Method for rolling friction stretching and retracting of rocker and rolling friction stretching and retracting digger or loader of rocker

A technology of rolling friction and telescopic arms, which is applied to mechanically driven excavators/dredgers, driving devices, earthwork drilling and mining, etc., which can solve the problems of reduced use efficiency and adaptability, large volume, large breaking force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

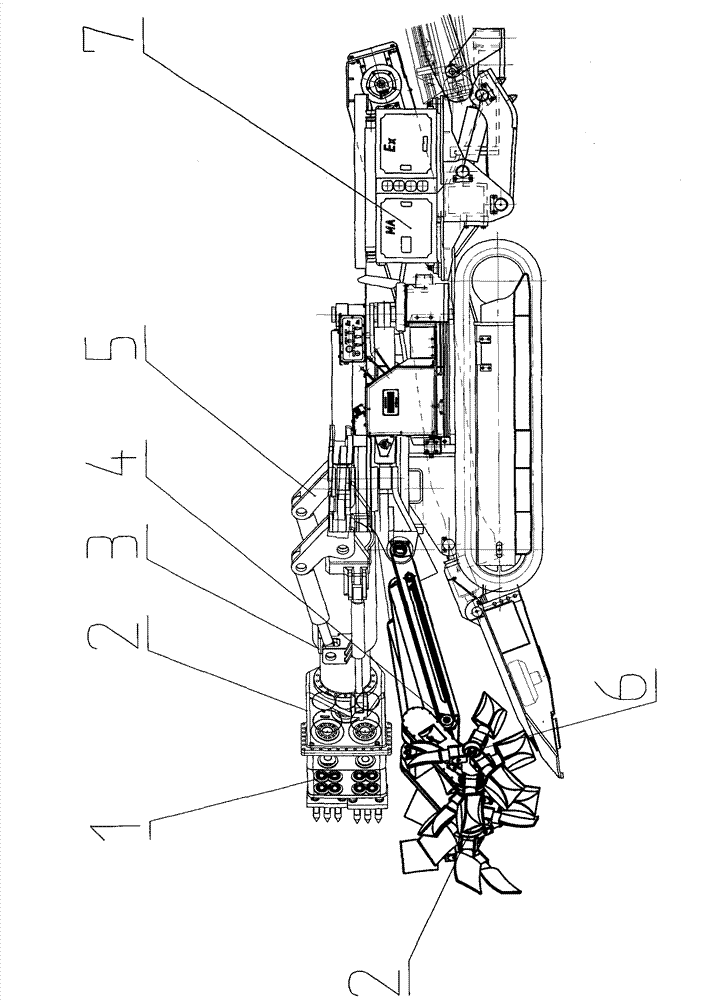

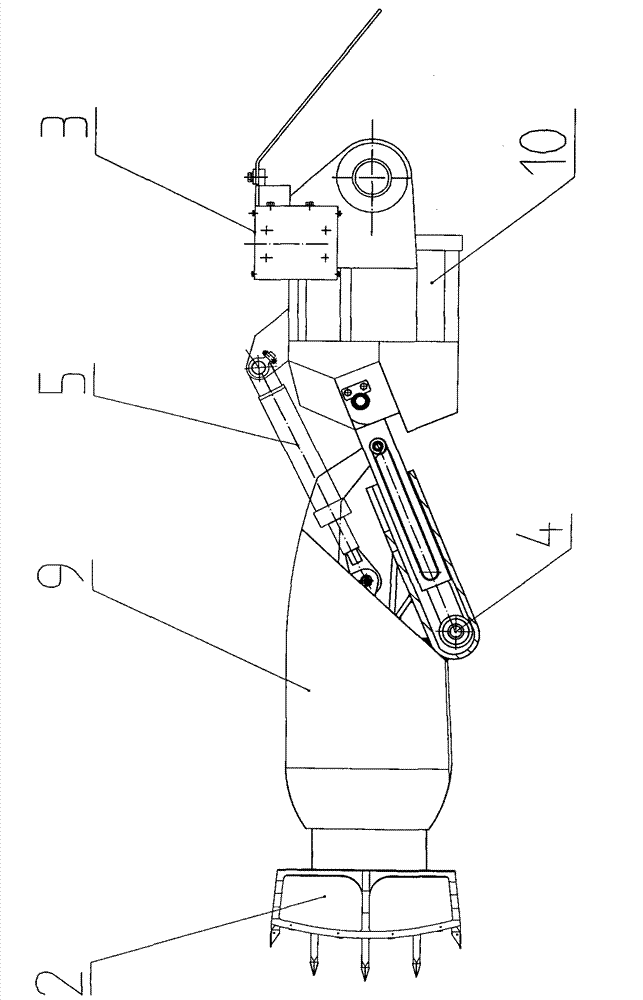

[0158] Figure 1 to Figure 9 It is the rocker arm rolling friction telescopic excavator or loader described in embodiment 1. The rocker arm rolling friction telescopic excavator or loader includes a rocker arm 3, a fuselage 7, a rolling body 4, a telescopic control member 5, a working head 2, a working head driving mechanism 6, etc., and the rocking arm 3 includes a telescopic arm 9, a telescopic support Arm 10 etc., rolling element 4 is arranged between telescopic arm 9 and telescopic support arm 10, telescopic control member 5 one end is connected with fuselage 7, telescopic control member 5 other end is connected with telescopic arm 9, rocking arm 3 is connected with fuselage 7 Connection, etc., the telescopic control part 5 controls the expansion and contraction of the telescopic arm 9, and the telescopic arm 9 moves through the rolling friction of the rolling body 4, etc., the working head 2 is arranged on the telescopic arm 9, etc., and the working head driving mechanism...

Embodiment 2

[0189] Such as Figure 10 to Figure 11 As shown, it is the rocker arm rolling friction telescopic excavator or loader shown in Embodiment 2. The difference from Embodiment 1 is that the rolling body 4 includes front rollers 14, rear rollers 15, etc., and the rocker arm 3 includes roller raceways 83 , telescopic arm 9, telescopic support arm 10, etc., the telescopic support arm 10 is connected with the fuselage 7, the roller raceway 83 is arranged on the telescopic arm 9 or is arranged on the telescopic support arm 10, and the front roller 14 and the rear roller 15 are arranged on the roller Rolling in the raceway 83, the front roller 14 and the rear roller 15 cooperate to support the telescopic arm through rolling friction, and the telescopic support arm is stretched by rolling friction.

[0190] Its concrete setting is: roller raceway 83 also comprises front roller raceway 17, rear roller raceway 16 etc., and front roller raceway 17 is arranged on telescopic arm 9, and rear r...

Embodiment 3

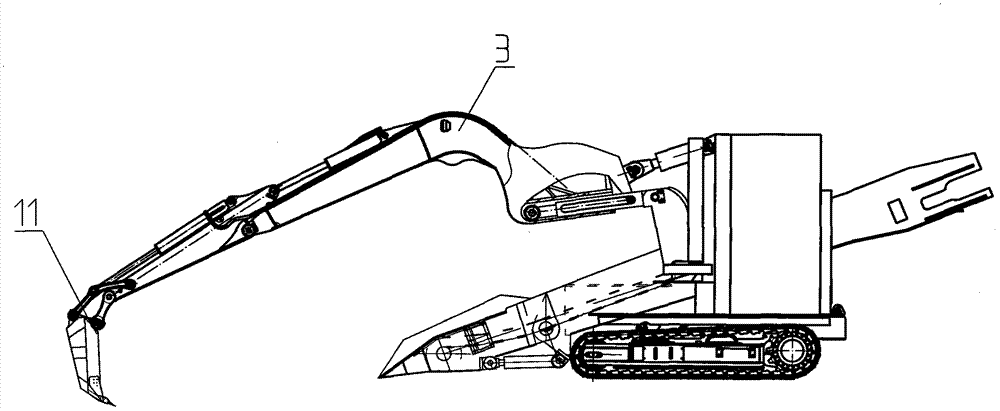

[0195] Such as Figure 12 As shown, it is the rocker arm rolling friction telescopic excavator or loader shown in Embodiment 3. The difference from Embodiment 1 is that the working head 2 includes a roller rake 12, etc., and the working head drive mechanism 6 includes a roller rake drive mechanism 21, etc. , the rocker arm 3 includes a rolling rake rocker arm 18, etc., and the telescopic control member 5 includes a rolling rake telescopic control member 19, etc., the rolling rake rocker arm 18 is hinged with the fuselage 7, and one end of the rolling rake telescopic control member 19 is hinged with the fuselage 7, and the other One end is connected with the telescopic arm 9, etc., and the rolling body 4 is arranged on the rolling rake rocker arm 18, etc., and the rolling body 4 supports the rolling rake rocking arm 18, etc. The rake driving mechanism 21 etc. are arranged on the roller rake rocker arm 18 or on the fuselage 7, etc., the roller rake 12 is hinged with the roller r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com