Reinforced premix mortar moisture-retention thickening agent and preparation method thereof

A water-retaining thickener and a technology for ready-mixed mortar, which are used in the preparation of enhanced ready-mixed mortar water-retaining thickener and the field of enhanced ready-mixed mortar water-retaining and thickening agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

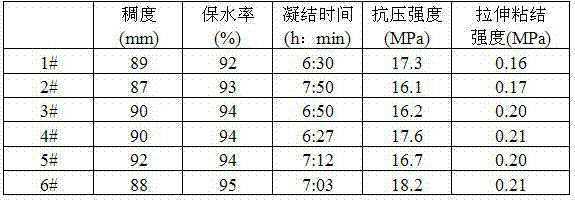

[0046] Table 1 is the raw material formula (parts by mass) for preparing the enhanced ready-mixed mortar water-retaining thickener of the present invention.

[0047] Table 1

[0048] 1# 2# 3# 4# 5# 6# Montmorillonite 50 50 50 60 60 90 Kaolin 30 20 10 0 0 5 halloy stone 0 20 20 30 20 5 fly ash 10 10 20 10 5 5 slag 10 0 0 0 5 5 Sodium lignosulfonate 0.5 1.0 1.0 1.0 0.5 0 Sodium dodecyl benzene sulfonate 0.1 0.1 0 0 0 0.1 sodium sulfate 4 4 4 4 4 0 salicylic acid 3 3 3 3 3 0 glucose 0.2 0.2 0.2 0.2 0.2 0.2

[0049] Its specific preparation method comprises the following steps:

[0050] (1) Pretreatment of raw materials, including drying of montmorillonite, kaolin, halloysite, fly ash and slag.

[0051] The water content of the raw materials is less than 0.5% by weight before entering the mill.

[0052] (2) Pre-mix the surfactant and montmorillonite ...

Embodiment 2

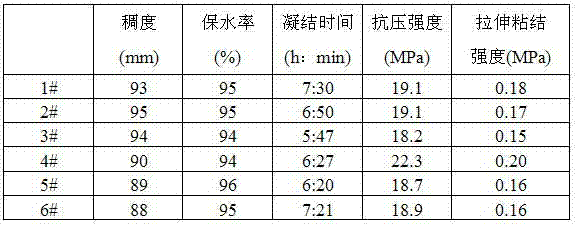

[0061] Table 4 is the raw material formula (parts by mass) for preparing the enhanced ready-mixed mortar water-retaining thickener of the present invention.

[0062] Table 4

[0063] 1# 2# 3# 4# 5# 6# Montmorillonite 80 80 80 80 80 80 Attapulgite Clay 5 5 5 5 5 5 halloy stone 5 5 5 5 5 5 fly ash 5 5 5 5 5 5 slag 5 5 5 5 5 5 Sodium lignosulfonate 0.1 0.1 0 0 0 0 Sodium dodecyl benzene sulfonate 0 0 0.1 0.1 0.1 0.1 sodium sulfate 3 0 1 2 3 3 salicylic acid 0 0 0.3 0.3 0.3 0.3 Zinc oxide 0 0 1 1 1 1

[0064] Its specific preparation method comprises the following steps:

[0065] (1) Pretreatment of raw materials, including drying of montmorillonite, attapulgite clay, halloysite, fly ash, and slag.

[0066] The water content of the raw materials is less than 0.5% by weight before entering the mill.

[0067] (2) Pre-mix the surfactant and montmorillon...

Embodiment 3

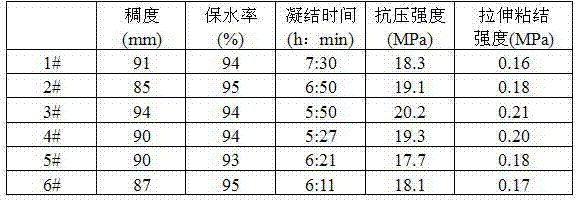

[0077] Table 7 is the raw material formula (parts by mass) for preparing the enhanced ready-mixed mortar water-retaining thickener of the present invention.

[0078] Table 7

[0079] 1# 2# 3# 4# 5# 6# Montmorillonite 80 80 80 50 50 50 Attapulgite Clay 10 10 10 0 0 0 halloy stone 0 0 0 20 20 20 Kaolin 0 0 0 10 10 10 fly ash 5 5 5 10 10 10 slag 5 5 5 10 10 10 cetyl ammonium bromide 0 0.1 0.5 0 0.1 0.5 Dioctyl sodium sulfosuccinate 0.1 0 0.1 0.1 0.1 0.1 sodium sulfate 3 0 1 2 3 3 salicylic acid 0 0 0.3 0.3 0.3 0.3 tartaric acid 1 1 1 1 1 1

[0080] Its specific preparation method comprises the following steps:

[0081] (1) Pretreatment of raw materials, including drying of montmorillonite, kaolin, attapulgite clay, halloysite, fly ash, and slag.

[0082] The water content of the raw materials is less than 0.5% by weight before entering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com