High-strength ultraviolet-resistant 3D (three-dimensional) printing material for building field and preparation method thereof

A UV-resistant, 3D printing technology, applied in the field of 3D printing materials, can solve the problems of self-extinguishing, easy dripping, unsatisfactory strength and UV resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

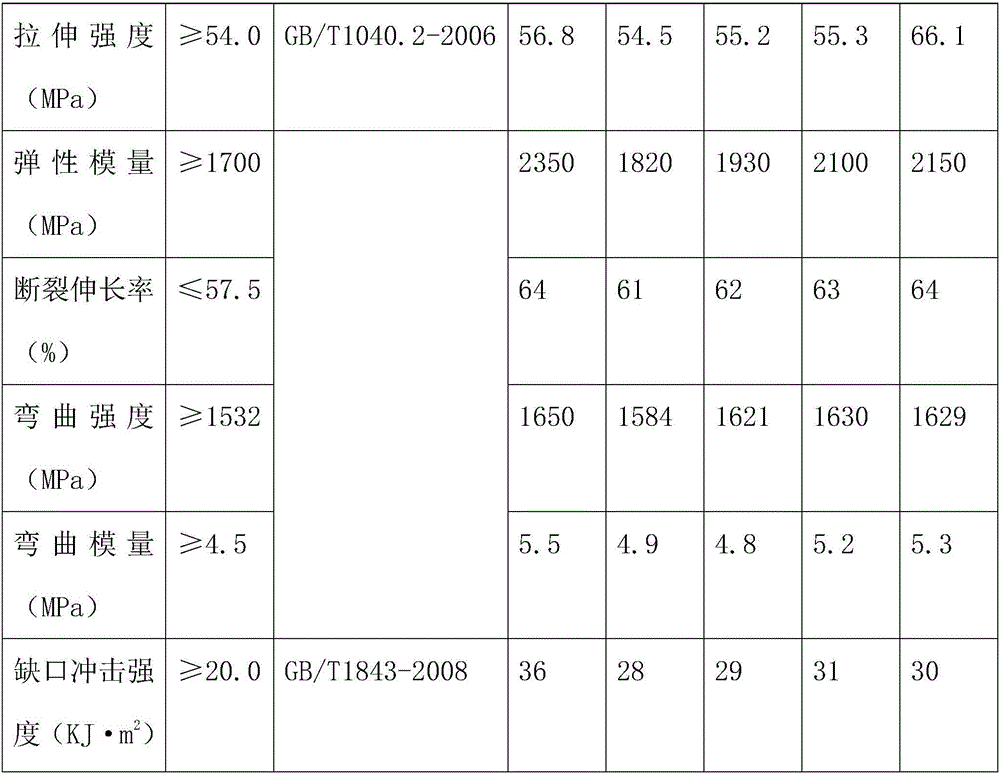

Embodiment 1

[0015] The present invention proposes a high-strength UV-resistant 3D printing material for the construction field, and its raw materials include, by weight, 100 parts of ABS resin, 40 parts of polyvinyl chloride, 30 parts of polypropylene, 22 parts of polycarbonate, and cis-butene 45 parts of dianhydride, 3.5 parts of phenolic resin, 6 parts of trimethyl phosphate, 5 parts of glass fiber, 5 parts of carbon fiber, 6.5 parts of methyl laurate, 4 parts of diphenylmethane bismaleimide, 5-sulfonic acid para 2 parts of monopotassium phthalate, 3.5 parts of 2,5-dihydroxyterephthalic acid, 2.5 parts of benzotriazole, 4 parts of polytetrafluoroethylene, 3.5 parts of sodium allyl sulfonate, 5 parts of methyl acrylate , 3.5 parts of n-propyl acrylate, 3.5 parts of magnesium stearate, 5.5 parts of dodecyl alcohol ester, 4 parts of silane coupling agent KH-560, 4.5 parts of benzoyl peroxide, 10 parts of hardening modifier, 10 parts of modified additives, 9 parts of modified fillers.

Embodiment 2

[0017] The present invention proposes a high-strength UV-resistant 3D printing material for the construction field. The raw materials include: 80 parts of ABS resin, 50 parts of polyvinyl chloride, 25 parts of polypropylene, 18 parts of polycarbonate, and cis-butene 60 parts of dianhydride, 2 parts of phenolic resin, 8 parts of trimethyl phosphate, 4 parts of glass fiber, 8 parts of carbon fiber, 4 parts of methyl laurate, 5 parts of diphenylmethane bismaleimide, 5 parts of sulfonic acid 1 part of monopotassium phthalate, 5 parts of 2,5-dihydroxyterephthalic acid, 1 part of benzotriazole, 6 parts of polytetrafluoroethylene, 2 parts of sodium allyl sulfonate, 8 parts of methyl acrylate , 1 part of n-propyl acrylate, 5 parts of magnesium stearate, 3 parts of dodecyl alcohol ester, 6 parts of silane coupling agent KH-560, 1 part of benzoyl peroxide, 15 parts of hardening modifier, 5 parts of modified additives, 12 parts of modified fillers.

[0018] A preparation method of a hig...

Embodiment 3

[0020]The present invention proposes a high-strength UV-resistant 3D printing material for the construction field, and its raw materials include, by weight, 120 parts of ABS resin, 30 parts of polyvinyl chloride, 35 parts of polypropylene, 18 parts of polycarbonate, and cis-butene 60 parts of dianhydride, 2 parts of phenolic resin, 8 parts of trimethyl phosphate, 4 parts of glass fiber, 8 parts of carbon fiber, 4 parts of methyl laurate, 5 parts of diphenylmethane bismaleimide, 5 parts of sulfonic acid 1 part of monopotassium phthalate, 5 parts of 2,5-dihydroxyterephthalic acid, 1 part of benzotriazole, 6 parts of polytetrafluoroethylene, 2 parts of sodium allyl sulfonate, 8 parts of methyl acrylate , 1 part of n-propyl acrylate, 5 parts of magnesium stearate, 3 parts of dodecyl alcohol ester, 6 parts of silane coupling agent KH-560, 1 part of benzoyl peroxide, 15 parts of hardening modifier, 5 parts of modified additives, 12 parts of modified fillers.

[0021] The hardening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com