Biodiesel prepared by non-edible vegetable oil and method thereof

A technology of edible vegetable oil and biodiesel, applied in biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve unseen problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Add 10 g of milk thistle oil (11.7 mmol) and 1.5 g of methanol (46.8 mmol) into a three-necked flask, stir evenly, heat to 35 °C, then add 1% of milk thistle oil weight potassium hydroxide as a catalyst, at 45 Stir the reaction at ℃ for 30 min; cool the reaction product, let stand to separate layers; use the method of vacuum distillation to recover excess methanol, and then add dilute sulfuric acid with a mass fraction of 5% to adjust the pH value of the system to close to Neutral, and then washed with distilled water until the water is clear and colorless; the product obtained above is subjected to vacuum distillation to obtain biodiesel.

[0016] Under this process, the yield of biodiesel is 45.8%

Embodiment 2

[0018] Add 10 g of milk thistle oil (11.7 mmol) and 4.5 g of methanol (140.6 mmol) into a three-necked flask, stir evenly, heat to 40 °C, and then add 1.2% of milk thistle oil weight potassium hydroxide as a catalyst, at 65 Stir the reaction at ℃ for 70 min; cool the reaction product, let stand to separate layers; use the method of vacuum distillation to recover excess methanol, and then add dilute sulfuric acid with a mass fraction of 10% to adjust the pH value of the system to close to Neutral, and then washed with distilled water until the water is clear and colorless; the product obtained above is subjected to vacuum distillation to obtain biodiesel.

[0019] Under this process, the yield of biodiesel is 87.7%

Embodiment 3

[0021] Add 10 g of milk thistle oil (11.7 mmol) and 5.6 g of methanol (175.0 mmol) into a three-necked flask, stir evenly, heat to 45 °C, and then add 3% of milk thistle oil weight potassium hydroxide as a catalyst, at 75 Stir the reaction at ℃ for 120 min; cool the reaction product and let it stand for stratification; use the method of vacuum distillation to recover excess methanol, and then add dilute sulfuric acid with a mass fraction of 15% to it to adjust the pH value of the system to close to Neutral, and then washed with distilled water until the water is clear and colorless; the product obtained above is subjected to vacuum distillation to obtain biodiesel.

[0022] Under this process, the yield of biodiesel is 85.4%

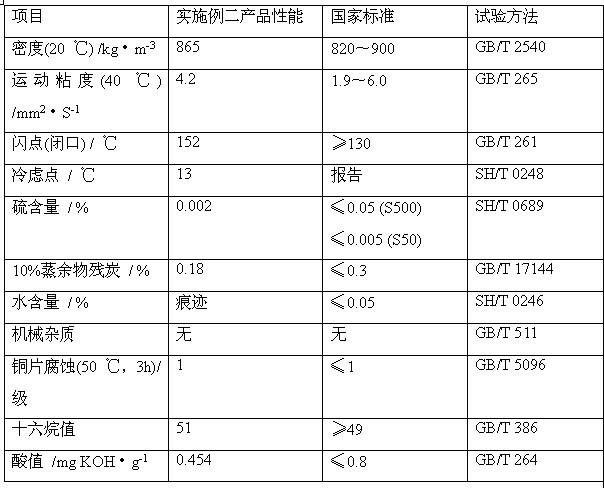

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com