Preparation method and application method of alkaline composite oxide catalyst

A composite oxide and catalyst technology, which is used in the preparation of methyl dodecanoate ethoxylate catalyst and the preparation of basic composite oxide catalyst, can solve the problems of difficult to scale industrialization, low catalyst activity, slow reaction speed and the like , to achieve the effects of cheap raw materials, high catalytic activity, and high reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

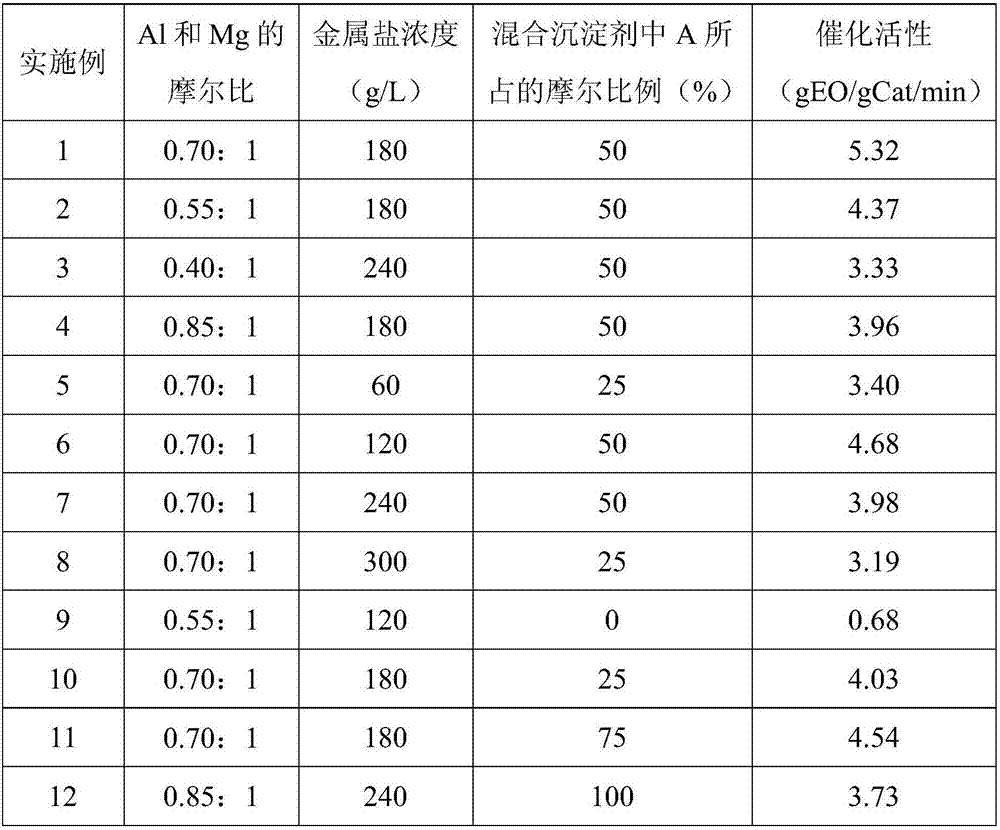

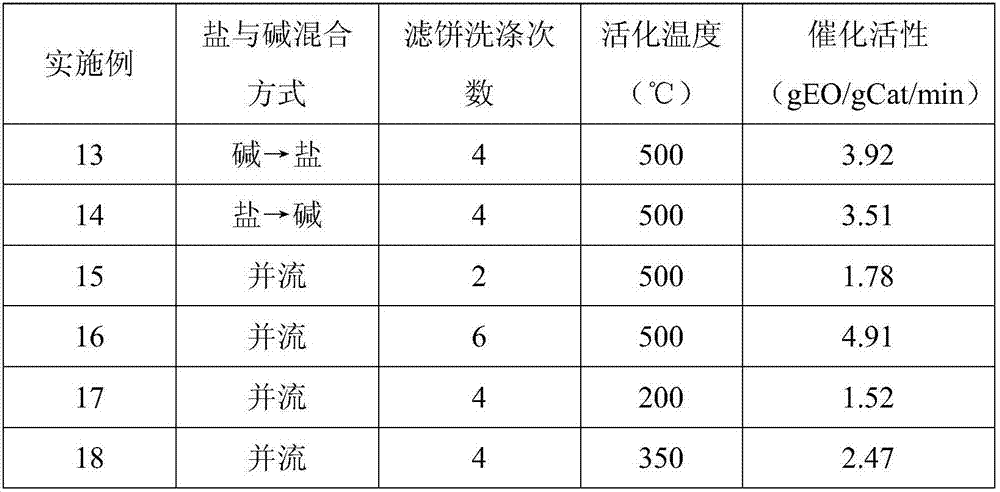

Embodiment 1

[0030] Take by weighing 22.50g magnesium nitrate, 22.68g aluminum nitrate and 251g deionized water respectively, stir and make salt all dissolve and mix homogeneously, salt solution and precipitant (mol ratio is 50% sodium hydroxide and carbonic acid Sodium mixture) was added into a 500ml three-necked flask at the same time, and the pH of the system was kept constant at about 10. It was aged at a constant temperature of 60°C for 8h, and then filtered. After several times of washing, the filter cake was dried in an oven at 65°C for 8h. Then calcined in a muffle furnace at 500°C for 5 hours, crushed into particles and sieved to select a sample with a mesh size of 50-100 mesh as a catalyst.

[0031] Add 0.95 g of the above-mentioned catalyst and 212 g of methyl dodecanoate into a 2.0 L pressure reactor, replace the air in the reactor with nitrogen for 3 times, heat up and vacuumize the water under stirring to remove the moisture in the reaction system. Connect the ethylene oxide ...

Embodiment 2

[0033] Take by weighing 25.22g magnesium nitrate, 19.96g aluminum nitrate and 251g deionized water respectively, stir and make salt all dissolve and mix homogeneously, salt solution and precipitating agent (mol ratio is 50% sodium hydroxide and carbonic acid Sodium mixture) was added into a 500ml three-necked flask at the same time, and the pH of the system was kept constant at about 10. It was aged at a constant temperature of 60°C for 8h, and then filtered. After several times of washing, the filter cake was dried in an oven at 65°C for 8h. Then calcined in a muffle furnace at 500°C for 5 hours, crushed into particles and sieved to select a sample with a mesh size of 50-100 mesh as a catalyst.

[0034] Add 0.95 g of the above-mentioned catalyst and 212 g of methyl dodecanoate into a 2.0 L pressure reactor, replace the air in the reactor with nitrogen for 3 times, heat up and vacuumize the water under stirring to remove the moisture in the reaction system. Connect the ethylen...

Embodiment 3

[0036] Take by weighing 38.23g magnesium nitrate, 22.01g aluminum nitrate and 251g deionized water respectively, stir and make salt all dissolve and mix homogeneously, salt solution and precipitant (mol ratio is 50% sodium hydroxide and carbonic acid Sodium mixture) was added into a 500ml three-necked flask at the same time, and the pH of the system was kept constant at about 10. It was aged at a constant temperature of 60°C for 8h, and then filtered. After several times of washing, the filter cake was dried in an oven at 65°C for 8h. Then calcined in a muffle furnace at 500°C for 5 hours, crushed into particles and sieved to select a sample with a mesh size of 50-100 mesh as a catalyst.

[0037]Add 0.95 g of the above-mentioned catalyst and 212 g of methyl dodecanoate into a 2.0 L pressure reactor, replace the air in the reactor with nitrogen for 3 times, heat up and vacuumize the water under stirring to remove the moisture in the reaction system. Connect the ethylene oxide s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com