Damping buffer device

A buffer device and buffer rod technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of large shear force of connecting bolts, shortened service life, poor sealing effect of buffer parts, etc., to achieve Good shock absorption and cushioning effect, prolong service life and increase contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

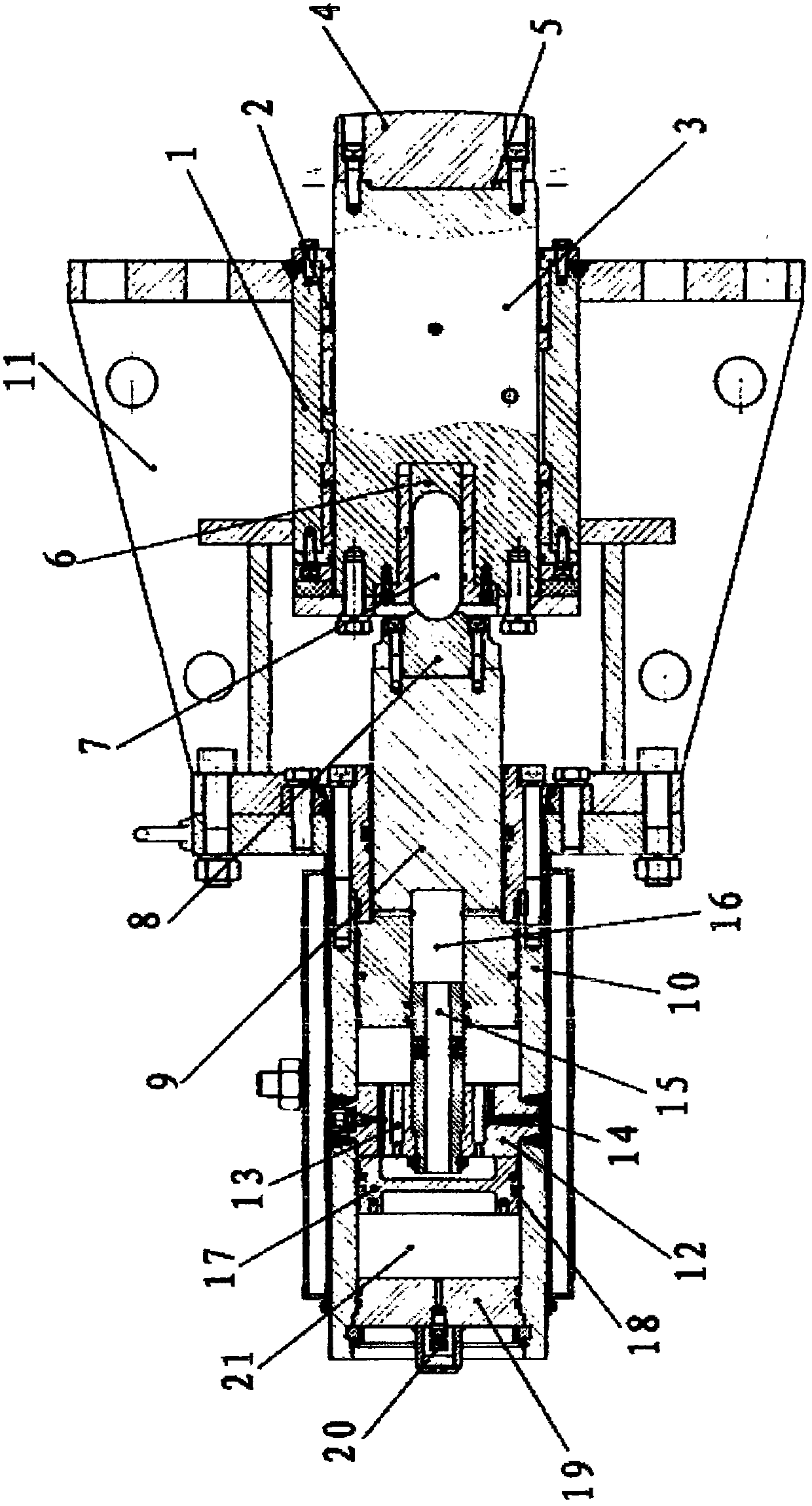

[0007] Referring to Figure 1, it includes a guide cylinder 1, three guide copper sleeves 2 are fixed on the inner wall of the guide cylinder, the guide column 3 is placed in the three guide copper sleeves, the front end of the guide column has a square groove, and the collision head 4 There is a square boss 5, the square boss is placed in the square groove on the guide column, the collision head and the guide column are connected together by bolts, the rear end of the guide column has a groove for the ball head rod, and the ball head rod seat 6 is placed on the At the bottom of the groove of the ball stud, the front end of the ball stud 7 is in contact with the ball stud seat, the rear end of the ball stud protrudes from the guide column, and there is a bumper 8 behind the ball stud, and the front end of the bumper There is a groove, the rear end of the ball-end rod is pushed in the groove of the bump block, and there is a piston rod 9 behind the bump block, and the bump block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com