and the high wear-resistant inner lining. A feeder bus-bar is further arranged between the polymer nano-thermal insulation layer and the high wear-resistant lining in a laid mode, concentric conductive rings are arranged at the two ends of the oil pipe body, and the concentric conducting rings are arranged at the ends of the oil pipe body and the high wear-resistant inner lining. According to the efficient thermal insulation heating oil pipe suitable for heavy oil exploitation, the high wear-resistant inner lining is arranged inside the oil pipe body, the polymer nano-thermal insulation layer is arranged between the oil pipe body and the high wear-resistant inner lining, and the high wear-resistant inner lining can bear the pressure of crude oil in an oil well and further protect the polymer nano-thermal insulation layer from being worn; and a heat preservation method is adopted to ensure constant temperature lifting of the crude oil, the plug removing heating element self-restoring PTC electrothermal film is designed inside the insulation layer, and the zeropollution, zero emission, maintenance-free and low energy consumption effects are truly achieved.

Owner:沧州润涛石油设备有限公司

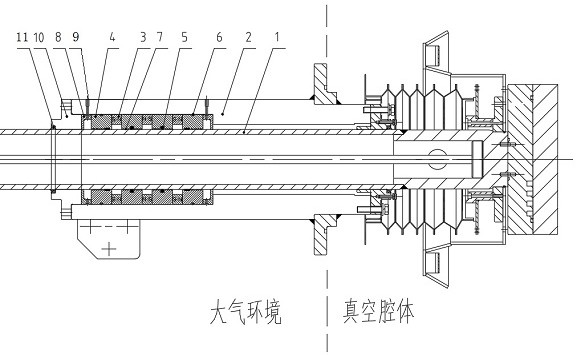

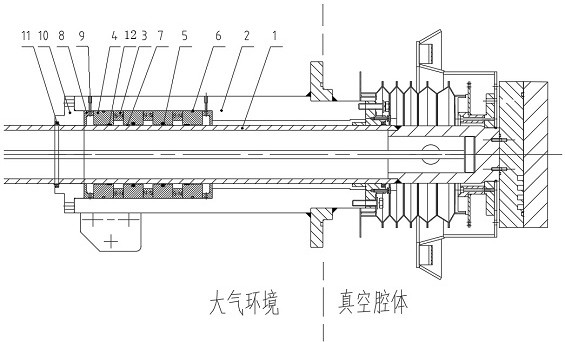

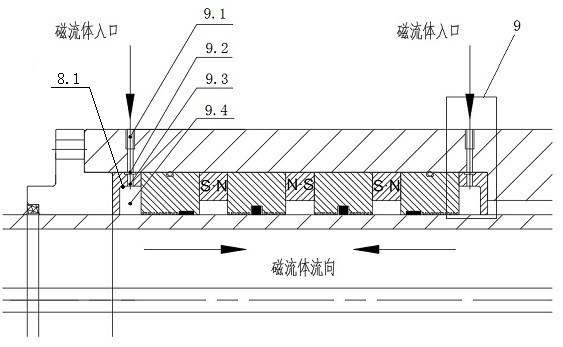

Axial magnetic fluid dynamic seal structure

The invention discloses an axial magnetic fluid dynamic seal structure. The axial magnetic fluid dynamic seal structure is characterized in that a shaft is arranged in a hollow shell; at least three permanent magnets are fixed between the excircle of the shaft and the inner wall of the shell in parallel; two sides of each permanent magnet are each provided with a pole shoe; a flow choking piece is only arranged at the center of the inner circular surface of at least one of two adjacent pole shoes of the permanent magnet in the middle position, and a first preset gap is formed between the flow choking piece and the shaft; first sealing elements are only arranged on the outer circular surfaces of the two pole shoes on the outermost side in the plurality of pole shoes; a magnetic fluid accommodating sealed space is formed between the pole teeth and the shaft, and a second preset gap is formed between each pole tooth and the shaft; magnetism isolating pieces are fixed to the axial outer sides of the two pole shoes on the outermost side in the plurality of pole shoes correspondingly; end covers are arranged at two ends of the hollow shell correspondingly; second sealing elements are arranged between the end covers and the shaft in a covering manner; and when the shell is vacuumized, the magnetic fluid accommodating sealed space is filled with a magnetic fluid, so that sealing is formed between the shaft and the pole teeth, and the first preset gap is smaller than the second preset gap.

Owner:SHANGHAI LIGOU SENSOR SCI & TECH

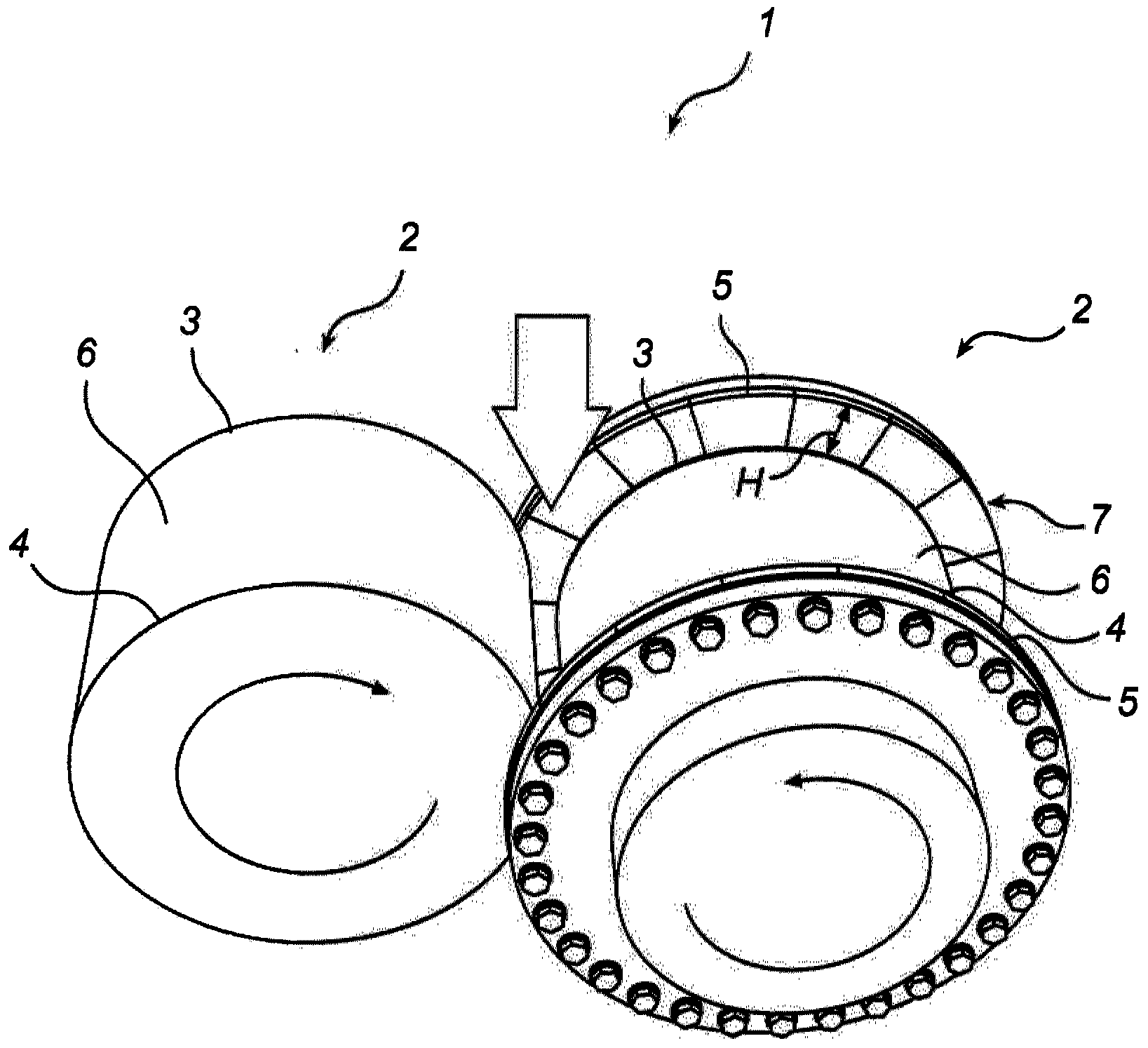

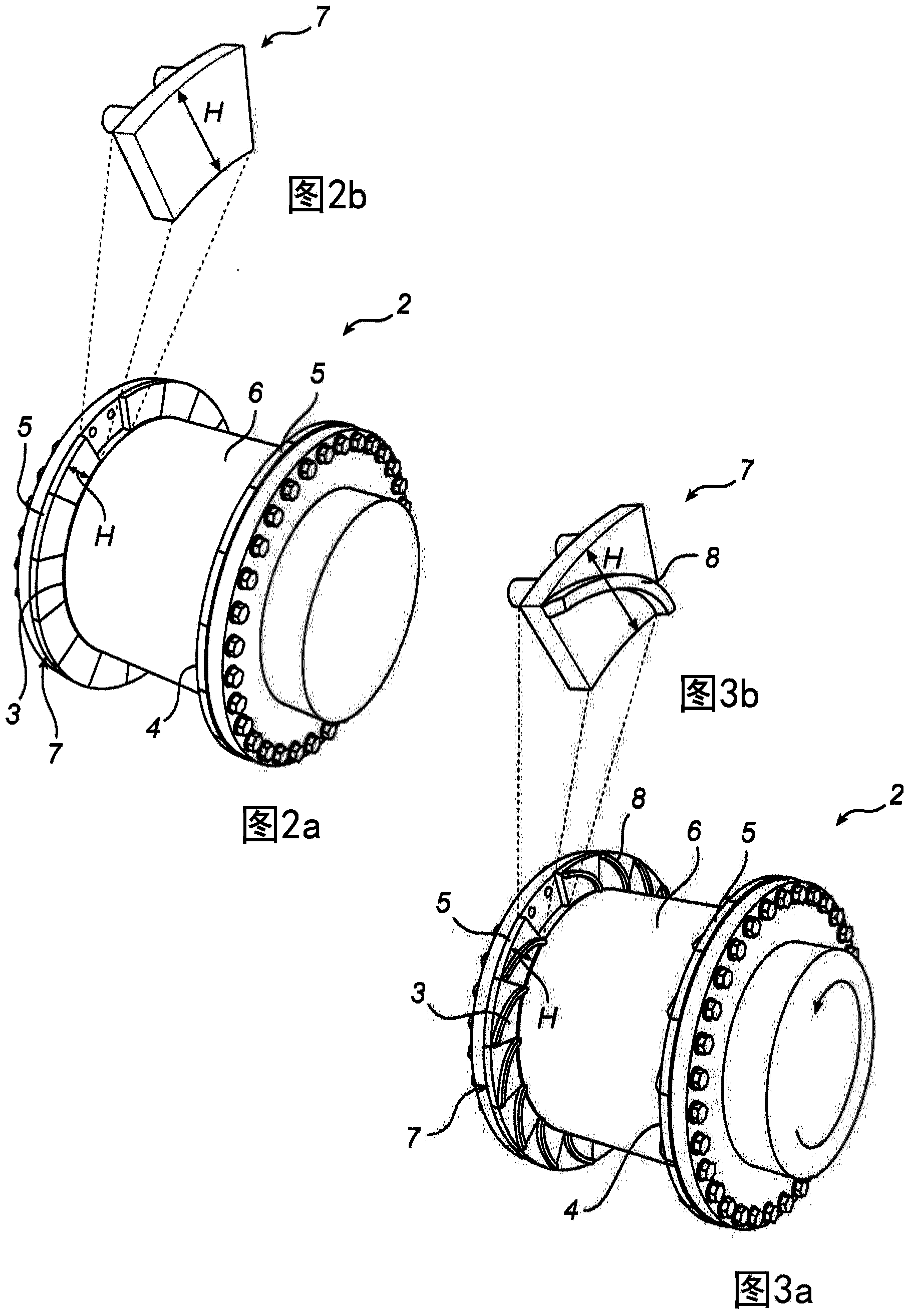

Roller crusher having at least one roller comprising a flange

The invention relates to a roller crusher (1) having two generally parallel rollers (2) arranged to rotate in opposite directions, towards each other,and separated by a gap, each roller (2) having a first end (3) and a second end (4). The roller crusher (1) comprises a flange (5) attached to at least one of said ends (3, 4) of one of said rollers (2). The flange (5) extending in a radial direction of said roller (2), and has a height (H) above an outer surface (6) of said roller (2) which is sufficient to extend across said gap substantially along a nip angle (alpha) of said roller crusher (1).

Owner:METABO MINERALS SWEDEN

Tablet computer portable bracket

The invention discloses a tablet computer portable bracket. The tablet computer portable bracket comprises a fixing device, a support device and a high-toughness connecting pipe for connecting the fixing device with the support device, wherein the fixing device comprises a fixing frame, a pressure block positioned in the fixing frame, and a hand screw connected with the pressure block; the pressure block is movably connected to the head of the hand screw; the support device comprises a support plate and at least two support frames movably connected with the support plate; the support plate is provided with two sliding chutes; the support frames slide in the sliding chutes through locking devices and are locked in the sliding chutes; cylinders extend from the two ends of the support frames; the top ends of the cylinders are provided with cylindrical bosses; the diameters of the cylindrical bosses are greater than the diameters of the cylinders. The tablet computer portable bracket is clamped on a bed or a table through the fixing device, a tablet computer is fixed by adjusting the support frames, and the tablet computer is pressed by adjusting a thickness adjusting screw, so that the tablet computer portable bracket is convenient to adjust, and is easy to use; moreover, places which are in contact with the tablet computer are provided with rubber, so that the tablet computer is prevented from being worn.

Owner:陈菊芳

Drilling device achieving transverse drilling conveniently

InactiveCN110644924ANot to be wornExtended service lifeDrilling rodsConstructionsStructural engineeringPetroleum engineering

The invention provides a drilling device achieving transverse drilling conveniently. The drilling device comprises a drill bit seat, a drill barrel and a straight barrel. The drill barrel is a cylindrical hollow barrel body and comprises a first end and a second end along the axis, wherein the first end and the second end are opposite. A drill bit is arranged at the first end. The second end is rotationally mounted on the drill bit seat. The drill barrel can rotate around the axis of itself. The straight barrel is arranged on the outer surface of the drill barrel in a sleeving manner and is coaxial with the drill barrel. A clearance is arranged between the inner wall of the straight barrel and the outer surface of the drill barrel. One end of the straight barrel is fixedly arranged on thedrill bit seat. The other end of the straight barrel extends towards the drill bit. A clearance is also arranged between the end face of the other end of the straight barrel and the drill bit. The outer diameter of the drill bit on the drill barrel is larger than the maximum outer diameter of the straight barrel. Multiple penetrating slag discharge holes are formed in the barrel wall of the straight barrel. The straight barrel is arranged outside the drill barrel in the sleeving manner, the drill barrel is protected against wear, meanwhile, the straight barrel and the drill barrel rise into adrilled hole together and are attached to the hole wall, soil and stone cannot fall off on the hole wall, and the drilled hole is more regular and smoother.

Owner:CHONGQING HONGGONG INSTRUCTIONAL MACHINE

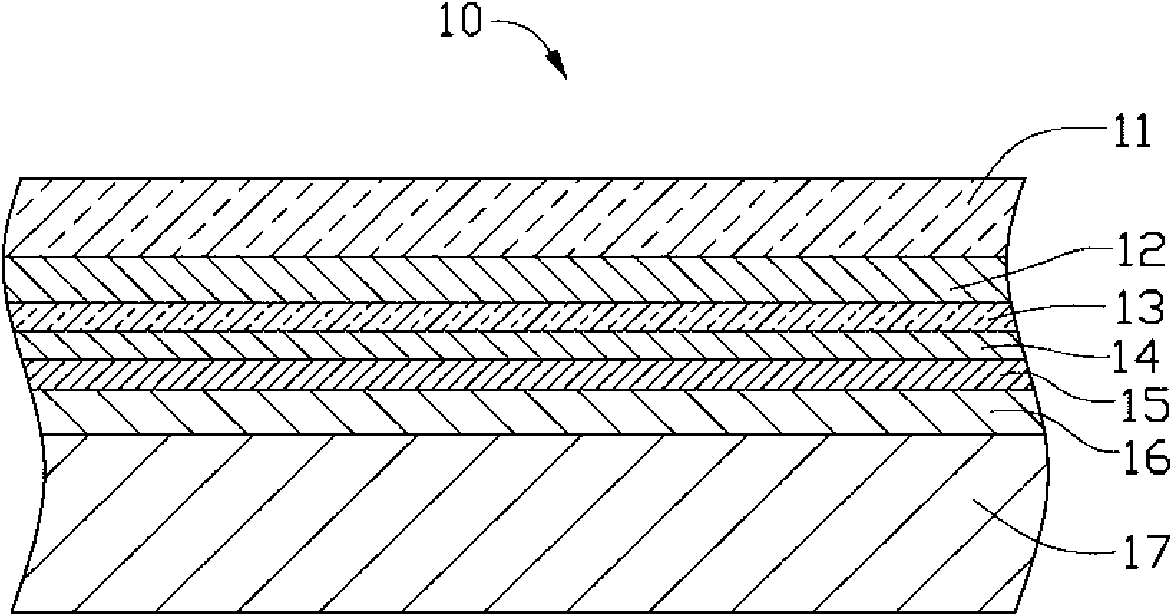

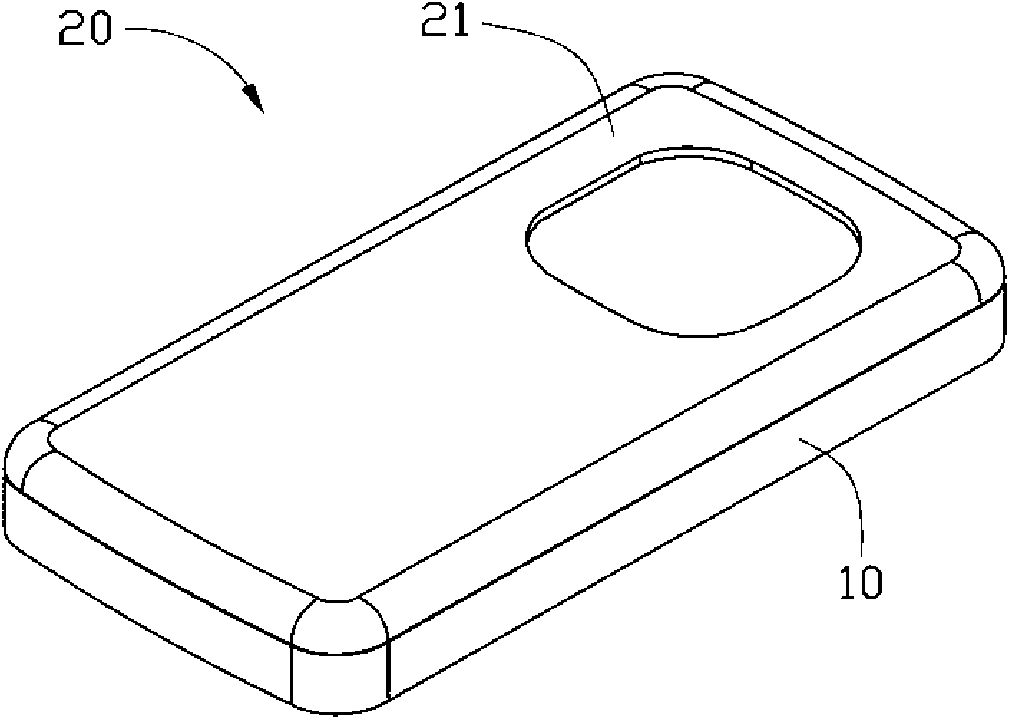

Shell and electronic device using the same

InactiveCN101925211AEasy to useNot easy to shiftElectroluminescent light sourcesTelephone set constructionsSurface layerEngineering

The invention provides a shell, which comprises an outer surface layer and a base. The shell further comprises a first conductive layer, an illuminating layer and a second conductive layer which are arranged between the outer surface layer and the base, wherein the illuminating layer is arranged between the first conductive layer and the second conductive layer; the first conductive layer and the second conductive layer are respectively provided with an electric connecting port; and the base is injected and molded on the second conductive layer. The invention also provides an electronic device using the shell.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

High-tension line warning light convenient to mount and maintain

InactiveCN105387417AEasy to installNot easy to move and dropLighting applicationsLighting support devicesEngineeringHigh tension line

The invention relates to a light for warning of a high-tension overhead line, in particular to a high-tension line warning light convenient to mount and maintain. The high-tension line warning light convenient to mount and maintain comprises a support and is characterized in that the support is made of an insulating material; a storage battery is mounted in the support; a warning light is mounted at the lower part of the support; a fixed mounting device for being fixedly mounted on the line is mounted at the upper part of the support; and a solar panel is mounted at the upper part of the fixed mounting device. With the structure, the high-tension line warning light convenient to mount and maintain has the advantages of being simple and firm in mounting and difficult in moving and falling, emitting light not by day but by night, protecting the environment, saving energy and having good warning effect.

Owner:XUCHANG SIDA ELECTRIC POWER EQUIP

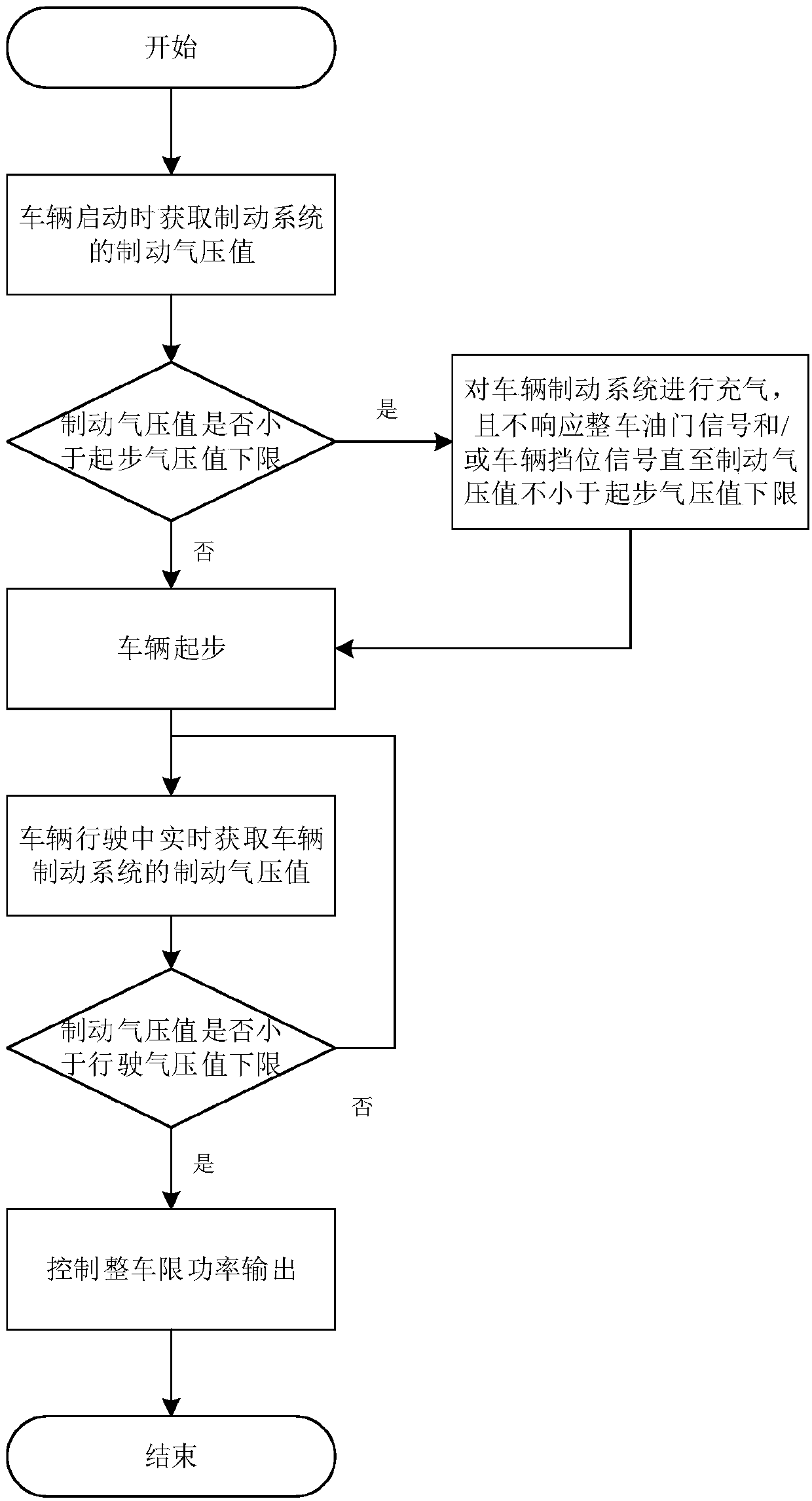

Air brake vehicle power safety control method and device

InactiveCN110861623AAvoid wear and tearNot to be wornBraking action transmissionBrake safety systemsBrake liningAir brake

The invention relates to the technical field of vehicle braking, in particular to an air brake vehicle power safety control method and device. The device comprises a controller and a pressure sensor used for detecting braking air pressure of a vehicle braking system. The input end of the controller is connected with the pressure sensor. When a vehicle is started, the controller obtains a braking air pressure value of the vehicle braking system, when it is judged that the braking air pressure value is smaller than the lower limit of a starting air pressure value, the vehicle braking system is controlled to be inflated, the whole vehicle is controlled not to respond to a whole vehicle accelerator signal and / or a vehicle gear signal until the braking air pressure value is no smaller than thelower limit of the starting air pressure value, power safety control over the air brake vehicle is achieved, and the problem that when the vehicle braking air pressure is low, power is still output, the vehicle is controlled to operate, and thus severe wear of brake linings is caused is solved.

Owner:HENAN SENYUAN HEAVY IND

Finger protector

The invention discloses a finger protector which comprises an arc-shaped baffle blocking a cutter point. A finger sleeve is arranged on the middle portion of the inner side of the arc-shaped baffle, rubber ring layers are arranged on the upper edge and the lower edge of the finger sleeve, and a gap is further formed in one side of the finger sleeve. The finger protector is provided with the arc-shaped baffle blocking the cutter point, the finger sleeve is arranged on the inner side of the arc-shaped baffle, the finger stretches into the finger sleeve and presses an article to be cut, the finger protector is convenient to use, the rubber ring layers are arranged on the upper edge and the lower edge of the finger sleeve, the finger is protected from abrasion, and the finger protector is simple in structure and easy to achieve, and has good application prospects.

Owner:刘祥

Wire harness cutting-off device

The invention discloses a wire harness cutting-off device and relates to the field of automobile wire harnesses. The wire harness cutting-off device comprises two handles, a base and a shearing platform; the shearing platform is arranged on the base with a cuboid structure; the two handles are symmetrically arranged at two sides of the shearing platform and are hinged with the shearing platform; a through hole is formed in the top of the shearing platform; a pressure column is sleeved by the through hole; a blade is arranged inside the shearing platform and is connected with the bottom of the pressure column; the top of the pressure column is provided with a connecting platform; a supporting rod I is hinged between the connecting platform and each handle; notches are formed in two sides of the shearing platform and are internally sleeved with push rods on which clamping pieces are arranged; a supporting rod II is hinged between each push rod and each handle; a shearing port is formed in the middle of the shearing platform; and both the blade and the clamping pieces are arranged in the shearing port. By using the cutting-off device, a wire harness can be fixed, so that the phenomenon that the efficiency is affected due to the slip off of the wire harness during cutting is avoided.

Owner:WUHU QIAOYUN & YOUXING ELECTRICAL IND CO LTD

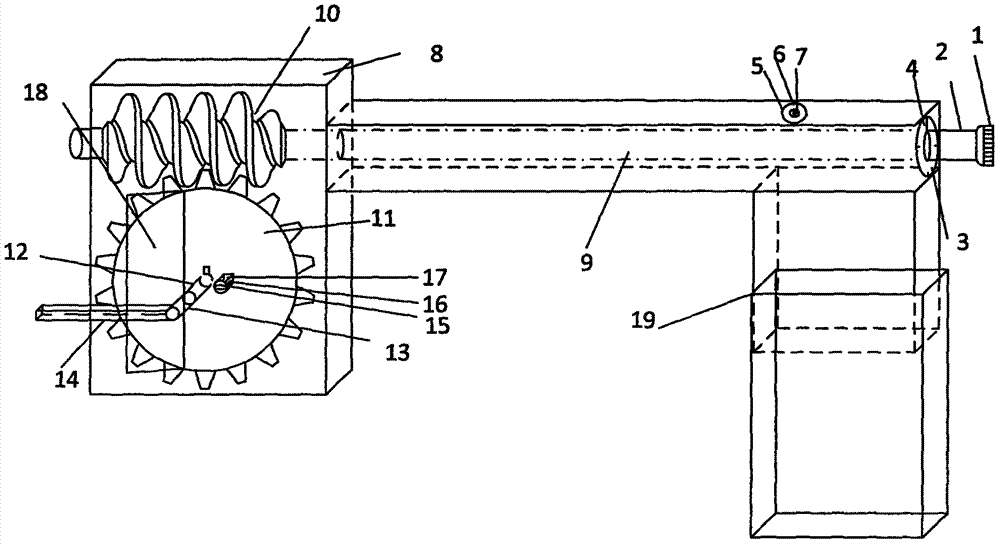

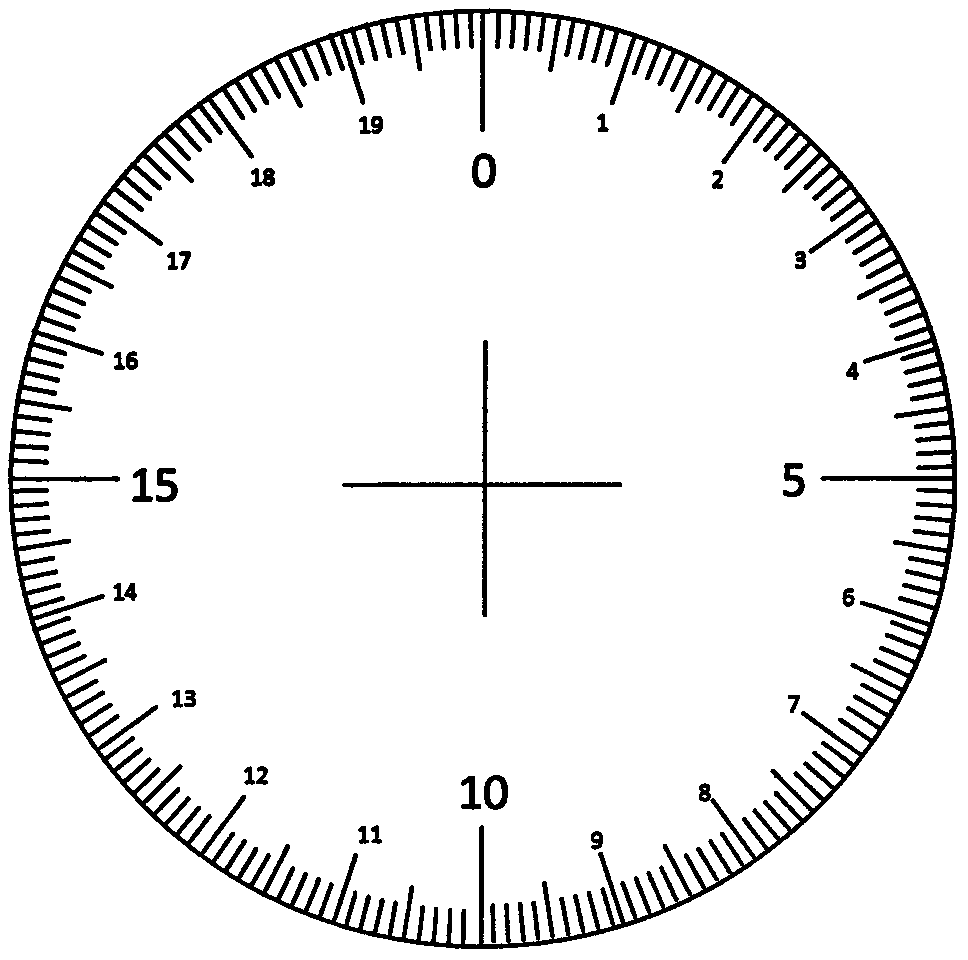

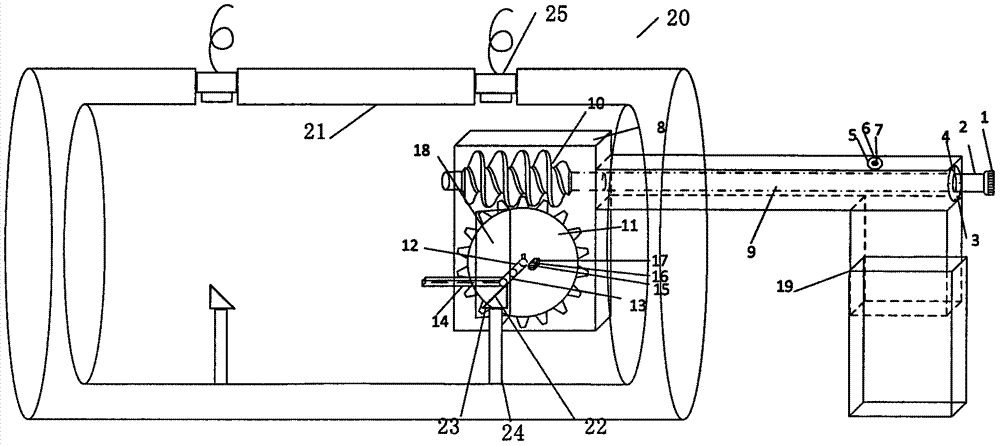

Simple device for measuring miniature angular changes of reflector plate of supersonic water meter

ActiveCN107255438ANot to be wornMeasuring range is unlimitedAngles/taper measurementsTesting/calibration for volume flowMeasurement deviceEngineering

The invention relates to a simple device for measuring the miniature angular changes of a reflector plate of a supersonic water meter. The device comprises a supporting housing for supporting a measurement device and protecting an internal structure, a supporting seat for the whole device, a rotating handle, a rotating handle connecting rod, an angle dial, a dial pointer, a bubble level apparatus, a worm connecting rod, a driving worm, a driven turbine, a driven turbine connecting rod, an angle measurement rotating rod, an illuminating lamp, and a plane reflector. The invention also provides a scrubbing method for the reflector plate of the supersonic water meter. The device causes no destructive disassembling, saves time and labor, is simple in operation, is high in measurement precision, can judge the state of the reflector plate while protecting the reflector plate from being worn, and achieves the reliable maintenance and protection of the supersonic water meter to certain degree.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com