Pre-wiring template

A pre-wiring and template technology, which is applied in the field of innovative process equipment and pre-wiring templates, can solve problems such as waste, easy wear and tear of sprayed plastic drawings, and inability to convert each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

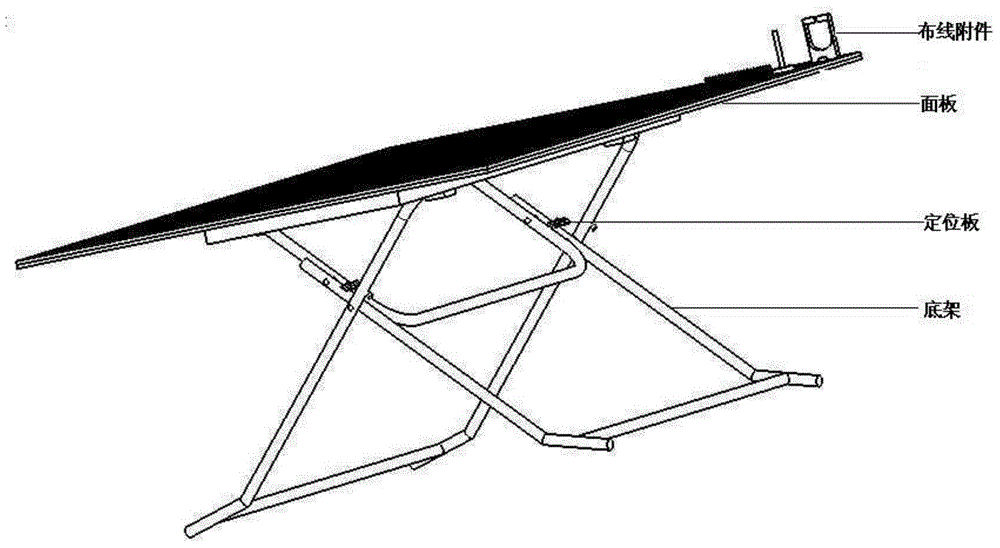

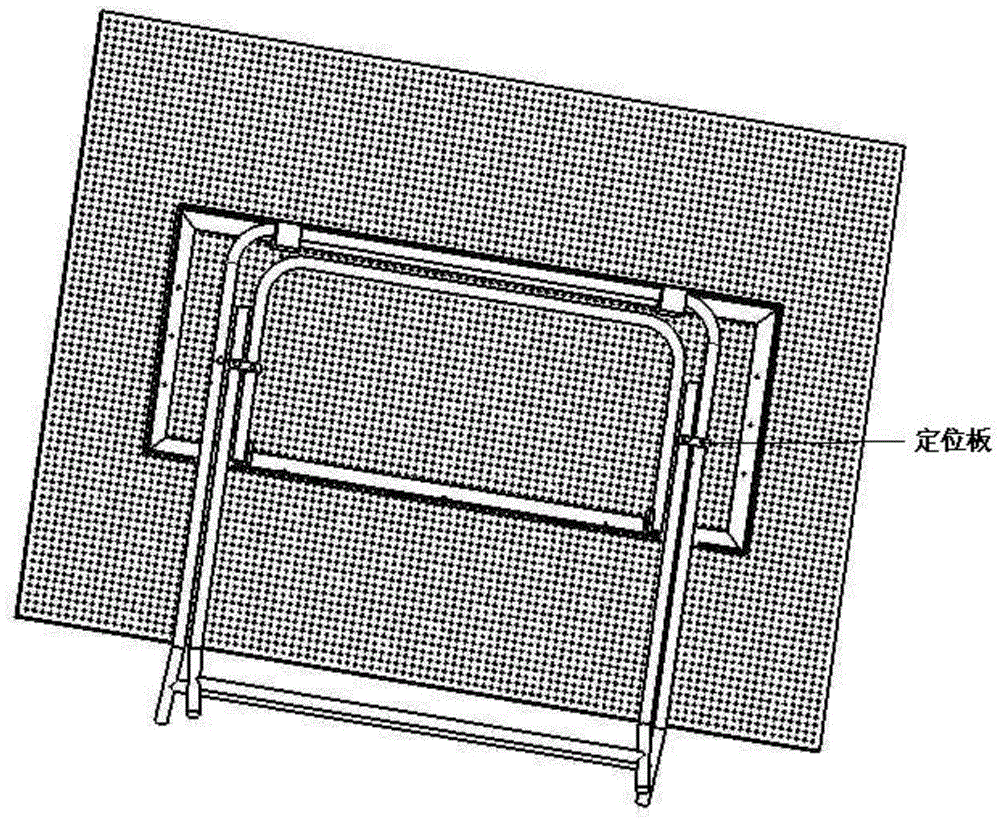

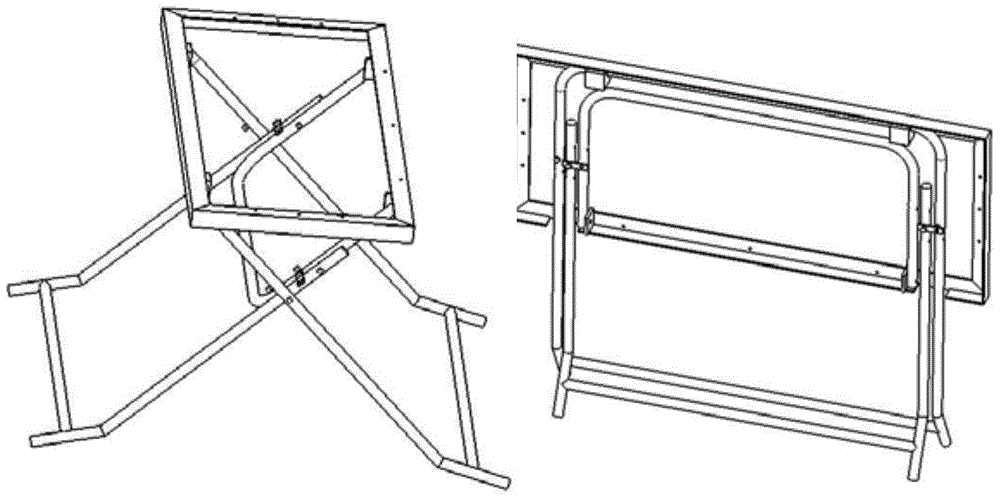

[0010] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a pre-wiring template is mainly composed of wiring accessories, panels, positioning boards and chassis.

[0011] First, sandwich the prepared wiring template spray pattern between two panels, and then fix the panel on the bracket. Bracket 1 and bracket 2 are stretched, and bracket 2 and bracket 3 are fixed together by a positioning plate to ensure that the horizontal state of the wiring template remains unchanged. Then install the wiring accessories through the small holes on the panel according to the plastic spraying diagram, and complete the pre-wiring process in the horizontal state according to the plastic spraying diagram; open the positioning plate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com