Preparation method of clay-based composite phase-change energy storage deicing (snow melting) material

A technology of composite phase change and energy storage materials, applied in the field of preparation of clay-based composite phase change energy storage deicing materials, can solve the problems of high maintenance cost, low work efficiency, high work intensity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

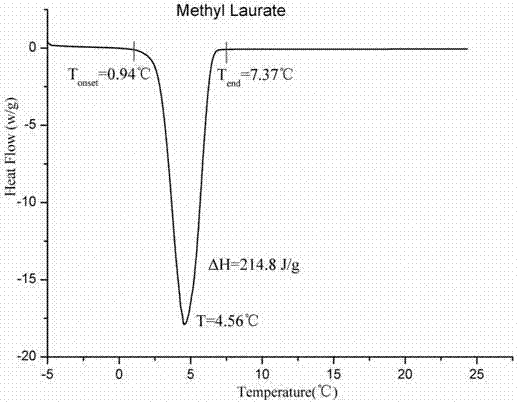

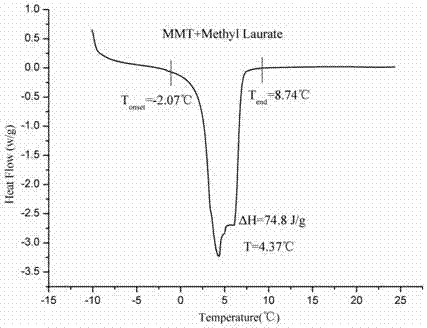

[0021] Get 10g of 200 mesh montmorillonite and place it on the bottom of the conical flask, then connect the vacuum pump to vacuumize the conical flask, open the phase change material 30g filled with methyl laurate and slowly add it dropwise to complete, then continue to keep the vacuum for 30min, put The obtained composite phase change material is filtered at 60°C to remove excess methyl laurate loaded on the surface of the montmorillonite, dried, and ground through a 200-mesh sieve to obtain a montmorillonite-based methyl laurate composite phase change material .

Embodiment 2

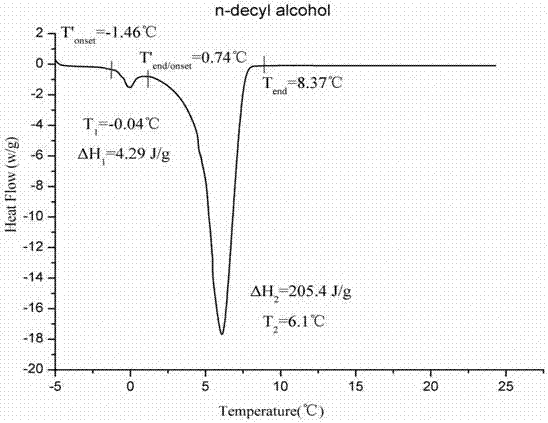

[0023] Take 200 mesh montmorillonite 10g and place it at the bottom of the Erlenmeyer flask, then connect the vacuum pump to vacuumize the Erlenmeyer flask, open the phase-change material containing decanol 30g and slowly add it dropwise until complete, and then continue to maintain the vacuum for 30min to obtain a composite The phase change material is filtered at 60°C to remove excess decanol loaded on the surface of the montmorillonite, dried, and ground through a 200-mesh sieve to obtain a montmorillonite-based decanol composite phase change material.

Embodiment 3

[0025] Take 200 mesh kaolinite 10g and place it at the bottom of the conical flask, then connect the vacuum pump to vacuumize the conical flask, open the phase change material containing methyl laurate 30g and slowly add it dropwise until completely, then continue to keep the vacuum for 30min, The obtained composite phase change material is filtered at 60°C to remove excess methyl laurate loaded on the surface of kaolinite, dried, and ground through a 200-mesh sieve to obtain a kaolinite-based methyl laurate composite phase change material .

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com