Roller crusher having at least one roller comprising a flange

A roll crusher and flange technology, applied in the direction of material forming presses, presses using rotating pressure components, presses, etc., can solve the problem that the roll parameters cannot be changed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

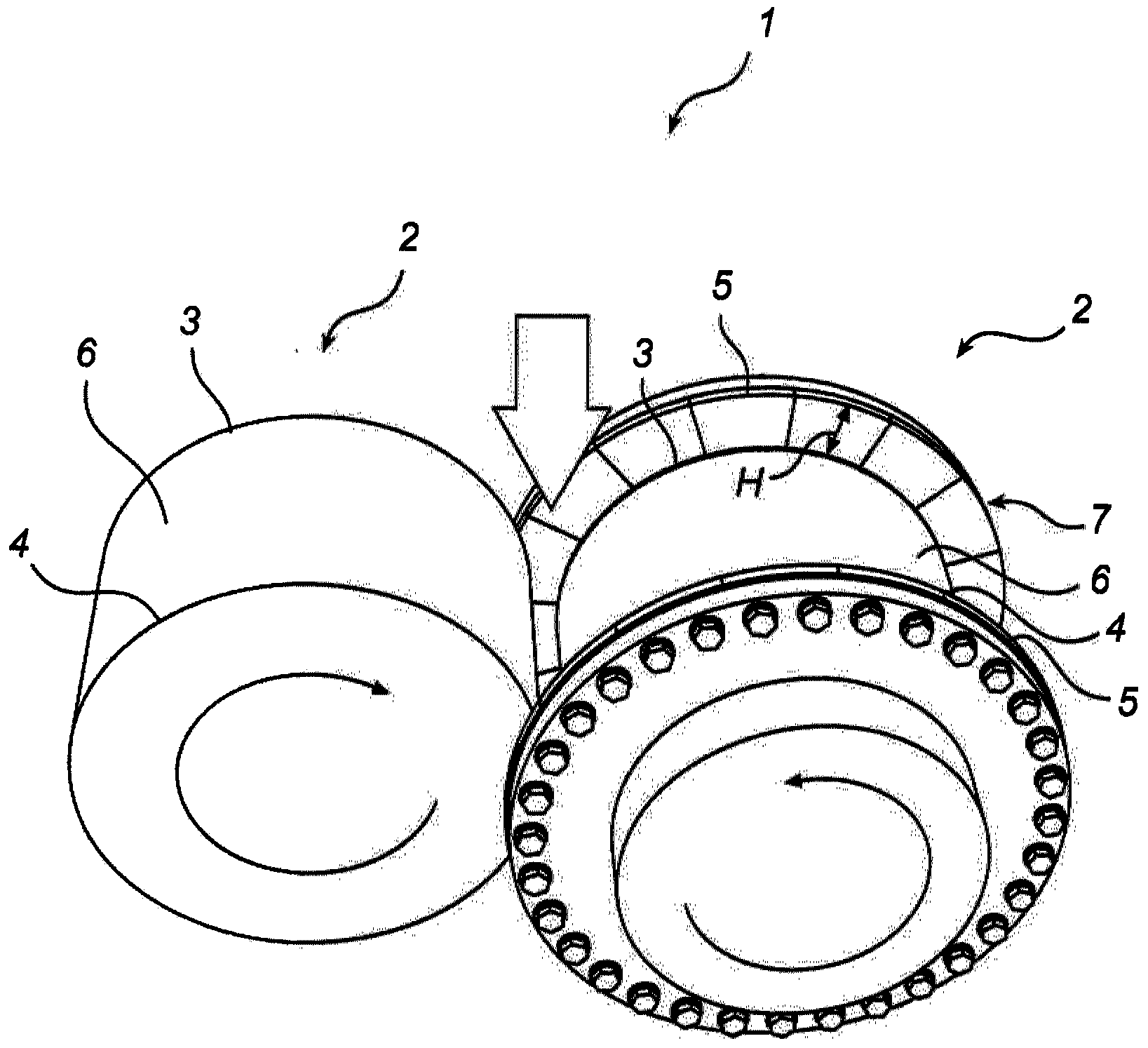

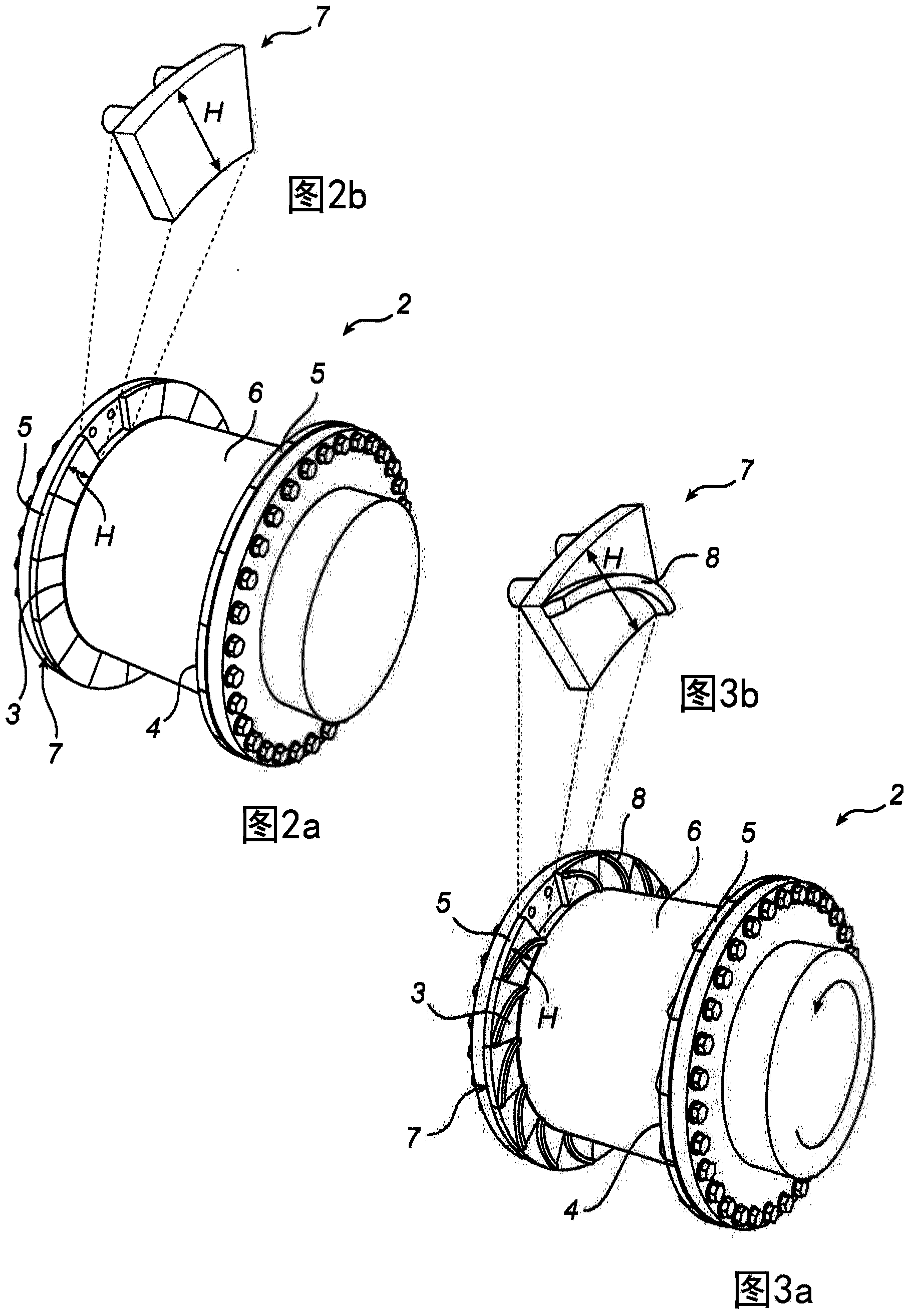

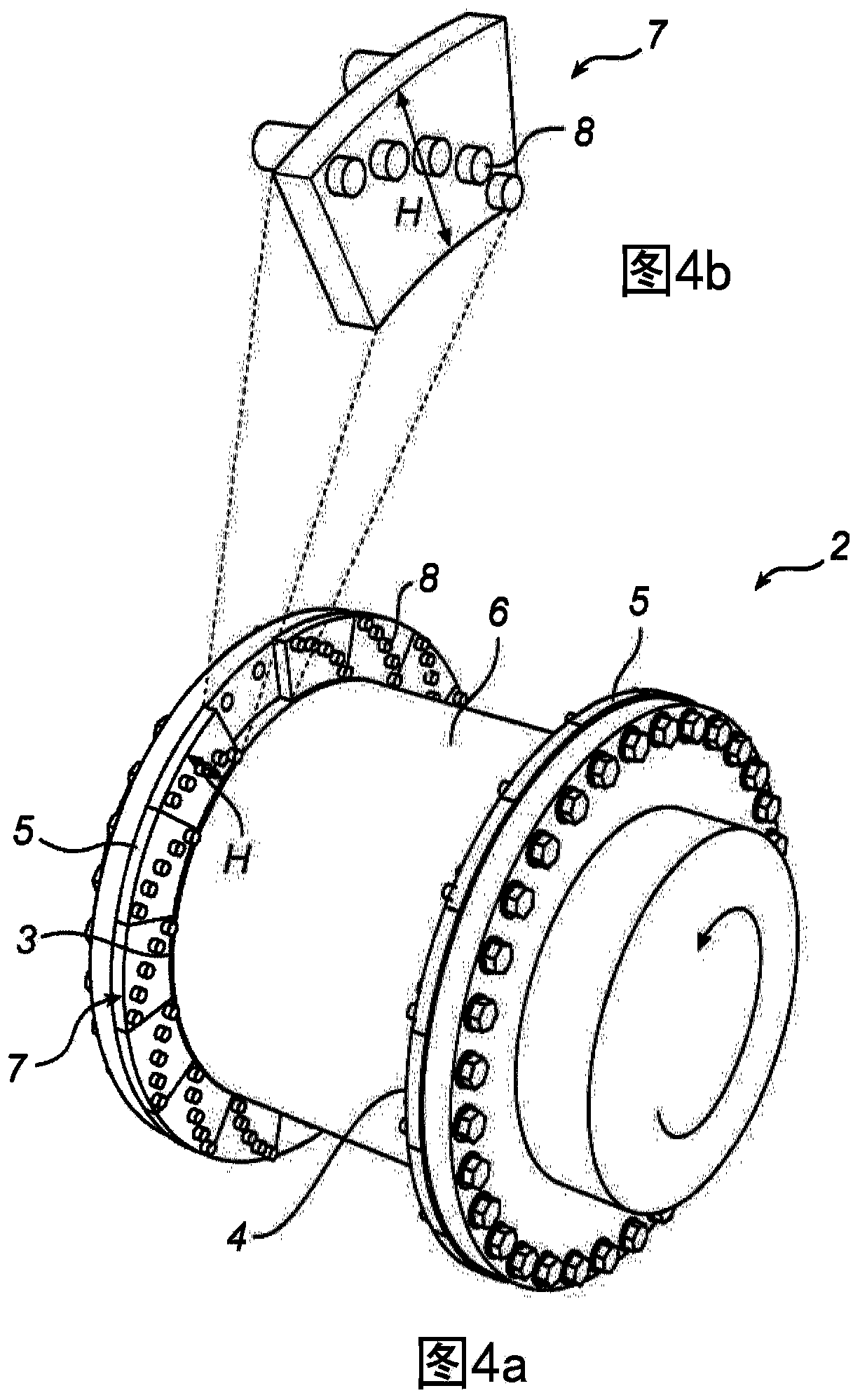

[0024] figure 1 A roll crusher 1 according to an exemplary embodiment of the invention is shown. The roll crusher 1 has two substantially parallel rolls 2 arranged to rotate in opposite directions towards each other and separated by a gap. Each roller 2 has a first end 3 and a second end 4 . The roll crusher 1 comprises a flange 5 attached to the first end 3 and the second end 4 of one of the two rolls 2 of the roll crusher 1 . The flange 5 extends radially of the roll 2 and has a height H beyond the outer surface 6 of the roll sufficient to extend across a gap substantially along the nip angle α of the roll crusher 1 . The height H is sufficient to extend across the gap substantially along the nip angle α of the roll crusher 1 when the gap is set to the maximum operating gap. The flange 5 is flat and helps to keep the material to be crushed on the outer surface 6 of the roll. That is to say, due to the presence of the flange 5 material is prevented from falling on the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com