Method for detecting atomization homogeneity of electronic cigarette atomizer

An electronic atomizer and uniformity technology, applied in the testing of machines/structural components, instruments, scientific instruments, etc., can solve the problems of inaccurate control and adjustment, inaccurate measurement, etc., and achieve small human influence factors and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

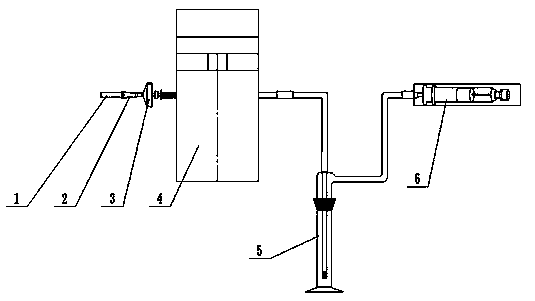

Method used

Image

Examples

Embodiment 1

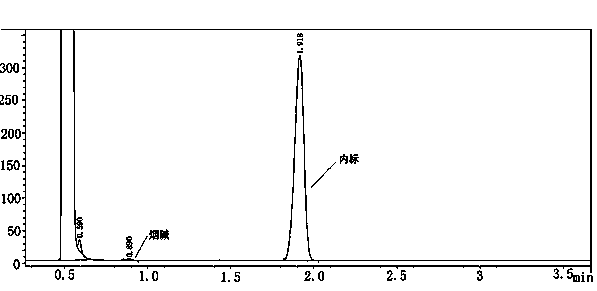

[0034] Example 1: Take 19 samples of No. 1 electronic cigarette, use a linear smoking machine to smoke in ISO mode, and use a trap with one channel without electronic cigarettes as a blank sample for nicotine determination. According to the above method, the nicotine in the smoke release after 50 continuous puffs of electronic cigarettes was determined. The measurement results are as follows:

[0035] The content of nicotine in No. 1 e-cigarette smoke emissions:

[0036]

[0037] The atomization uniformity of the electronic cigarette atomizer is expressed in SD as 0.0036.

Embodiment 2

[0038]Example 2: 19 No. 2 electronic cigarette samples were taken and smoked in the ISO mode with a linear smoking machine, and the trap of one channel was not filled with electronic cigarettes as a blank sample for nicotine determination. According to the above method, the nicotine in the smoke release after 50 continuous puffs of electronic cigarettes was determined. The measurement results are as follows:

[0039] The content of nicotine in the smoke emission of No. 2 electronic cigarette:

[0040]

[0041] The atomization uniformity of the electronic cigarette atomizer is expressed in SD as 0.0141. The above uniformity test shows that the atomization uniformity of the No. 2 electronic cigarette atomizer is not as good as that of the No. 1 electronic cigarette atomizer. The performance of the atomizer can be improved, and corresponding adjustments can be made to improve the atomization uniformity .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com