Preparation method for phenyl heptadecane

A technology of phenylheptadecane and phenyloctadecanoic acid, which is applied in the field of production of β-mannanase, can solve the problems of high energy consumption, high temperature, and poor safety, and achieve low energy consumption, low price, and safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

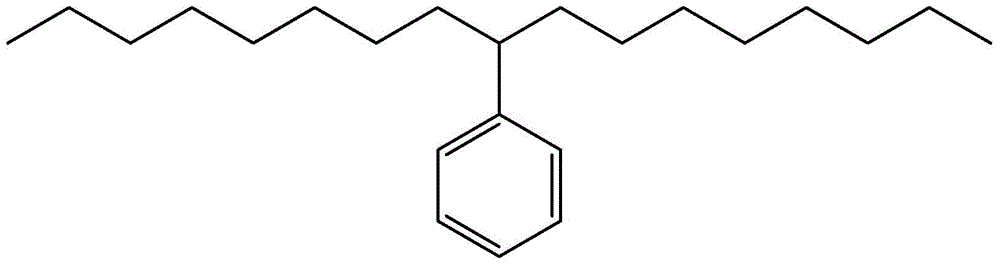

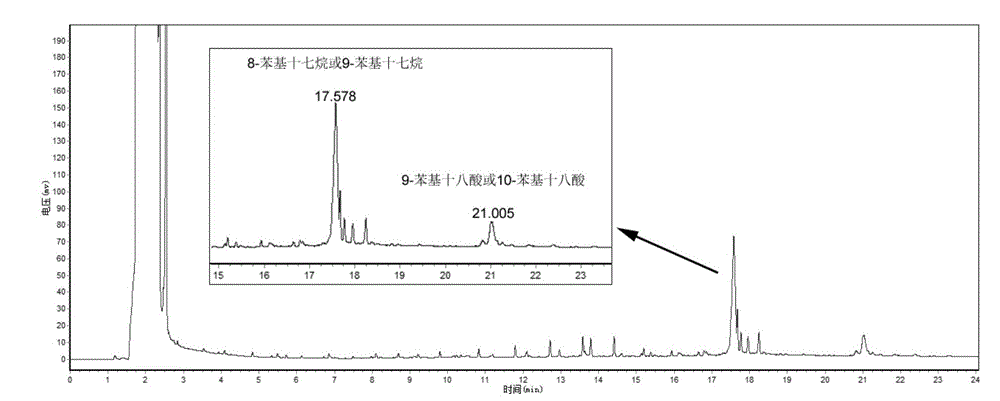

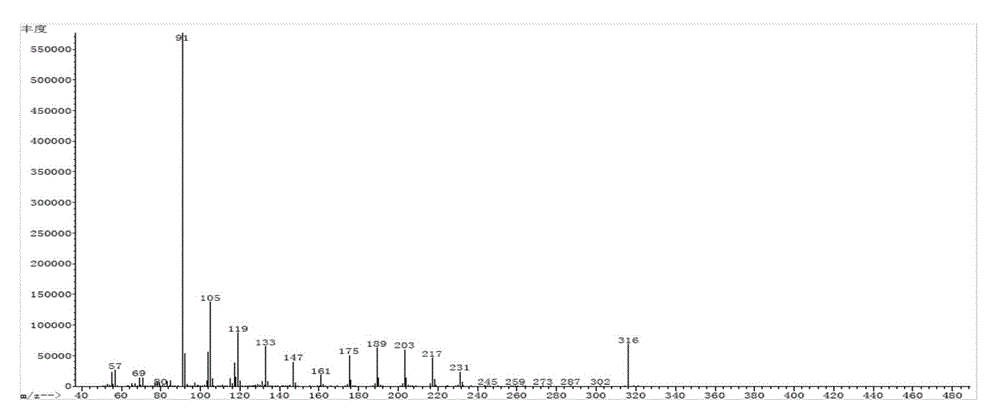

[0024] Take by weighing 9-phenyl octadecanoic acid or 10-phenyl octadecanoic acid 20g, catalyst 1.0g (mass ratio 20:1), join in the reactor, pass into N in the reactor 2 Gas for 20 minutes and seal the autoclave. Set the reaction temperature to 170°C, the reaction time to 6h, and the stirring speed to 300r / min. After the reaction, the obtained product was suction-filtered under reduced pressure, and after the catalyst was removed, 8-phenylheptadecane or 9-phenylheptadecane was obtained with a yield of 61.85%. The molecular structure of 9-phenylheptadecane is shown in figure 1 shown.

Embodiment 2

[0026] Take by weighing 9-phenyl octadecanoic acid or 10-phenyl octadecanoic acid 20g, catalyst 1.0g (mass ratio 20:1), join in the reactor, pass into N in the reactor 2 Gas for 20 minutes and seal the autoclave. Set the reaction temperature to 180°C, the reaction time to 6h, and the stirring speed to 300r / min. After the reaction, the obtained product was suction-filtered under reduced pressure, and the catalyst was removed to obtain 8-phenylheptadecane or 9-phenylheptadecane with a yield of 93.47%.

Embodiment 3

[0028] Take by weighing 9-phenyl octadecanoic acid or 10-phenyl octadecanoic acid 20g, catalyst 1.0g (mass ratio 20:1), join in the reactor, pass into N in the reactor 2 Gas for 20 minutes and seal the autoclave. Set the reaction temperature to 190°C, the reaction time to 6h, and the stirring speed to 300r / min. After the reaction, the obtained product was suction-filtered under reduced pressure, and the catalyst was removed to obtain 8-phenylheptadecane or 9-phenylheptadecane with a yield of 67.51%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com