SEBS rubber additive, preparation method and SEBS rubber thereof

An additive and rubber technology, which is applied in the field of SEBS rubber, can solve the problems of SEBS rubber odor, etc., and achieve the effect of suppressing the styrene gas volatilized by plasticization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

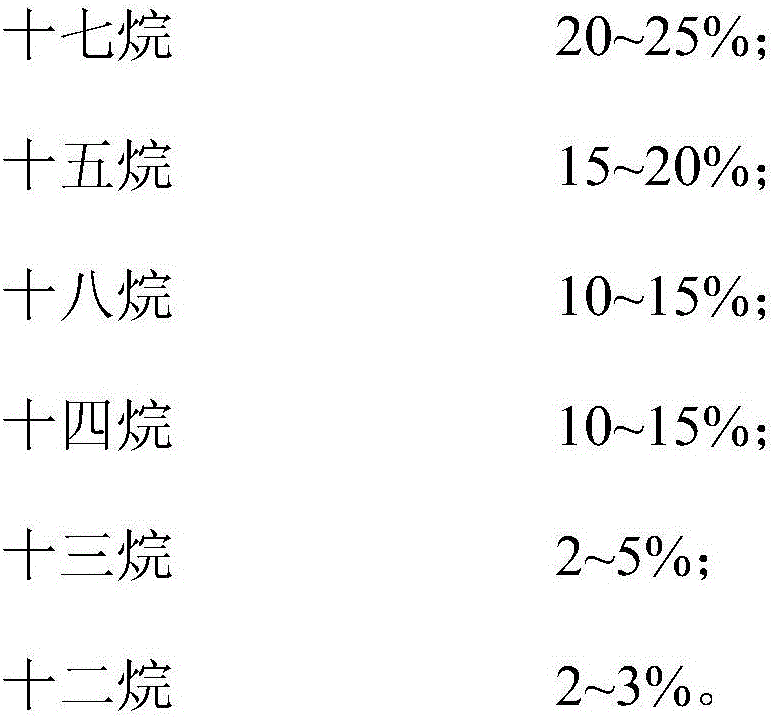

[0039] The SEBS rubber additive of the present embodiment, by mass percent, comprises the following components:

[0040]

[0041]

[0042] The preparation method of the SEBS rubber additive of the present embodiment may further comprise the steps:

[0043] (1) Mix the raw materials according to the ratio, add hexane with a mass ratio of 1:1 to the raw materials for dilution, add water and a solvent of 5wt% by weight of the raw materials for segmental extraction, and obtain crude oil ;

[0044] (2) Purifying the crude oil with clay and recovering the solvent to obtain the SEBS rubber additive.

[0045] SEBS rubber in the present embodiment, by mass parts, comprises the following components:

[0046] 10 parts of SEBS rubber;

[0047] SEBS rubber additive 100 parts.

Embodiment 2

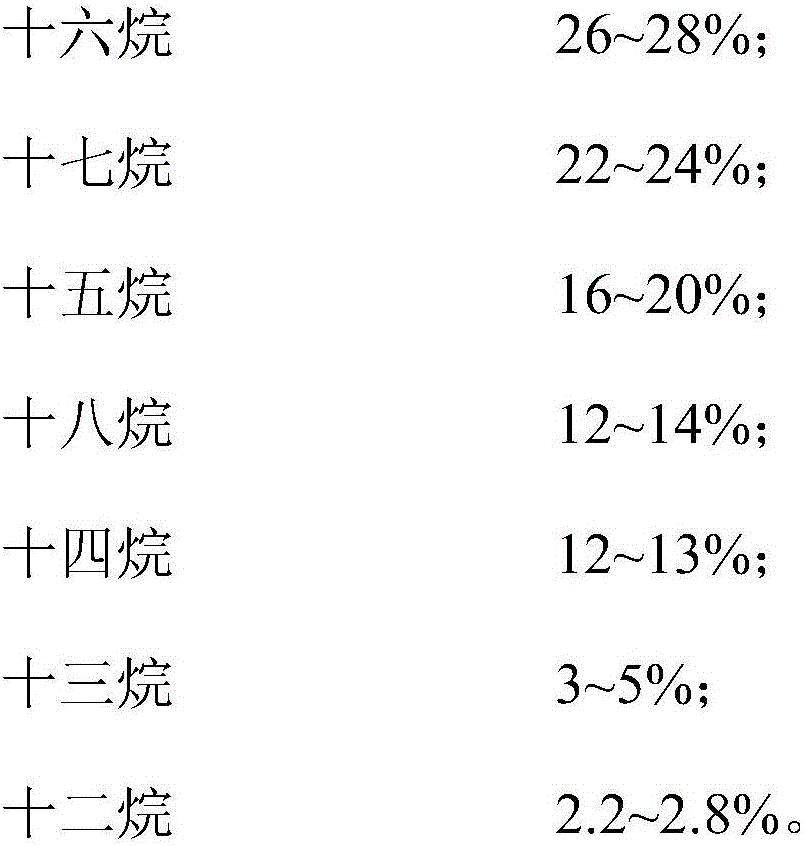

[0049] The SEBS rubber additive of the present embodiment, by mass percent, comprises the following components:

[0050]

[0051] The preparation method of the SEBS rubber additive of the present embodiment may further comprise the steps:

[0052] (1) Mix the raw materials according to the ratio, add hexane with a mass ratio of 1:1 to the raw materials for dilution, add water and a solvent of 5wt% by weight of the raw materials for segmental extraction, and obtain crude oil ;

[0053] (2) Purifying the crude oil with clay and recovering the solvent to obtain the SEBS rubber additive.

[0054] SEBS rubber in the present embodiment, by mass parts, comprises the following components:

[0055] 10 parts of SEBS rubber;

[0056] 100 parts of SEBS rubber additive;

[0057] Antioxidant 5 parts.

Embodiment 3

[0059] The SEBS rubber additive of the present embodiment, by mass percent, comprises the following components:

[0060]

[0061] The preparation method of the SEBS rubber additive of the present embodiment may further comprise the steps:

[0062] (1) Mix the raw materials according to the ratio, add hexane with a mass ratio of 1:1 to the raw materials for dilution, add water and a solvent of 5wt% by weight of the raw materials for segmental extraction, and obtain crude oil ;

[0063] (2) Purify the crude oil with clay and recover the solvent to obtain SEBS rubber additive.

[0064] SEBS rubber in the present embodiment, by mass parts, comprises the following components:

[0065] SEBS 10 copies;

[0066] 99 parts of SEBS rubber additive;

[0067] 1 part of white carbon black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com