Disinfection emulsion, preparation method thereof and disinfection wet tissue prepared by using disinfection emulsion

A technology of emulsions and active agents, applied in the fields of botanical equipment and methods, disinfectants, chemicals for biological control, etc., can solve the problems of high surface tension, slipping, insufficient surface adhesion of objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A disinfectant emulsion. The raw materials of the disinfectant emulsion include the following components in weight ratio: 0.5-5 parts of polyhexamethylene biguanide, 2-10 parts of film-forming agent, 1-5 parts of nonionic surfactant, cationic surfactant 1-10 parts of agent, 50-200 parts of deionized water;

[0030] Wherein, the nonionic surfactant and / or cationic surfactant contains a fatty alcohol group, and the carbon chain of the fatty alcohol group is C10~C18; the film forming agent is selected from methyl laurate, tridecyl One or more of alcohol, cetyl alcohol, stearyl alcohol and propylene glycol phenyl ether.

[0031] Specifically, in this implementation, 0.5 parts of polyhexamethylene biguanide, 2 parts of film-forming agent, 2 parts of nonionic surfactant, 5 parts of cationic surfactant, and 87.5 parts of deionized water;

[0032] Wherein, the nonionic surfactant is specifically EO-PO polyether; the cationic surfactant is dodecyl dihydroxyethyl betaine.

[00...

Embodiment 2

[0043] Embodiment 2 With reference to Example 1, the difference is that the raw material of the disinfectant emulsion of Example 2 also includes a co-activator, and the co-activator is selected from polyquaternium salt, myristoyl propyl dimethylamine, hydrogen peroxide and one or more of chlorhexidine, the mass ratio of the coactivator to polyhexamethylene biguanide is (1-5): (1-5), specifically 1:5, The purpose is to improve the disinfection effect of the disinfection emulsion of the present invention and reduce the production cost accordingly.

[0044] Specifically, in this implementation, 1.5 parts of polyhexamethylene biguanide, 0.5 parts of myristoyl propyl dimethylamine, 4 parts of film-forming agent, 3 parts of nonionic surfactant, 8 parts of cationic surfactant, deionized water 80 copies;

[0045] Wherein, the nonionic surfactant is specifically EO-PO polyether; the cationic surfactant is dodecyl dihydroxyethyl betaine.

[0046] The film-forming agent is specifically...

experiment example 1

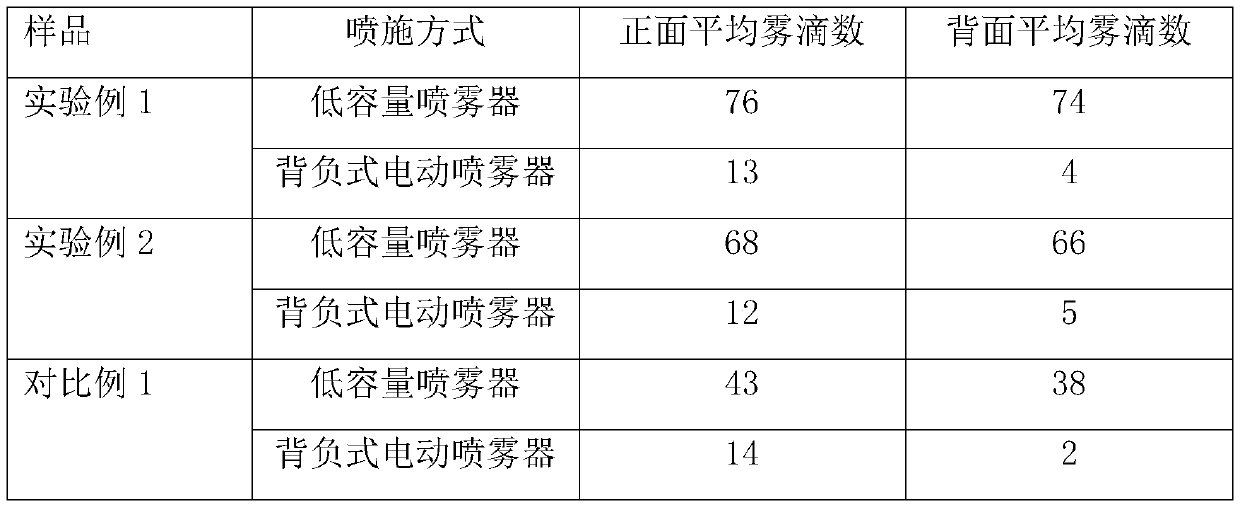

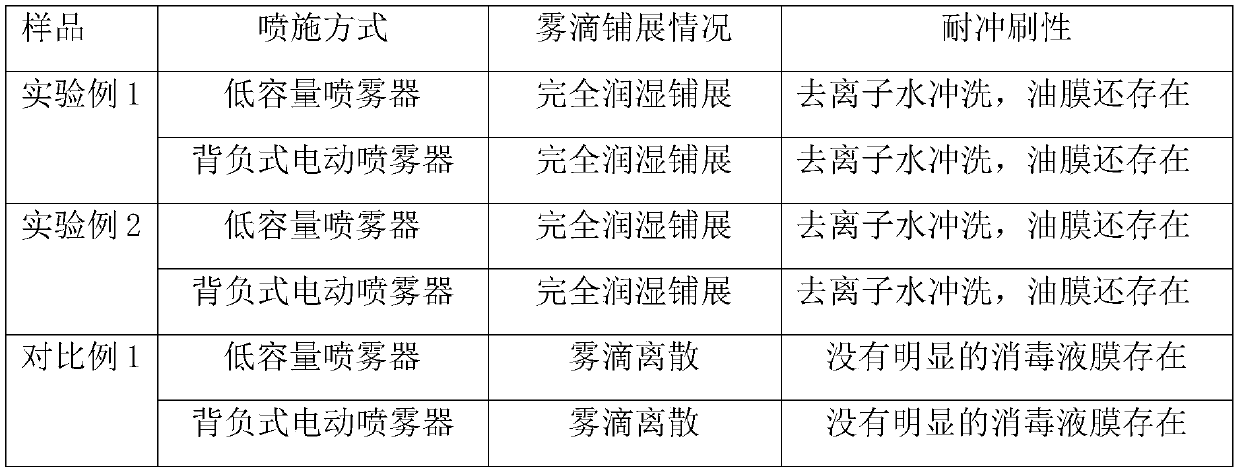

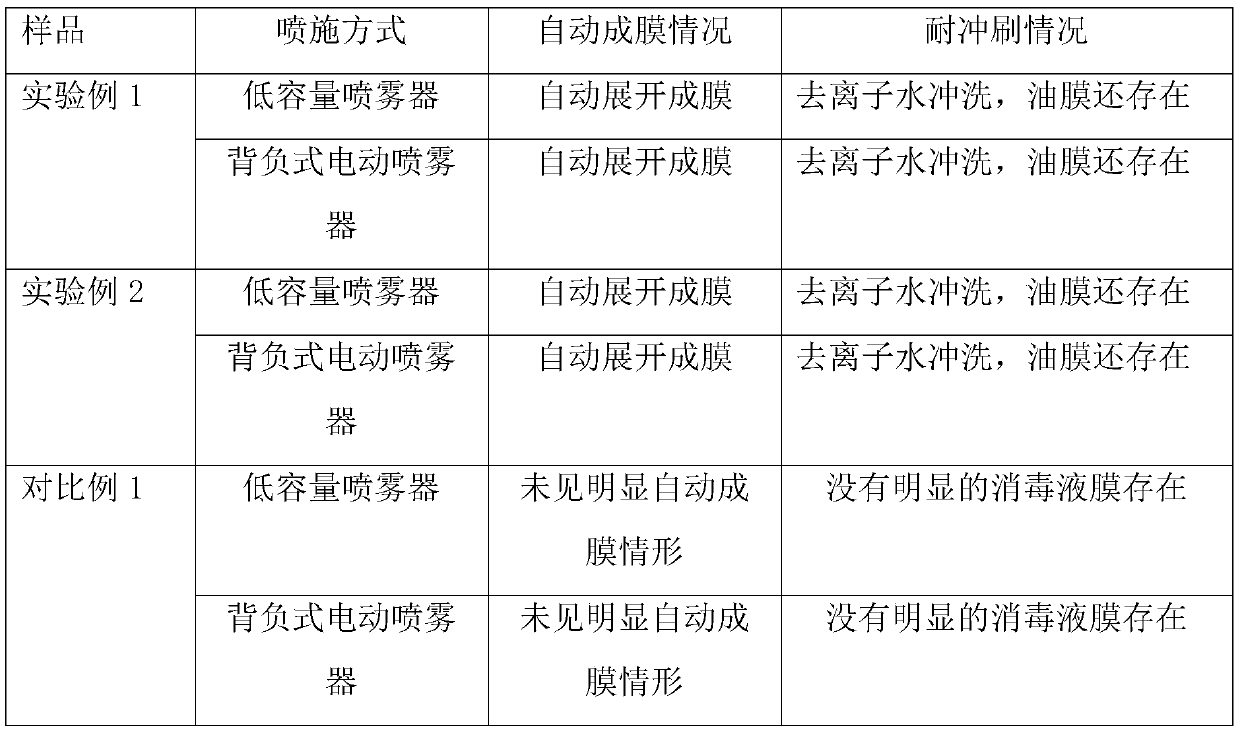

[0060] spray test

[0061] The purpose of this experiment is to test the difference in dispersibility of the mist droplets formed by the disinfectant emulsion of the present invention and the disinfectant solution of Comparative Example 1. During the test, place a 2m x 1m cardboard vertically at a distance of 5 meters from the mist outlet of the spray, place 20 water-sensitive test papers evenly on the front of the cardboard, and place 20 water-sensitive test papers evenly on the back. The specification is 76mm×26mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com