Surfactant composition, its application and point load performance evaluating method

A surfactant and composition technology, applied in the field of point load performance evaluation, can solve the time-consuming problems of cracking performance and slow crack growth resistance performance, and achieve the effects of small human influence factors, shortening evaluation time, and accurate control of operating parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

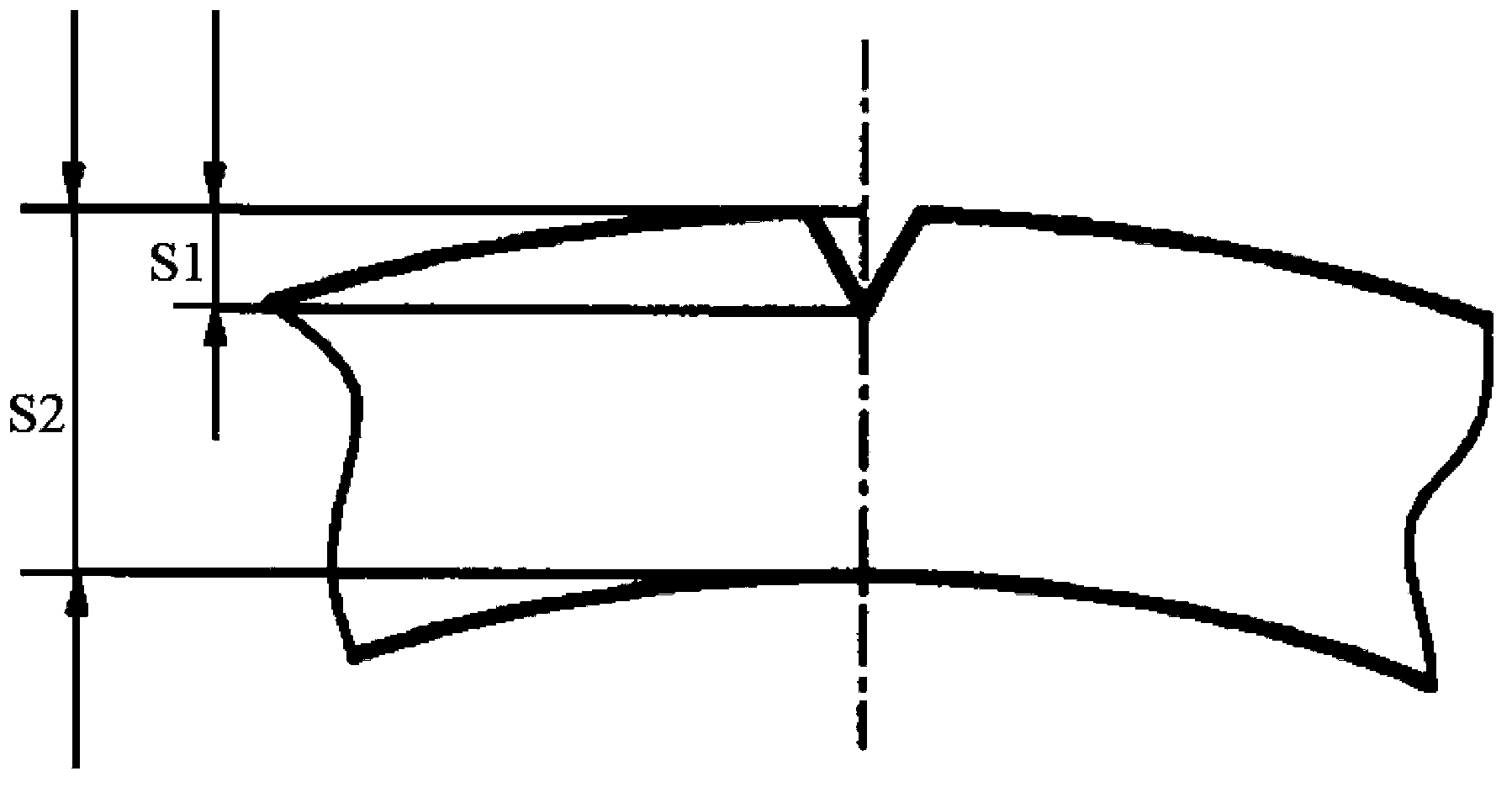

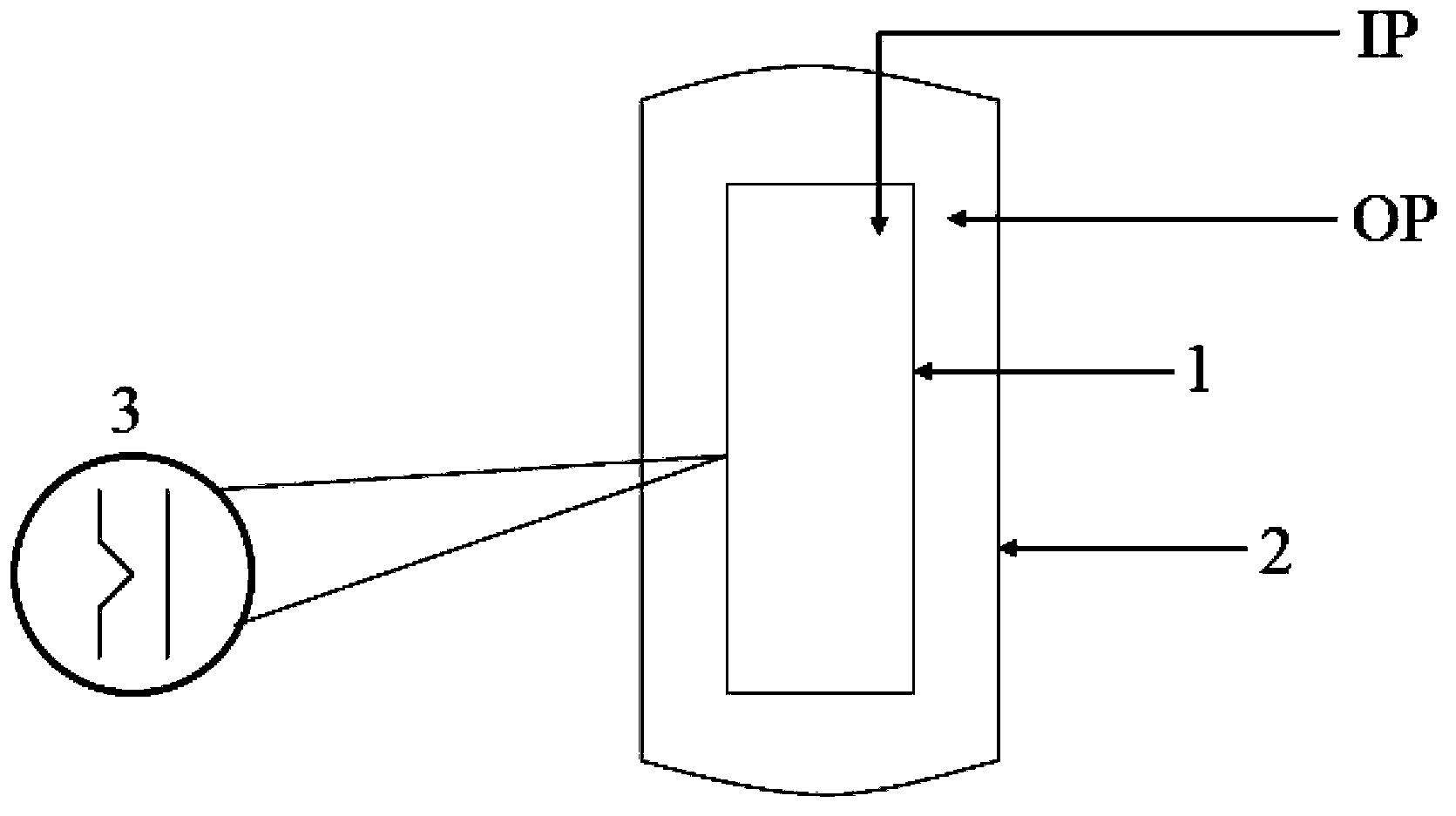

Image

Examples

Embodiment 1

[0052] This example serves to illustrate the surfactant composition of the present invention.

[0053] Surfactant solution A1 was prepared by mixing 2 parts by weight of Arkopal N 100 surfactant, 0.1 part by weight of sodium dodecylbenzenesulfonate and 97.9 parts by weight of deionized water.

Embodiment 2

[0055] This example serves to illustrate the surfactant composition of the present invention.

[0056] Surfactant solution A2 was prepared by mixing 2 parts by weight of Arkopal N 100 surfactant, 0.1 part by weight of sodium cetylbenzenesulfonate and 97.9 parts by weight of deionized water.

Embodiment 3

[0058] This example serves to illustrate the surfactant composition of the present invention.

[0059] Surfactant solution A3 was prepared by mixing 2 parts by weight of Arkopal N 100 surfactant, 0.05 parts by weight of sodium dodecylsulfonate and 97.95 parts by weight of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com