Grease quantitative analysis method based on near-infrared transmission and reflection spectrum technology

A technology of near-infrared spectroscopy and spectral technology, which is applied in the field of quantitative analysis of oil based on near-infrared transflective spectroscopy technology, which can solve the problems that affect the speed and efficiency of oil reception, the detection results are greatly affected by human factors, and cannot be effectively and quickly identified. , to achieve less human influence factors, improve the efficiency of inspection and reception, and reduce the effect of deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

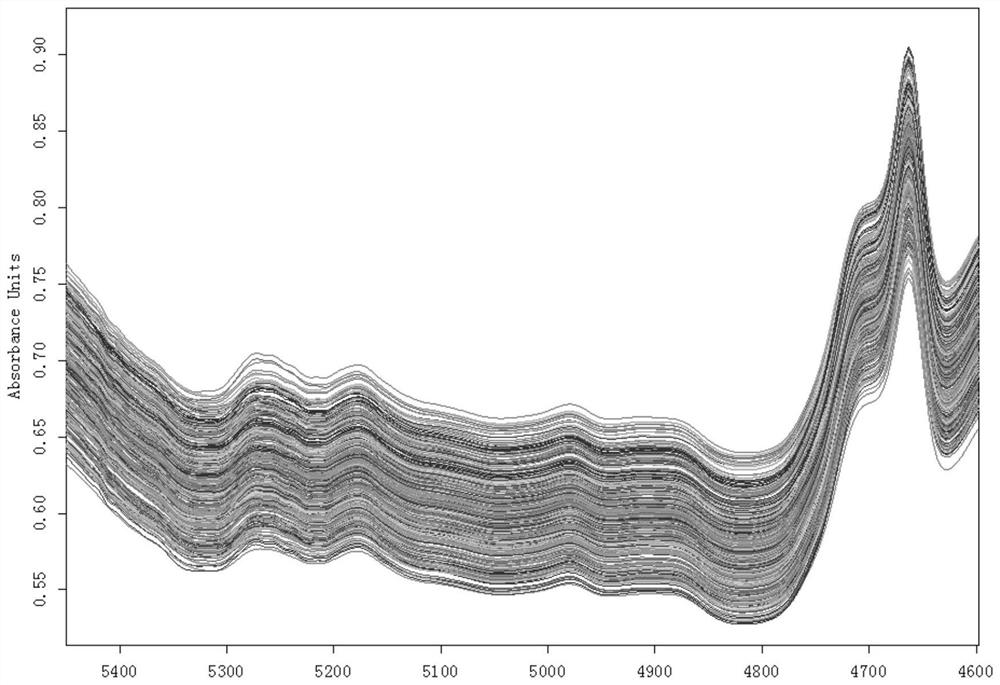

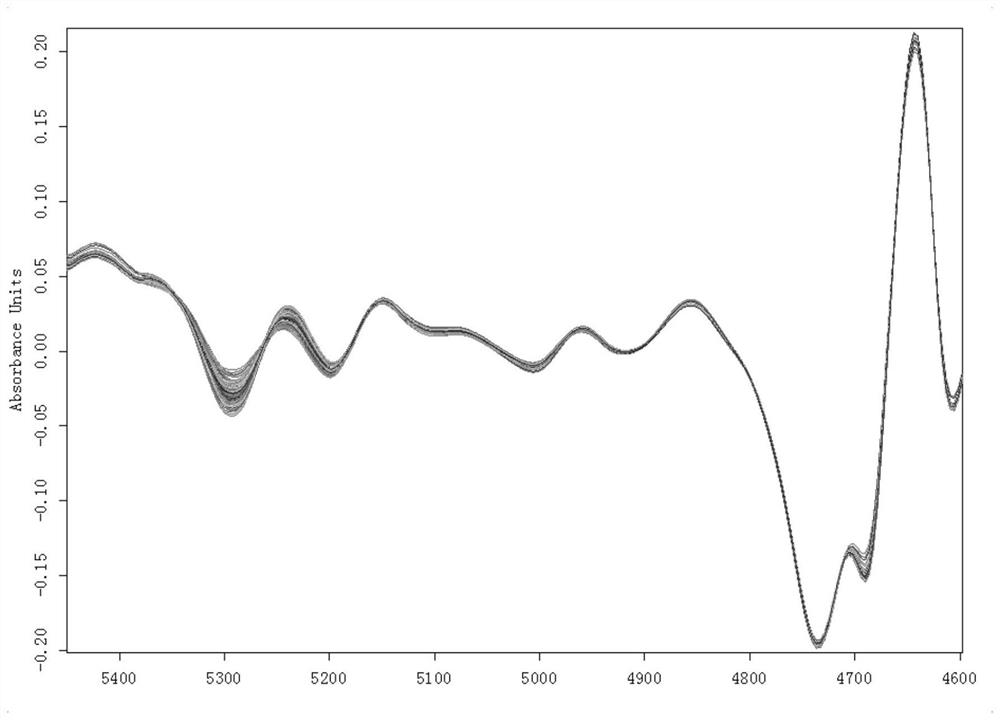

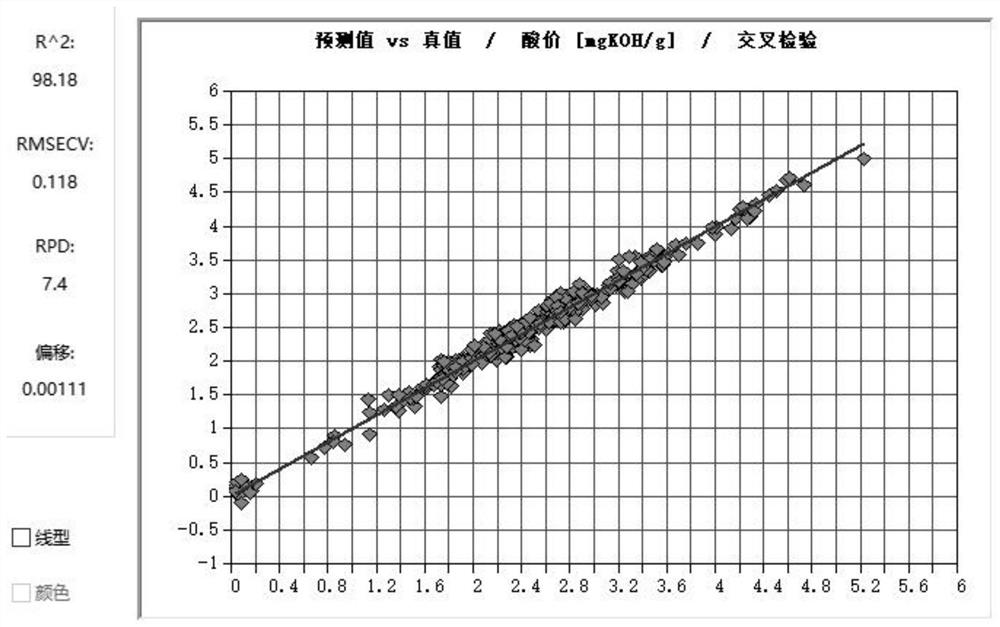

[0044] Transflectance spectroscopy is an advanced technology for rapid detection of liquid components. Compared with transmission, the optical path of transflectance is doubled. Because it is extremely sensitive to temperature, it is difficult to establish spectral acquisition parameters and spectral processing methods, resulting in Modeling is very difficult, and its application in the feed industry is basically blank. Using transmission-reflection spectroscopy combined with computer algorithms, the "fast, efficient, and zero-reagent" quantitative detection of feed oils is realized, and the results are highly accurate, stable, and easy to operate.

[0045]A kind of oil quantitative analysis method based on near-infrared transmission and reflection spectroscopy provided by the present invention, this embodiment takes soybean oil as an example, but not limited to soybean oil, cottonseed oil, rapeseed oil, palm oil, chicken oil, etc. can also be used to quantify oil The analytic...

Embodiment 2

[0066] A kind of grease quantitative analysis method based on near-infrared transflective spectroscopy technology provided by the present invention, the present embodiment takes lard as an example, comprises the following steps:

[0067] 1. If the lard sample is semi-solidified or solid, put the lard sample in the sample container, then place it in a water bath at 40-50°C to re-dissolve, preferably at 45°C, take it out, shake it well and let it stand for 5-10 minutes , and then use the sample cup to take several lard samples, each 1 ~ 5mL. 1 to 2 parts are used for wet chemical detection of various indicators of lard; 1 part is used for sample scanning. The scanned sample is preferably 2mL, and then placed in a constant temperature metal bath that has been preheated for 25 to 35 minutes for 25 to 55 minutes. Set at 50°C, preferably preheat for 30 minutes, keep warm for 50 minutes, and perform near-infrared spectrum scanning.

[0068] The wet chemical value test results of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com