Method for preparing biodiesel through three-stage selective hydrodeoxygenation

A biodiesel and selective hydrogenation technology, applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve the problems of poor product quality, easy scaling of the bed, easy deactivation of catalysts, etc., and reduce condensation coking. , the effect of inhibiting coking and avoiding catalyst deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

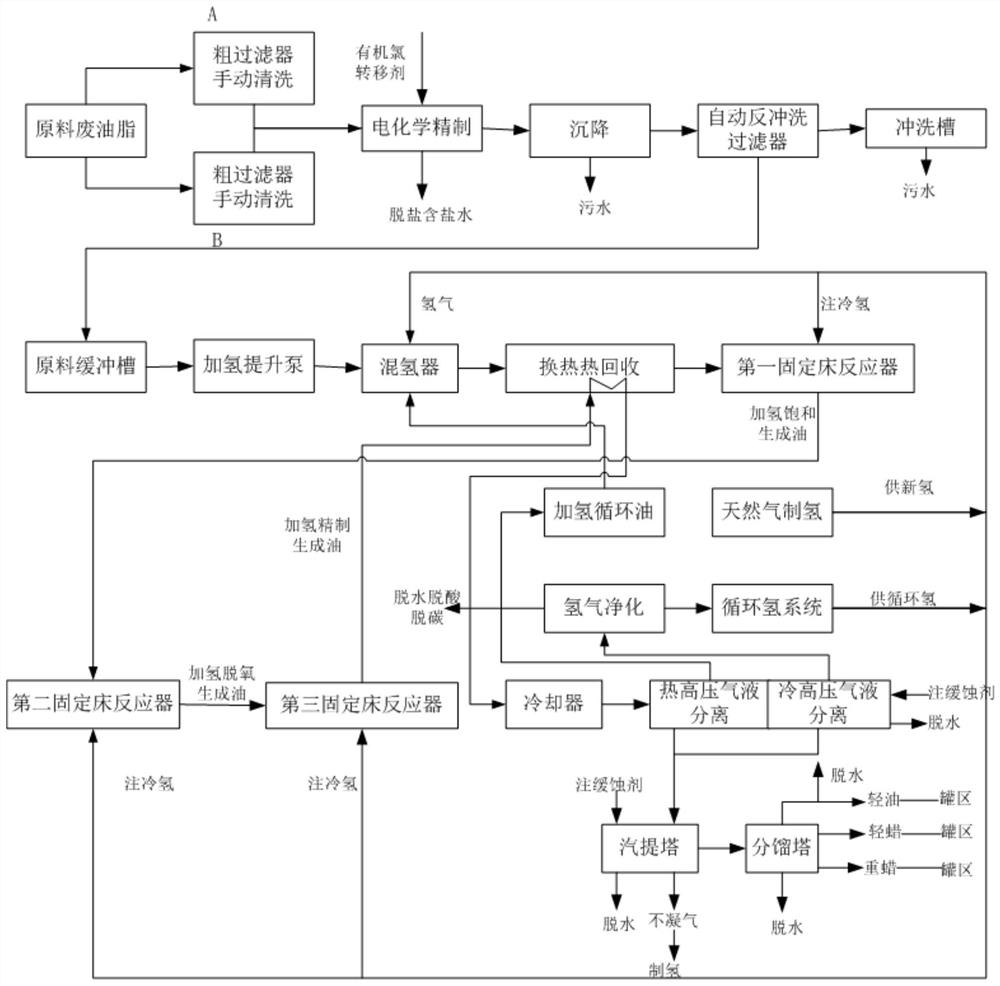

[0061] This embodiment provides a method for preparing biodiesel by three-stage selective hydrodeoxygenation, the method comprising the following steps:

[0062] S1. Coarsely filter and clean the raw material waste oil; then desalinate through electrochemical refining, then settle and discharge sewage through a settling tank, backwash and filter, and obtain the pretreated raw material waste oil;

[0063] Mix the pretreated raw material waste oil with hydrogen and exchange heat in the heat exchange heat recovery equipment, and then add it to the oil tank with a temperature of 200°C, a pressure of 5.5MPa, a reaction volume space velocity of 0.8, and a hydrogen-oil ratio of 820:1. In the first fixed-bed reactor, the hydrogenation saturation reaction is carried out under the action of the catalyst to obtain hydrogenation saturation to generate oil;

[0064] During this process, the reaction temperature is controlled by passing cold hydrogen (circulating hydrogen) into the first fi...

Embodiment 2

[0074] This embodiment provides a method for preparing biodiesel by three-stage selective hydrodeoxygenation, the method comprising the following steps:

[0075] S1. Coarsely filter and clean the raw material waste oil; then desalinate through electrochemical refining, then settle and discharge sewage through a settling tank, backwash and filter, and obtain the pretreated raw material waste oil;

[0076] Mix the pretreated raw material waste oil with hydrogen and exchange heat in the heat exchange heat recovery equipment, and then add it to a gas tank with a temperature of 240°C, a pressure of 5.9MPa, a reaction volume space velocity of 1, and a hydrogen-oil ratio of 850:1. In the first fixed-bed reactor, the hydrogenation deoxygenation saturation reaction is carried out under the action of the catalyst to obtain hydrogenation saturation to generate oil;

[0077] During this process, the reaction temperature is controlled by passing cold hydrogen (circulating hydrogen) into th...

Embodiment 3

[0087]This embodiment provides a method for preparing biodiesel by three-stage selective hydrodeoxygenation, the method comprising the following steps:

[0088] S1. Coarsely filter and clean the raw material waste oil; then desalinate through electrochemical refining, then settle and discharge sewage through a settling tank, backwash and filter, and obtain the pretreated raw material waste oil;

[0089] Mix the pretreated raw material waste oil with hydrogen and exchange heat in the heat exchange heat recovery equipment, and then add it to a gas tank with a temperature of 280°C, a pressure of 6.5MPa, a reaction volume space velocity of 1.1, and a hydrogen-oil ratio of 870:1. In the first fixed-bed reactor, the hydrogenation deoxygenation saturation reaction is carried out under the action of the catalyst to obtain hydrogenation saturation to generate oil;

[0090] During this process, the reaction temperature is controlled by passing cold hydrogen (circulating hydrogen) into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com