Composite phase-change temperature-adjusting material and preparation method thereof, multi-phase-change temperature-adjusting fiber and preparation method and application of multi-phase-change temperature-adjusting fiber

A composite phase-change and temperature-regulating fiber technology, applied in the fiber field, can solve problems such as the narrow field of heat storage and temperature-regulating fibers, and restrictions on the popularization and application of phase-change energy storage cellulose fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

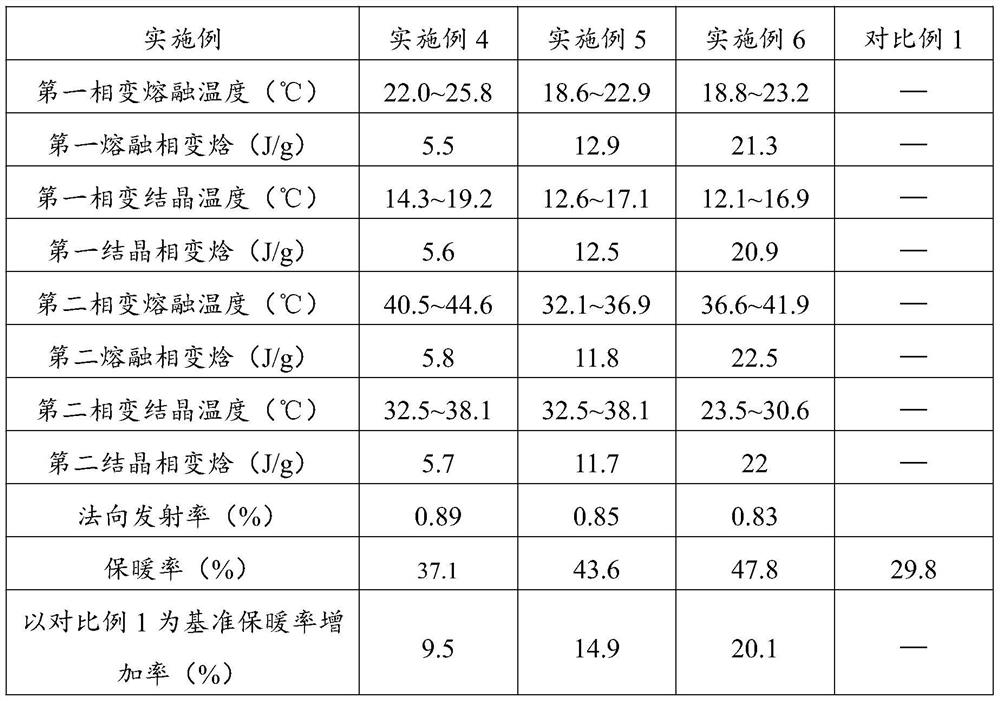

Examples

preparation example Construction

[0043] In the present invention, the preparation method of the phase change energy storage microcapsules preferably includes the following steps:

[0044] The capsule core material, capsule wall material and water are first mixed and then emulsified and dispersed to obtain an oil-in-water emulsion;

[0045] The oil-in-water emulsion is subjected to complex coacervation reaction and secondly mixed with a curing agent for cross-linking reaction to obtain phase-change energy storage microcapsules.

[0046] In the invention, the capsule core material, capsule wall material and water are first mixed and then emulsified and dispersed to obtain the oil-in-water emulsion. In the present invention, the first mixing preferably includes the following steps:

[0047] Dissolving the capsule wall material in water to obtain a capsule wall material solution;

[0048] The capsule core material is melted and mixed with the capsule wall material solution.

[0049] The invention dissolves the c...

Embodiment 1

[0099] Dissolve gelatin and gum arabic in water at 45°C according to the mass ratio of 1:1 to obtain a capsule wall material solution with a total mass concentration of gelatin and gum arabic of 12%; mix n-heptadecane melted at 25°C with the capsule wall material solution (the mass ratio of the total mass of gelatin and gum arabic gum and n-heptadecane is 3:2) carry out emulsification dispersion with the rotating speed of 1860r / min in the water bath of 25 DEG C after, every 30min detect the particle diameter of an emulsion, when the emulsion When the D90 particle size is 1.55 μm, the emulsification and dispersion are stopped to obtain an oil-in-water emulsion;

[0100] After the pH value of the oil-in-water emulsion is adjusted to 3, the complex coagulation reaction is carried out for 35 minutes at a temperature of 10° C. and a rotating speed of 1000 r / min; after the pH value of the feed liquid after the complex coagulation reaction is adjusted to 7.0, and Dialdehyde (the mass...

Embodiment 2

[0106] Dissolve gelatin and gum arabic in water at 55°C according to the mass ratio of 1:1 to obtain a capsule wall material solution with a total mass concentration of gelatin and gum arabic of 20%; mix n-hexadecane melted at 27°C with the capsule wall material solution (the mass ratio of the total mass of gelatin and gum arabic and n-hexadecane is 2:2) afterward, carry out emulsification dispersion with the rotating speed of 2100r / min in the water bath of 32 ℃, every 30min detect the particle diameter of an emulsion, when the emulsion When the D90 particle size is 1.265 μm, stop emulsification and dispersion to obtain an oil-in-water emulsion;

[0107] After the pH value of the oil-in-water emulsion was adjusted to 4, the complex coagulation reaction was carried out for 28 minutes at a temperature of 18° C. and a rotating speed of 1225 r / min; after the complex coagulation reaction, the pH value of the feed liquid was adjusted to 7.5 and more POM (the mass ratio of paraformal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com