Method and device for separating and extracting high value-added fatty acid methyl ester in animal and vegetable oil through electromagnetic wave vacuum distillation

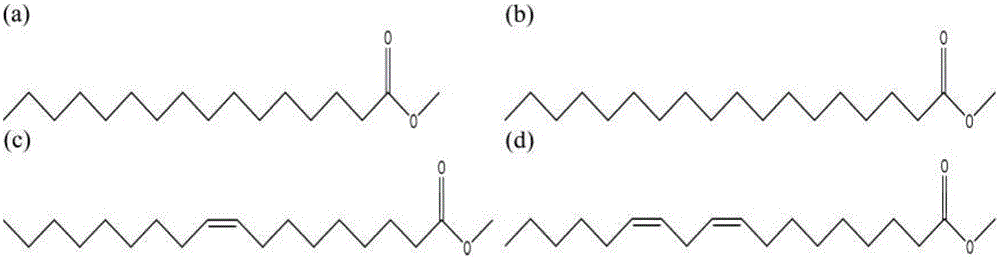

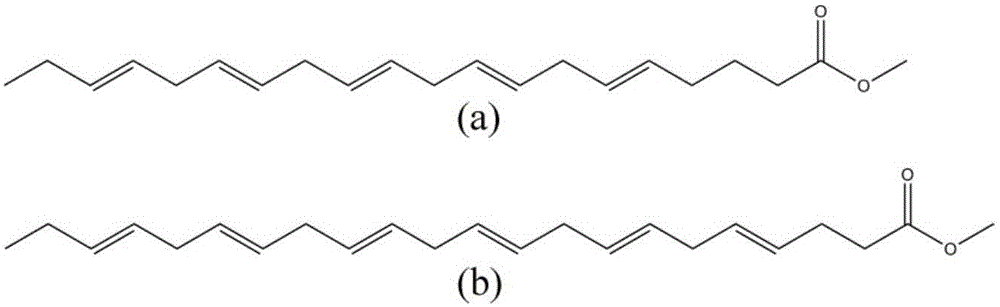

A technology for animal and vegetable oils and fatty acid methyl esters, which is used in fatty acid esterification, fatty acid production, and oil/fat refining, etc., to achieve the effects of reducing resource waste, easy industrial production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

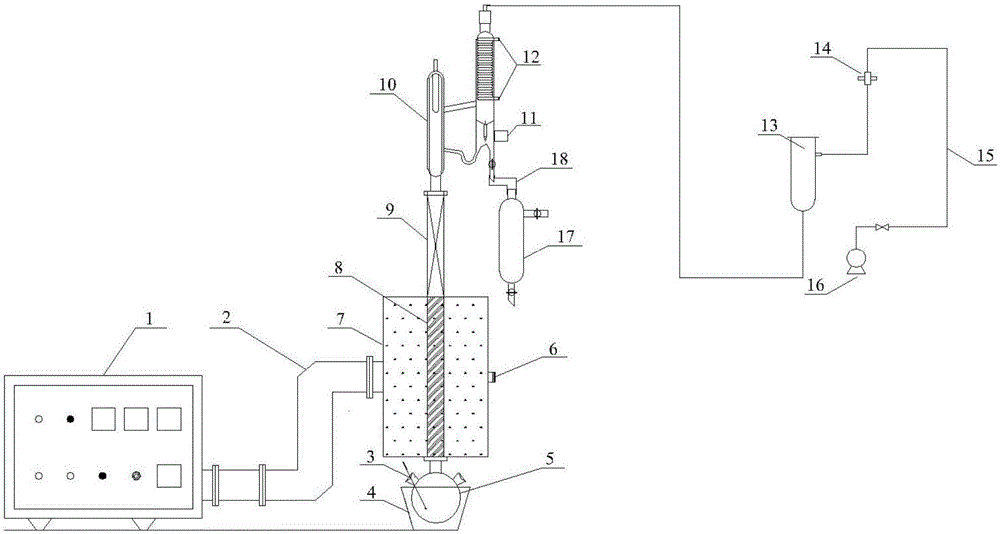

Method used

Image

Examples

Embodiment 1

[0044] The raw material used in this example is a vegetable oil with high acid value, and the acid value is 27.9 mgKOH / g as measured by the national standard GB-T5530-2005 method.

[0045] (1) The pretreatment of vegetable oil, concrete steps are:

[0046] (a) Take the ionic liquid [BHSO with a mass ratio of 1:4:34 3 MIM]HSO 4 , Vegetable oil and methanol are added to the reaction vessel together; the reaction vessel is placed in a 50°C water bath, and the mixture in the vessel is stirred until the vegetable oil and methanol are in the ionic liquid [BHSO 3 MIM]HSO 4 Fully react under the catalysis of the catalyst to generate a variety of fatty acid methyl ester mixtures with an acid value less than 1;

[0047] (b) After the reaction is over, separate the ionic liquid by decantation and a variety of fatty acid methyl ester mixtures with an acid value of less than 1, and the various fatty acid methyl ester mixtures are biodiesel;

[0048] (c) the separated [BHSO 3 MIM]HSO ...

Embodiment 2

[0053] The raw material used in this example is industrial waste palm oil, and the acid value measured by the national standard GB-T5530-2005 method is 9.53mgKOH / g.

[0054] (1) The pretreatment of waste palm oil, concrete steps are:

[0055] (a) Take an ionic liquid with a mass ratio of 1:2:20 [(CH 3 CH 2 ) 3 N(CH 2 ) 3 SO 3 H][C 7 h 7 o 3 S], industrial waste palm oil and methanol are added to the reaction vessel together; the reaction vessel is placed in a 60°C water bath, and the mixed solution in the vessel is stirred until the waste palm oil and methanol fully react to form acid under the catalysis of the ionic liquid Mixtures of various fatty acid methyl esters with a value less than 1;

[0056] (b) After the reaction is over, separate the ionic liquid by decantation and a variety of fatty acid methyl ester mixtures with an acid value of less than 1, and the various fatty acid methyl ester mixtures are biodiesel;

[0057] (c) the separated [(CH 3 CH 2 ) 3 N...

Embodiment 3

[0062] The raw material used in this example is waste high-acid value corn oil, and the acid value is 17.8 mgKOH / g as measured by the national standard GB-T5530-2005 method.

[0063] (1) The pretreatment of corn oil, concrete steps are:

[0064] (a) Take the ionic liquid [Bmim]Br-FeCl with a mass ratio of 1:3:36 3 , corn oil and methanol are added to the reaction vessel together; the reaction vessel is placed in a 60°C water bath, and the mixed solution in the vessel is stirred until the corn oil and methanol fully react under the catalysis of the ionic liquid to form a preform with an acid value less than 1. Processed product - a mixture of various fatty acid methyl esters;

[0065] (b) After the reaction is over, separate the ionic liquid by decantation and a variety of fatty acid methyl ester mixtures with an acid value of less than 1, and the various fatty acid methyl ester mixtures are biodiesel;

[0066] (c) the separated [Bmim]Br-FeCl 3 After removing a small amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com