Wheat bran oil production technology using subcritical butane extraction

A wheat bran and production technology technology, which is applied in the directions of fat oil/fat production, fat production, etc., can solve the problems of no extraction rate, high wheat bran oil extraction process, etc., and achieves the effects of high extraction rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

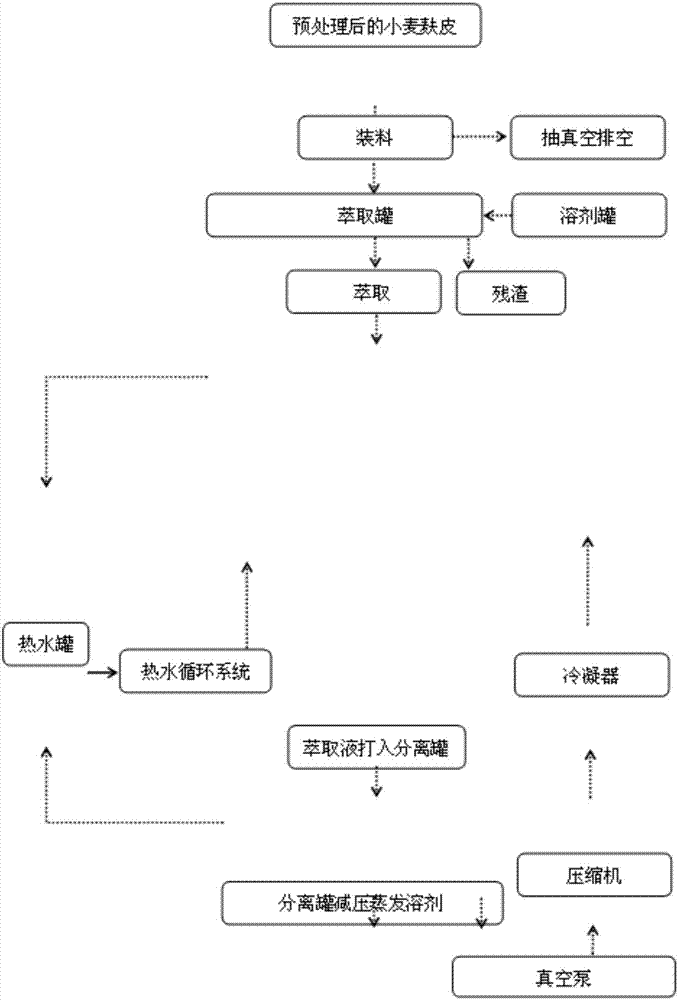

Method used

Image

Examples

Embodiment 1

[0028] 1 Experimental materials and equipment

[0029] 1.1 Experimental materials

[0030] Wheat bran (large flakes) commercially available

[0031] 1.2 Experimental reagents

[0032] Butane: Henan Xinxiang Xinyang Steel Cylinder Co., Ltd.

[0033] Sodium methoxide, HCl-methanol solution, anhydrous sodium sulfate: commercially available, all analytically pure;

[0034] n-Hexane: commercially available, chromatographically pure

[0035] 1.3 Experimental Instruments

[0036] CBE-30+5L subcritical fluid extraction laboratory complete set of equipment: Henan Subcritical Biotechnology Co., Ltd.

[0037] JZC-30TSE electronic balance: Fuzhou Kedi Electronic Technology Co., Ltd.

[0038] Agilent GCMS (GC7890b+MS5977b): Agilent Corporation of the United States

[0039] Syringe microporous membrane filter (□13mm, pore size 0.45μm): Changzhou Ruikang Medical Equipment Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com