Axial magnetic fluid dynamic seal structure

A dynamic sealing structure and axial magnetic technology, applied in the field of metallurgy, can solve the problems of easy aging of rubber rings, adding magnetic fluid, time-consuming and labor-intensive maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ;

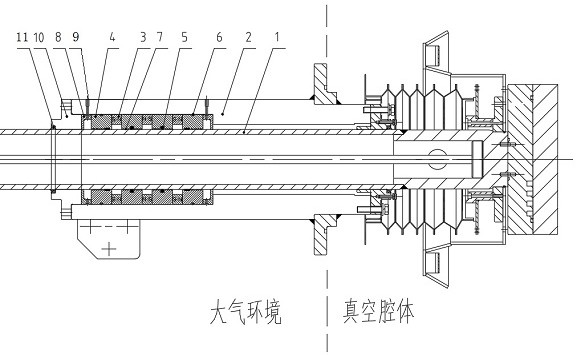

[0072] Such as figure 1 As shown, the present invention provides an axial magnetic fluid dynamic sealing structure, and the structure of the present invention is connected to the cavity of the vacuum precision casting furnace mold chamber as an example, including:

[0073] Shaft 1, which is arranged in a hollow housing 2, and can move back and forth in the housing 2;

[0074] At least three permanent magnets 3 are fixed side by side between the outer circle of the shaft 1 and the inner wall of the housing 2, and the total number of permanent magnets is an odd number;

[0075] A plurality of pole pieces 4, one pole piece 4 is arranged on both sides of each permanent magnet 3;

[0076] The baffle 5 is only arranged at the center of the inner circular surface of at least one of the two pole pieces 4 adjacent to the permanent magnet 3 in the middle position. It has no contact with the shaft 1 and a first gap is formed between it and the shaft 1. The preset gap is used to block t...

no. 2 example ;

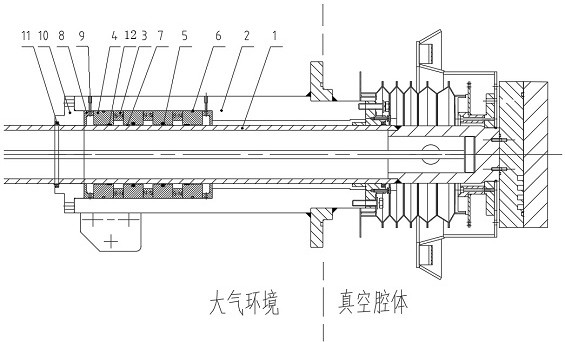

[0088] Such as figure 1 combine figure 2 As shown, the present invention provides an axial magnetic fluid dynamic sealing structure, and the structure of the present invention is connected to the cavity of the vacuum precision casting furnace mold chamber as an example, including:

[0089] Shaft 1, which is arranged in a hollow housing 2, and can move back and forth in the housing 2;

[0090] At least three permanent magnets 3 (permanent magnets 3 can be added in pairs according to the actual situation), fixed side by side between the outer circle of the shaft 1 and the inner wall of the housing 2;

[0091] A plurality of pole pieces 4, one pole piece 4 is arranged on both sides of each permanent magnet 3;

[0092] The baffle 5 is only arranged at the center of the inner circular surface of at least one of the two pole pieces 4 adjacent to the permanent magnet 3 in the middle position. It has no contact with the shaft 1 and a first gap is formed between it and the shaft 1. ...

no. 3 example ;

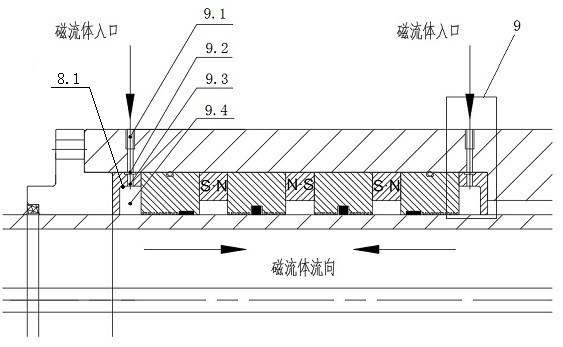

[0110] Such as image 3 As shown in 2, the present invention provides an axial magnetic fluid dynamic sealing structure, and the structure of the present invention is connected to the cavity of the vacuum precision casting furnace mold chamber as an example, including:

[0111] Shaft 1, which is arranged in a hollow housing 2, and can move back and forth in the housing 2;

[0112] At least three permanent magnets 3 (permanent magnets 3 can be added in pairs according to the actual situation), fixed side by side between the outer circle of the shaft 1 and the inner wall of the housing 2;

[0113] A plurality of pole pieces 4, one pole piece 4 is arranged on both sides of each permanent magnet 3;

[0114] The baffle 5 is only arranged at the center of the inner circular surface of at least one of the two pole pieces 4 adjacent to the permanent magnet 3 in the middle position. It has no contact with the shaft 1 and a first gap is formed between it and the shaft 1. The preset ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com