Method for preparing hydrogenated biodiesel by catalyzing directional hydrodeoxygenation of grease

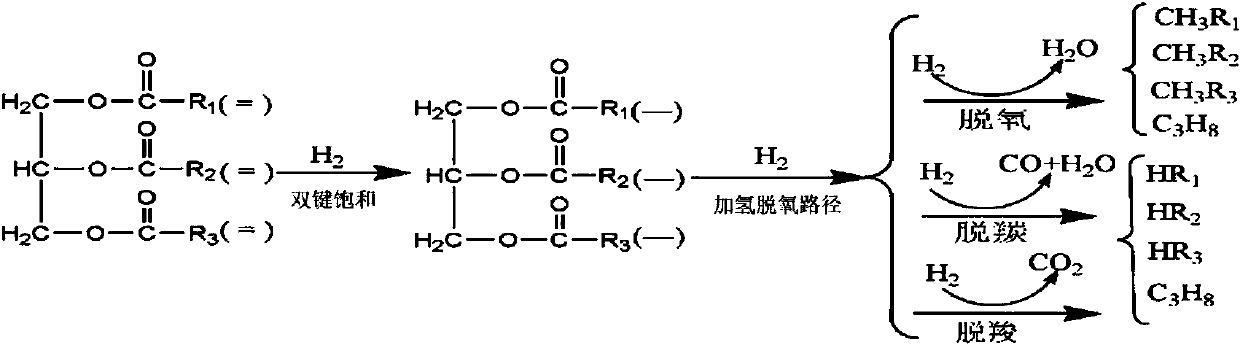

A biodiesel, hydrodeoxygenation technology, applied in fatty acid hydrogenation, chemical instruments and methods, biofuels, etc., to reduce the reaction temperature and time, avoid the defect of easy inactivation in contact with water, and reduce the generation of reaction moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

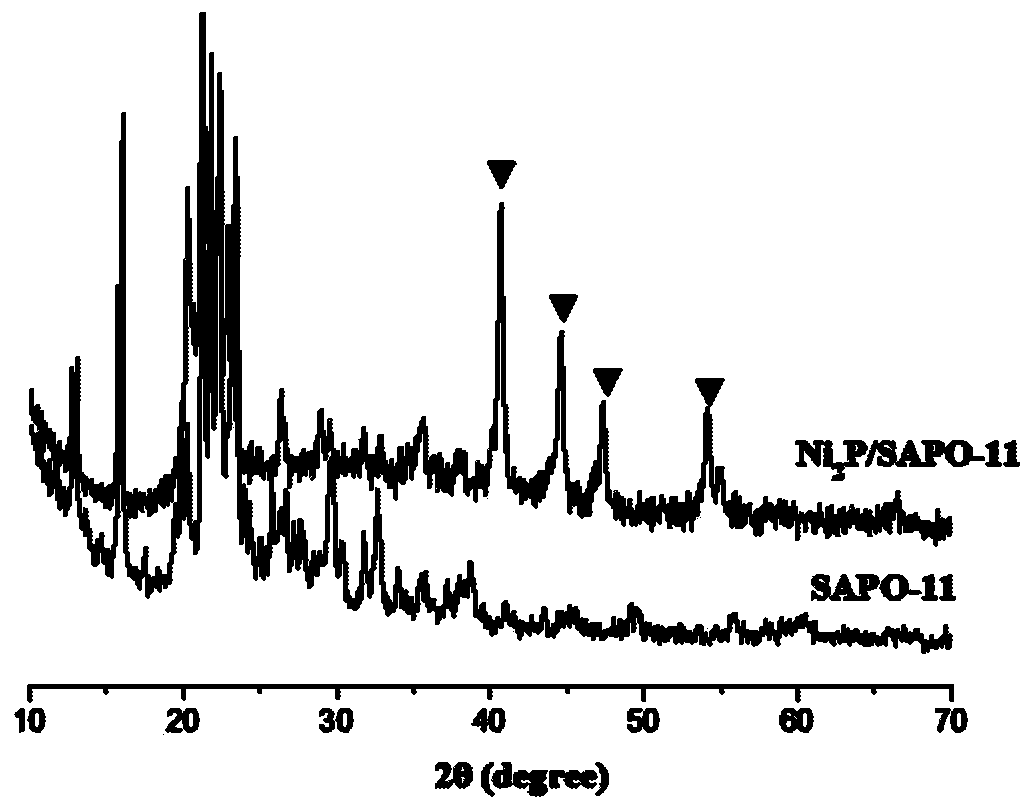

[0030] Catalyst Ni 2 The preparation method of P / SAPO-11:

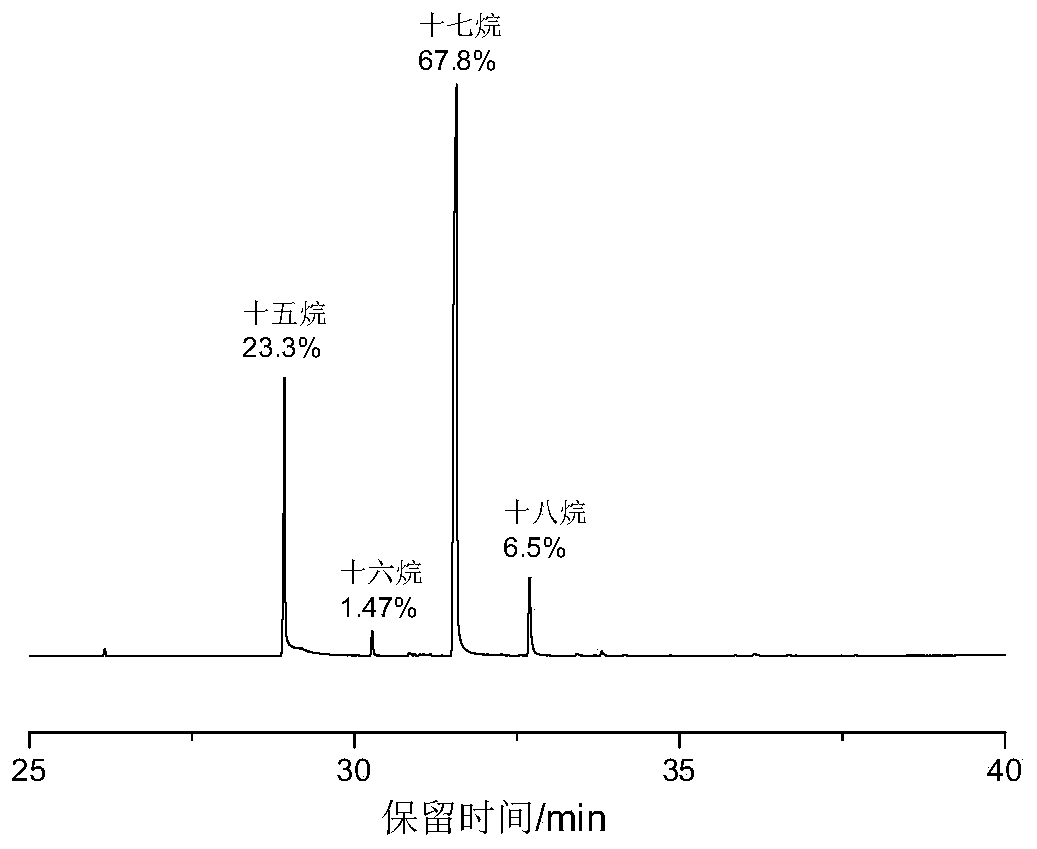

[0031] The content of control nickel element is 15wt.% of carrier quality, and the nickel nitrate hexahydrate and the diammonium hydrogen phosphate metered by the mol ratio of nickel and phosphorus are 1: 1 are dissolved in deionized water, and evenly transferred in the crucible to be dissolved, Add SAPO-11, ultrasonically impregnate for 30min, transfer the impregnating solution into an oven at 80°C and dry for 12h, and finally move it to a muffle furnace at 550°C for calcination for 4h, crush it through an 80-mesh sieve, and obtain a catalyst precursor; add the catalyst precursor to In a tube furnace, hydrogen is introduced to carry out temperature-programmed reduction, and H 2 The flow rate is 150mL / min, the temperature is raised to 250°C at 10°C / min, the temperature is raised to 350°C at 5°C / min, and finally the temperature is raised to 650°C at 1°C / min, and the temperature is maintained at 650°C for 3 hours; Aft...

Embodiment 2

[0037] Catalyst Ni 2 The preparation method of P / SAPO-11:

[0038] The content of control nickel element is 10wt.% of carrier quality, and the nickel nitrate hexahydrate and the ammonium dihydrogen phosphate that will be measured as 1: 1 by the molar ratio of nickel and phosphorus are dissolved in deionized water, and evenly transfer in the crucible to be dissolved, Add SAPO-11, ultrasonically impregnate for 30min, transfer the impregnating liquid into an oven at 80°C and dry for 12h, and finally move it to a muffle furnace at 550°C for calcination for 4h, crush it through a 80-mesh sieve, and obtain a catalyst precursor; add the catalyst precursor to In the high-temperature tube furnace, hydrogen gas is introduced to carry out temperature-programmed reduction. The H2 flow rate is 150mL / min, and the temperature is raised to 250°C at 10°C / min, then to 350°C at 5°C / min, and finally to 1°C / min. 650°C, keep a constant temperature of 650°C for 3 hours; after the reduction is compl...

Embodiment 3

[0042] Catalyst Ni 2 The preparation method of P / SAPO-11:

[0043] Control the content of nickel element to be 5wt.% of carrier quality, be that nickel nitrate hexahydrate and diammonium hydrogen phosphate metered by the mol ratio of nickel and phosphorus are 1: 1 and be dissolved in deionized water, wait to be dissolved and evenly transfer in the crucible, Add SAPO-11, ultrasonically impregnate for 30min, transfer the impregnating liquid into an oven at 80°C and dry for 12h, and finally move it to a muffle furnace at 550°C for calcination for 4h, crush it through a 80-mesh sieve, and obtain a catalyst precursor; add the catalyst precursor to In the high-temperature tube furnace, hydrogen gas is introduced to carry out temperature-programmed reduction. The H2 flow rate is 150mL / min, and the temperature is raised to 250°C at 10°C / min, then to 350°C at 5°C / min, and finally to 1°C / min. 650°C, keep a constant temperature of 650°C for 3 hours; after the reduction is completed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com