Method for qualitatively and quantitatively testing and analyzing impurities in steel

A technology for testing and analyzing inclusions, which is applied in the direction of material analysis by measuring secondary emissions, material analysis, and material analysis by optical means, which can solve the problems of inability to know the type of inclusions, large human errors, and large influence of parameter settings and other issues, to achieve the effects of small human influence factors, specific evaluation results, and accurate analysis and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

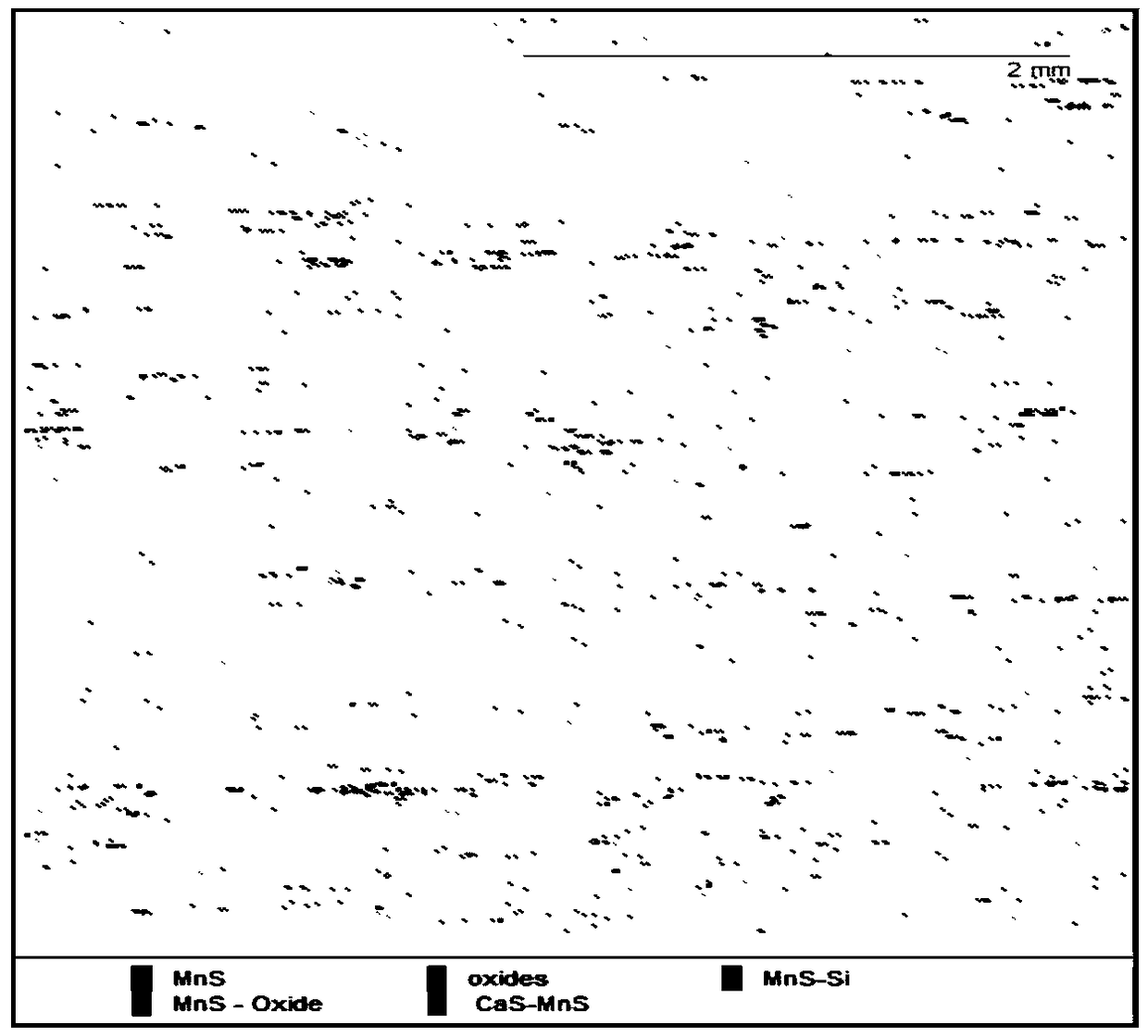

[0084] Such as figure 1 As shown, according to the metallographic sample preparation method, the gear steel sample to be tested is ground and polished, and the inclusions of the sample to be tested are observed in a metallographic microscope. The size range is greater than 1 μm and below 20 μm. Used for signal strength calibration when searching for inclusions.

[0085] Put the sample into the sample chamber, and fix it on the corresponding supporting base to ensure that the working distance is about 17mm, and then vacuumize. When the vacuum degree reaches the requirement, turn on the power, accelerate the acceleration voltage and filament current. In this embodiment, the acceleration voltage setting value is 20Kv, and the test area is set by the two-point method. After confirming one point, focus to the clearest, and then move the sample Determine the position of another point on the platform, focus to the clearest, and the rectangular area determined by the two points is th...

Embodiment 2

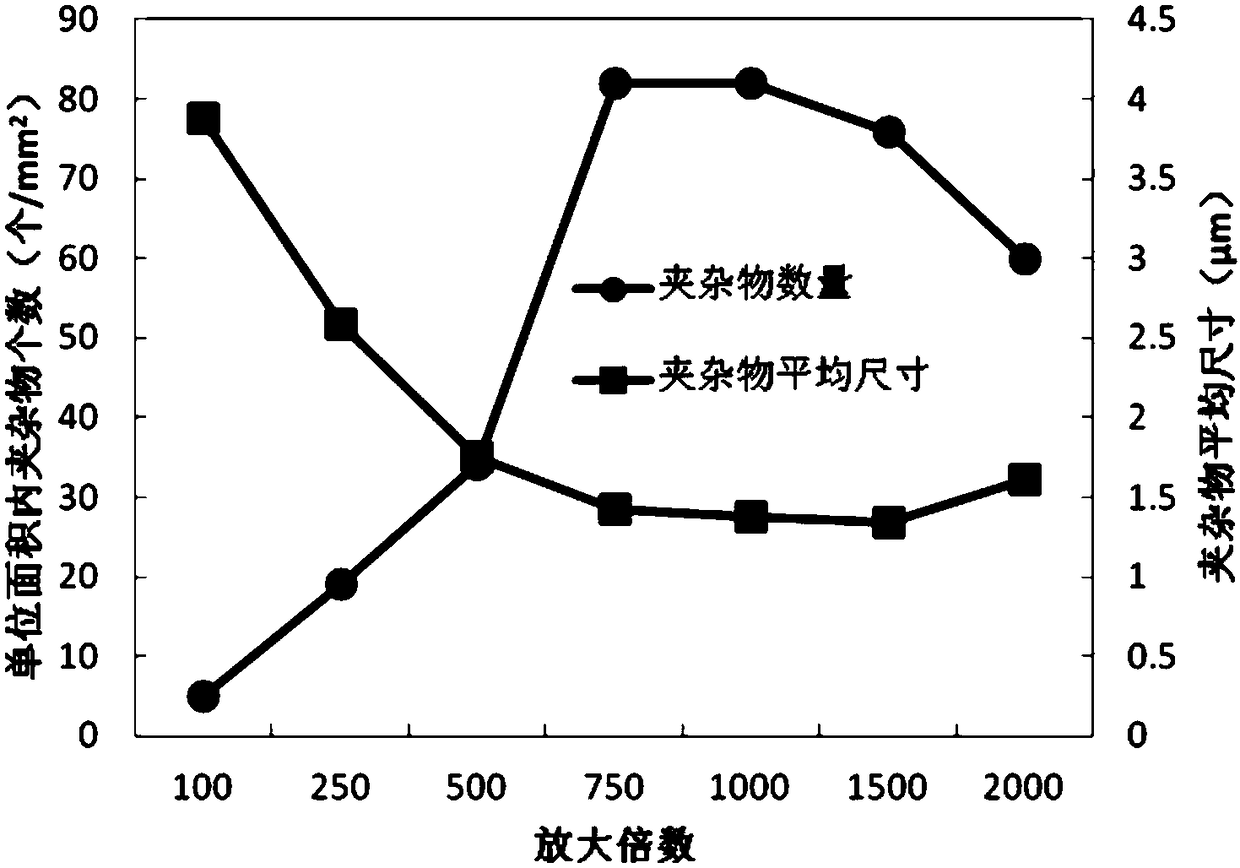

[0090] Such as figure 2 As shown, after grinding and polishing the bearing steel sample according to the metallographic sample preparation method, the inclusions of the sample to be tested were observed in a metallographic microscope, most of the inclusions were in the size range of 1.5 μm, and an aluminum strip was pasted on the edge of the sample surface , used for signal strength calibration when searching for inclusions.

[0091] Put the sample into the sample chamber, and fix it on the corresponding supporting base to ensure that the working distance is about 17mm, and then vacuumize. When the vacuum degree reaches the requirement, the power is turned on, and the accelerating voltage and filament current are accelerated. In this embodiment, the setting value of the accelerating voltage is 20Kv, and the test area is set by the two-point method. After determining one point, focus to the clearest point, then move the sample stage to determine another point position, focus ...

Embodiment 3

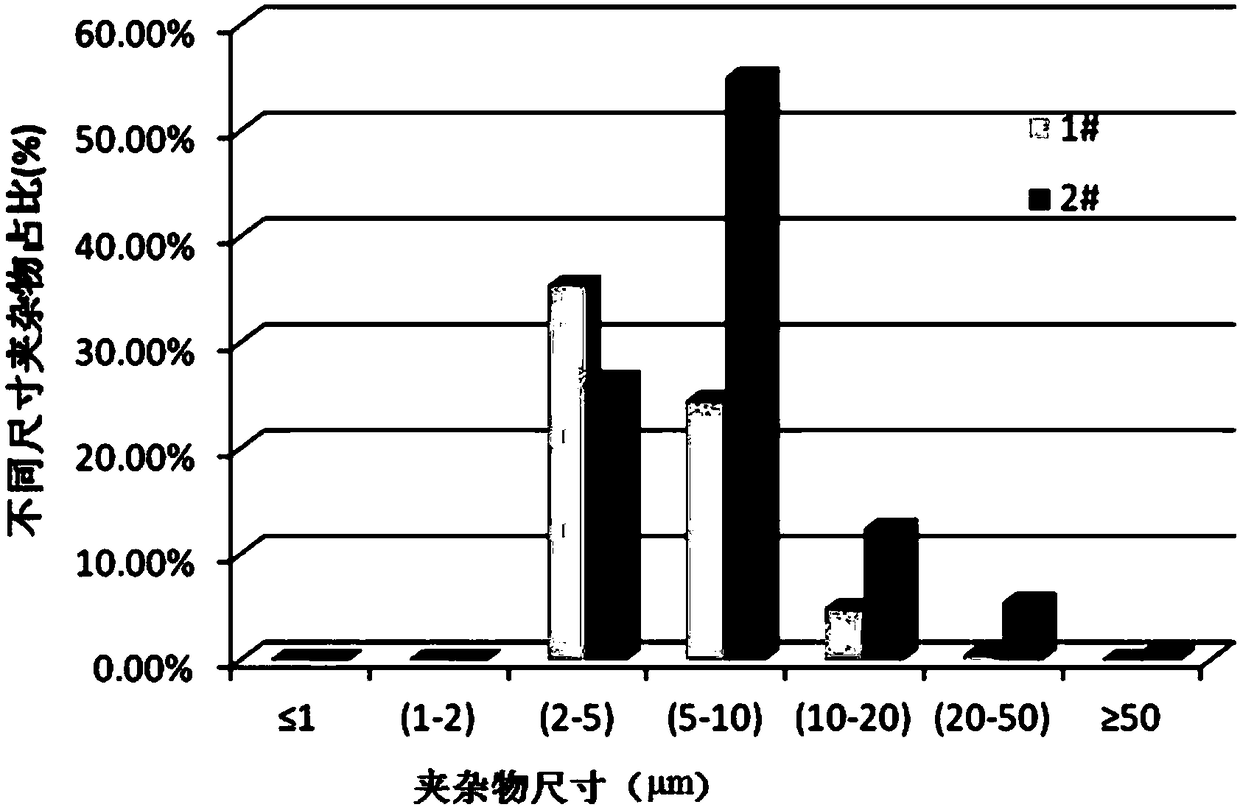

[0096] Such as Figure 3 to Figure 4 As shown, two common carbon steel samples (1# and 2# in table 2) are selected, and the method of the present invention is used to evaluate the inclusions. First, the two samples are polished to ensure that the surface is smooth, smooth and free of foreign matter. Observing the inclusions of the sample to be tested in a metallographic microscope, most of the inclusions have a size range greater than 1 μm and less than 20 μm. Using the method of the present invention to detect inclusions, first paste a small piece of aluminum strip on the edge of the sample surface for Signal strength calibration when searching for inclusions. Put the sample into the sample chamber, and fix it on the corresponding supporting base so that the working distance is about 17mm, and then vacuumize it. When the vacuum degree reaches the requirement, turn on the power, accelerate the voltage and filament current. In this embodiment, the acceleration voltage setting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com