Patents

Literature

84 results about "Methyl linoleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

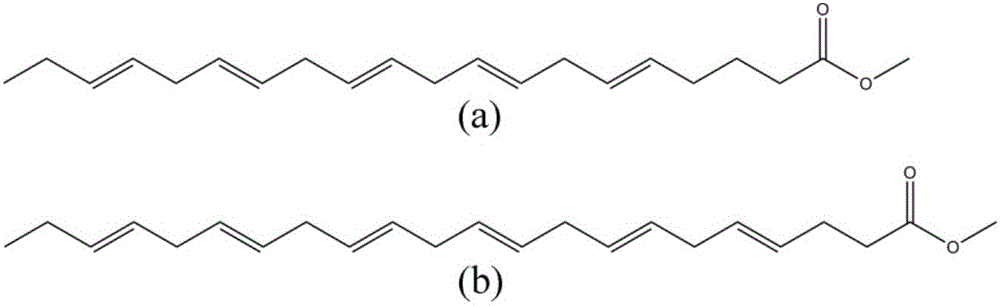

Methyl linoleate. [′meth·əl lə′nō·lē‚āt] (organic chemistry) C19H34O2 A combustible, colorless liquid with a boiling point of 212°C; soluble in alcohol and ether; used in the manufacture of detergents, emulsifiers, lubricants, and textiles, and in medical research.

Detection method for tea seed oil adulteration based on ratio of main fatty acids

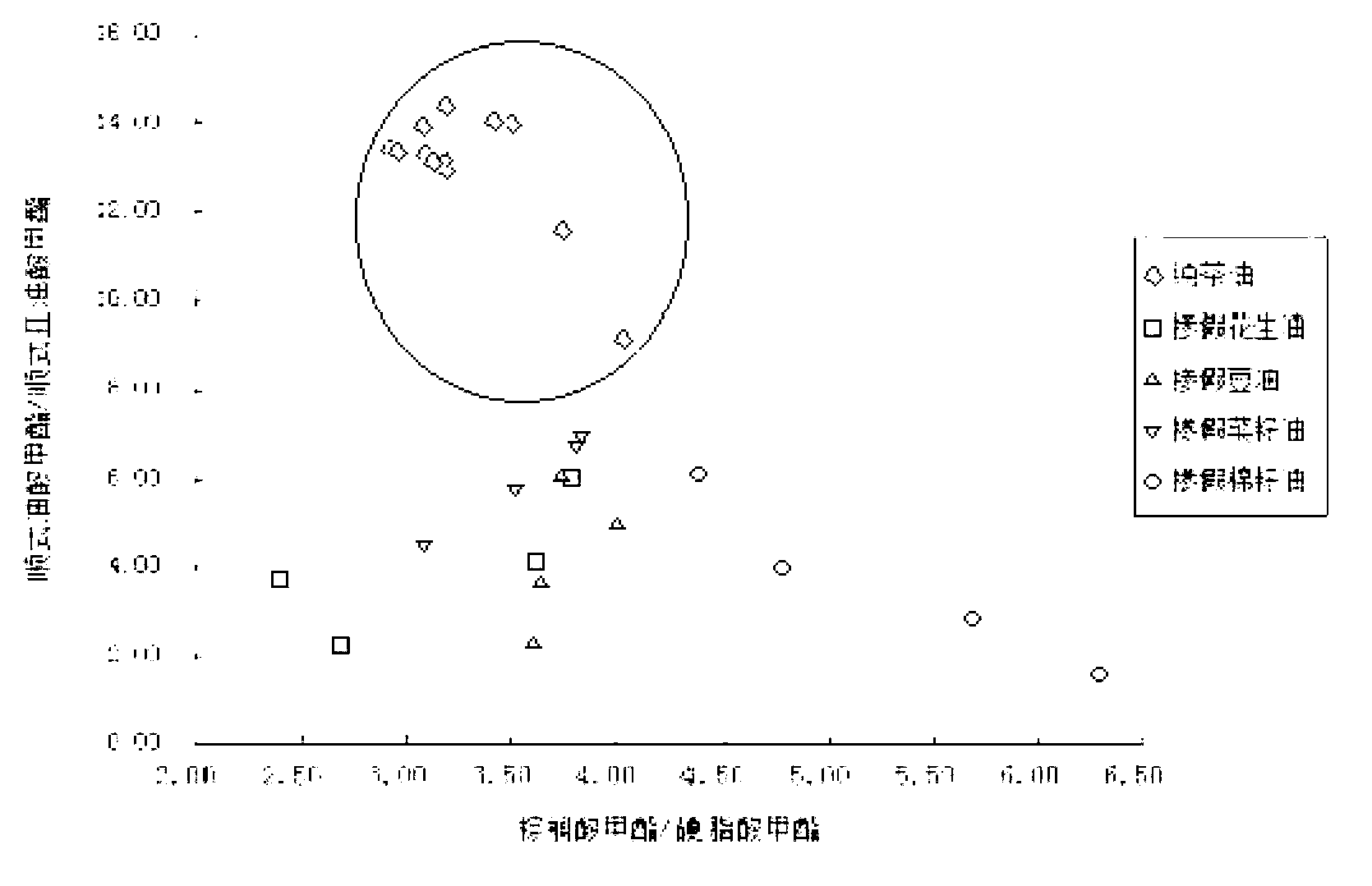

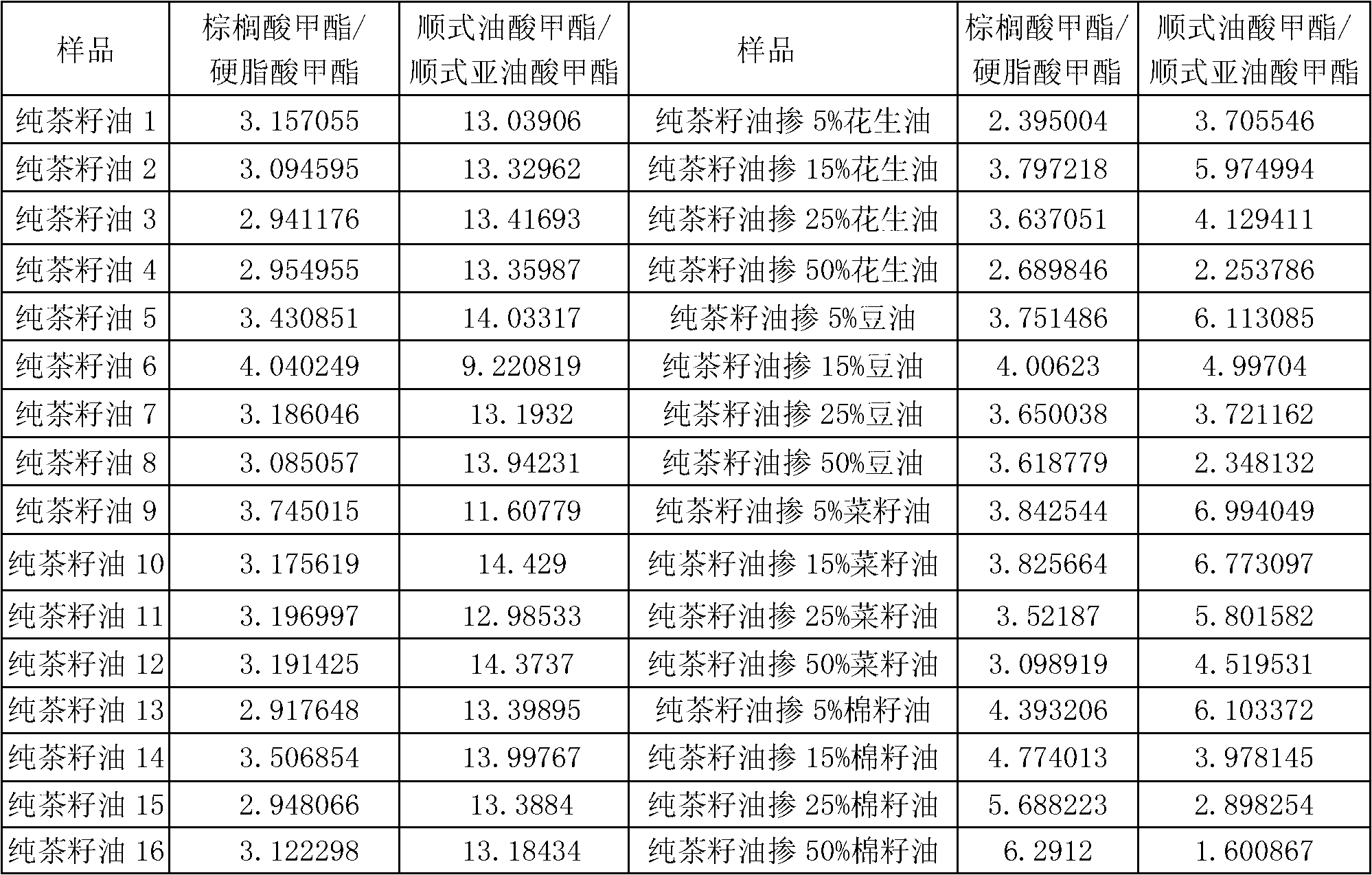

A detection method for tea seed oil adulteration based on ratio of main fatty acids obtains the contents of main fatty acids in pure tea seed oil and adulterated tea seed oil samples by applying gas chromatography and mass spectrometry technology (GC-MS technology), and intuitively presents the distribution characteristic of fatty acids of grease-adulterated pure tea oil by adopting a two-dimensional diagram of methyl cis-oleate / methyl cis-linoleate and methyl palmitate / methyl stearate, so as to qualitatively identify adulteration of tea oil.

Owner:HUNAN AGRICULTURAL UNIV

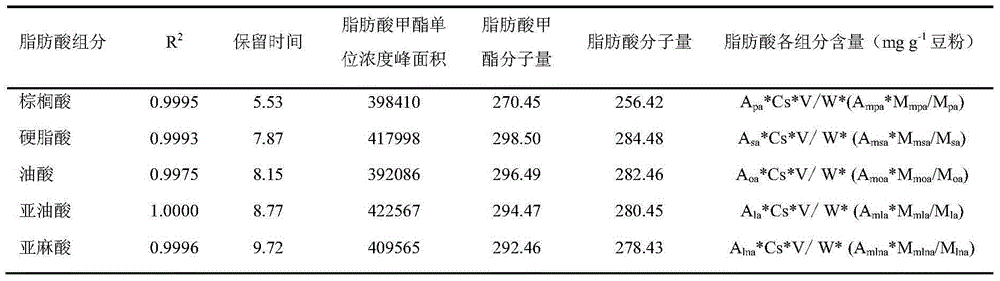

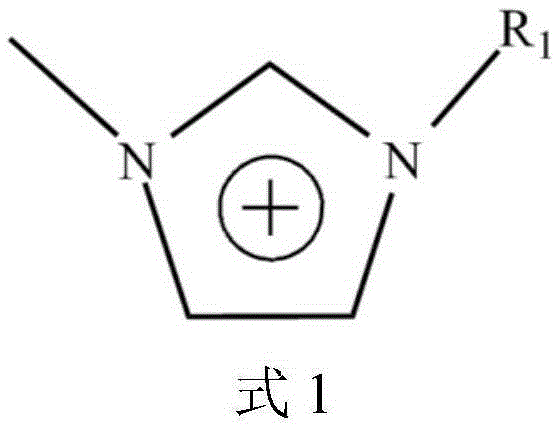

Gas chromatography method for qualitatively and quantitatively detecting soya fatty acid components

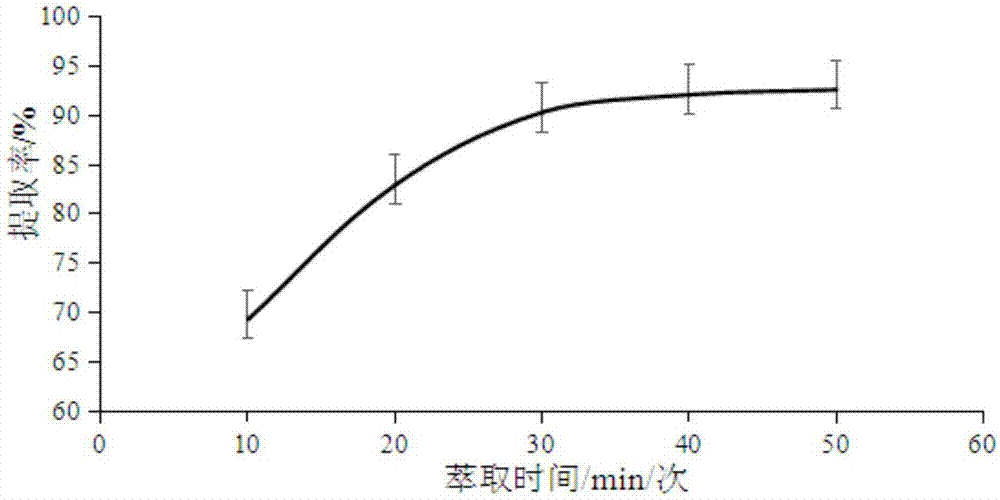

ActiveCN105044229AImprove extraction efficiencyImprove accuracyComponent separationGas phaseMethyl oleate

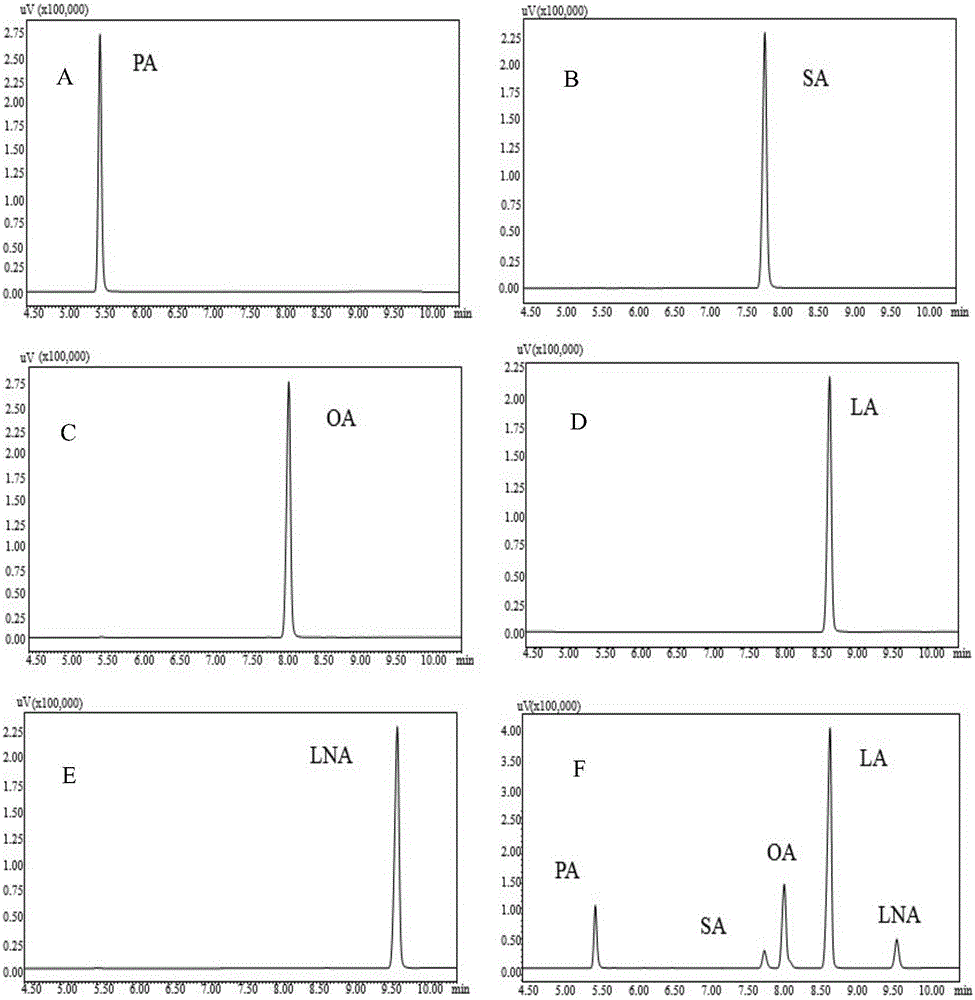

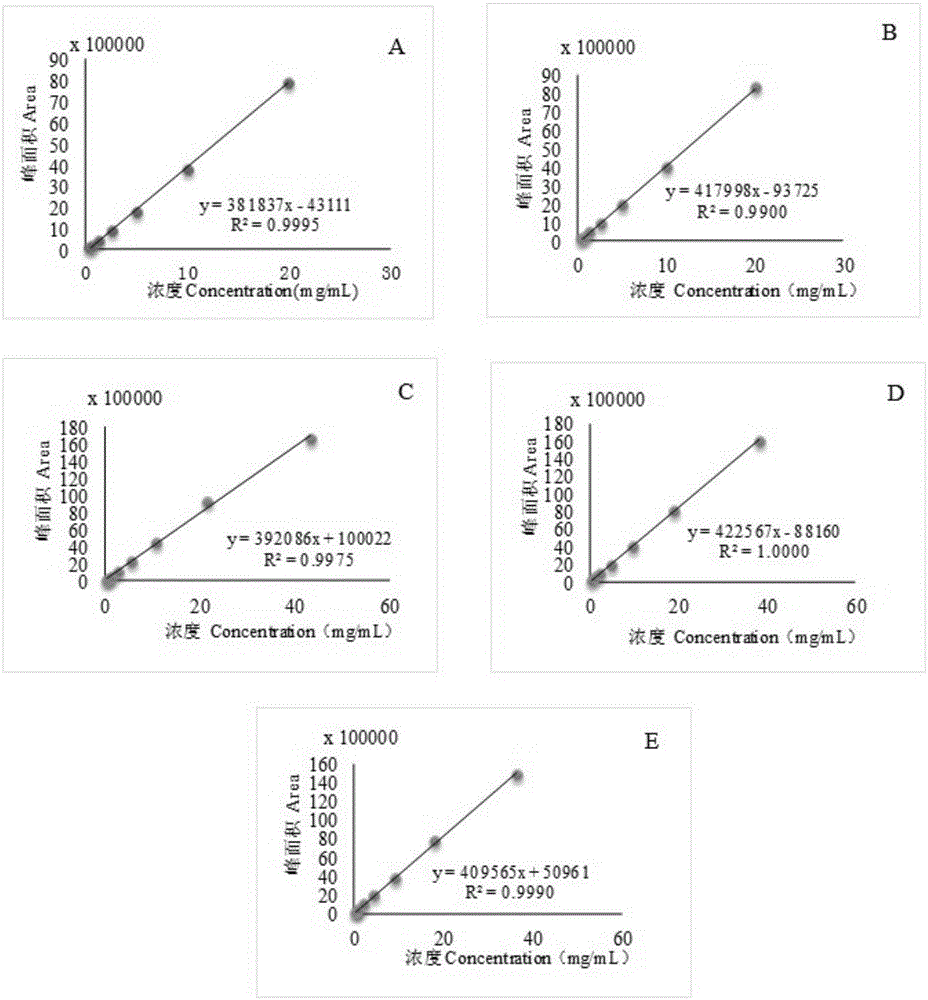

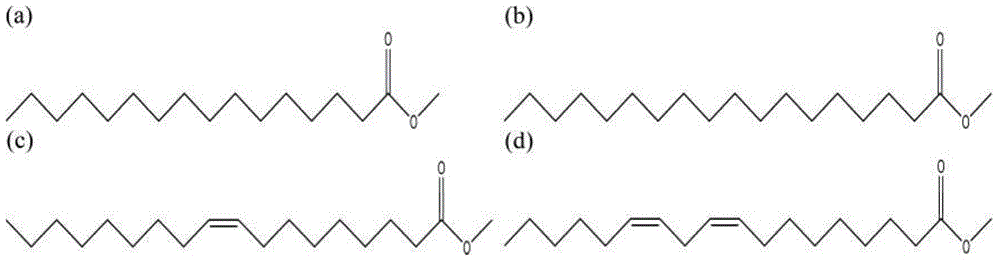

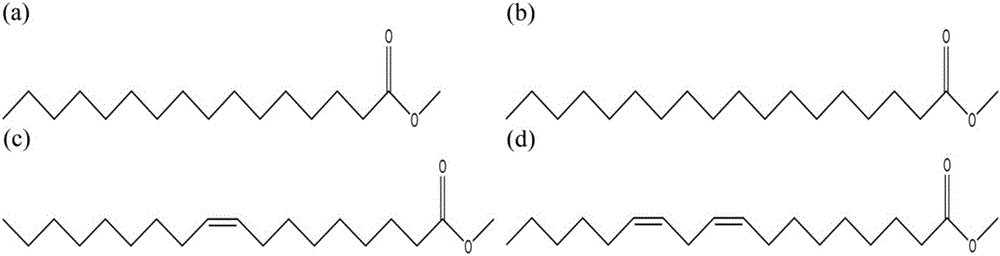

The invention relates to a gas chromatography method for qualitatively and quantitatively detecting soya fatty acid components. The gas chromatography method is characterized in that fatty acids in soya seeds are extracted by adopting methods of heating and methylating and detected by adopting a gas chromatography, and the actual content of the fatty acid components in the soya seeds can be accurately detected according to a standard curve and a regression equation of standard samples of five fatty acid methyl esters (methyl palmitate, methyl stearate, methyl oleate, methyl linoleate and methyl linolenate). The method is applicable to qualitative and quantitative analysis of the fatty acid components of the soya seeds, is simple and convenient to operate, easy to control and easy to popularize, can be used for detecting relative percentage content of the five fatty acid components and accurately calculating the absolute content of each fatty acid component in the soya seeds, and has an important meaning in soya fatty acid detecting and breeding.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

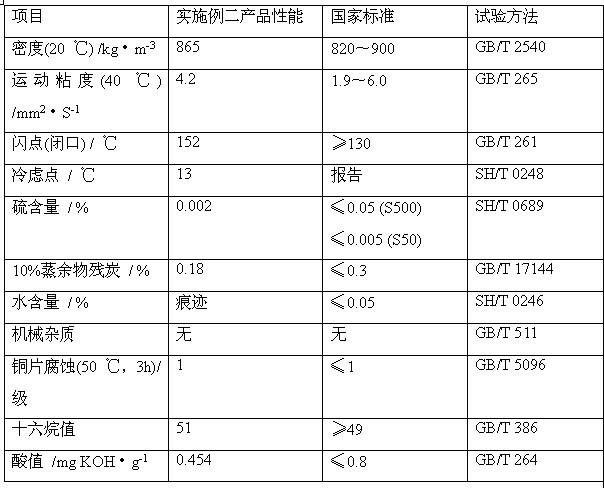

Biodiesel prepared by non-edible vegetable oil and method thereof

InactiveCN102585927AExcellent cetane numberExcellent flash pointFatty acid esterificationBiofuelsMethyl linoleateVegetable oil

The invention relates to biodiesel prepared by non-edible vegetable oil and a method thereof, which belong to the biodiesel field. By-product milk thistle oil produced during the production process of Silibinin serves as a raw material for preparing the biodiesel. The biodiesel is obtained by transesterification of the milk thistle oil and methyl alcohol under the condition of a catalyst. Gas chromatography-mass spectrometry analysis results show that main components of the biodiesel prepared by the milk thistle oil serving as the raw material are methyl oleate and methyl linoleate. The biodiesel is high in cetane number, excellent in performance and capable of meeting China current biodiesel standard. In addition, the biodiesel is simple in process, mild in reaction condition, low in cost and capable of achieving large-scale production.

Owner:JIANGSU UNIV

Corrosion-resistant high-temperature-resistant cable material

InactiveCN106009317AImprove heat resistanceImprove corrosion resistanceRubber insulatorsInsulated cablesEpoxyMethyl linoleate

The invention discloses a corrosion-resistant high-temperature-resistant cable material. The material is prepared from, by weight, 10-20 parts of hydrogenated butadiene-acrylonitrile rubber, 60-80 parts of ethylene propylene terpolymer, 20-40 parts of modified polyurethane, 20-40 parts of carbon black, 20-40 parts of kaolin, 4-6 parts of epoxy acetyl methyl linoleate, 40-60 parts of flame-retardant agent, 0.5-1.5 parts of gamma-aminopropyltriethoxysilane, 1-1.5 parts of dicumyl peroxide, 0.1-0.3 part of zinc stearate, 0.2-0.4 part of accelerant CZ, 4-6 parts of Ca / Zn composite stabilizer and 2-4 parts of polyethylene wax. The cable material is good in high temperature resistance, high in corrosion resistance and good in mechanical property.

Owner:ANHUI HAIRONG CABLE

Low-temperature-resistant impact-resistant PVC (polyvinyl chloride) pipe material easy to machine

InactiveCN104961995AImprove wear resistanceImprove impact resistanceMethyl linoleateDi-tert-butyl peroxide

The invention discloses a low-temperature-resistant impact-resistant PVC (polyvinyl chloride) pipe material easy to machine. The low-temperature-resistant impact-resistant PVC pipe material easy to machine comprises , by weight, 60 to 80 parts of PVC, 20 to 40 parts of modified thermoplastic polyurethane elastomer, 4 to 6 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 15 to 20 parts of silane coupling modified kaolin, 20 to 40 parts of silane coupling modified magnesium hydroxide, 8 to 12 parts of organic phosphine, 10 to 15 parts of epoxidized methyl linoleate, 20 to 25 parts of triethyl citrate, 1 to 3 parts of dicumyl peroxide, 0.5 to 1.5 parts of di-tert-butyl peroxide, 0.5 to 1.5 parts of dibutyltin dilaurate, 3 to 5 parts of organic tin stabilizer, 1 to 2 parts of calcium stearate, 2 to 3 parts of barium stearate, 1 to 2 parts of anti-aging agent AW, 0.5 to 2 parts of anti-aging agent RD, 3 to 5 parts of silicone powder, 2 to 4 parts of paraffin and 2 to 4 parts of titanium dioxide. The low-temperature-resistant impact-resistant PVC pipe material is easy to machine, resistant to low temperature and high in impact resistance.

Owner:ANHUI ZHENGSHI NEW BUILDING MATERIAL

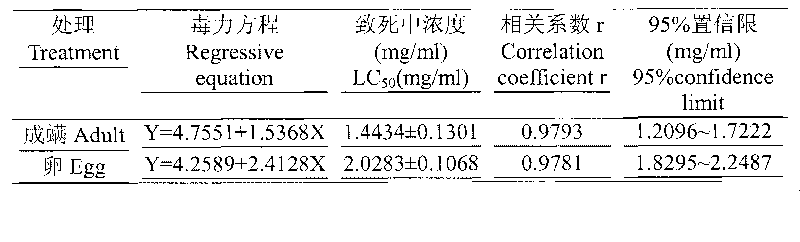

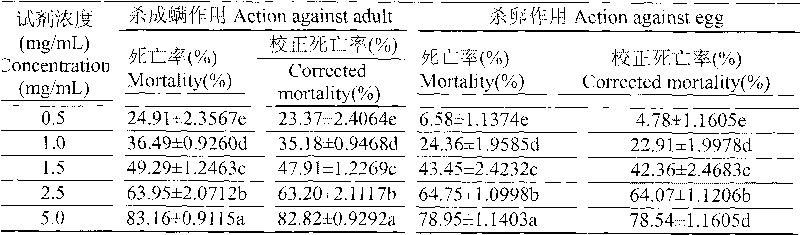

Methyl linoleate acaricide and preparation method therof

InactiveCN101731216AImprove compatibilityGood development resourceBiocideAnimal repellantsAcaricideMethyl linoleate

The invention relates to a plant acaricide suitable for preventing and controlling mites on cash crops, i.e. fruit trees, vegetables, and the like as well as a preparation and application thereof. The plant acaricide is prepared by adding a surface active agent, an emulsifying agent, a penetrating agent, a potentiating agent, and the like in Methyl linoleate. The plant acaricide is a plant source acaricide which has high efficiency and low toxicity and residual, is harmonic with the environment, and the like.

Owner:BEIJING UNIV OF AGRI

Method for preparating ethyl linoleate by catalysis of composite solid ultra-strong acid

InactiveCN101139288ALarge specific surface areaHigh catalytic activityPhysical/chemical process catalystsOrganic compound preparationMethyl linoleateAdditive ingredient

The present invention is a method of preparing the linoleic acid ethyl ester with the composite solid superacid catalyst. The production method the of linoleic acid ethyl ester in the existing industrialized production is the esterification reaction between the linoleic acid and the anhydrous ethanol ester with the concentrated sulfuric acid as the catalyst. The method has the problems of the large discharge of the acidic wastewater, the serious corrosion of the production equipment and so on. Therefore, the industrialized production urgently needs an environment-friendly solid acid catalyst. The method of preparing the linoleic acid ethyl ester with the composite solid superacid catalyst of the present invention is that the linoleic acid and the anhydrous ethanol with the molar ratio of 1 to between 1 and 10 are added into the reactor in order; the mixed solution is added with the SO42- / TiO2-SiO2, the composite solid superacid catalyst, whose weight is 1 to 10 percent of the weight of the linoleic acid; the mixed solution is stirred and heated with the protection of the nitrogen; the reaction is done for 2 to 10 hours at the return temperature of 40 DEG C; the solution is delaminated statically after the reaction; the products on the upper layer are decompressed and distilled under the pressure of minus 98.8 to minus 99.3 kPa; the distilled ingredients are collected at the temperature between 162 and 172 DEG C; then the refined inoleic acid ethyl ester can be got. The method of the present invention is suitable for the preparation of the linoleic acid ethyl ester in the industry.

Owner:HEILONGJIANG UNIV

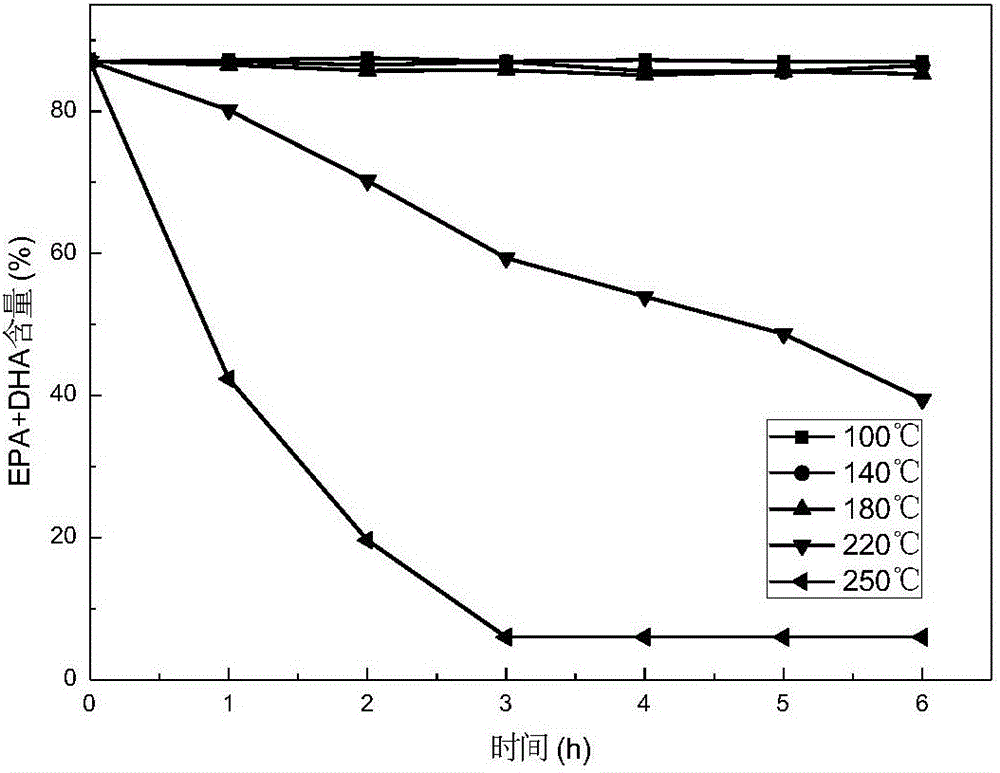

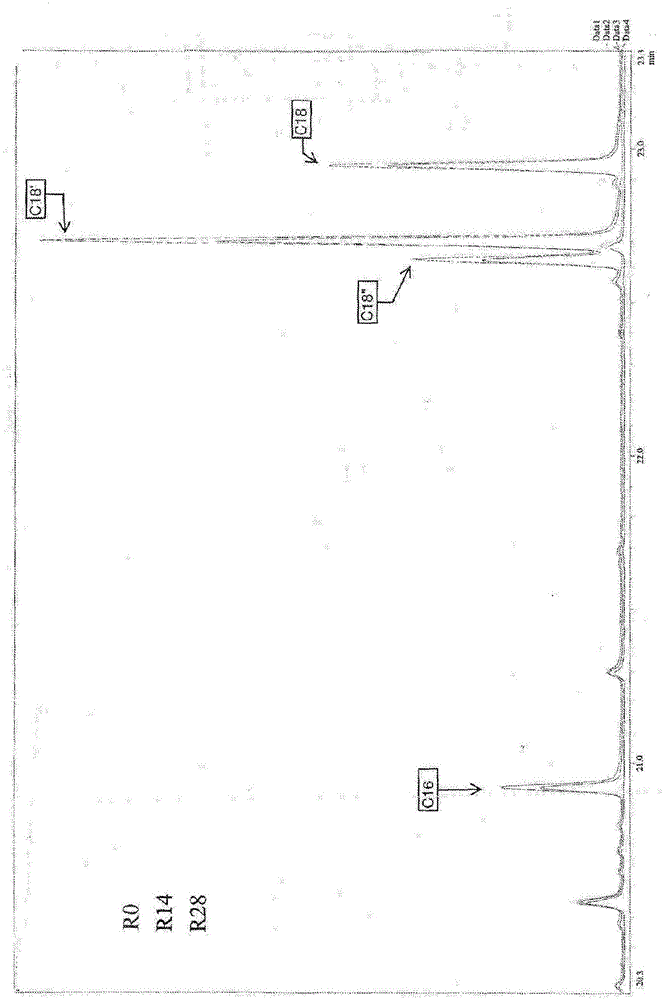

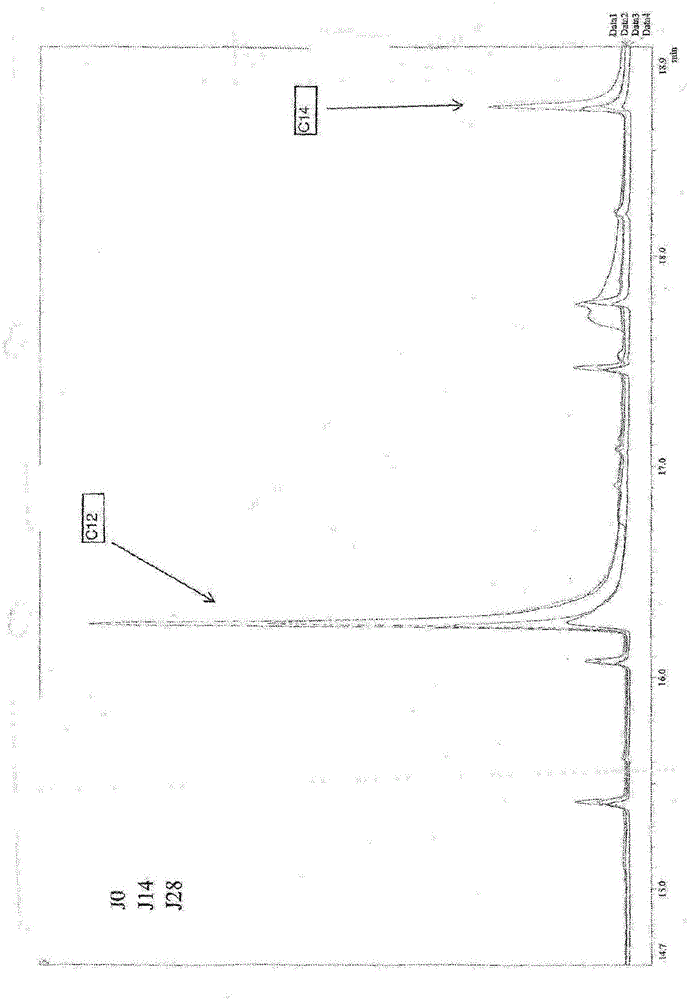

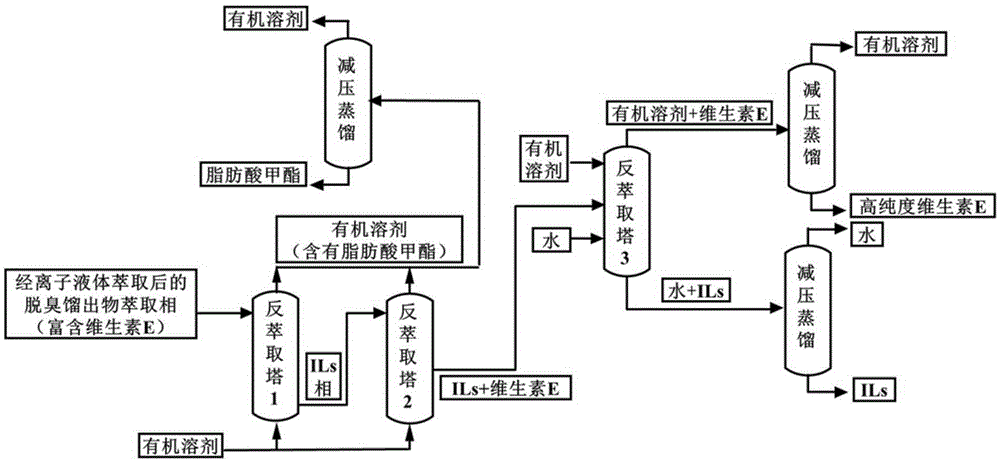

C18 series fatty acid and C20-C22 series fatty acid fine separation method

ActiveCN105062694AMild reaction conditionsSimple processFatty acid esterificationFatty-oils/fats refiningCarbon numberMethyl linoleate

The invention discloses a C18 series fatty acid and C20-C22 series fatty acid fine separation method. The method includes: pretreating the raw material animal and vegetable oil by a ionic liquid to obtain high-yield and low-acid value biodiesel, i.e. a mixture of a variety of fatty acid methyl esters, with the process being simple, green and environment-friendly; then placing the obtained biodiesel in a pressured reduced rectification tower kettle, taking the ionic liquid as an extraction agent to conduct extraction pressured reduced rectification, and collecting methyl stearate, methyl oleate and methyl linoleate or eicosapentaenoic acid methyl ester and docosahexaenoic acid methyl ester with mass percentage purity of over 98% at the tower top. The method provided by the invention makes up the blank of the prior art, has a convenient operation process, provides the operation process for separation of long-chain fatty-acid methyl esters with a same carbon number, different double-bond numbers and poor heat sensitivity, and lays the foundation for fine separation of fatty acid methyl ester.

Owner:天津领碳能源环保科技有限责任公司

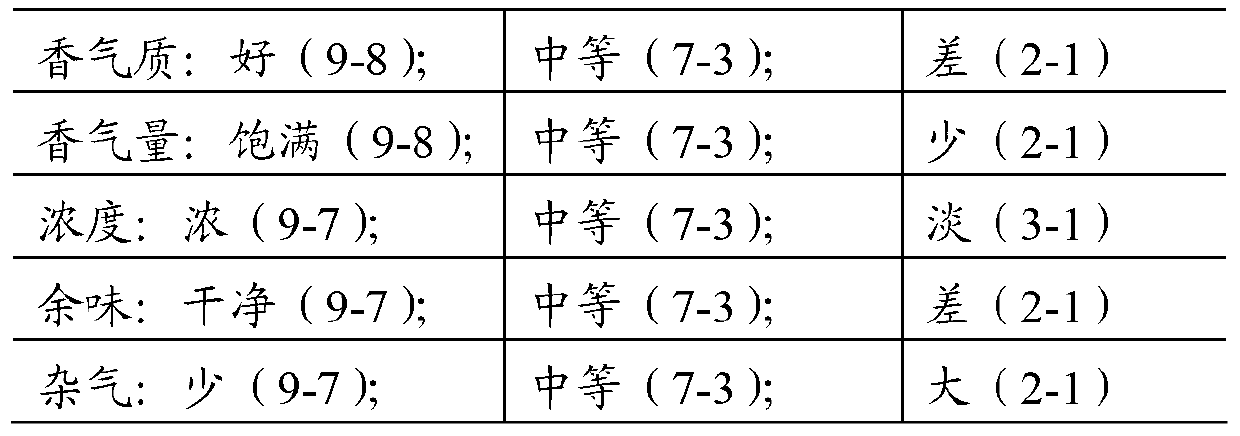

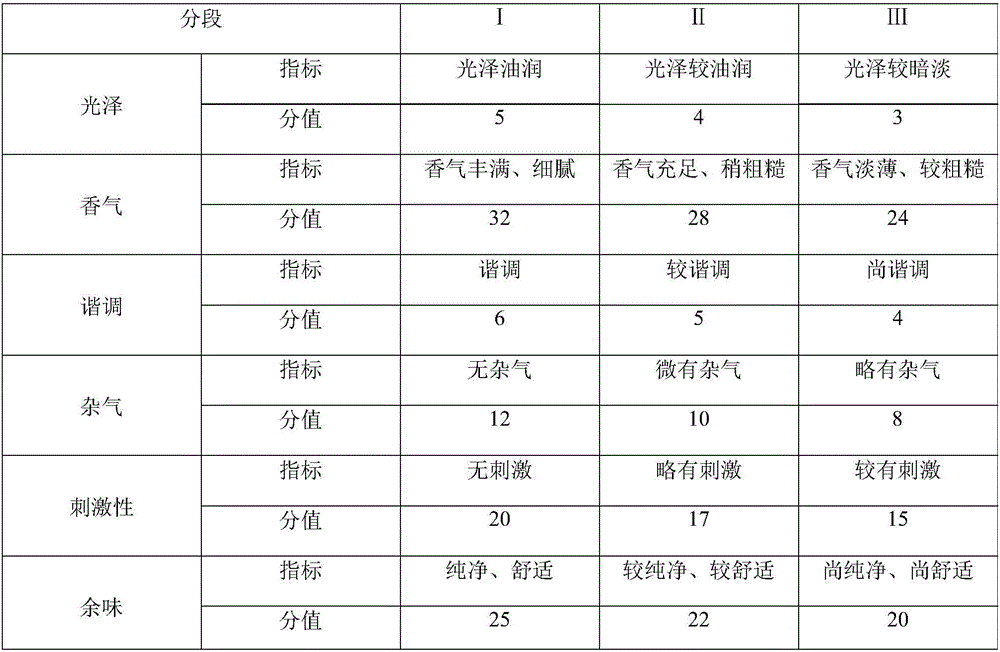

Tobacco essence capable of improving cigarette taste and fragrance

ActiveCN103343053ASmoke is soft and delicateClean aftertasteTobacco preparationEssential-oils/perfumesMethyl linoleateEnvironmental health

The invention relates to a tobacco essence capable of improving cigarette taste and fragrance, and relates to an application of the tobacco essence in cigarette. The tobacco essence mainly contains propylene glycol, a Chinese date extract, a salvia extract, a rosa laevigata extract, rhodinol, guaiacol, carvone, methyl linoleate and alpha-pinene. By using the tobacco essence provided by the invention, the smoke has the effects of being exquisite, soft, clean in aftertaste, less in irritation and moistening, and the tobacco quality is improved.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD

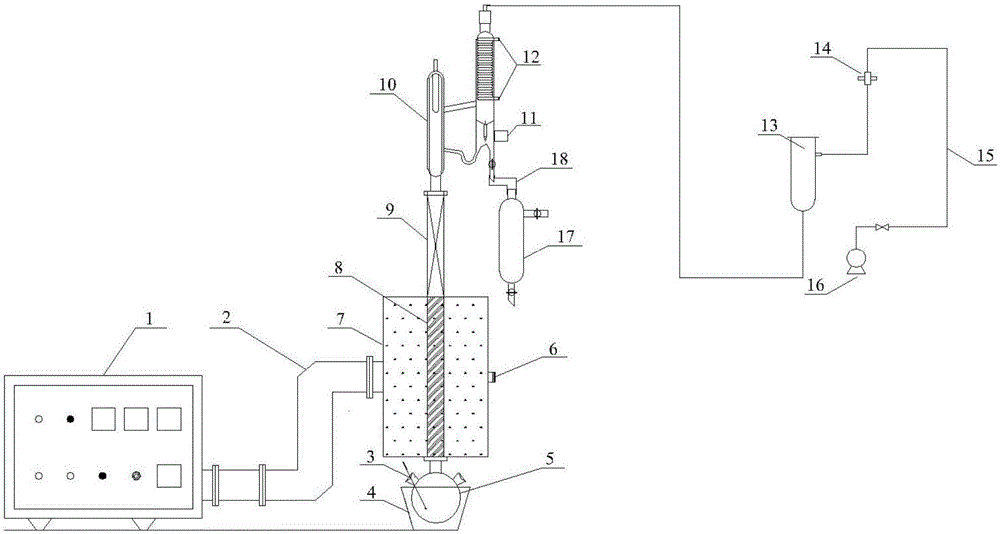

Intra-tower pump suction type high vacuum distillation method and device for precise separation of C16-C22 fatty acids

ActiveCN105695104AIncrease the compression ratioFast pumping speedOrganic compound preparationFatty acids production/refiningOil and greaseMethyl linoleate

The invention discloses an intra-tower pump suction type high vacuum distillation method and device for precise separation of C16-C22 fatty acids. The high vacuum distillation method comprises the following steps: firstly taking heat sensitive materials with a high additional value, such as animal and vegetable oil, as raw materials, adopting plasma liquid and the like as an esterification and transesterification catalyst, and obtaining mixture of multiple fatty acid methyl esters with high yield in one step; secondly, in a distillation tower with almost zero pressure drop, carrying out high vacuum distillation operation on the formed multiple fatty acid methyl esters through catalysis; and finally separating and purifying, so that single fatty acid methyl esters such as timnodonic acid methyl ester, docosahexoenoic acid methyl ester, methyl palmitate, methyl stearate, methyl oleate and methyl linoleate with the mass fraction more than 98% respectively are obtained. The whole technological method is simple and clear, the operation is simple, the equipment cost is low, the energy is saved, and the enlargement can be easily realized.

Owner:TIANJIN UNIV

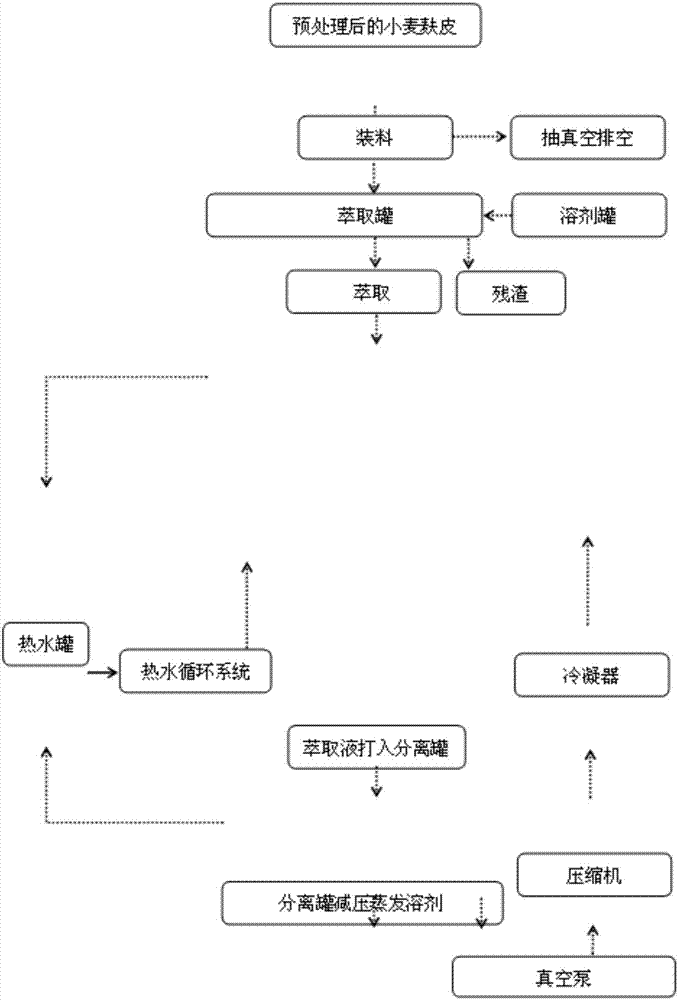

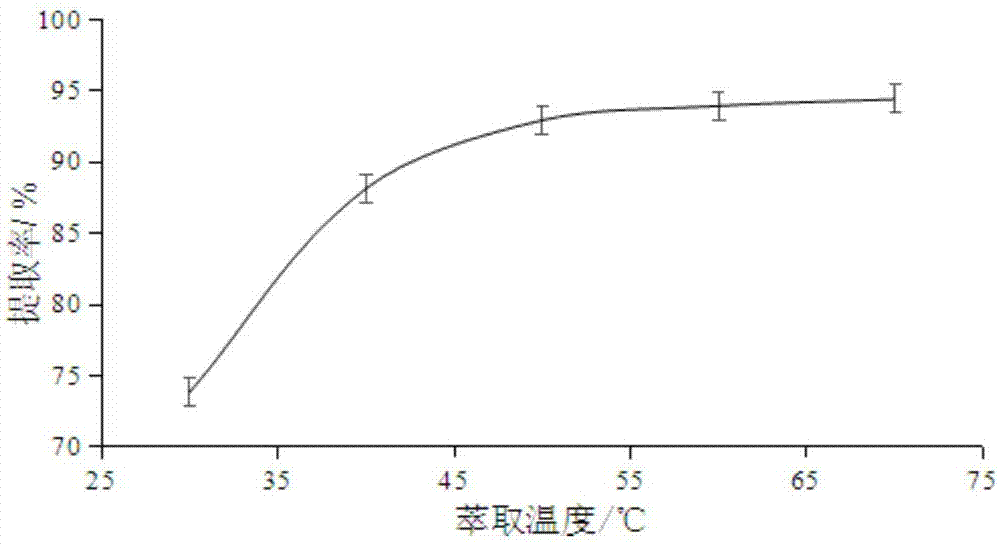

Wheat bran oil production technology using subcritical butane extraction

InactiveCN107338106ASimple processHigh extraction rateFatty-oils/fats productionMethyl linoleateDistillation

The invention discloses a wheat bran oil production technology using subcritical butane extraction, and belongs to the field of food engineering. Wheat bran undergoes subcritical butane extraction multiple times, and the obtained extract liquid undergoes reduced pressure distillation to remove an extractant to obtain the wheat bran oil containing methyl palmitate, methyl linoleate and methyl oleate. The wheat bran is cyclically extracted by adopting a subcritical butane technology, and technologic optimization researches of factors affecting the yield of the wheat bran oil are carried out by adopting Box-Benhnken center combination response surface test design in order to obtain optimum technologic parameters; and a gas chromatograph-mass spectrometer (GC-MS) is used to analyze the fatty acid components of the wheat bran oil obtained through the subcritical extraction in order to provide reference for the development and the utilization of wheat bran resources. The wheat bran oil production technology is simple, allows the extraction rate to reach up to 86.92%, is suitable for industrial application, and provides a new way for the further utilization of the wheat bran.

Owner:QILU UNIV OF TECH

Rubber sleeve for bushing of automobile steering device

The invention discloses a rubber sleeve for a bushing of an automobile steering device. The rubber sleeve comprises raw materials in parts by weight as follows: 40-60 parts of natural rubber, 20-35 parts of butadiene styrene rubber, 20-40 parts of butadiene rubber, 0.5-3 parts of N,N'-m-phenylene dimaleimide, 0.5-1.5 parts of a vulcanization accelerator M, 1-3 parts of zinc oxide, 2-5 parts of stearic acid, 1-3 parts of epoxy acetyl methyl linoleate, 5-10 parts of carbon black, 5-15 parts of nano silicone dioxide, 40-60 parts of ceramic fiber, 20-40 parts of bentonite glass bead composite microspheres, 0.5-2.5 parts of an organosilane crosslinked polyethylene crosslinking agent, 1-3 parts of an anti-aging agent AW and 1-3 parts of an anti-aging agent RD. The rubber sleeve is wear-resistant, unlikely to deform, good in anti-aging performance and long in service life.

Owner:宁国天运橡塑制品有限公司

Maca essence for cigarette crackable capsules and application of maca essence in cigarette

InactiveCN106947598AImprove softness and roundnessImprove fullnessTobacco smoke filtersEssential-oils/perfumesMethyl linoleateCapric triglycerides

The invention belongs to the technical field of production of filter sticks of cigarette and particularly relates to a patent application of a maca essence for cigarette crackable capsules and an application of the maca essence in the cigarette. The maca essence contains a maca extract, methyl linoleate, 3,4-dimethyl phenol, D-limonene, indole and caprylic capric triglyceride. The maca essence can be used for preparing maca cigarette crackable capsules, and the crackable capsules can be added into the filter sticks so as to prepare crackable capsule type cigarette. By providing the maca essence special for the cigarette crackable capsules and combining with a complete crackable capsule production process, the cigarette crackable capsule product with stable and uniform forming quality can be prepared; and by adding the crackable capsules into a cigarette filter, the irritation of the cigarette can be well weakened, the fragrances of the cigarette can be improved and enriched, and the fragrance richness, sensory quality and smoking interestingness of the cigarette can be remarkably improved, so that the maca essence has relatively good application values and popularization and application significances in the design, development, production and sales of the crackable capsule type cigarette.

Owner:CHINA TOBACCO HENAN IND

Highly resilient and high strength rubber material for buffer cushion

The invention discloses a highly resilient and high strength rubber material for buffer cushion. The rubber material comprises the following raw materials in parts by weight: 60 to 80 parts of butadiene rubber, 30 to 50 parts of brominated butyl rubber, 20 to 30 parts of hydrogenated nitrile rubber, 60 to 80 parts of composite filling material, 10 to 20 parts of microencapsulated red phosphorus, 10 to 15 parts of zinc borate, 10 to 20 parts of magnesium hydroxide, 15 to 25 parts of tributyl citrate, 35 to 45 parts of epoxy acetyl methyl linoleate, 2 to 4 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 0.2 to 0.3 part of stannous octoate, 0.1 to 0.2 part of promoter M, 0.1 to 0.3 part of promoter CZ, 4 to 6 parts of rare earth stabilizer, 2 to 3 parts of Ca / Zn composite stabilizer, 0.3 to 0.5 part of anti-aging agent RD, 0.2 to 0.3 part of anti-aging agent D, and 4 to 6 parts of silicone powder, wherein the composite filling material comprises modified cerium oxide, modified lignin, and nano kaolin. The provided rubber material has the advantages of good resilience and high strength.

Owner:宁国天运橡塑制品有限公司

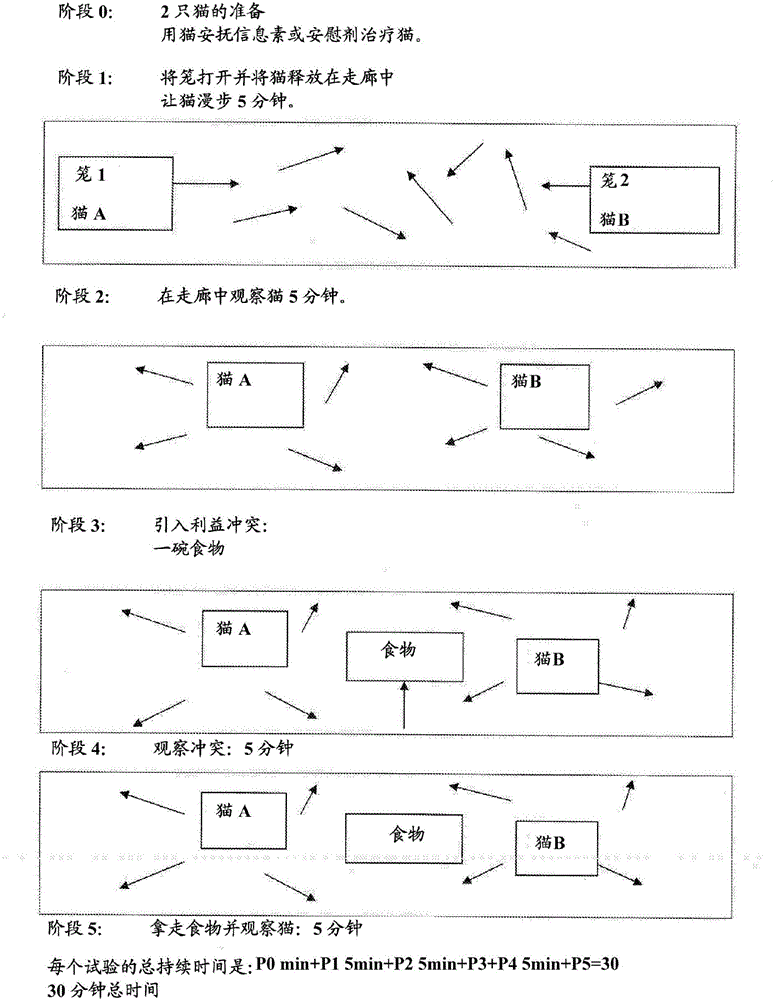

Cat appeasing pheromone

The present invention relates to a semiochemical composition comprising methyl palmitate, methyl linoleate, methyl oleate methyl stearate, methyl laurate, methyl myristate, salts thereof, derivatives thereof, isomers thereof and / or structural analogues thereof that have an appeasing effect in cats and / or also effects social facilitation in cats, and an acceptable vehicle. Solutions such as spot-on formulations of long duration are also encompassed. Methods to effect appeasing in a cat and / or social facilitation in cats are also disclosed.

Owner:INST OF INFORMATION CHEM & APPLIED ANIMAL BEHAVIOR

Cat face pheromone and application thereof

PendingCN112516128AAlleviate or relieve stressful behaviorLow costNervous disorderEster active ingredientsMethyl linoleateDIMETHYL SEBACATE

The invention discloses cat face pheromone and application thereof. The cat face pheromone comprises a cat face pheromone analogue and a solvent, and the cat face pheromone analogue comprises methyl laurate, methyl myristate, methyl palmitate, methyl oleate, methyl linoleate and dimethyl sebacate. The cat face pheromone can be used for preparing a preparation for reducing and relieving anxiety andconflicts after a cat is blended into a new environment, is suitable for a scene that the surrounding environment of the cat is changed, and can ease or relieve stress behaviors of the cat in the newenvironment, such as abnormal emotion and even pathological diseases; and meanwhile, since dimethyl heptanedioate and dimethyl azelate which are relatively high in price are not adopted for the cat face pheromone analogue and the cat face pheromone, the cost of the used raw materials is relatively low, the product is suitable for mass production, the purity of the raw materials is improved, the product quality is improved, and the effect is exerted.

Owner:上海弗艾柏生物科技有限公司

Method for extracting natural vitamin E through two-step reextraction method

The invention discloses a method for extracting natural vitamin E through a two-step reextraction method. The method comprises the following steps that an extract phase of deodorization distillate extracted through ionic liquid is subjected to two-step method reextraction; an extraction agent of reextraction in the first step is an organic solvent, and the use amount of the organic solvent accounts for 10% to 100% of the mass of the extract phase; an extraction agent of reextraction in the second step is an organic solvent and water, and the mass ratio of the organic solvent to the water is (0.1-0.6):(0.3-1.2); the organic solvent is saturated alkane. The method for extracting natural vitamin E has high extracting efficiency, the use amount of the solvent is greatly reduced, the purity of obtained natural vitamin E reaches 99.2% to the maximum degree, meanwhile, the recovery rate of natural vitamin E is 97.5%, and the concentration of methyl linoleate is 0.8%. The method is easy to operate, the related solvent can be recycled, and industrial production is facilitated.

Owner:EAST CHINA UNIV OF SCI & TECH

Method and device for separating and extracting high value-added fatty acid methyl ester in animal and vegetable oil through electromagnetic wave vacuum distillation

ActiveCN105001997AReduce wasteHigh yieldFatty acid esterificationFatty acids production/refiningMethyl linoleateOil and grease

The invention discloses a method and device for separating and extracting high value-added fatty acid methyl ester in animal and vegetable oil through electromagnetic wave vacuum distillation. According to the method, biodiesel with acid value lower than 1, namely, a mixture of various types of fatty acid methyl ester, is obtained by preprocessing the oil with the animal and vegetable oil such as fish oil and methyl alcohol as the raw materials and ionic liquid as the catalyst; the obtained biodiesel is fine divided to extract poor-heat-sensitivity eicosapentaenoic acid methyl ester with purity of 98%, poor-heat-sensitivity docosahexaenoic acid methyl ester with purity of 98% or high value-added products such as methyl stearate, methyl oleate and methyl linoleate which are quite similar in structure by changing the physical properties of all components in the biodiesel through the electromagnetic wave vacuum distillation coupling technology. The blank of the prior art is made up, the operation procedure is convenient, the operation process is provided for separation of the poor-heat-sensitivity fatty acid methyl ester with similar structures and high added values, and the foundation is laid for fine separation of the fatty acid methyl ester.

Owner:天津领碳能源环保科技有限责任公司

Anti-impact flame-retardant cable material

InactiveCN105860238AImprove high temperature resistanceIncrease elasticityRubber insulatorsPlastic/resin/waxes insulatorsMethyl linoleateEpoxy

The invention discloses an anti-impact flame-retardant cable material. The anti-impact flame-retardant cable material is prepared from the raw materials in parts by weight: 20-30 parts of propylene-ethylene segmented copolymer, 30-50 parts of ethylene-vinyl acetate copolymer, 30-40 parts of silicone rubber, 40-60 parts of compound packing, 1-2 parts of epoxy acetyl methyl linoleate, 2-3 parts of epoxidized soybean oil, 45-55 parts of compound flame retardant, 2-3 parts of vinyl triethoxysilane, 2-3 parts of 2,5-dimethyl-2,5-di-tert-butyl peroxide hexane, 0.4-0.6 part of diethylene triamine, 0.4-0.6 part of accelerant M, 0.2-0.4 part of accelerant BZ, 1-3 parts of Ca / Zn compound stabilizer, 1-3 parts of rare earth stabilizer, 0.3-0.4 part of antioxidant 1076, 0.4-0.6 part of antioxidant 1010 and 3-5 parts of paraffin. The anti-impact flame-retardant cable material is high in impact resistance and good in flame retardance.

Owner:ANHUI WANTAI CABLE

Method for preparing heat-insulating hollow roof tile from basalt composite short fibers

The invention discloses a method for preparing a heat-insulating hollow roof tile from basalt composite short fibers. The method comprises the following steps: mixing basalt short fibers, a coupling agent and water, centrifuging, drying, adding an ASA copolymer and a styrene-methyl methacrylate-maleic anhydride polymer, stirring at the temperature of 185-200 DEG C for 20-50 minutes, cooling to room temperature, crushing and sieving to obtain a fiber-reinforced ASA polymer; stirring the fiber reinforced ASA polymer, polyamide resin, ASA-g-GMA resin, epoxy fatty acid methyl ester, dibutyltin dilaurate, epoxy acetyl methyl linoleate, a high-strength filler and a plasticizer to obtain a premix; uniformly mixing an antioxidant and an ultraviolet light absorber, adding from a side feeding hole of a double-screw extruder, adding the premix from a main feeding hole of the double-screw extruder, extruding, granulating, molding, demolding, and cooling to room temperature to obtain the heat-insulating hollow roof tile.

Owner:合肥尚华新材料技术研究院有限责任公司

Application of ethyl linoleate to prevention and treatment of pine wilt diseases

The invention relates to application of ethyl linoleate to prevention and treatment of pine wilt diseases. A method of using the ethyl linoleate for preventing and treating the pine wilt diseases, provided by the method, comprises the step of placing the ethyl linoleate in pines containing propagation type pine wood nematodes. The method provided by the invention can be used for the governing of pines infected with pine wood nematodes in forest. The invention can solve the problems of mass propagation and fast diffusion of the pine wood nematodes in pine wood nematode epidemic situation generating places.

Owner:INST OF ZOOLOGY CHINESE ACAD OF SCI

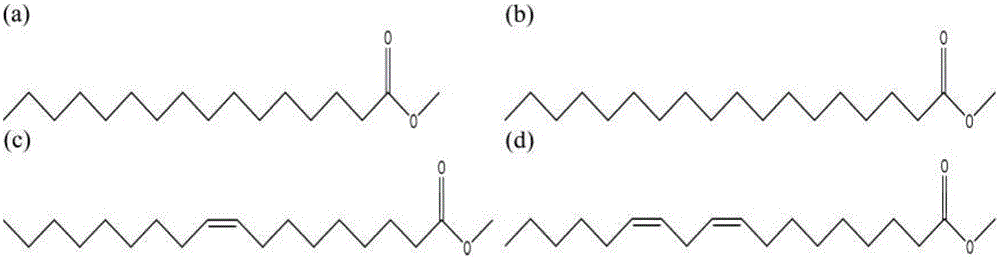

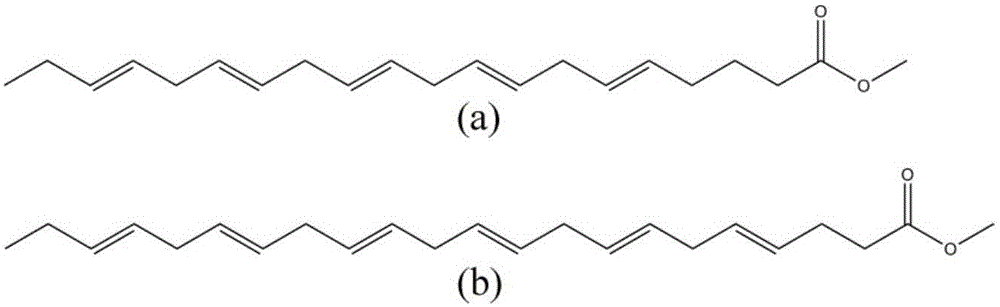

Method for preparing high-content conjugated linoleic acid with vegetable oil

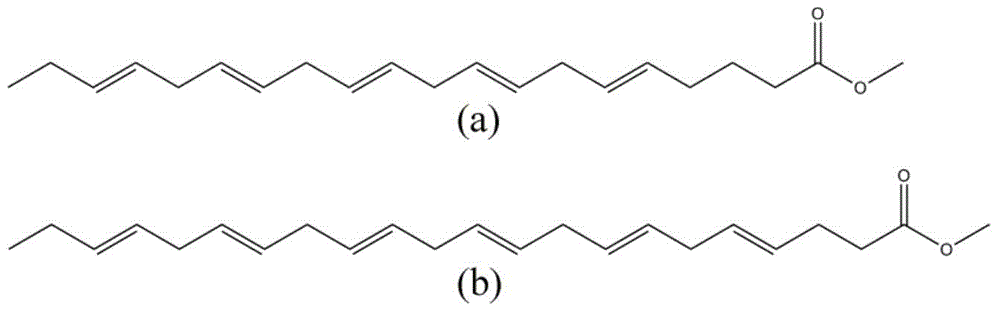

ActiveUS20170275228A1Expand sourceIncrease added valueFatty acid esterificationComponent separationMethyl linoleateIsomerization

A method for preparing high-content conjugated linoleic acid (CLA) through Purification of vegetable oil includes alcoholysis, purification and isomerization of vegetable oil. Alcoholysis is for preparing corresponding methyl ester or ethyl ester with glyceride; purification of methyl ester or ethyl ester is for obtaining methyl linoleate or ethyl linoleate of content over 85% through silver-based silica gel column chromatography; high-content CLA is obtained after alkali-catalyzed conjugation of methyl linoleate or ethyl linoleate, and CLA products are prepared as needed. This invention changes the status quo of preparing high-content CLA with safflower oil alone, expands sources of CLA, and develops an efficient technology for separation and purification of linoleic acid. The CLA obtained is of high purity and meets applications in pharmaceutical, health care products and other industries.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

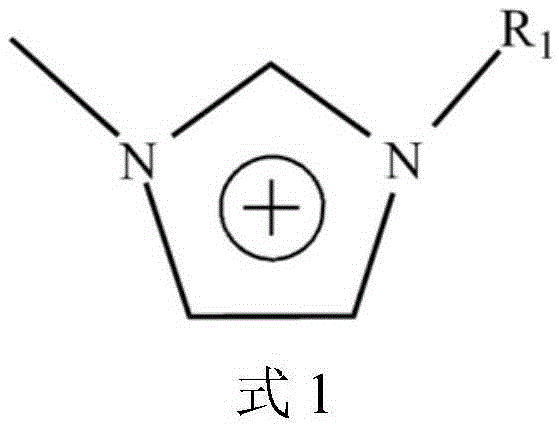

Process for room-temperature ion liquid-catalytic preparation of ethyl linoleate

InactiveCN101070282AEasy to separateNot easy to loseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMethyl linoleateTetrafluoroborate

This invention relates to a method of ion liquid through catalysis preparing linoleic acid ethyl ester at room temperature. The invention takes linoleic acid and absolute ethyl alcohol as raw material, use 1 - alkyl- 3 - methyl glyoxaline tetra- fluoborate ion liquid through catalysis to preapre linoleic acid ethyl ester. The invention mix the linoleic acid and absolute ethyl alcohol according to mol ratio of 1 : 2 to 10, then add ion liquid catalyst about 5 to 6% linoleic acid quality to the mixture, whip and heat under nitrogen shield, takes reaction 2 to 10 hours at 40 deg circumfluence temperature,then decant upper offspring, takes underpressure rectification at minus 98.6 to minus 99.2kpa, collect fraction of 158 to 171 deg, gain refined linoleic acid ethyl ester product.

Owner:HEILONGJIANG UNIV

Low-smoke, halogen-free and oil-resistant K3-class communication mobile cable for 1E type nuclear power plants

InactiveCN106220919AHigh surface adsorptionGood dispersionRubber insulatorsPlastic/resin/waxes insulatorsEpoxyMethyl linoleate

The invention discloses a low-smoke, halogen-free and oil-resistant K3-class communication mobile cable for 1E type nuclear power plants. The low-smoke, halogen-free and oil-resistant K3-class communication mobile cable comprises a cable core and sheath layers. The sheath layers are made of, by weight, 20-40 parts of nitrile rubber, 5-15 parts of butadiene styrene rubber, 10-18 parts of ethylene propylene diene monomer rubber, 0.5-1.5 parts of zinc oxide, 1-3 parts of organosilane crosslinked polyethylene crosslinking agents, 1-2 parts of stearic acid, 1-2 parts of epoxy acetyl methyl linoleate, 0.5-1.5 parts of phenol formaldehyde resin, 0.1-0.6 part of dibenzothiazyl disulfide, 1-2 parts of anti-aging agents MBZ, 1-2 parts of anti-aging agents SP, 15-35 parts of diatomaceous earth, 5-15 parts of graphene nano-sheets, 10-20 parts of modified lignin, 10-30 parts of barite powder and 5-10 parts of activated calcium carbonate. The low-smoke, halogen-free and oil-resistant K3-class communication mobile cable has the advantages of good oil resistance, abrasion resistance, low-smoke and halogen-free properties and flame retardance, excellent mechanical properties and aging resistance and long service life.

Owner:赵俊

Waterproof cable with compact structure and small gap

InactiveCN106751853AGood mutual adsorptionHigh mechanical strengthRubber insulatorsFiberMethyl linoleate

The invention discloses a waterproof cable with a compact structure and a small gap. The cable comprises a conductor and a jacket layer covering the outer side of the conductor, wherein the jacket layer is prepared from the following raw materials in parts by weight: 26 to 32 parts of nitrile rubber, 20 to 35 parts of silicone rubber, 10 to 20 parts of chlorinated polyethylene, 1.5 to 2.5 parts of dicumyl peroxide, 1 to 2 aprts of N,N'-m-phenylenedimaleimide, 0.3 to 0.4 part of potassium ammonium dichromate, 0.4 to 0.8 part of poly-p-nitrosobenzene, 0.4 to 1.2 parts of dioctyl phthalate, 2 to 4 parts of bis(2-ethylhexyl) phthalate, 2 to 4 parts of chlorinated paraffin, 45 to 65 parts of white carbon black, 4 to 10 parts of diatomite, 8 to 12 parts of sepiolite, 10 to 18 parts of modified corn fibers, 1.5 to 2.5 parts of 2-ethylhexyl 9,10-epoxyoctadecanoate, 1.5 to 2.5 parts of epoxidized methyl linoleate, 1.5 to 2.5 parts of tributyl citrate, 8 to 16 parts of wheat protein, 1.5 to 3.5 parts of zinc stearate, 1 to 2 parts of antioxidant 264, and 2 to 3 parts of ultraviolet absorbent UV-531.

Owner:JINYUAN ELECTRIC GRP

Tobacco essence capable of improving quality of cigarettes and preparation method of tobacco essence

InactiveCN106281681AReduce stimulationImprove cigarette aromaTobacco preparationTobacco treatmentMethyl linoleateAdditive ingredient

The invention discloses tobacco essence capable of improving the quality of cigarettes and a preparation method of the tobacco essence. The tobacco essence is prepared from raw materials in parts by weight as follows: 16-20 parts of an inula flower extract, 10-12 parts of rose essential oil, 10-12 parts of eugenol, 8-10 g parts citronellol, 8-10 parts of damascenone, 6-8 parts of malic acid, 6-8 parts of isoamyl alcohol, 3-5 parts of methyl linoleate, 3-5 parts of carvone, 3-5 parts of geranyl acetate and 3-5 parts of anthemis tinctoria flower oil. The provided tobacco essence can effectively improve the cigarette aroma, soften smoke, reduce stimulation and improve the taste; besides, inula flowers have the efficacy of moistening the lung to arrest cough, effective ingredients of the inula flowers can be sucked in a body in the smoking process and have the functions of moistening the lung, reducing phlegm and stopping cough, stimulation of the smoke to the respiratory tract mucosa is relieved, and harm of cigarettes is reduced.

Owner:CHANGDE ZHUFENG PACKAGE FILMS

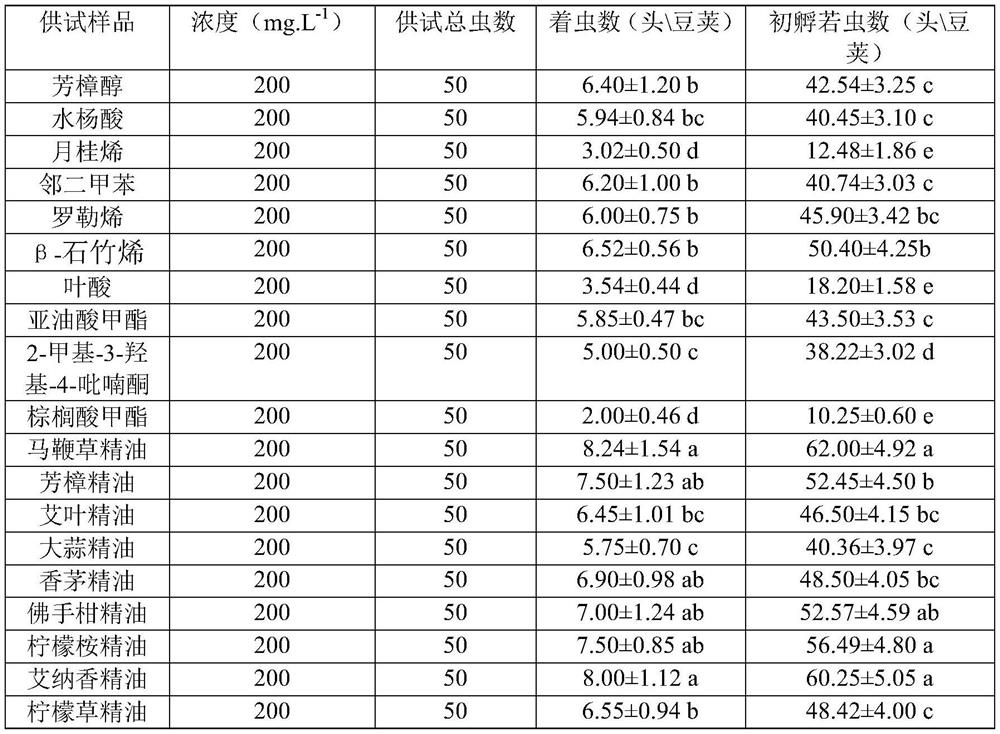

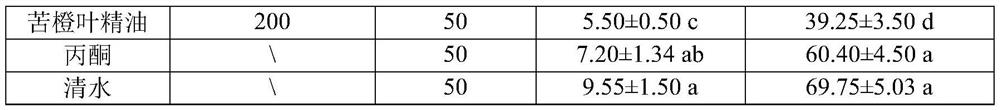

Thrip repellent and application thereof

PendingCN113826652AObvious repellent ovipositing effectLow infestationBiocideAnimal repellantsMethyl linoleateXylylene

The invention discloses a thrip repellent and application thereof. Active substances of the thrip repellent comprise any one or more of folic acid, myrcene, methyl palmitate, linalool, salicylic acid, o-xylene, ocimene, beta-caryophyllene, methyl linoleate, 2-methyl-3-hydroxy-4-pyrone, cinnamomum camphora essential oil, folium artemisiae argyi essential oil, garlic essential oil, citronella essential oil, lemon grass essential oil and bitter orange leaf essential oil, wherein folic acid, myrcene and methyl palmitate have the strongest repelling effect on the oviposition of the flower thrips, and the use concentration is low. The research, development and application of the plant essential oil repellent for flower thrips and even thrip pests can be guided.

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Rubber material of baseball core

The invention discloses a rubber material of a baseball core. The rubber material is prepared from the following raw materials in parts by weight: 60 to 80 parts of natural rubber, 20 to 40 parts of isoprene rubber, 50 to 70 parts of filler, 1 to 2 parts of tributyl citrate, 1 to 2 parts of epoxy acetyl methyl linoleate, 40 to 50 parts of nanometer magnesium hydroxide, 10 to 15 parts of zinc borate, 1 to 3 parts of Si69, 1 to 2 parts of sulfur, 0. 5 to 0.7 part of dicumyl peroxide, 0.1 to 0.3 part of accelerant D, 0.2 to 0.3 part of accelerant TMTD, 4 to 6 parts of Ca / Zn (calcium / zinc) composite stabilizer, 0.4 to 0.6 part of anti-aging agent, 0.2 to 0.4 part of antioxidant, and 2 to 4 parts of polyethylene wax, wherein the filler comprises modified montmorillonite, hollow glass microbeads, and modified microcrystalline cellulose. The rubber material has the advantages that the anti-impact property, toughness and elasticity are good, the weight is light, and the durability and ball striking effect are better.

Owner:天长市良文运动器材有限公司

Green pollution-free mercapto silk adsorbent

InactiveCN104162412AImprove adsorption capacityEasy to controlOther chemical processesMethyl linoleateFiber

The invention discloses a green pollution-free mercapto silk adsorbent. The adsorbent comprises the following substances by weight: 15 to 20 parts of silk, 35 to 46 parts of mercaptoacetic acid, 1 to 9 parts of epoxy acetyl methyl linoleate, 5 to 11 parts of trihexyl citrate, 10 to 17 parts of hypochloric acid, 5 to 9 parts of expanded graphite, 3 to 5 parts of triphenyl phosphine, 6 to 7 parts of redispersible latex powder, 11 to 24 parts of a composite fiber, 3 to 14 parts of sawdust of Schefflera arboricola and 11 to 16 parts of starch. The adsorbent provided by the invention has high adsorption efficiency, a fast adsorption speed and good desorption performance; a preparation process for the absorbent is simple, has easily controllable conditions and low production cost and can easily realize industrial production; the absorbent has good physical and chemical stability and excellent mechanical strength; since the absorbent has a large specific surface area, small specific gravity and high mercapto content, the absorbent has high metal adsorption capacity; and the absorbent has the advantages of no pollution to the environment, low production cost, biodegradability of waste, etc.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

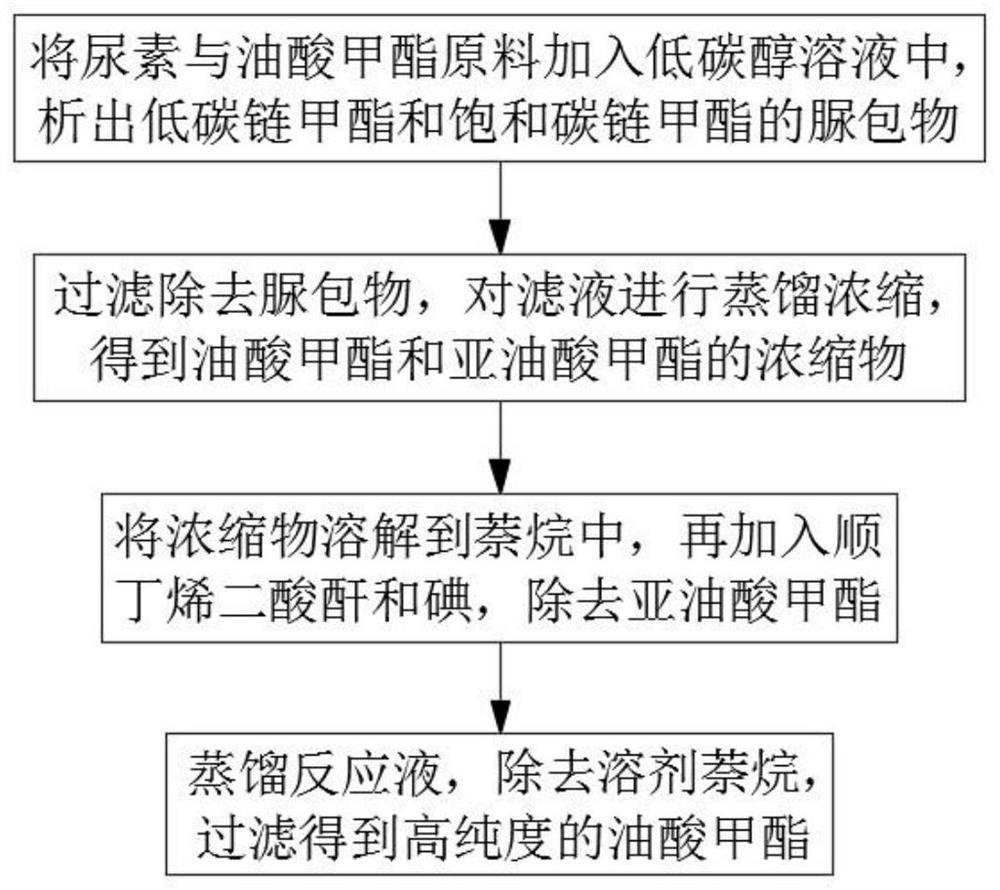

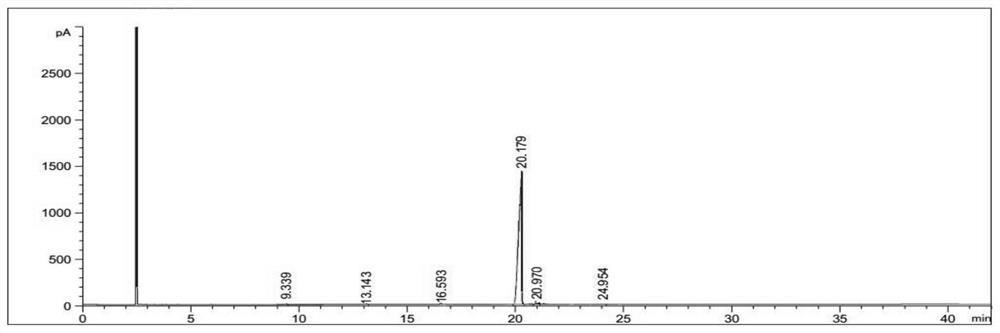

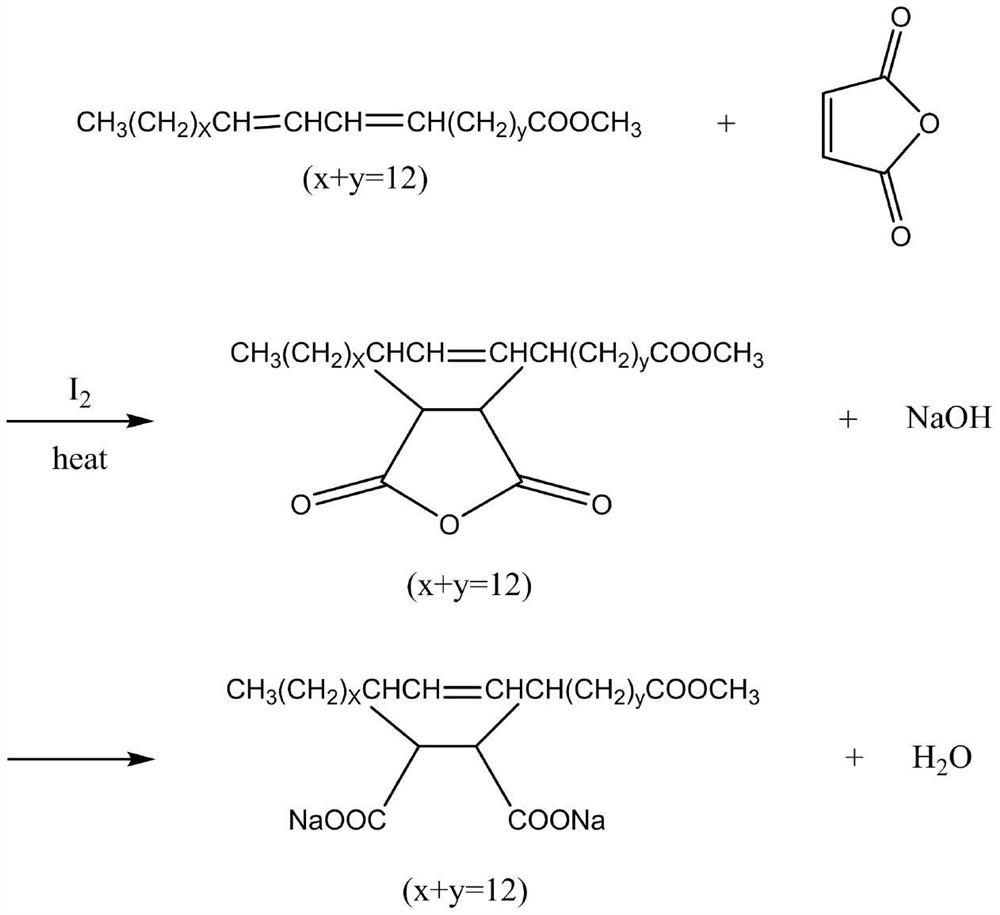

Preparation method of high-purity methyl oleate

PendingCN111777513AGood colorHigh purityOrganic compound preparationCarboxylic acid esters separation/purificationMethyl linoleateTricarboxylic acid

The invention discloses a preparation method of high-purity methyl oleate, and relates to the technical field of purification of methyl oleate. The preparation method comprises the following steps: adding urea and methyl oleate raw materials into a low-carbon alcohol solution, heating and dissolving to obtain a uniform solution, cooling and freezing the uniform solution, separating out a urea inclusion of low-carbon chain methyl ester and saturated carbon chain methyl ester, filtering to remove the urea inclusion, distilling and concentrating the filtrate to obtain a concentrate of methyl oleate and methyl linoleate, dissolving the concentrate into naphthane, then adding maleic anhydride and iodine, heating to react until methyl linoleate in the concentrate generates C22 tribasic carboxylic acid methyl ester, adding a sodium hydroxide solution, distilling the reaction solution obtained in the S3, removing the solvent naphthane, and filtering to remove the C22 sodium tricarboxylate, thereby obtaining the high-purity methyl oleate. Saturated fatty acid methyl ester in methyl oleate is removed through a urea inclusion method, then polyunsaturated fatty acid methyl ester is removed through a reaction method, and therefore high-purity methyl oleate is obtained.

Owner:杭州国盛新材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com