Method for preparing heat-insulating hollow roof tile from basalt composite short fibers

A technology of short fiber and basalt, which is applied in the field of hollow roof tiles, can solve the problems of affecting the surface quality of products, increasing maintenance costs, and destroying the beauty of houses, etc., and achieves high dimensional stability, long service life, and guaranteed surface gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

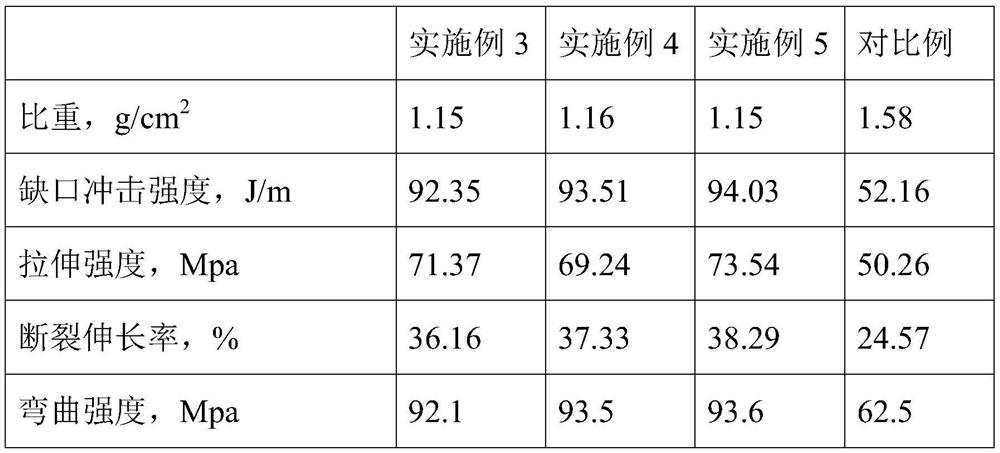

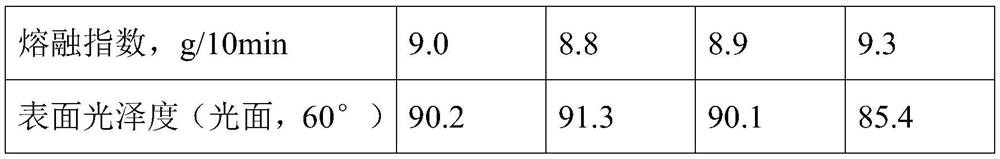

Examples

Embodiment 1

[0023] A method for preparing heat-insulating hollow roof tiles by using basalt composite short fibers, comprising the steps of:

[0024] S1. Mix 10kg basalt short fiber, 3kg coupling agent, and 80kg water, stir at 80°C for 2h, centrifuge, dry at 90°C for 10h, send it into a high-speed mixer, add 40kg of fluidity 3-4g / min, Vicat softening The point is 102-105°C, the notched impact strength is 12-15KJ / m 2 ASA copolymer, 2kg styrene-methyl methacrylate-maleic anhydride polymer, stirred at 200°C for 20min at a high speed, the stirring speed was 800r / min, cooled to room temperature, pulverized, and passed through a 60-mesh sieve to obtain fiber-reinforced ASA polymer thing;

[0025] S2, 60kg fiber-reinforced ASA polymer, 30kg polyamide resin, 5kg ASA-g-GMA resin, 1kg epoxy fatty acid methyl ester, 0.2kg dibutyltin dilaurate, 1kg epoxyacetyllinolenic acid methyl ester, 30kg two Titanium boride, 2kg oxidized polyethylene wax are dropped into a high-speed mixer and stirred for 15mi...

Embodiment 2

[0029] A method for preparing heat-insulating hollow roof tiles by using basalt composite short fibers, comprising the steps of:

[0030] S1. Mix 15kg basalt short fiber, 1kg coupling agent, and 100kg water, stir at 60°C for 5h, centrifuge, dry at 80°C for 20h, send it into a high-speed mixer, add 30kg of fluidity 3-4g / min, Vicat softening The point is 102-105°C, the notched impact strength is 12-15KJ / m 2 ASA copolymer, 4kg styrene-methyl methacrylate-maleic anhydride polymer, stirred at 185°C for 50min at a high speed, the stirring speed was 600r / min, cooled to room temperature, pulverized, and passed through a 60-mesh sieve to obtain fiber-reinforced ASA polymer thing;

[0031] S2, 80kg fiber reinforced ASA polymer, 20kg polyamide resin, 10kg ASA-g-GMA resin, 0.2kg epoxy fatty acid methyl ester, 1kg dibutyltin dilaurate, 0.2kg epoxyacetyllinolenic acid methyl ester, 50kg Calcined pottery clay and 1kg disproportionated rosin were put into a high-speed mixer and stirred for ...

Embodiment 3

[0035] A method for preparing heat-insulating hollow roof tiles by using basalt composite short fibers, comprising the steps of:

[0036] S1. Mix 12kg basalt short fiber, 2.5kg coupling agent, and 85kg water, stir at 75°C for 3h, centrifuge, dry at 88°C for 13h, send it into a high-speed mixer, add 37kg of Vicat with a fluidity of 3-4g / min The softening point is 102-105°C, the notched impact strength is 12-15KJ / m 2 ASA copolymer, 2.5kg styrene-methyl methacrylate-maleic anhydride polymer, stirred at 195°C for 30min at a high speed, with a stirring speed of 750r / min, cooled to room temperature, pulverized, and passed through a 60-mesh sieve to obtain fiber-reinforced ASA polymer;

[0037] S2, 65kg fiber reinforced ASA polymer, 28kg polyamide resin, 6kg ASA-g-GMA resin, 0.8kg epoxy fatty acid methyl ester, 0.4kg dibutyltin dilaurate, 0.8kg epoxyacetyllinolenic acid methyl ester, 25kg fly ash, 10kg polypropylene fiber, 1.7kg hydroxy silicone oil were put into a high-speed mixer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com