Method for producing oriented silicon steel with excellent magnetic property

A technology of oriented silicon steel and production method, applied in the direction of tension/pressure control, etc., can solve the problems of frequent repair of heating furnace, large slab burning loss, difficult precise control, etc., achieves small human influence factors, improves magnetic properties of finished products, and is easy Precisely Controlled Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Normalize steel plates with multiple components. The main components of steel plates are shown in Table 1:

[0055] Table 1 Unit: weight percentage

[0056] NO.

Si

C

Als

N

Mn

S

1

3.03

0.0456

0.0264

0.0078

0.12

<0.0060

2

3.22

0.0507

0.0261

0.0081

0.12

<0.0060

[0057] 3

3.41

0.0542

0.0269

0.0083

0.12

<0.0060

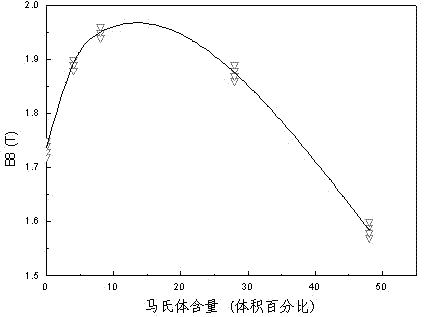

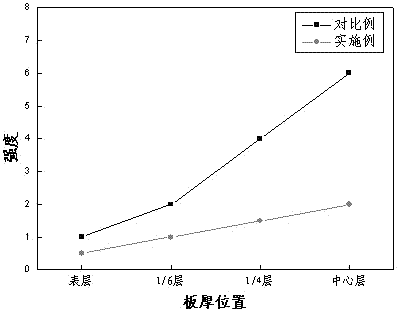

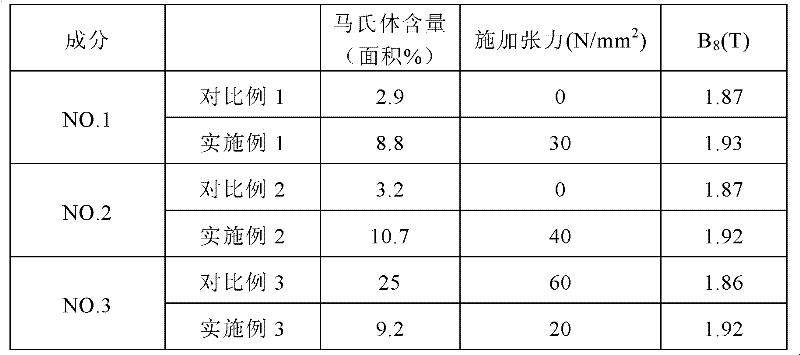

[0058] The steel plate with the above composition is heated to 1200°C and kept for 180 minutes. Then roll directly to 2.0mm. The hot-rolled plate is subjected to two-stage normalization treatment, first heating to 1200°C, then cooling to 900°C in 200s, and then quenching the steel plate in 100°C water. By adjusting the tension roller installed in the furnace or changing at least one treatment of the front and rear tension rollers to change the normalized phase transition (range: 900℃ to 500℃) the stress of the steel plate (1~200N / mm) 2 ), to achieve the purpose of optimizing the martensite content and its distr...

Embodiment 2

[0064] The main chemical composition of the steel plate is: Si 3.05wt%, C 0.060wt%, Als 0.0290wt%, N 0.0077wt%, Mn 0.13wt%, S<0.006wt%.

[0065] The steel plate with the above composition is heated to 1200°C and kept for 180 minutes. Then roll directly to 2.0mm. The hot-rolled plate is subjected to two-stage normalization treatment, first heating to 1100°C, then cooling to 1000°C in 50s, and then quenching the steel plate in 50°C water. By adjusting the tension roller installed in the furnace or changing at least one treatment of changing the crimping tension, the stress of the steel plate during the normalized phase change (range: 900°C to 500°C) (1~200N / mm) 2 ), to achieve the purpose of optimizing the content and distribution of martensite in the normalized plate, so that it is in the range of obtaining better magnetic properties of the finished product.

[0066] After pickling, the steel plate was subjected to 5 passes of single-stage cold rolling, of which the 3rd and 4th pas...

Embodiment 3

[0071] The main chemical composition of the steel plate is: Si 2.9wt%, C 0.048wt%, Als 0.0255wt%, N 0.0073wt%, Mn 0.10wt%, S<0.006wt%.

[0072] The steel plate with the above composition is heated to 1200°C and kept for 180 minutes. Then roll directly to 2.0mm. The hot-rolled sheet is subjected to two-stage normalization treatment, first heating to 1100°C, then cooling to 900°C in 100s, and then quenching the steel sheet in 80°C water. By adjusting the tension roller installed in the furnace or at least one treatment of changing the crimping tension, the stress of the steel plate during the normalization phase change (range: 900℃ to 500℃) (1~200N / mm) 2 ), to achieve the purpose of optimizing the martensite content and its distribution in the normalized plate, so that it is within the range of obtaining better magnetic properties of the finished product.

[0073] After pickling, the steel plate was subjected to 5 passes of single-stage cold rolling, of which the 3rd and 4th passes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com