Patents

Literature

80 results about "Methyl laurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyl Laurate is also insoluble in water, although it is soluble in most organic solvents. It produces a slight odor that can range from floral to “winey.” This laurate can be used in a wide range of applications including the manufacturing of lubricants, metalworking fluids, solvents, oiling agents and many others.

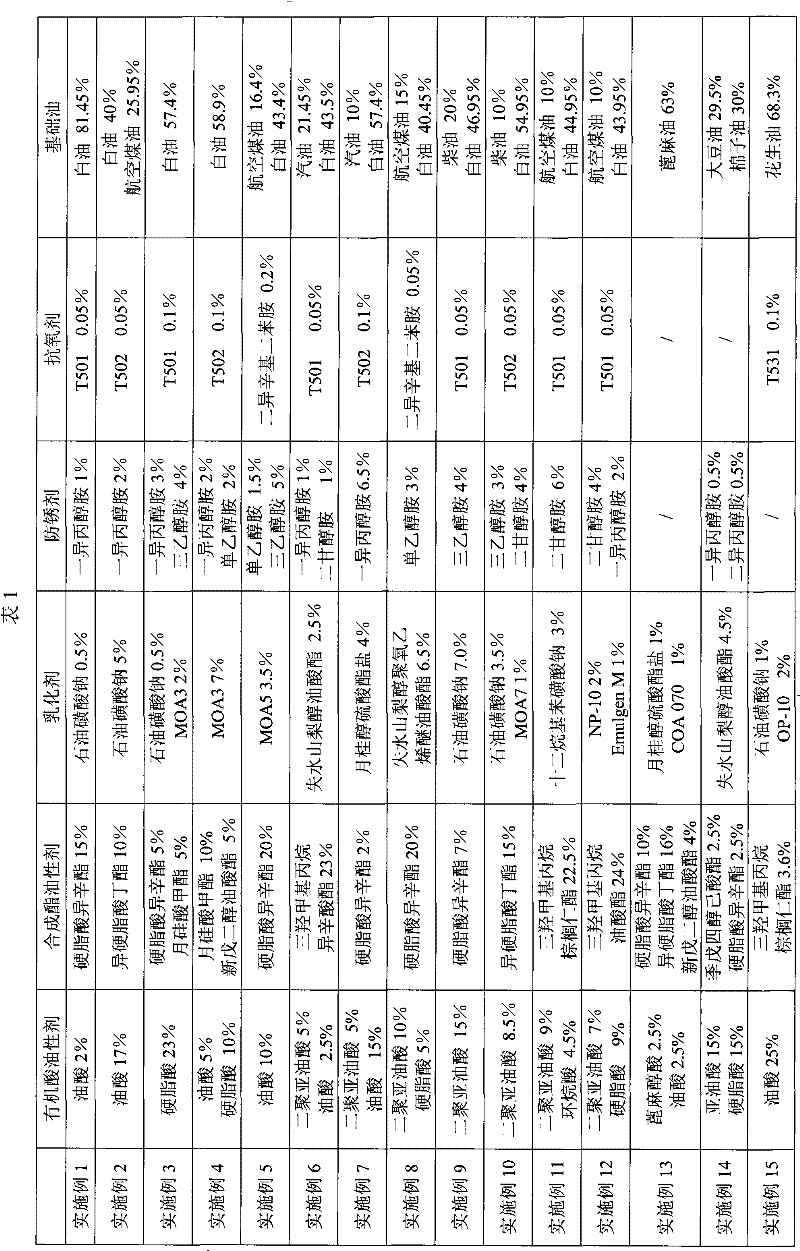

Drilling fluid lubricating agent

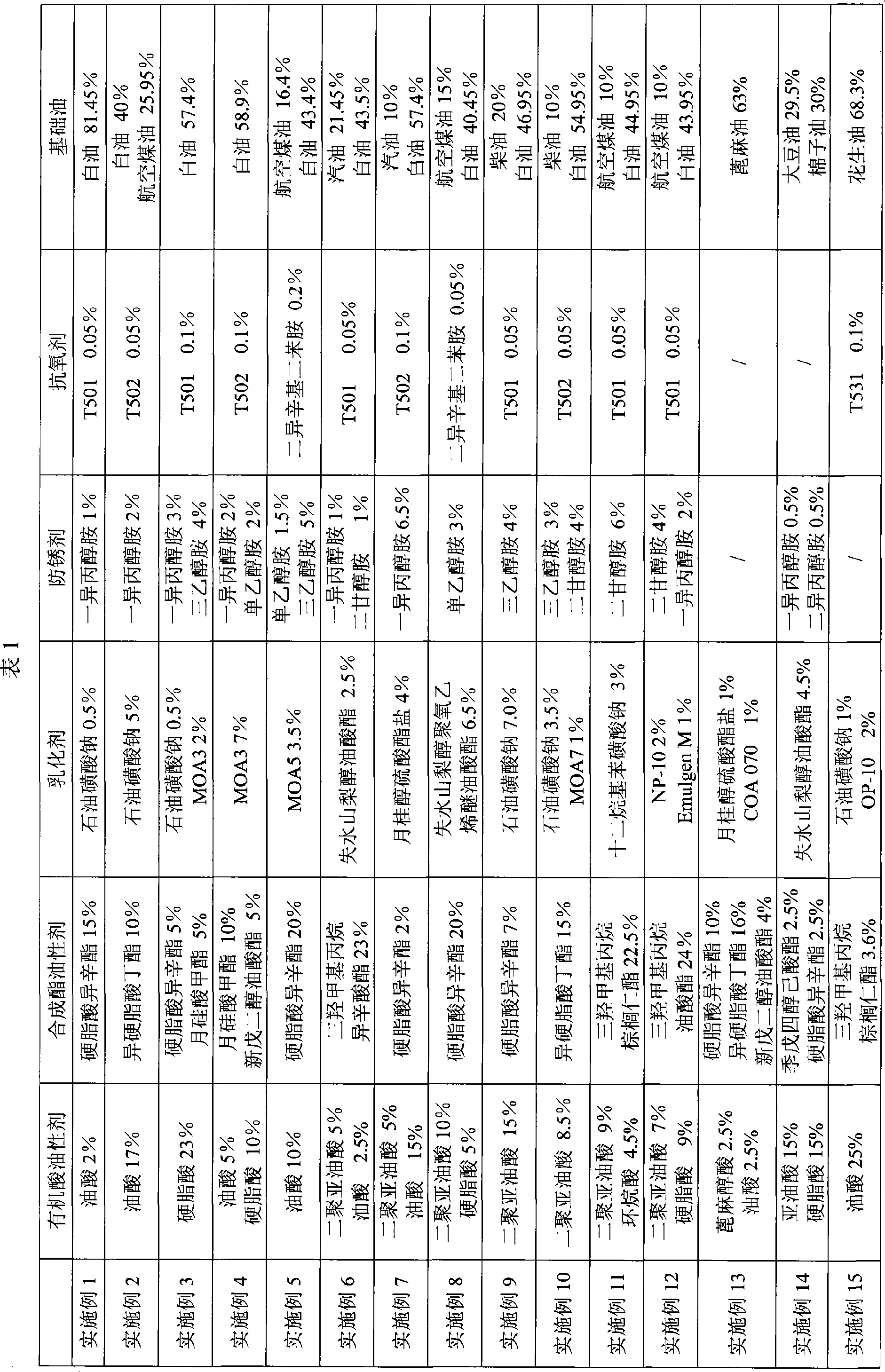

ActiveCN101486896AMeet the requirements of lubricating performanceImprove the lubrication effectDrilling compositionStearateTrimethylolpropane

The invention relates to a lubricant for drilling fluid, which essentially solves the problems of the prior art that the lubricant for drilling fluid has poor lubricating property in the high-density drilling fluid. The lubricant for drilling fluid comprises the following components calculating by weight percentage: a) 1 to 35 percent of long-chain organic acid oiliness agent; b) 1 to 35 percent of synthetic ester oiliness agent; c) 0.1 to 8 percent of emulsifier; and d) 25 to 90 percent of base oil; in which the synthetic ester oiliness agent is selected from at least one of isooctyl stearate, butyl isostearate, trimethylolpropane trioleate, trimethylolpropane palm kernel ester, trimethylolpropane ethylhexoate, neopentyl glycol oleate, methyl laurate or pentaerythritol caproate, therefore, the technical proposal solves the problem preferably, and can be used in the industrial production of lubricant for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP

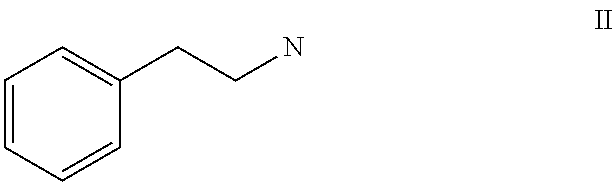

Topical formulation

ActiveUS20110028460A1Improve throughputBiocidePeptide/protein ingredientsSodium acetateSODIUM LAURYL SULFOACETATE

It has been discovered that certain combinations compounds are excellent penetration enhancers and, as such, can be incorporated in a topical formulation to facilitate administration of active agents. The increased penetration enhancement can also lead to a reduction in the total concentration of skin irritants in the formulation. There is described herein a topical formulation comprising (i) at least one active agent; (ii) a first compound, and (iii) a second compound, wherein the first compound and second compound are different, and each is selected from the group consisting of N-lauroyl sarcosine, sodium octyl sulfate, methyl laurate, isopropyl myristate, oleic acid, glyceryl oleate and sodium lauryl sulfoacetate.

Owner:CRESCITA THERAPEUTICS INC

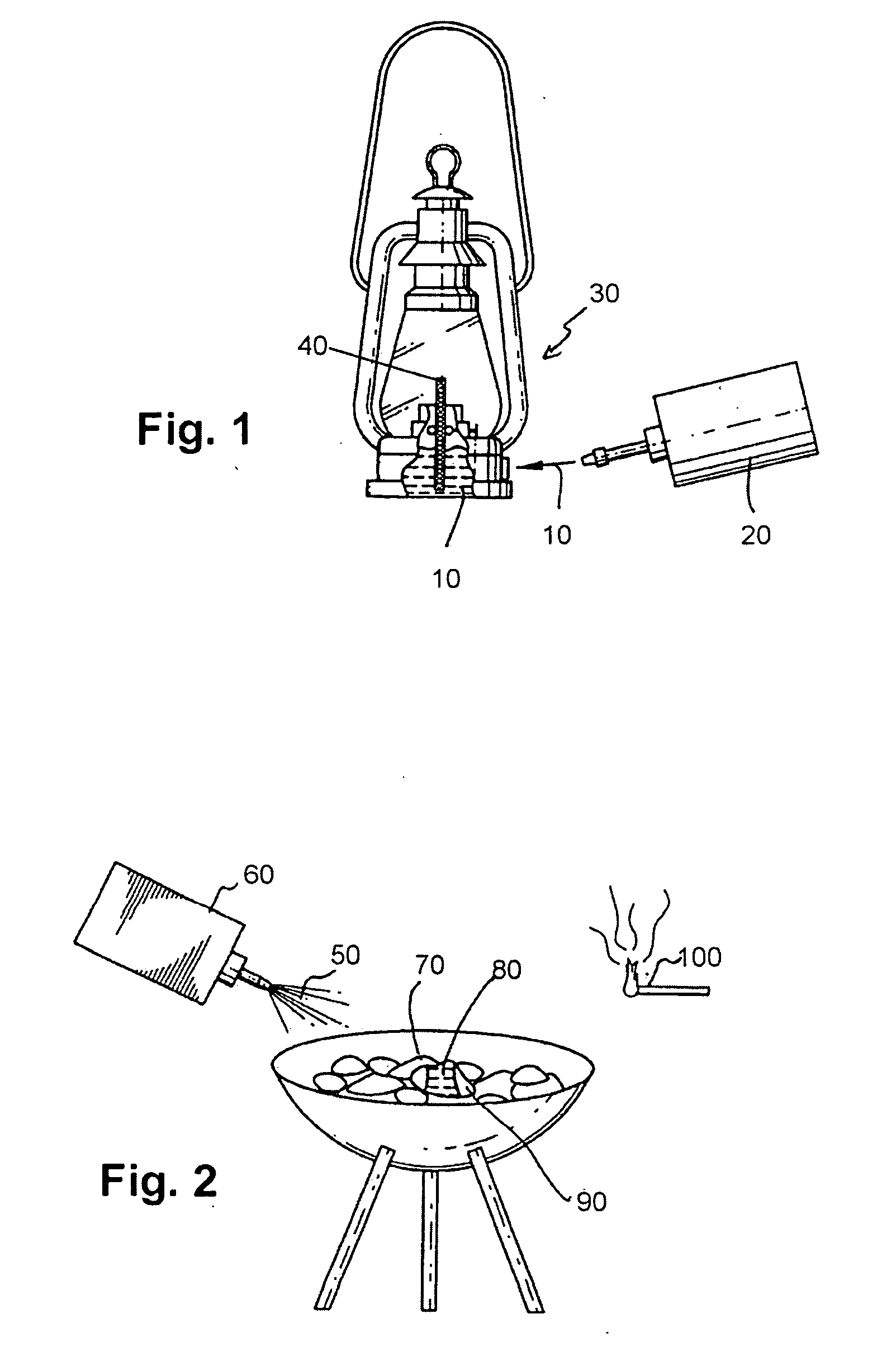

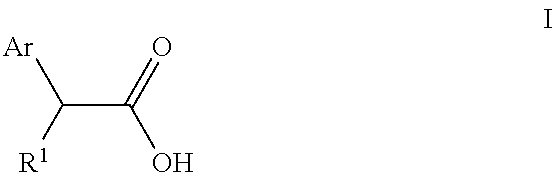

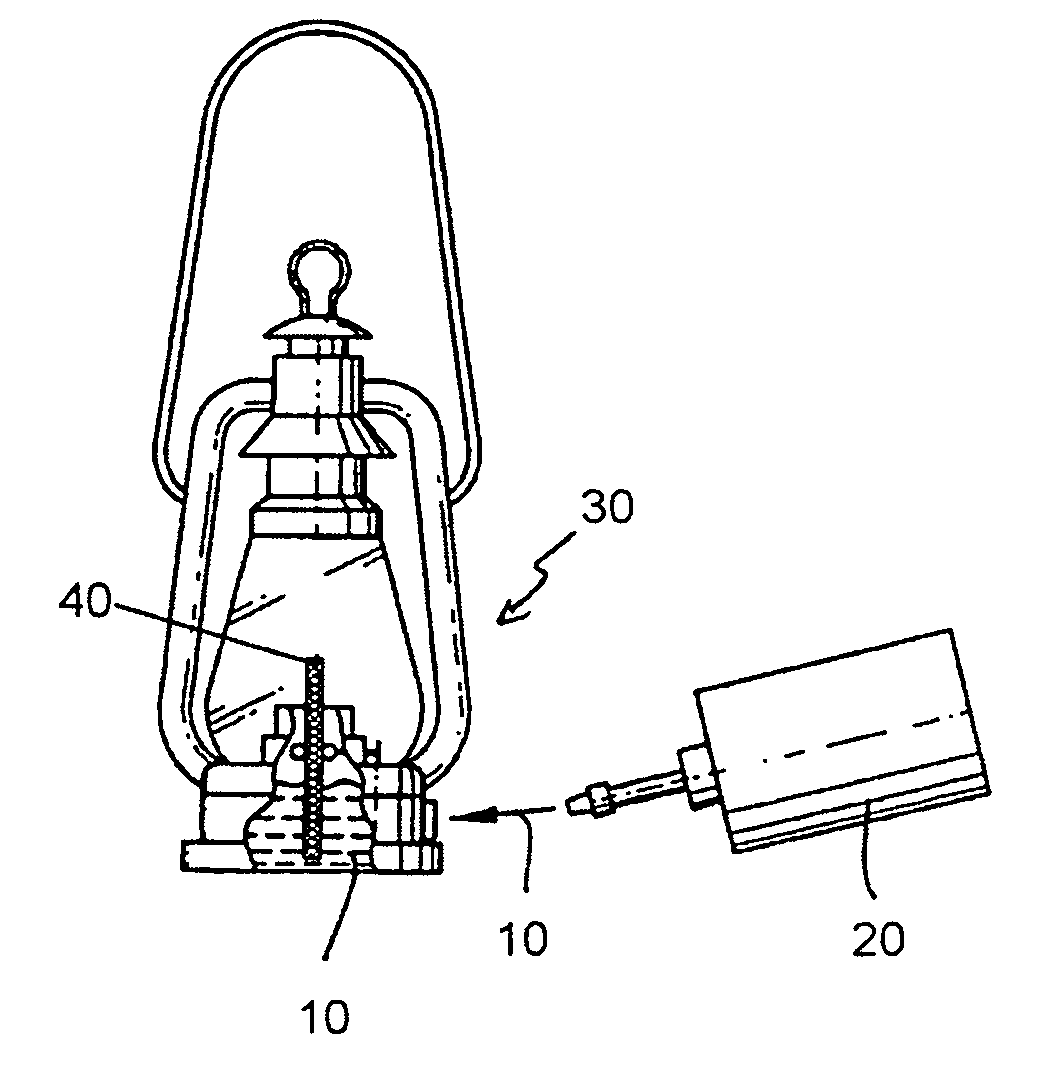

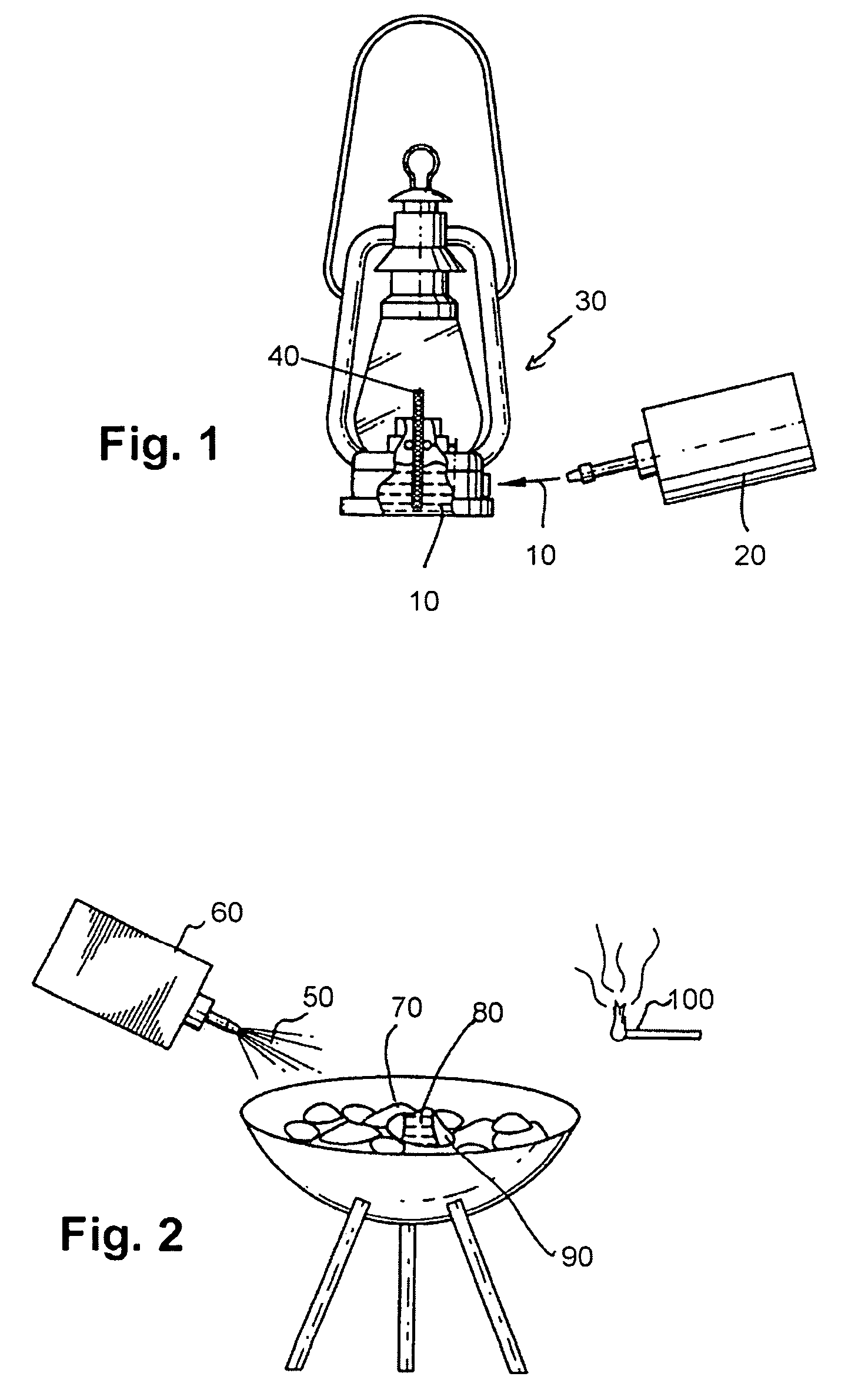

Lamp oil composition and lighter fluid composition

InactiveUS20050115145A1SaferEasy to manufactureCapillary burnersLiquid carbonaceous fuelsAlcoholLighter fuel

Lamp oil compositions including methyl palmitate, methyl stearate, myristyl alcohol, an alcohol with less than six carbons, preferably ethyl alcohol, and fragrance. Also disclosed herein are lighter fluid compositions which include methyl laurate, methyl stearate, ethyl alcohol and fragrance.

Owner:LUMETIQUE

Topical formulation

ActiveUS8343962B2Improve throughputBiocidePeptide/protein ingredientsSODIUM LAURYL SULFOACETATEActive agent

It has been discovered that certain combinations compounds are excellent penetration enhancers and, as such, can be incorporated in a topical formulation to facilitate administration of active agents. The increased penetration enhancement can also lead to a reduction in the total concentration of skin irritants in the formulation. There is described herein a topical formulation comprising (i) at least one active agent; (ii) a first compound, and (iii) a second compound, wherein the first compound and second compound are different, and each is selected from the group consisting of N-lauroyl sarcosine, sodium octyl sulfate, methyl laurate, isopropyl myristate, oleic acid, glyceryl oleate and sodium lauryl sulfoacetate.

Owner:CRESCITA THERAPEUTICS INC

Lamp oil composition and lighter fluid composition

InactiveUS7524339B2Not to damageTransportation safetyCapillary burnersLiquid carbonaceous fuelsAlcoholLighter fuel

Lamp oil compositions including methyl palmitate, methyl stearate, myristyl alcohol, an alcohol with less than six carbons, preferably ethyl alcohol, and fragrance. Also disclosed herein are lighter fluid compositions which include methyl laurate, methyl stearate, ethyl alcohol and fragrance.

Owner:LUMETIQUE

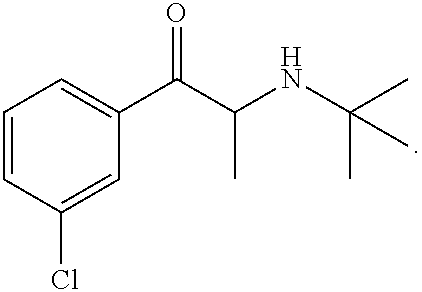

Topical formulation including diclofenac, or a pharmaceutically acceptable salt thereof

InactiveUS7795309B2Improve throughputOrganic active ingredientsBiocideSODIUM LAURYL SULFOACETATEMethyl laurate

There is described a topical formulation. The topical formulation comprises: (i) diclofenac or a pharmaceutically acceptable salt thereof, (ii) a first compound, and (iii) a second compound. The first compound and second compound are different, and each is selected from the group consisting essentially of N-lauroyl sarcosine, sodium octyl sulfate, methyl laurate, isopropyl myristate, oleic acid, glyceryl oleate and sodium lauryl sulfoacetate. It has been discovered that certain combination of compounds are excellent penetration enhancers and, as such, can be incorporated in a topical formulation to facilitate administration of diclofenac or a pharmaceutically acceptable salt thereof. The increased penetration enhancement can also lead to a reduction in the total concentration of skin irritants in the formulation.

Owner:CRESCITA THERAPEUTICS INC

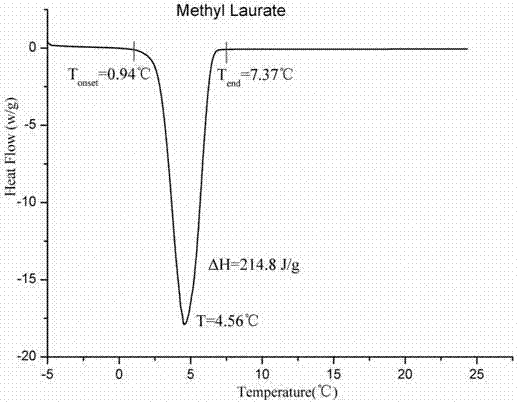

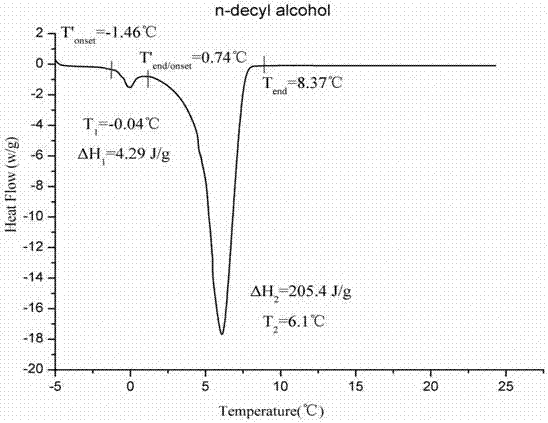

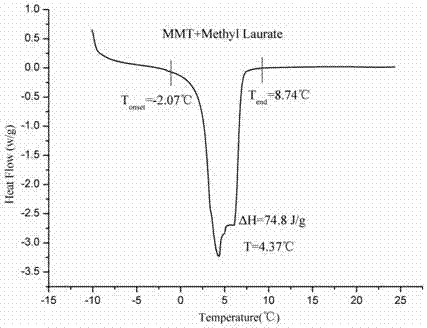

Preparation method of clay-based composite phase-change energy storage deicing (snow melting) material

The invention discloses a preparation method of a clay-based composite phase-change energy storage deicing (snow melting) material. The preparation method is characterized in that a composite phase-change energy storage material is prepared from a low-temperature organic phase-change material and a clay material, wherein the low-temperature organic phase-change material is prepared by single-element or multi-element mixing of various organic phase-change materials and is then physically compounded with the treated clay to prepare the clay-based composite phase-change energy storage deicing (snow melting) material. The low-temperature organic phase-change material is selected from polyethylene glycol-300, polyethylene glycol-400, polyethylene glycol-500, polyethylene glycol-600, decyl alcohol, undecanol, dodecanol, heptylic acid, octanoic acid, nonanoic acid, capric acid, methyl laurate, methyl myristate, methyl palmitate, tetradecane, pentadecane, hexadecane, heptadecane, octodecane, nonadecane and the like. The clay material is selected from kaolinite, montmorillonite, bentonite, vermiculite, halloysite, sepiolite, attapulgite, perlite, diatomite, rectorite, zeolite, silicon dioxide, dolomite, calcite and illite. The prepared composite phase-change energy storage deicing (snow melting) material is proper in phase-change temperature (0-5 DEG C), high in phase-change latent heat and high in heat stability.

Owner:CENT SOUTH UNIV

Fullerene, boron and nitrogen containing lubricant and preparation method thereof

ActiveCN105062618AImprove the lubrication effectImprove wear resistanceAdditivesSolubilityFriction reduction

The invention discloses a fullerene, boron and nitrogen containing lubricant and a preparation method thereof. An additive is prepared from polar modified fullerene C60, methyl laurate and nitrogen-containing borate, wherein a weight ratio of polar modified fullerene C60 to methyl laurate to nitrogen-containing borate is 1: (2-3): (20-25). The polar modified fullerene C60 is prepared from fullerene C60, concentrated sulfuric acid, concentrated hydrochloric acid and tall oil acid through reaction. The additive is the fullerene, boron and nitrogen containing lubricant, serves as a friction modifier, an anti-wear agent and an antioxidant of lubricating oil especially lubricating oil for an internal combustion engine, has remarkable friction reduction and oil saving effects, and further has the advantages of energy saving and environment protection due to absence of sulfur, phosphorus and chlorine; a production method is simple, the cost is low, oil solubility is good, and the yield is high.

Owner:王严绪

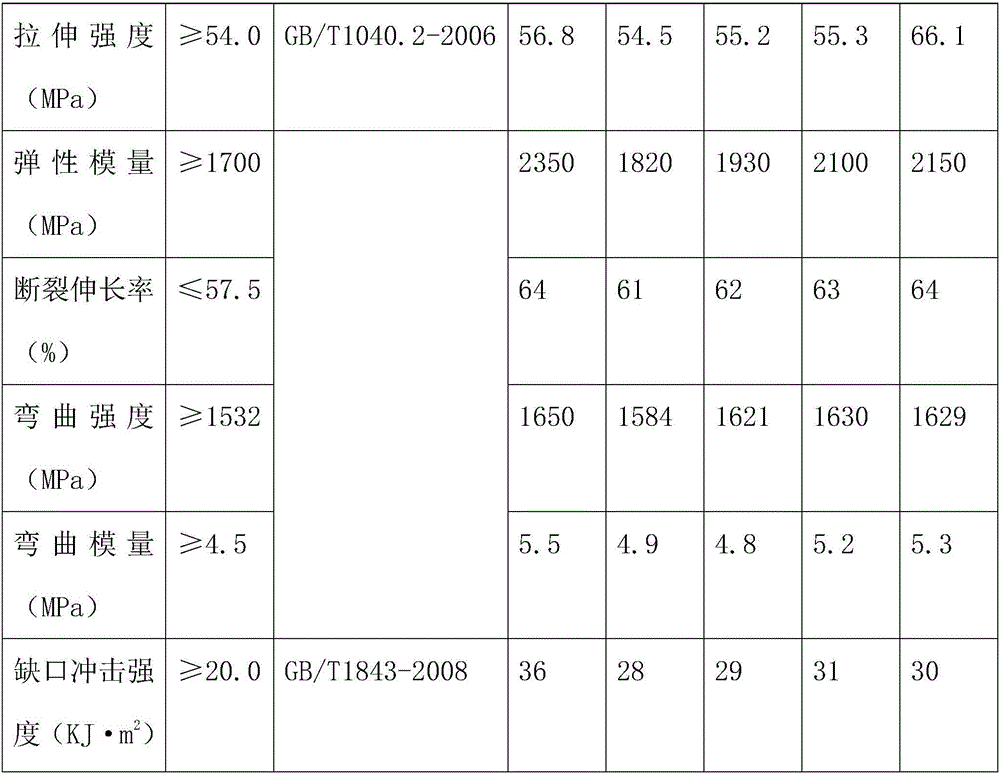

High-strength ultraviolet-resistant 3D (three-dimensional) printing material for building field and preparation method thereof

InactiveCN107177155AWell mixedImprove rigidityAdditive manufacturing apparatusPolyvinyl chlorideDibenzoyl Peroxide

The invention discloses a high-strength ultraviolet-resistant 3D (three-dimensional) printing material for the building field. The high-strength ultraviolet-resistant 3D printing material is prepared from the following raw materials including ABS resin, polyvinyl chloride, polypropylene, polycarbonate, maleic anhydride, phenolic resin, trimethyl phosphate, glass fiber, carbon fiber, methyl laurate, N,N'--4,4'--diphenylmethane-bismaleimide, 5-sulfonic acid mono-potassium terephthalate, 2,5-dihydroxyterephthalic acid, benzotriazole, polytetrafluoroethylene, sodium allylsulfonate, methyl acrylate, n-propyl acrylate, magnesium stearate, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, silane coupling agents KH-560, benzoyl peroxide, hardness enhancing modifying agents, modification auxiliary agents and modification fillers. The invention also provides a preparation method of the high-strength ultraviolet-resistant 3D printing material for the building field. The prepared 3D printing material has high strength and excellent ultraviolet-resistant performance.

Owner:HEFEI SKE INTELLIGENT TECH

Molybdenum alloy lubricant additive and preparation method thereof

InactiveCN105062623AObvious fuel-saving effectEnergy saving and environmental protectionAdditivesSolubilityAntioxidant

The invention discloses a molybdenum alloy lubricant additive and a preparation method thereof. The additive is prepared from mixed amide, sodium molybdate, boric acid, tungsten oxide, polyenoic acid polyamine and polyethylene glycol, wherein the mixed amide is prepared from coconut oil, triethanolamine and methyl laurate through a reaction. The additive is an oil-soluble molybdenum, boron, tungsten and nitrogen complex, serves as a friction modifier, an anti-wear agent and an antioxidant of a lubricant especially a lubricant for an internal combustion engine, has significant oil saving effect, and further has the advantages of energy saving and environmental protection because the additive contains no sulfur and phosphorus; the preparation method has the advantages of simplicity, low cost, good oil solubility and high yield.

Owner:王严绪

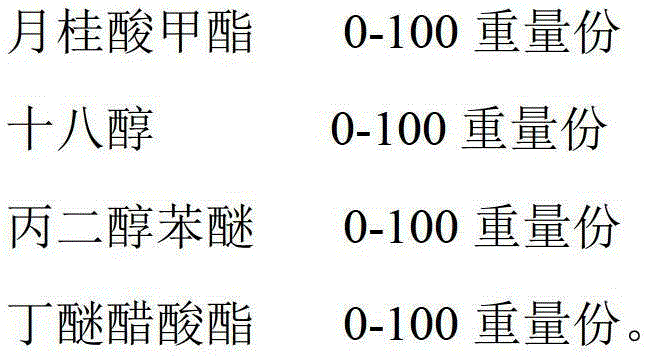

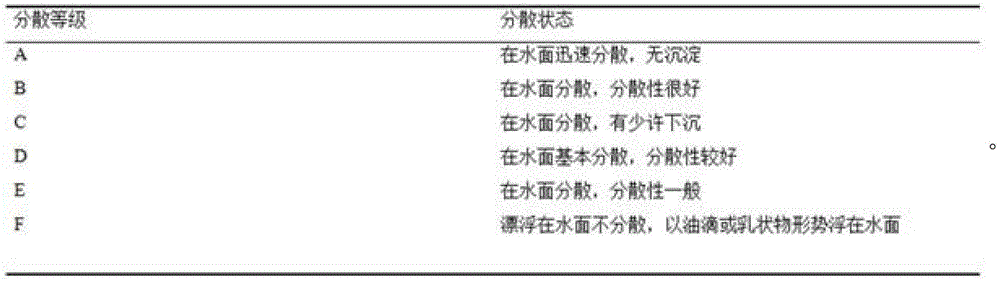

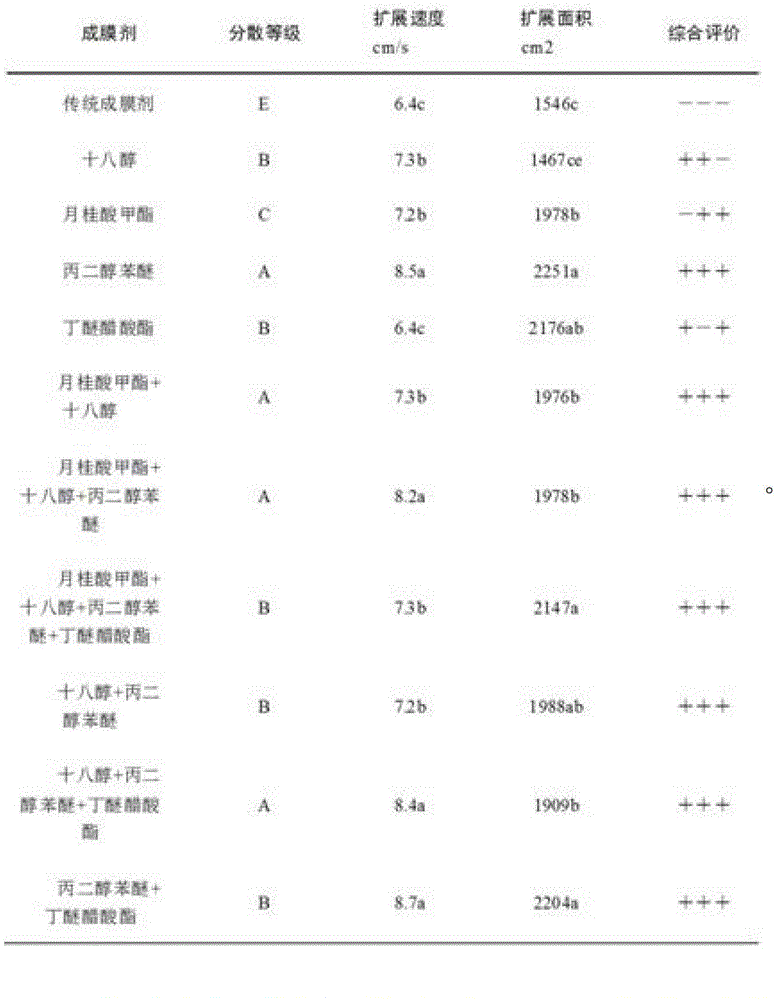

Film forming agent of film developing oil agent

The invention discloses a film forming agent of a film developing oil agent, which comprises 0-100 parts by weight of methyl laurate, 0-100 parts by weight of octadecanol, 0-100 parts by weight of propylene glycol phenyl ether and 0-100 parts by weight of butyl ether acetic ester. Compared with the traditional film forming agent, the film forming agent disclosed by the invention is good in film forming effect and wider in generality and is applicable to developing a plurality of film developing oil agent products containing pesticide active ingredients; and the developing performances of drugs in the liquid level of a paddy field are good. The invention further discloses a film developing oil agent containing the film forming agent and a preparation method of the film developing oil agent.

Owner:GAUNGXI TIANYUAN BIOCHEM

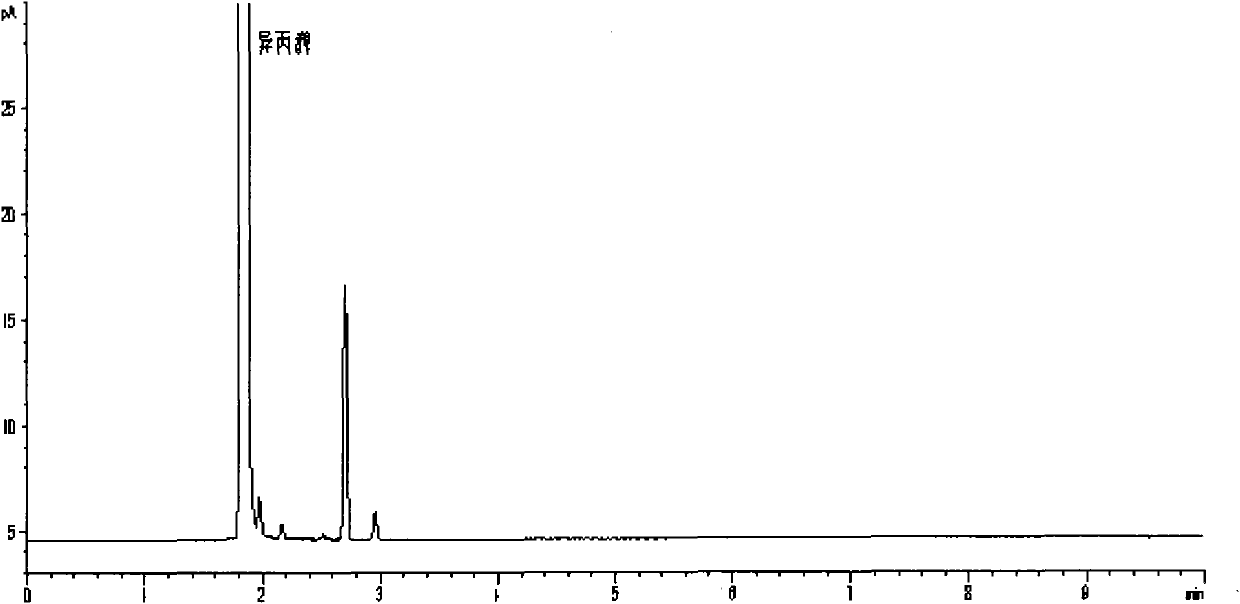

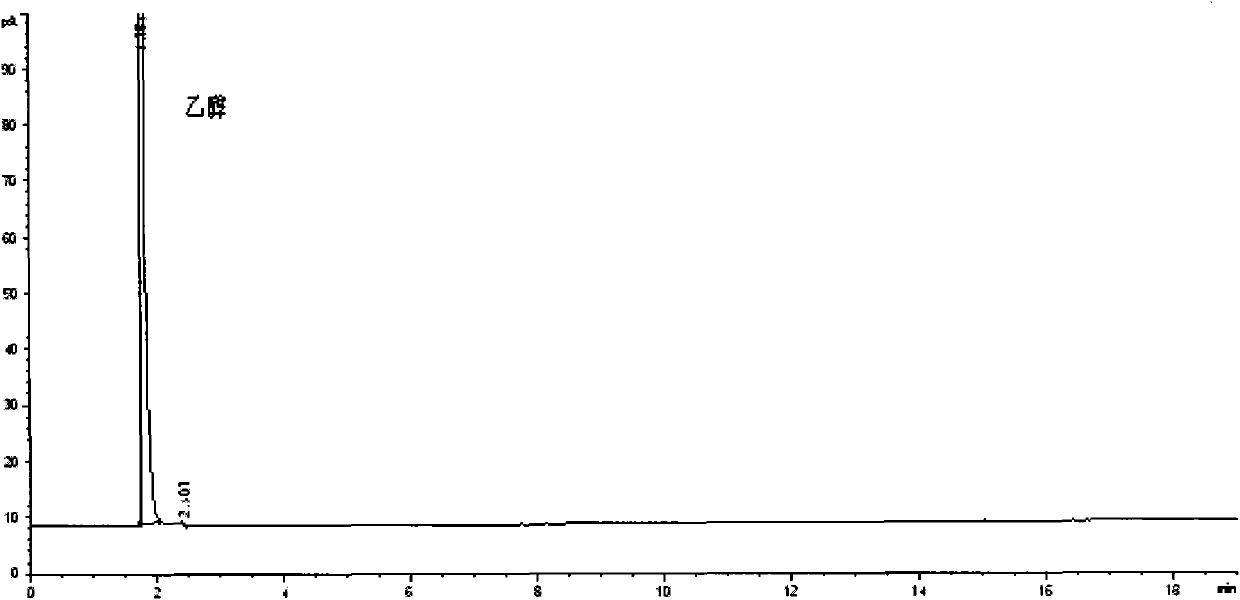

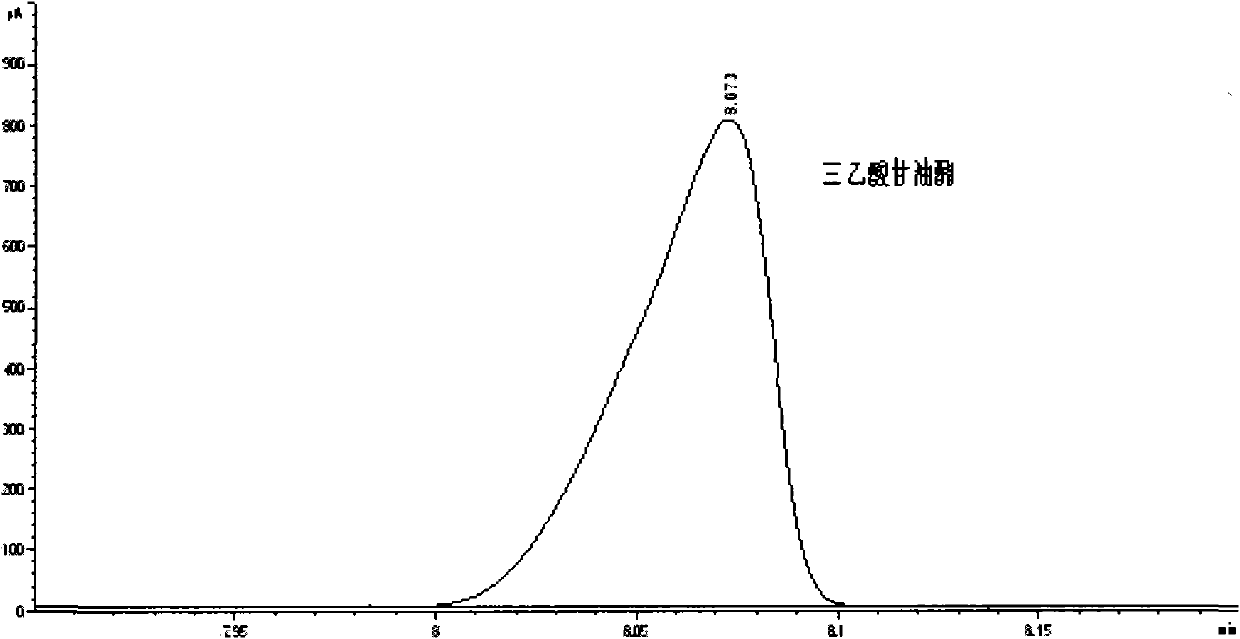

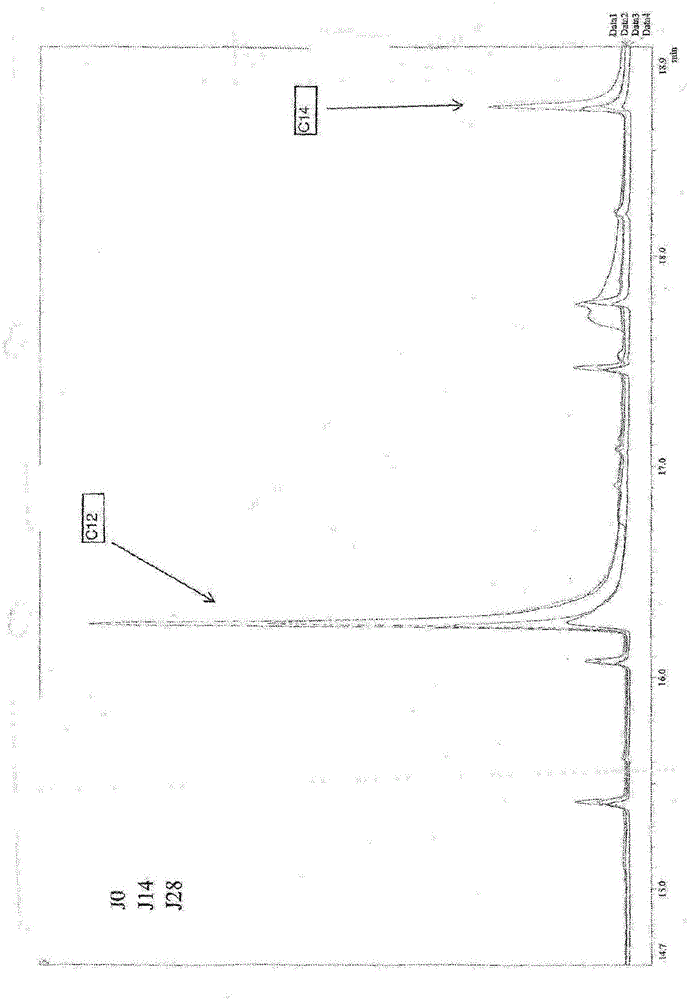

Method for detecting glyceroltriacetate in cigarette filter rods

The invention discloses a method for detecting glyceroltriacetate in cigarette filter rods, which uses gas chromatography and uses isopropanol as a solvent. In the method provided by the invention, the isopropanol serving as the solvent can achieve the same gasification effect as ethanol, and is small in toxin and insusceptible to deliquescence and causing hydrolysis of glyceroltriacetate. In theinvention, methyl laurate or propylene carbonate which is used as an internal standard substance is insusceptible to decomposition in light and can be stored easily, a chromatographic column which isa weak / medium-polarity chromatographic column, weak-polarity chromatographic column or medium-polarity chromatographic column has less impurity peaks and small baseline drift. When the method provided by the invention is used for detecting the glyceroltriacetate in the cigarette filter rods, large-batch detection can be realized and the detection result is accurate.

Owner:CHINA TOBACCO GUANGDONG IND

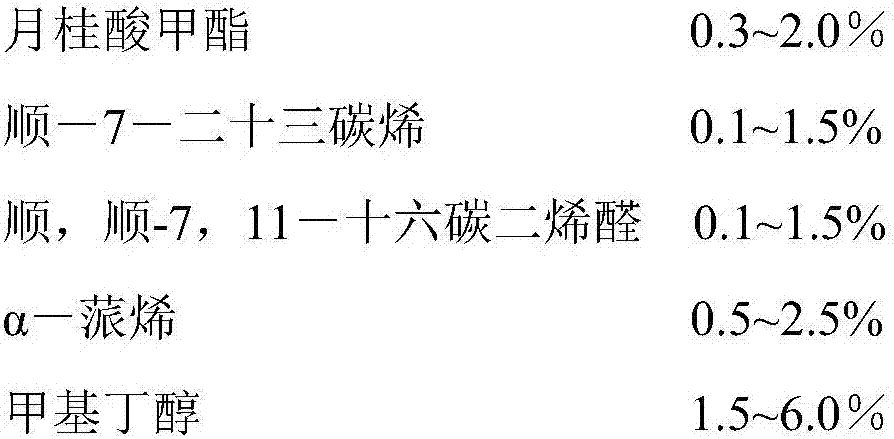

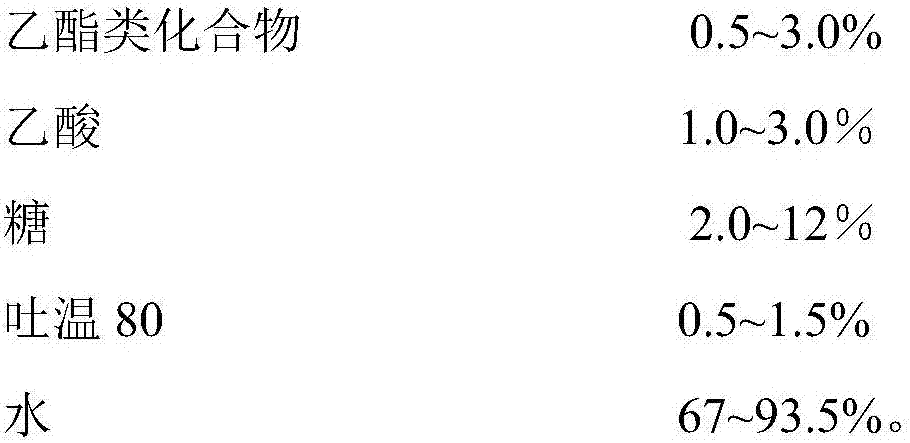

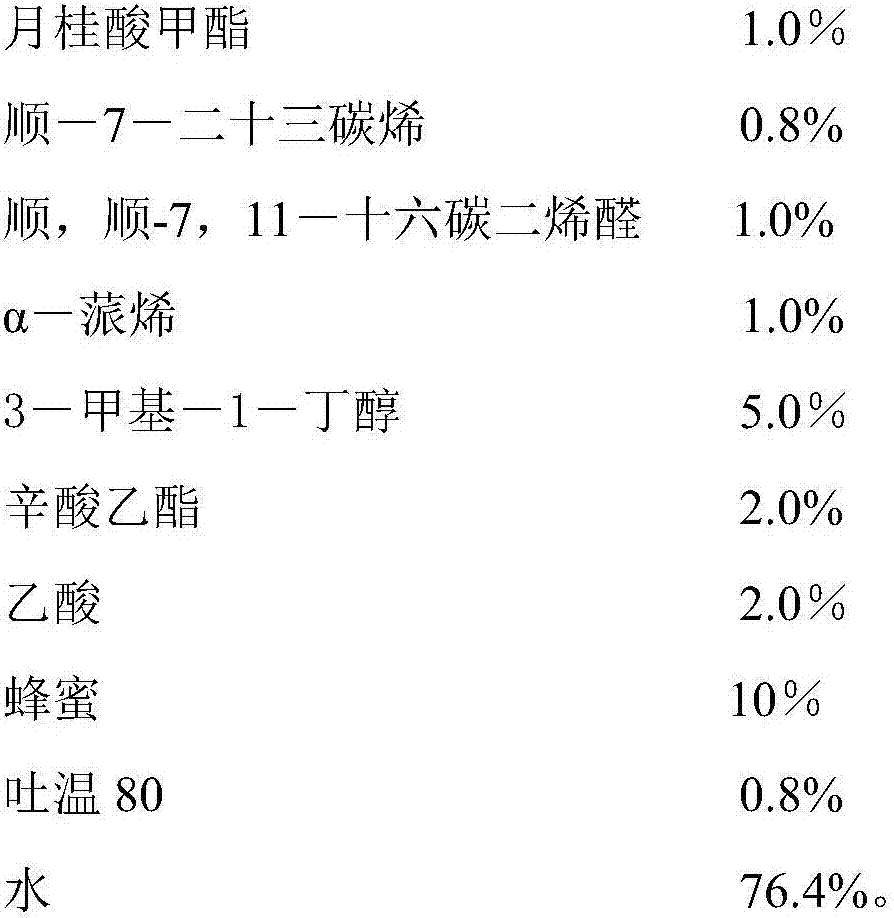

Drosophila attractant

InactiveCN106942225ANo pollutionDoes not affect food safetyBiocidePest attractantsSimple Organic CompoundsDrosophila dunni

The invention discloses a drosophila attractant. The drosophila attractant is composed of following ingredients: 0.3 to 2.0% of methyl laurate, 0.1 to 1.5% of cis-7-tricosene, 0.1 to 1.5% of cis, cis-7,11-hexadecadienal, 0.5 to 2.5% of alpha-pinene, 1.5 to 6.0% of methylbutanol, 0.5 to 3.0% of an ethyl ester compound, 1.0 to 3.0% of acetic acid, 2.0 to 12% of sugar, 0.5 to 1.5% of tween 80, and 67 to 93.5% of water. The organic compounds in the drosophila attractant are all natural ingredients from plants and insects, fruit eating safety is not influenced, no pollution is caused, natural enemies are not hurt, the drosophila attractant possesses obvious attractant effect on drosophila female and male imagines, and especially possesses better attractant effect on female drosophila.

Owner:全国农业技术推广服务中心

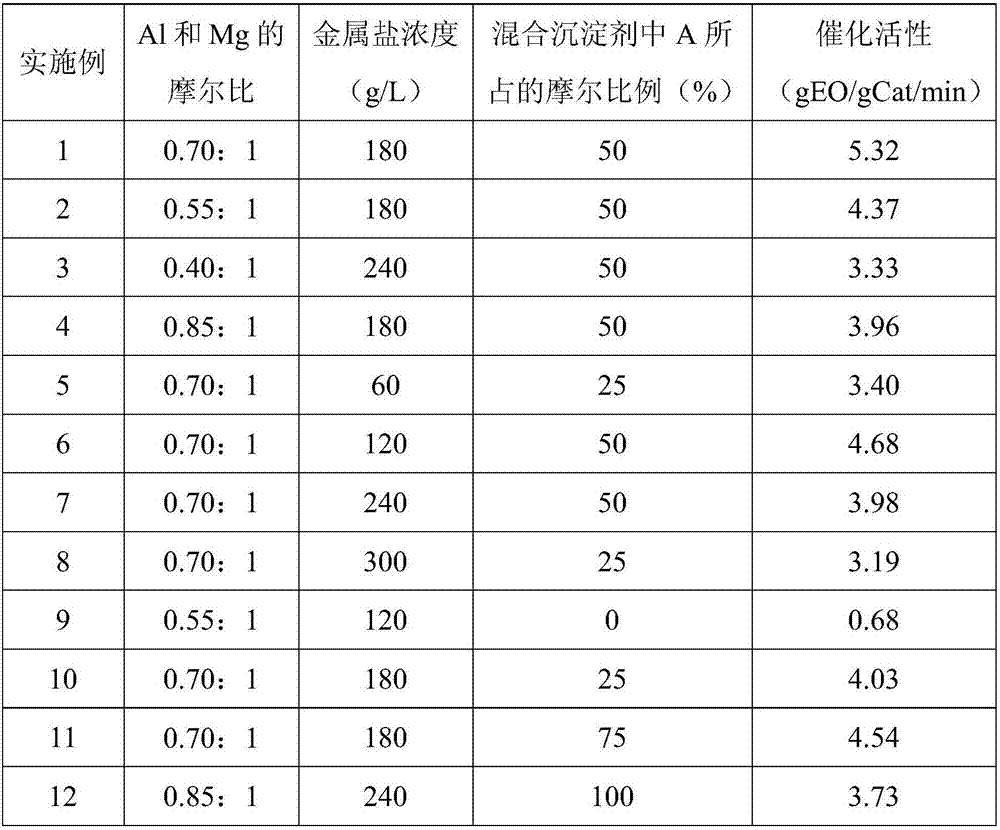

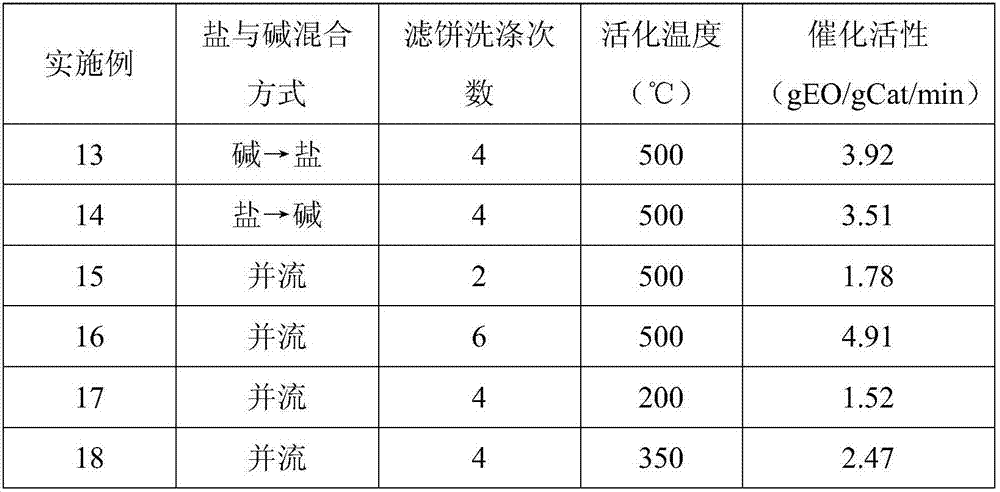

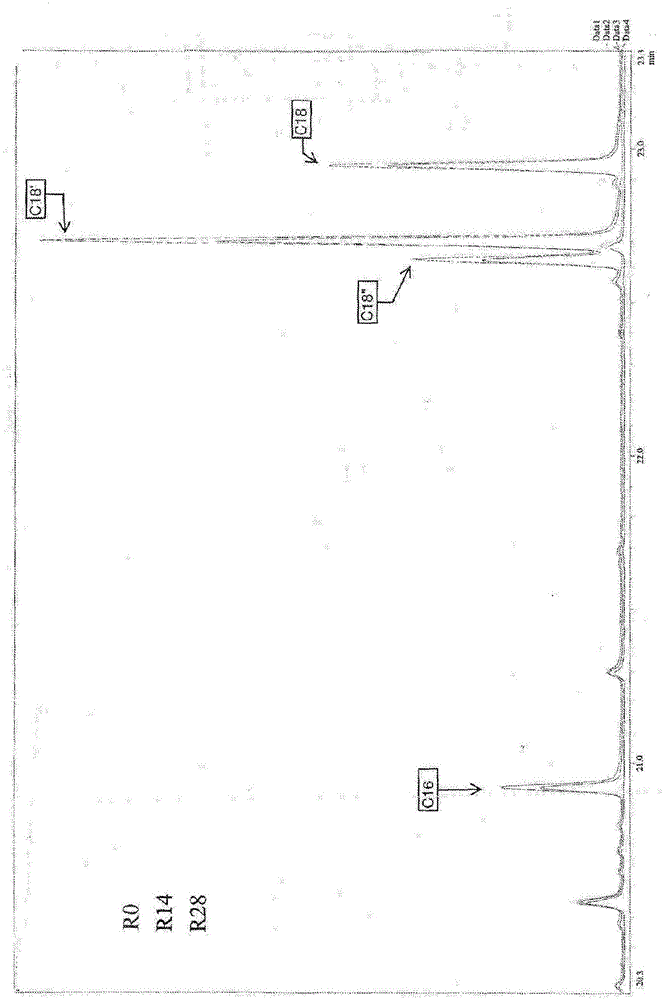

Preparation method and application method of alkaline composite oxide catalyst

ActiveCN107159177ASimple processHigh catalytic activityOrganic compound preparationCarboxylic acid esters preparationMethyl laurateFatty acid methyl ester

The present invention relates to a preparation method and an application method of an alkaline composite oxide catalyst, and belongs to the technical field of synthesis of fatty acid methyl ester ethoxylate. The preparation method comprises: mixing a metal salt solution and a precipitating agent to obtain a mixture; controlling the temperature of the solution, and maintaining the pH value of the solution at 8.0-10.0 during the mixing process; standing and aging the obtained solution, carrying out suction filtration, and washing the filter cake; and drying the filter cake, calcining, and screening to achieve a certain mesh to obtain the catalyst. According to the present invention, with the application of the catalyst in preparation of methyl laurate ethoxylates, the high catalytic activity can be provided, the reactivity of the catalyst can be up to 5.32 gEO / gCat / in, and the reuse rate of the catalyst is high.

Owner:ZHEJIANG HUANGMA NEW MATERIALS TECH CO LTD

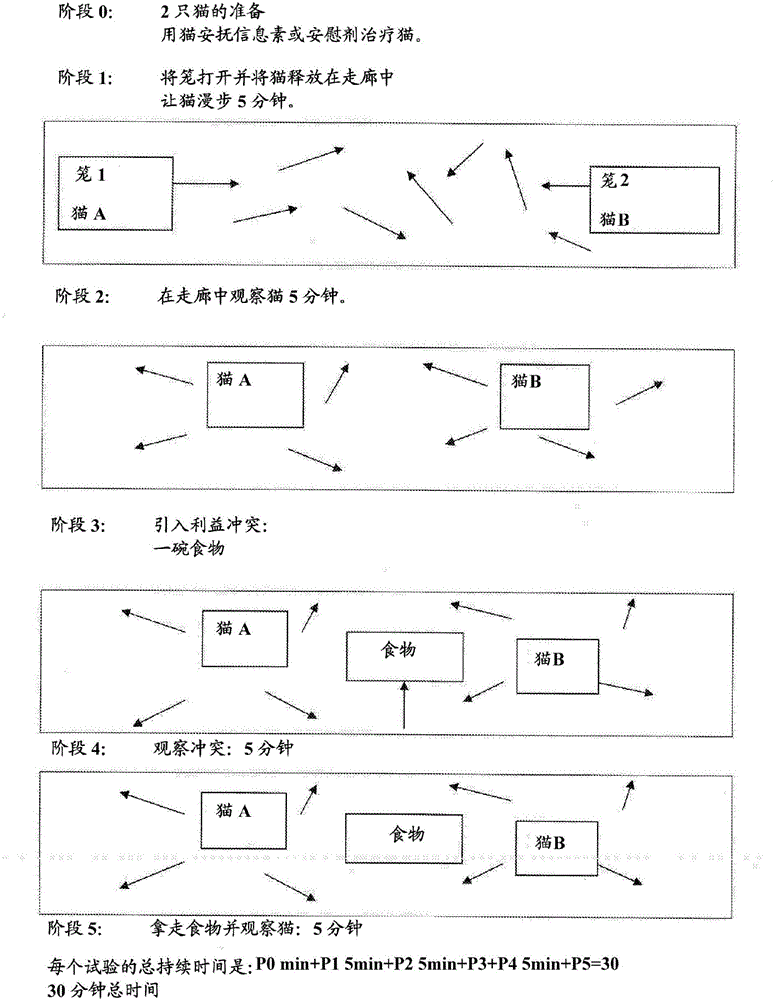

Cat appeasing pheromone

The present invention relates to a semiochemical composition comprising methyl palmitate, methyl linoleate, methyl oleate methyl stearate, methyl laurate, methyl myristate, salts thereof, derivatives thereof, isomers thereof and / or structural analogues thereof that have an appeasing effect in cats and / or also effects social facilitation in cats, and an acceptable vehicle. Solutions such as spot-on formulations of long duration are also encompassed. Methods to effect appeasing in a cat and / or social facilitation in cats are also disclosed.

Owner:INST OF INFORMATION CHEM & APPLIED ANIMAL BEHAVIOR

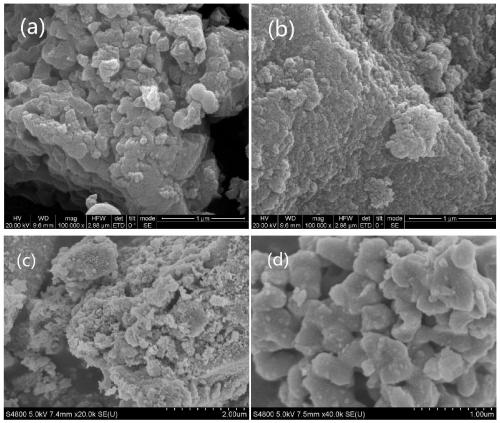

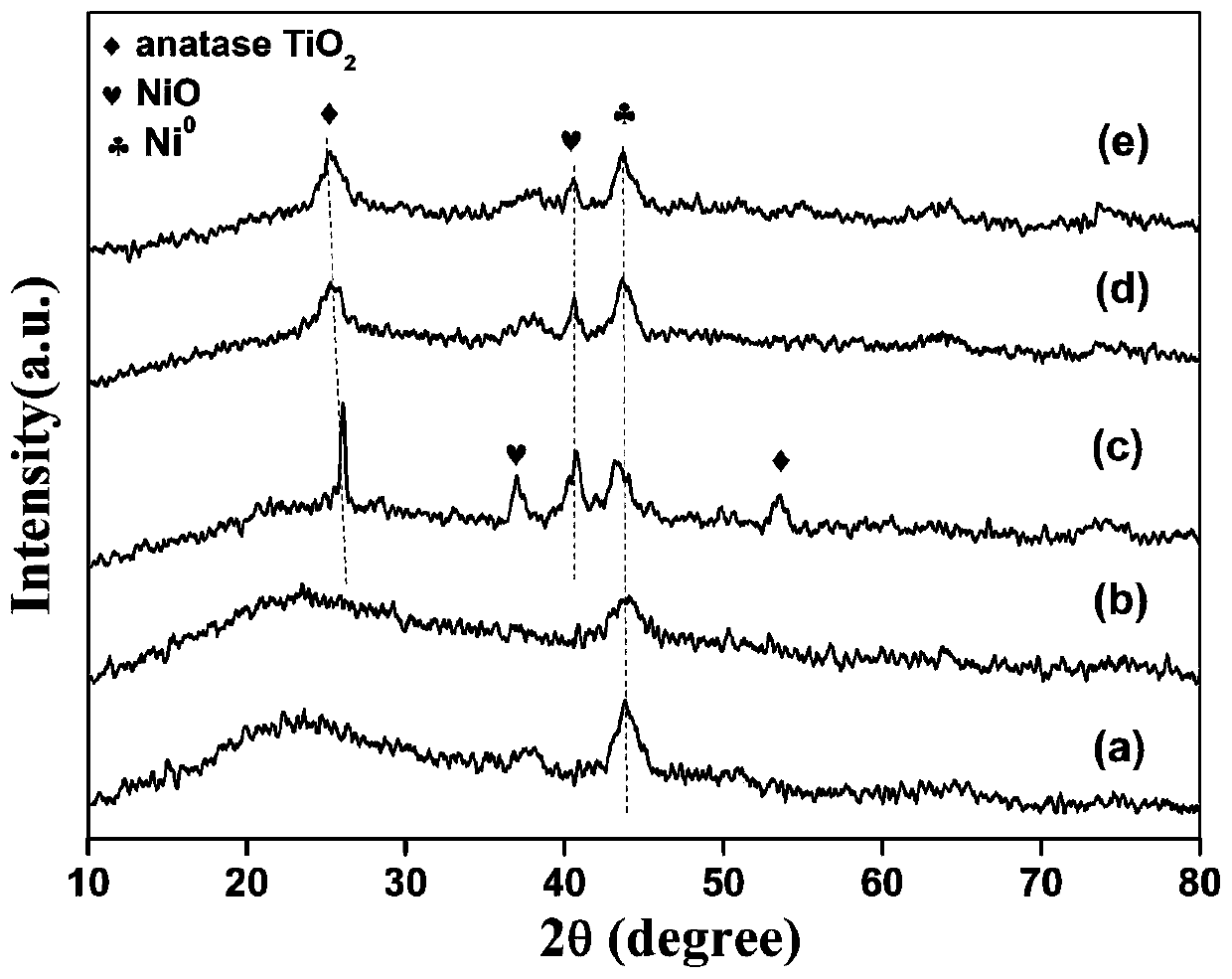

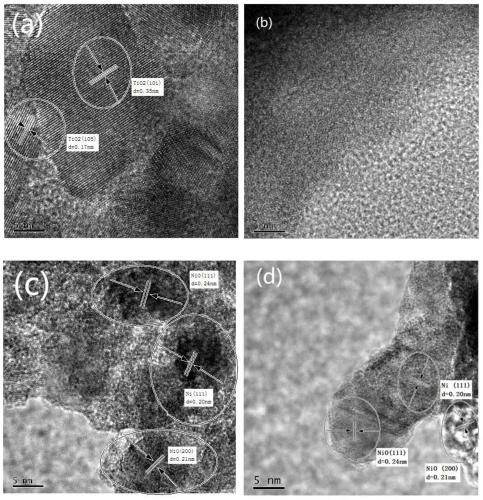

Sulfur-free nickel-molybdenum bimetallic hydrodeoxygenation catalyst

ActiveCN111111679AEasy to manufactureHigh catalytic activityCatalystsHydrocarbon preparation catalystsLiquid productPtru catalyst

The invention discloses a sulfur-free nickel-molybdenum bimetallic catalyst Ni-Mo / TiO2-SiO2 and a method for catalyzing hydrodeoxygenation of fatty acid methyl ester by the sulfur-free nickel-molybdenum bimetallic catalyst Ni-Mo / TiO2-SiO2. The catalyst has the advantages of high catalytic activity, strong carbon deposition resistance, easiness in separation from a liquid product and the like. Whenthe mass ratio of the catalyst to the reaction raw material methyl laurate to the reaction solvent is 0.1: 1: 20, the reaction temperature is 300 DEG C, and the reaction time is 4 hours, the mass yield of the obtained hydrodeoxygenation product n-dodecane product is up to 92%, and the purity mass percent of the product is up to 95%.

Owner:XIANGTAN UNIV

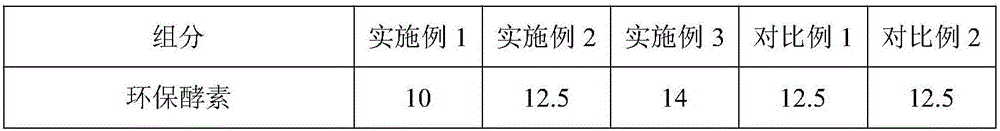

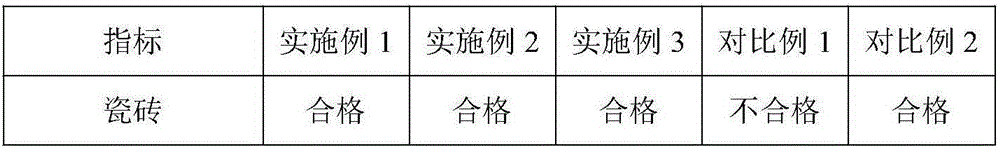

Environment-friendly antibacterial toilet detergent and preparation method thereof

InactiveCN106635560ALess corrosiveRapid sterilizationInorganic/elemental detergent compounding agentsSurface-active detergent compositionsSulfonateDisinfectant

The invention belongs to the field of daily chemical products, and particularly relates to an environment-friendly antibacterial toilet detergent and a preparation method thereof. The environment-friendly antibacterial toilet detergent is prepared from the following components in percentage by weight: 10 to 14 percent of environment-friendly enzyme, 10 to 14 percent of methyl laurate sodium sulfonate, 10 to 14 percent of citric acid, 5 to 10 percent of concentrate powder, 5 to 10 percent of weed odorant, 5 to 10 percent of germicidal disinfectant and 28 to 55 percent of water. The environment-friendly antibacterial toilet detergent has the advantages of low corrosion, rapid sterilization, high cleaning performance, high biodegradability and the like.

Owner:叶宗瑞

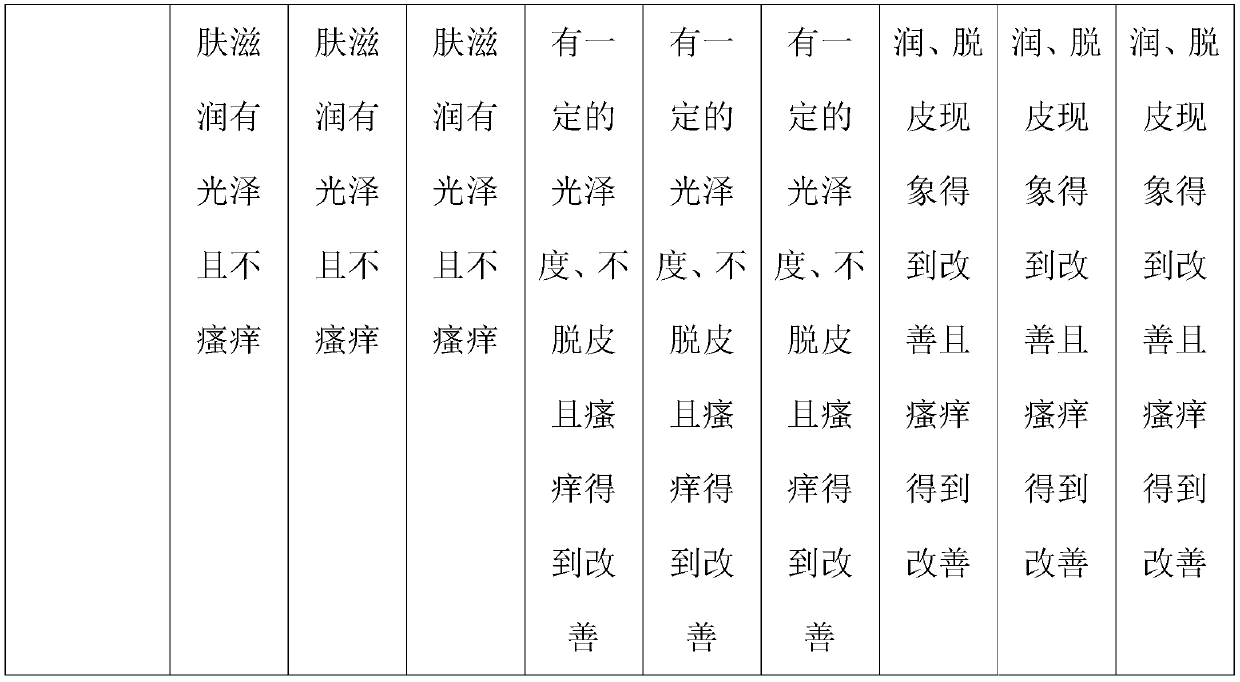

Cat face pheromone and application thereof

PendingCN112516128AAlleviate or relieve stressful behaviorLow costNervous disorderEster active ingredientsMethyl linoleateDIMETHYL SEBACATE

The invention discloses cat face pheromone and application thereof. The cat face pheromone comprises a cat face pheromone analogue and a solvent, and the cat face pheromone analogue comprises methyl laurate, methyl myristate, methyl palmitate, methyl oleate, methyl linoleate and dimethyl sebacate. The cat face pheromone can be used for preparing a preparation for reducing and relieving anxiety andconflicts after a cat is blended into a new environment, is suitable for a scene that the surrounding environment of the cat is changed, and can ease or relieve stress behaviors of the cat in the newenvironment, such as abnormal emotion and even pathological diseases; and meanwhile, since dimethyl heptanedioate and dimethyl azelate which are relatively high in price are not adopted for the cat face pheromone analogue and the cat face pheromone, the cost of the used raw materials is relatively low, the product is suitable for mass production, the purity of the raw materials is improved, the product quality is improved, and the effect is exerted.

Owner:上海弗艾柏生物科技有限公司

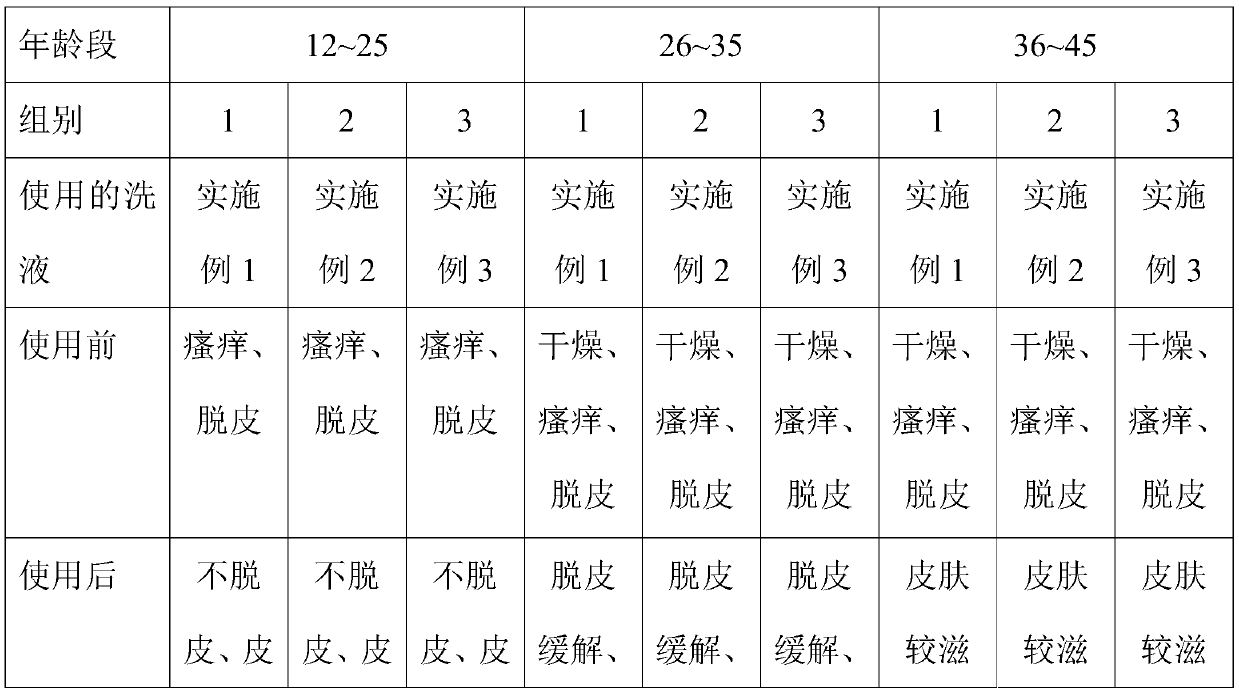

Plant-derived skin healthcare lotion and preparation method thereof

InactiveCN111407707ARelieve itchingSolve peelingAntibacterial agentsCosmetic preparationsPlant SourcesMethyl laurate

The invention discloses a plant-derived skin healthcare lotion and a preparation method thereof. The plant-derived skin healthcare lotion contains the following components in parts by mass: 76-79 parts of an agent A, 15.6-17.7 parts of an agent B, 0.55-1 part of an agent C and 2.75-3 parts of an agent D, wherein the agent B consists of cocamide MEA, sodium methyl 2-sulfolaurate and a plant extract. The preparation method comprises the following steps: heating the agent A to be 80-90 DEG C; adding the agent B into the agent A, and carrying out constant-temperature stirring for 13-20 minutes; adding the agent C, and carrying out constant-temperature stirring for 28-32 minutes; and carrying out cooling until the temperature is 45 DEG C or below, keeping a constant-temperature state, adding the agent D, and carrying out stirring for 25-35 minutes. The functional plant extract infiltrates into skin so as to condition a skin environment, so that the pesticide effect is exerted, bacteria andfungi on the skin can be inhibited, the flaking speed of the skin is decreased, the skin itch is delayed, the blood circulation of the skin is promoted, the skin grease is removed, and the absorptionof hair follicles to nutrients is improved.

Owner:广州路标科技有限公司

Anti-pilling agent for knitting, and preparation method and application thereof

The invention discloses an anti-pilling agent for knitting, and a preparation method and application thereof. The anti-pilling agent for the knitting is prepared from the following raw components in parts by mass: 15 to 20 parts of dehydrated sorbitan fatty acid ester polyoxyethylene ether, 8 to 10 parts of stearic acid, 35 to 40 parts of rosin ethyl ester, 10 to 15 parts of hydrogenated rosin methaester, 15 to 20 parts of methyl laurate, 10 to 20 parts of polyethylene glycol, 3 to 5 parts of dicarbonate, 3 to 5 parts of zinc nitrate, 2 to 3 parts of potassium bicarbonate, 10 to 12 parts of glycerinum, and 180 to 190 parts of water. The raw components of the anti-pilling agent for the knitting disclosed by the invention have a very good synergistic effect; the obtained treatment agent has very high stability; a knitted fabric which is treated by the anti-pilling agent is durable and wear-resistant and does not pill.

Owner:JIANGSU SUYANG SERVICE CAP CO LTD

Active solvent for relieving sump oil blockage of water injection well

The invention provides an active solvent for relieving sump oil blockage of a water injection well. The active solvent is prepared by mixing fatty acid methyl ester, a penetrating agent and organic alkali, wherein the weight percent of the penetrating agent is 1-5%; the weight percent of the organic alkali is 5-20%; and the others are fatty acid methyl ester; the penetrating agent is selected from isooctyl alcohol polyoxyethylene ether-4, isooctyl alcohol sulphonated succinate or isooctyl alcohol polyoxyethylene ether phosphate-4; the organic alkali is selected from one or more of triethanolamine, triethylamine, diethylamine or dimethylamine; the fatty acid methyl ester is selected from one or more of methyl laurate, methyl palmitate, methyl oleate and methyl stearate; and the fatty acid methyl ester has strong dissolving capacity on the sump oil; the sump oil injected on an infiltration surface of the water injection well can be dissolved, and pushed away from the infiltration surface of the water injection well; tallate and methanol can be generated after the sump oil is hydrolyzed in stratum; the carried sump oil can be precipitated to advance towards the deep part of the stratum continuously. Thus, the effect of the sump oil on the infiltration surface of a near well is relieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Drilling fluid lubricating agent

ActiveCN101486896BMeet the requirements of lubricating performanceImprove the lubrication effectDrilling compositionOrganic acidPentaerythritol

The invention relates to a lubricant for drilling fluid, which essentially solves the problems of the prior art that the lubricant for drilling fluid has poor lubricating property in the high-density drilling fluid. The lubricant for drilling fluid comprises the following components calculating by weight percentage: a) 1 to 35 percent of long-chain organic acid oiliness agent; b) 1 to 35 percent of synthetic ester oiliness agent; c) 0.1 to 8 percent of emulsifier; and d) 25 to 90 percent of base oil; in which the synthetic ester oiliness agent is selected from at least one of isooctyl stearate, butyl isostearate, trimethylolpropane trioleate, trimethylolpropane palm kernel ester, trimethylolpropane ethylhexoate, neopentyl glycol oleate, methyl laurate or pentaerythritol caproate, therefore, the technical proposal solves the problem preferably, and can be used in the industrial production of lubricant for drilling fluid.

Owner:CHINA PETROLEUM & CHEM CORP

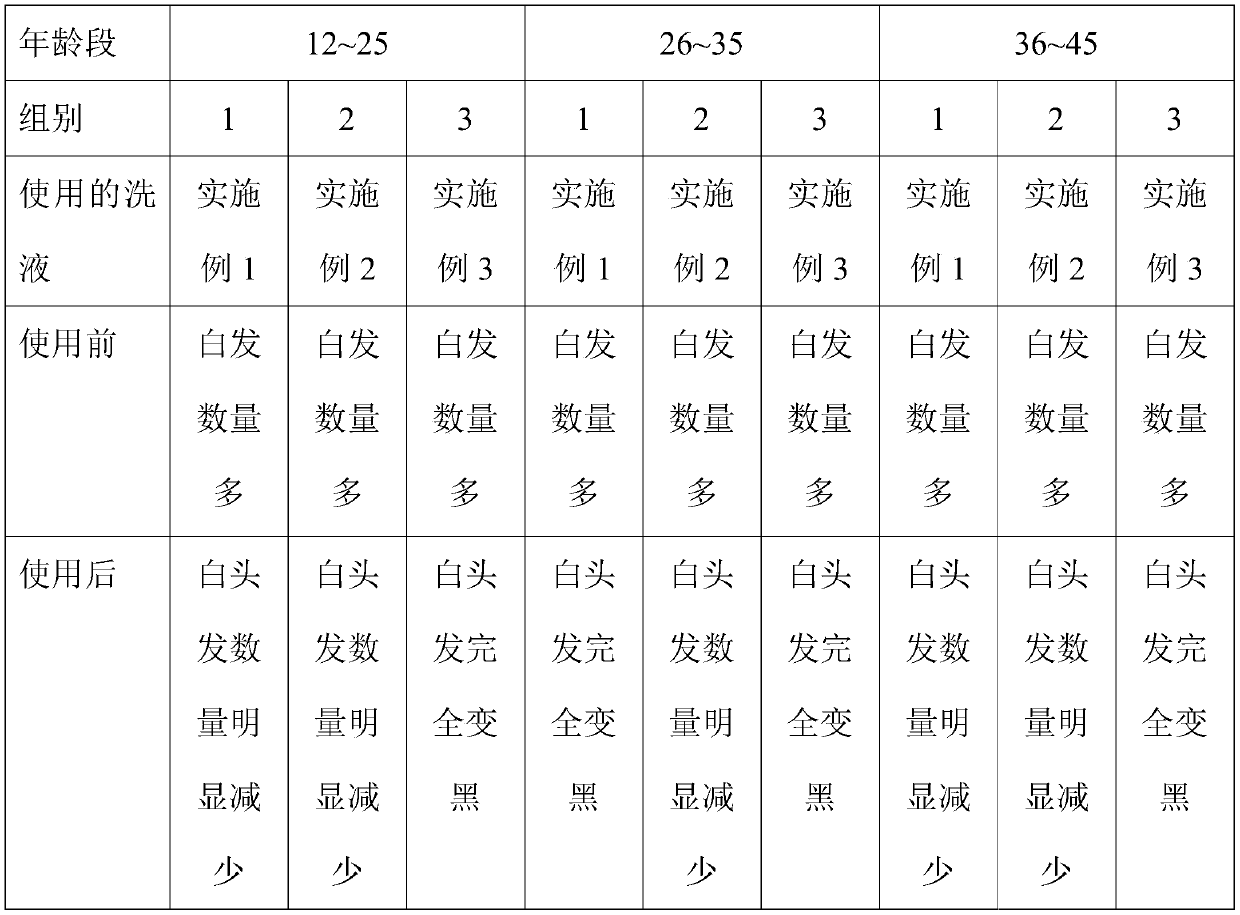

Hair blacking essence capable of changing white hair into black hair and a preparation method thereof

PendingCN111467277APromote formationImprove unimpededCosmetic preparationsHair cosmeticsTyrosineTyrosinase

The invention discloses a hair blacking essence capable of changing white hair into black hair and a preparation method thereof. The hair blacking essence capable of changing white hair into black hair comprises the following components in parts by mass of 76-79 parts of an agent A, 15.6-17.7 parts of an agent B, 0.55-1 part of an agent C and 2.75-3 parts of an agent D, wherein the agent B is prepared from cocamide MEA, sodium methyl 2-sulfolaurate and a plant extract; the preparation method comprises the steps of raising the temperature of the agent A to 80-90 DEG C; adding the agent B into the agent A, and stirring at constant temperature for 13-20 minutes; then adding the agent C, and stirring for 28-32 minutes at constant temperature; and cooling to 45 DEG C or below, keeping the temperature constant, adding the agent D into the mixture, and stirring for 25-35 minutes. All the traditional Chinese medicines coordinate and promote one another, formation of melanin particles is promoted, a transport channel is unblocked, synthesis and transfer of primary pigment cells are promoted, and the activity of tyrosinase is enhanced, so that the white hair contains melanin, and the effectof blackening from white is achieved.

Owner:广州路标科技有限公司

Fishing net prepared from ceramic powder-modified plastic

InactiveCN105801980AEasy to processImprove mechanical propertiesFibre typesMonocomponent polyolefin artificial filamentPolyethylene terephthalate glycolFlexural strength

The invention discloses a fishing net prepared from ceramic powder-modified plastic. The fishing net is prepared from the following components: methyl laurate, a nylon 6 and polyvinylidene chloride mixture, polyethylene, ceramic powder, polyethylene terephthalate, medium vinyl polybutadiene rubber, polypropylene fiber, aluminum oxide powder, rosin and an assistant modifier. By combination of the advantages of the raw materials of the nylon and polyvinylidene chloride mixture, the polyethylene and the like, modified treatment is carried out by the ceramic powder as the material; auxiliary modified treatment is carried out on the raw materials by the raw materials of the aluminum oxide powder, the rosin, the assistant modifier and the like; the improved material has good mechanical property; the prepared fishing net has high strength, good tenacity and high impact resistance; the bending strength is greatly improved; especially, the tensile strength and the weather resistance are greatly improved; the service lifetime of the fishing net is 1.5 times that of an ordinary fishing net in the same complicated environment; and the tensile strength is 0.8 times that of the ordinary fishing net.

Owner:巢湖市强力渔业有限责任公司

Formula for heat-conducting antistatic nylon oil conduit

The invention discloses a formula for a heat-conducting antistatic nylon oil conduit. The formula comprises, by weight, 100 parts of nylon, 5 to 6 parts of polytetrafluoroethylene, 10 to 12 parts of sodium allysulfonate, 2.5 to 3 parts of methyl laurate, 3 to 5 parts of alkyl quaternary ammonium salt, 2 to 3 parts of nanometer tin oxide, 0.5 to 1 part of an organic fiber and 0.5 to 1 part of an auxiliary agent. The heat-conducting antistatic nylon oil conduit provided by the invention has the advantages of low cost of the formula, fast heat conduction and antistatic performance and is especially applicable to an automobile.

Owner:青岛永卓真塑料制品有限公司

Method for synthesizing methyl laurate by recycling cerium phosphotungstate catalyst

InactiveCN103012135AReduced activityAchieve recyclingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryWater insoluble

The invention relates to a method for synthesizing methyl laurate by recycling a cerium phosphotungstate catalyst, which belongs to the technical field of chemical industry. The method comprises the following steps of: adding lauric acid and absolute methanol to a reaction kettle in proportion; adding cerium phosphotungstate accounting for 7%-7.5% of the weight of the lauric acid as the catalyst; decompressing and evaporating unreacted methanol after heating reflux reaction; carrying out centrifugal separation on the methyl laurate and the solid cerium phosphotungstate catalyst which are positioned in the reaction kettle to obtain the methyl laurate on an upper layer and the solid cerium phosphotungstate catalyst on a lower layer; dissolving the lower solid cerium phosphotungstate catalyst by using deionized water, and adding hydrochloric acid to blend the pH value of a solution (1, filtering to remove water-insoluble carbon deposits and obtain a cerium phosphotungstate water solution, and concentrating and crystallizing the cerium phosphotungstate water solution to obtain the solid cerium phosphotungstate used as the catalyst for next reaction). The method disclosed by the invention recycles the cerium phosphotungstate as the catalyst of the reaction of the lauric acid and the absolute methanol and achieves the transformation rate of the lauric acid more than 97% every time.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

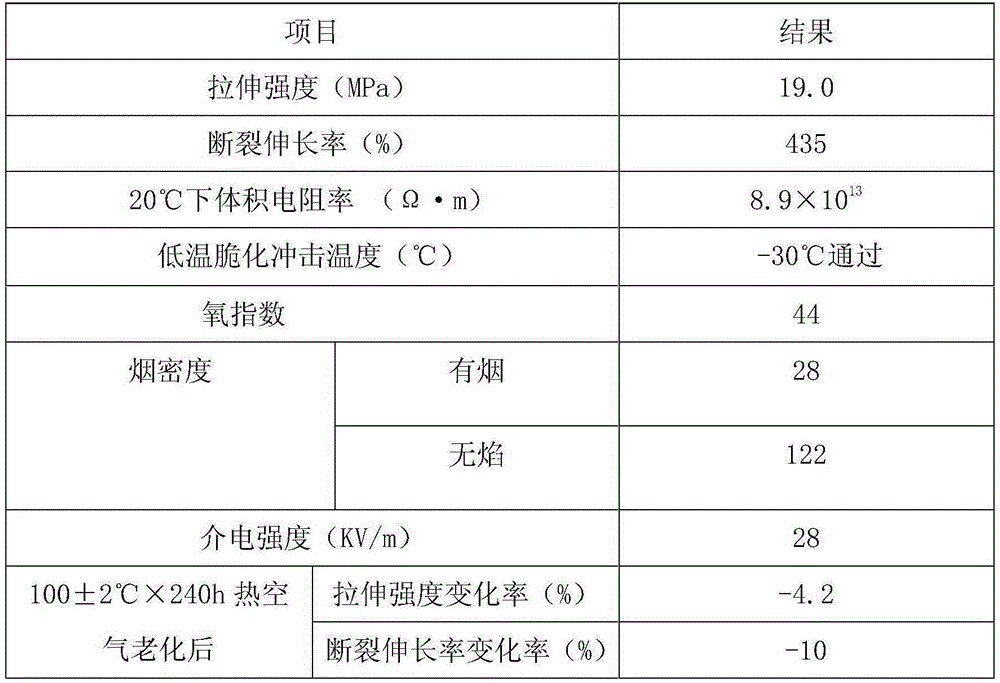

A kind of matte flame-retardant polyvinyl chloride wire and cable material and preparation method thereof

ActiveCN103524932BFlame retardant hasOil resistantInsulated cablesInsulated conductorsCalcium silicateMicrocrystalline wax

The invention provides a fog-face fire-retardant polyvinyl chloride electric wire and cable material prepared from the following raw materials in parts by weight: 60-80 parts of polyvinyl chloride, 15-20 parts of an organosilicone modified thermoplastic phenolic resin, 1-2 parts of calcium silicate, 8-10 parts of wood flour, 40-50 parts of calcium carbonate, 40-50 parts of epoxidized triethylhexanoin, 4-5 parts of palm oil, 4-10 parts of methyl laurate, 20-30 parts of magnesium hydroxide, 3-5 parts of decabromodiphenyl ethane, 1.0-2.0 parts of ammonium molybdate, 3-7 parts of a stabilizer, 0.5-1.5 parts of microcrystalline wax, 1-2 parts of sodium selenite, 8-10 parts of aluminium hypophosphite, 1-2 parts of ammonium polyphosphate, 1-2 parts of alcohol ester-12, and 8-10 parts of a modified filler. The fog-face fire-retardant polyvinyl chloride electric wire and cable material has the characteristics of flame retardancy, oil resistance, aging resistance, and acid and alkali resistance, and has lower specific density and low cost.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Metal rolling oil and preparation method thereof

The invention discloses metal rolling oil and a preparation method thereof. The metal rolling oil is prepared form following raw materials by weight: 20-40 parts of dipatassium sulfoacetate, 10-20 parts of cetyl octanoate, 10-18 parts of methyl laurate, 12-13 parts of formaldehyde, 7-9 parts of ammonium chloride, 7-12 parts of sodium dodecyl sulfate, 1-6 parts of thiocarbamide, 10-20 parts of sulfuric acid and 4-6 parts of boric acid. According to the metal rolling oil and the preparation method, the raw material cost is low, preparation of the metal rolling oil is simple, the cost is reduced and at the same time effects are guaranteed and economic benefit of products is improved. The lubricating property of the metal rolling oil is 12% higher than the lubricating property of common rolling oil. In addition, products machined by using the metal rolling oil provided by the invention have good glossiness and no rolling scars.

Owner:湖南澳克科姆能源科技有限公司

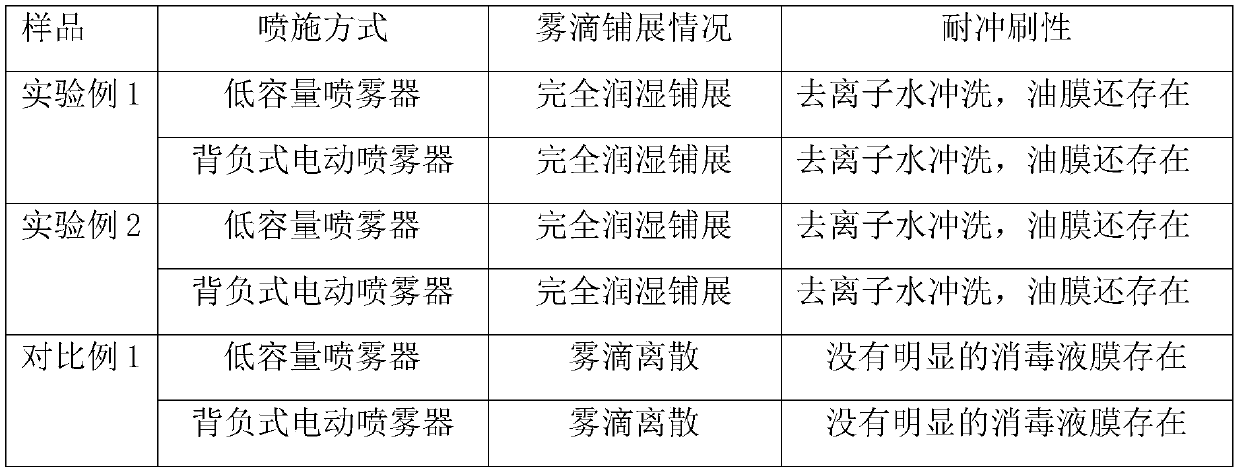

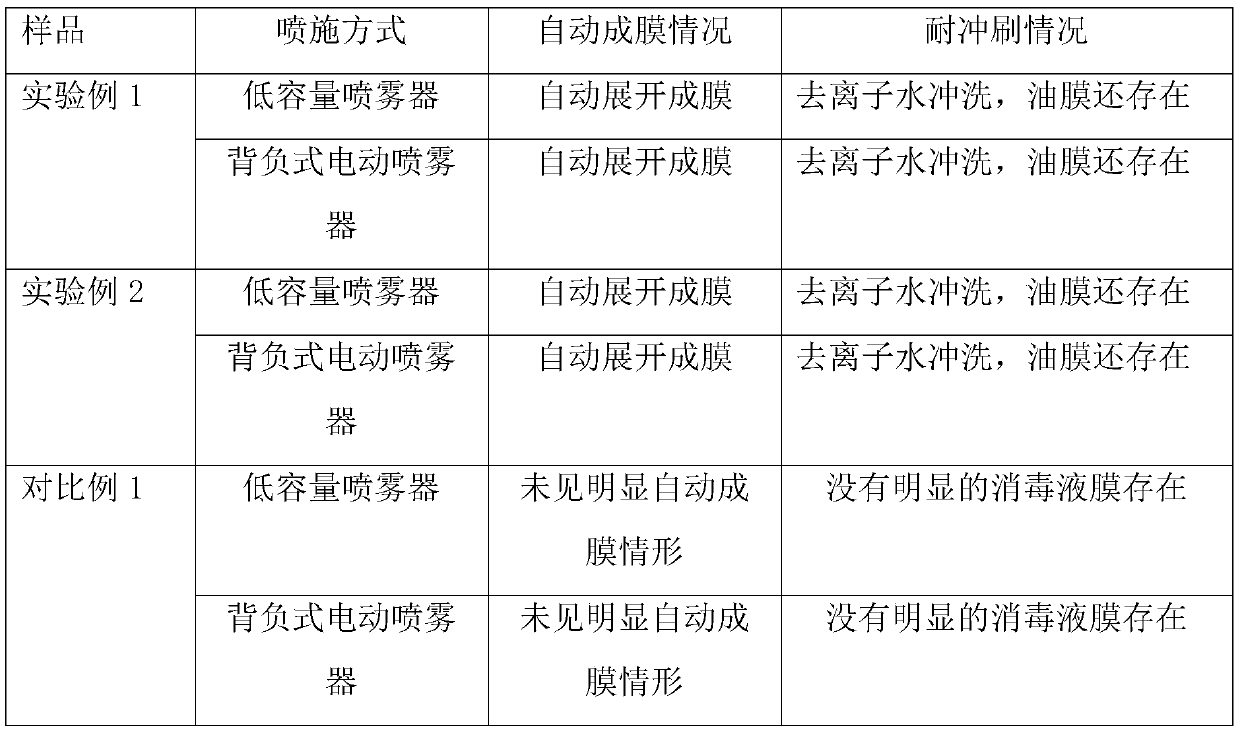

Disinfection emulsion, preparation method thereof and disinfection wet tissue prepared by using disinfection emulsion

InactiveCN111374142AReduce surface tensionNot easy to slipBiocideDisinfectantsPhenyl EthersActive agent

The invention discloses a disinfection emulsion, a preparation method thereof and a disinfection wet tissue prepared from the disinfection emulsion. Raw materials of the disinfection emulsion comprisethe following components in parts by weight: 0.5-5 parts of polyhexamethylene biguanide, 2-10 parts of a film-forming agent, 1-5 parts of a nonionic surfactant, 1-10 parts of a cationic surfactant and 50-200 parts of deionized water. The nonionic surfactant and / or the cationic surfactant contains a fatty alcohol group, and the carbon chain of the fatty alcohol group is C10-C18; the film-forming agent is selected from one or more of methyl laurate, tridecanol, hexadecanol, octadecanol and propylene glycol phenyl ether. The disinfection emulsion disclosed by the invention has the advantages ofgood stability, capability of automatically forming a film on a low surface and automatically expanding to form a film, long shelf life, good sterilization persistence and high safety, so that a disinfection wet tissue product prepared from the disinfection emulsion also has corresponding characteristics.

Owner:天天向上(宁波)医疗科技有限公司

Aluminum profile chromate-free passivation treating solution good in film forming property and preparation method thereof

InactiveCN105132899AReduce pollutionImprove antioxidant capacityMetallic material coating processesSilicon dioxideSodium sulfate

The invention discloses an aluminum profile chromate-free passivation treating solution good in film forming property. The aluminum profile chromate-free passivation treating solution is prepared from the raw materials of, by weight, 10-10.5 parts of cerous nitrate, 2-2.2 parts of potassium permanganate, 0.3-0.4 part of methyl laurate, 0.6-0.8 part of octadecanol, 0.3-0.4 part of butyl ether acetate, 0.5-0.6 part of ammonium dihydrogen phosphate, 0.6-0.8 part of styrene, 0.2-0.3 part of acrylamide, 0.4-0.5 part of crylic acid, 0.05-0.1 part of azodiisobutyronitrile, 0.5-0.6 part of sodium allylsulfonate, 0.02-0.03 part of lauryl sodium sulfate, 0.9-1 part of cetane, 0.3-0.4 part of nano silica, 0.3-0.4 part of nano titania and an appropriate amount of deionized water. By means of the treating solution, the coating performance of paint can be improved, and a formed film is more compact and uniform; by the utilization of the methyl laurate, the octadecanol, the butyl ether acetate and the ammonium dihydrogen phosphate, film forming can be promoted, and the compact oxidation film can be formed rapidly.

Owner:ANHUI FUHUANG STEEL STRUCTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com