Production of diesel-oil from pepper seed

A technology of biodiesel and pepper seed oil, which is applied in the direction of biological raw materials, biofuels, petroleum industry, etc., can solve the problems that pepper seed biodiesel has not yet been used, and achieve the effect of improving use value and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

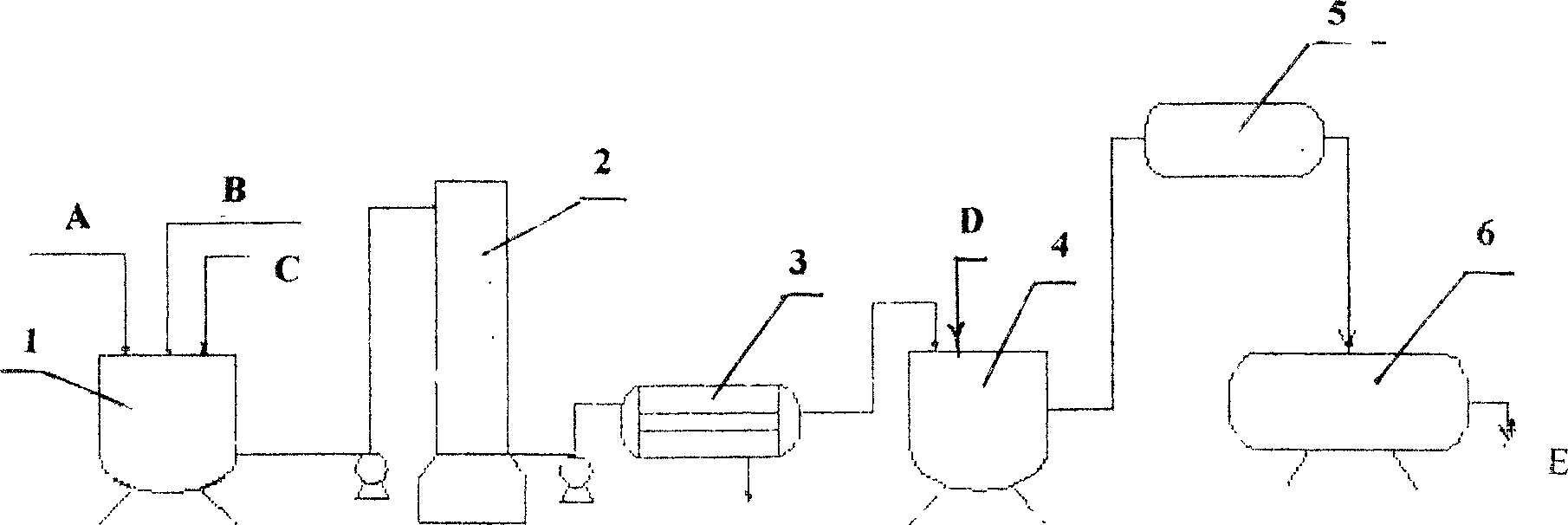

[0016] 1. 1000kg of refined pepper seed oil A with impurities less than 3‰, 800kg of methanol B with a concentration of 95%, and 15kg of concentrated sulfuric acid C with a concentration of 99% are put into the esterification kettle 1, mixed together, and steamed Heating and maintaining at 62°C, the reaction was continued for 4 hours while excess methanol was vented by distillation.

[0017] 2. After allowing the reactant in the esterification kettle 1 to stand for 2 hours, after draining the acidic water part with a larger specific gravity in the lower part, the remaining reactant is sent to the washing tower 2 for washing to make it neutral.

[0018] 3. After the reactants are washed with water, they are then sent to the dehydration tower 3, which is heated with steam 6, kept at 80°C, and kept stirring for 1 hour, then precipitated for 1.5 hours, and after the water part with a larger specific gravity is discharged from the lower part (this The procedure is called dehydratio...

Embodiment 2

[0022] 1. Put 1000kg of pepper seed oil A with refined impurities less than 3‰ by weight, 400kg by weight of methanol B with a concentration of 98%, and 8kg by weight of concentrated sulfuric acid C with a concentration of 98%, put them in the esterification kettle 1, and mix them together , heated by steam and maintained at 75°C, and continued to react for 8 hours, while discharging excess methanol through distillation.

[0023] 2. After allowing the reactant in the esterification kettle 1 to stand for 1 hour, after draining the acidic water part with a larger specific gravity in the lower part, the remaining reactant is sent to the washing tower 2 for washing to make it neutral.

[0024] 3. After the reactants are washed with water, they are then sent to the dehydration tower 3, which is heated with steam 6, kept at 60°C, and stirred continuously for 1 hour, then precipitated for 1.5 hours, and after the water part with a larger specific gravity is discharged from the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com