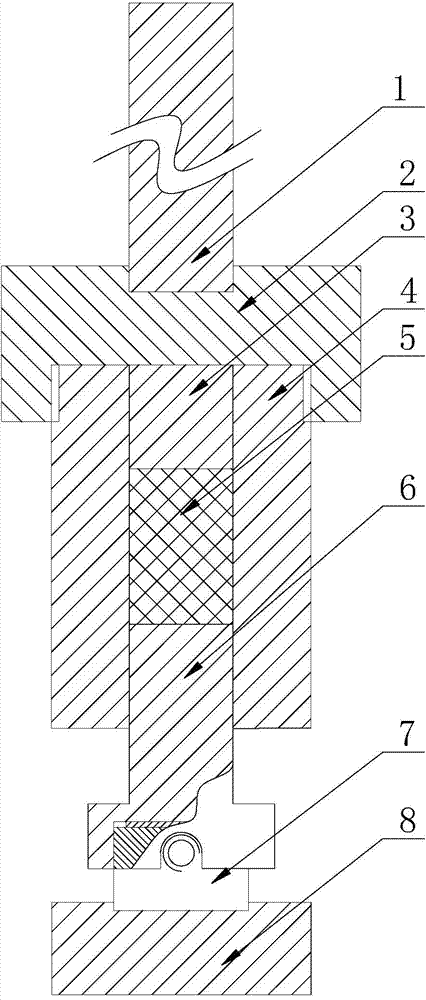

Explosive column stress measurement device under low-speed hammer-dropping impact loading

A technology of stress measurement and drop weight, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of inconsistent cross-sectional shape and size, affecting pressure measurement, low data reliability, etc., to achieve less human influence factors and pressure transmission. Stable and simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

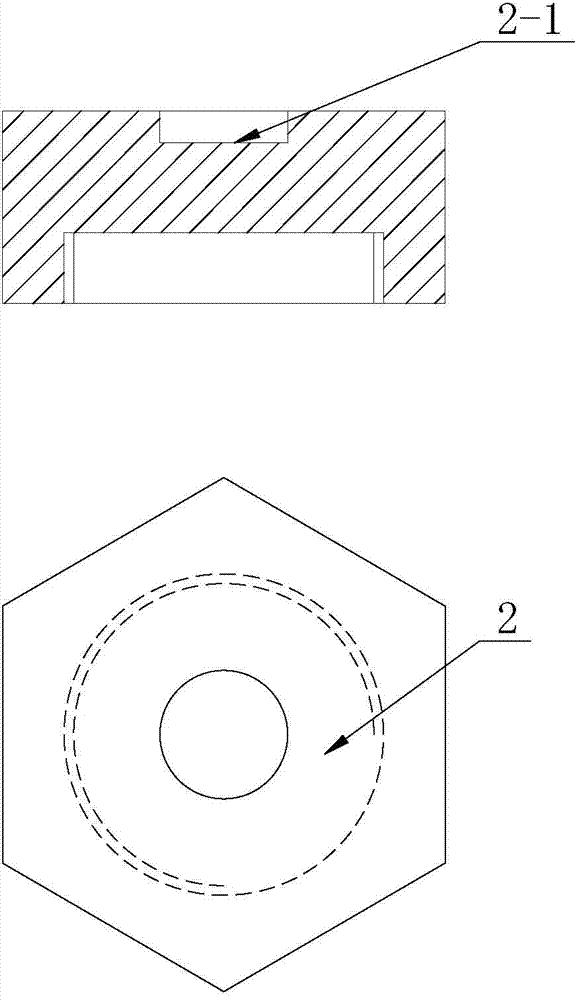

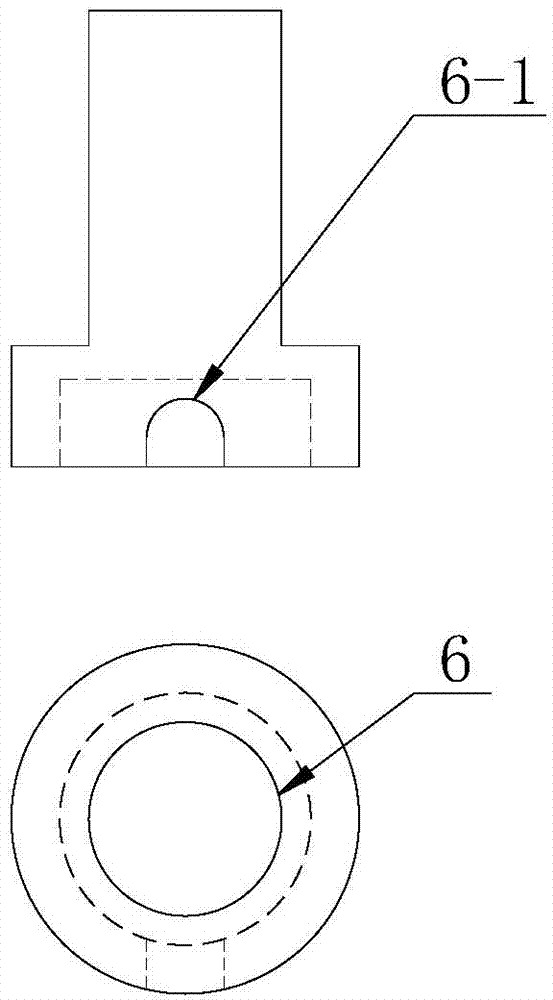

Method used

Image

Examples

Embodiment 1

[0018] The samples are press-packed B explosives. The sizes of the powder columns are Φ20×20mm, Φ20×10mm, and Φ20×15mm. The test temperature is 23°C, the relative humidity is 52%, and the drop weight is 30kg. The drop height is 300mm. The assembly method is as follows: The method is described, and the test results are shown in Table 1.

[0019] Table 1 The peak pressures in the impact process of B explosives with different sizes

[0020] size

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com