Sulfur-free nickel-molybdenum bimetallic hydrodeoxygenation catalyst

A deoxygenation catalyst, hydrodeoxygenation technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst, carbon compound catalyst, etc. Strong carbon ability, inhibition of C=C bond breakage, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

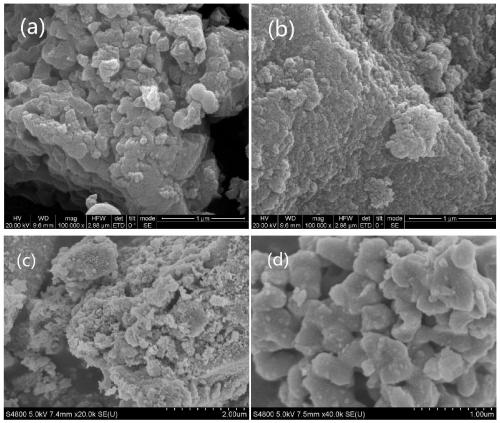

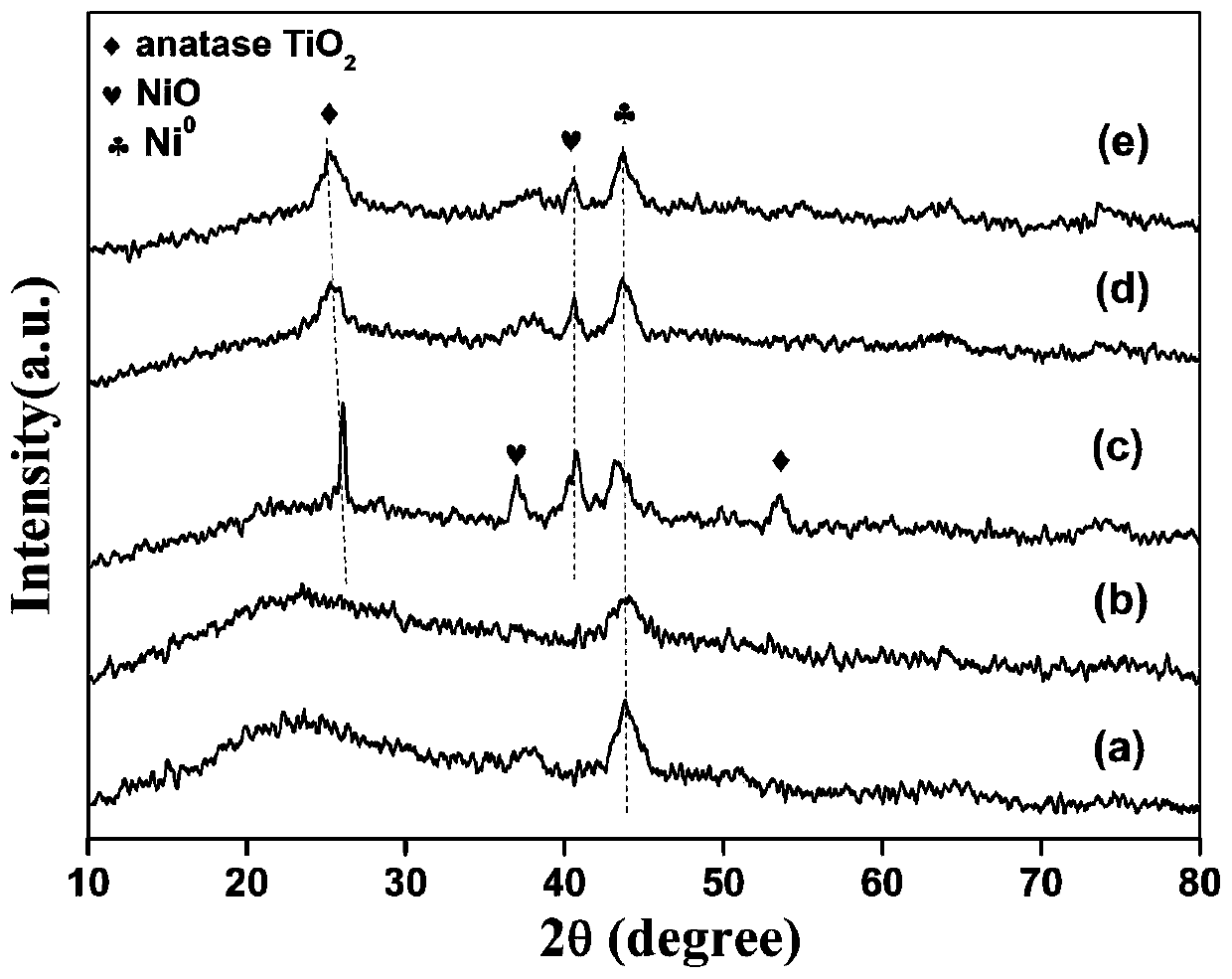

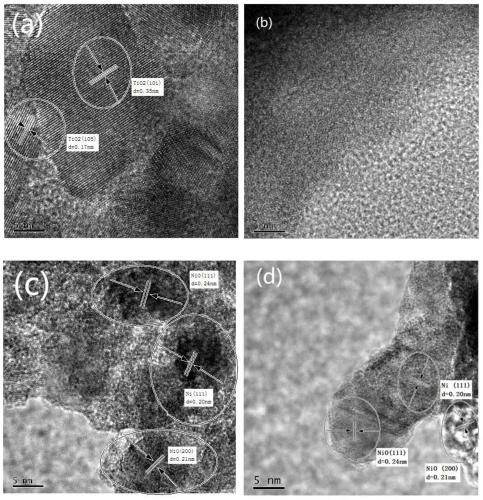

[0040] 1. Sulfur-free nickel-molybdenum bimetallic hydrodeoxygenation catalyst Ni-Mo / TiO 2 -SiO 2 preparation of

[0041] Dissolve tetrabutyl titanate (TBOT) and tetraethyl orthosilicate (TEOS) in a certain amount of distilled water at a molar ratio of 1:1, specifically add 2mmol TBOT and 2mmol TEOS and dissolve in 40ml deionized water to form a total molar The mixed solution with a concentration of 0.10 mol / L was stirred and mixed at 40° C. for 6 hours, and then 37 wt % ammonia water was slowly added dropwise to the mixed solution until the pH of the solution was 10, and the dropping rate was controlled at 2 drops / second. The obtained precipitate was milky white. After continuing to stir at the same temperature for 6 hours, the obtained precipitate was suction-filtered, washed with deionized water and absolute ethanol several times until the filter cake was neutral, and placed in a constant temperature drying oven at 100°C. After drying overnight, place it in a box-type muf...

Embodiment 2

[0045] Embodiment 2 operation steps are the same as embodiment 1, but active component Ni and TiO in the catalyst 2 -SiO 2 The mass ratio of the hydrodeoxygenation product n-dodecane is 0.05:1, and the mass yield of hydrodeoxygenation product n-dodecane is 83%, and the product purity mass percentage is 85%.

Embodiment 3

[0046] Embodiment 3 operating steps are the same as embodiment 1, but active component Ni and TiO in the catalyst 2 -SiO 2 The mass ratio of the hydrodeoxygenation product n-dodecane is 0.15:1, and the mass yield of hydrodeoxygenation product n-dodecane is 81%, and the product purity mass percentage is 83%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com