Epoxy activated affinity chromatography medium

A chromatography medium and epoxy-activated technology, applied in the field of epoxy-activated affinity chromatography medium, can solve problems such as reduction in the number of ligand coupling, matrix damage, and reduced efficiency of affinity chromatography, achieving a large number, The density of epoxy groups is high, which is conducive to the effect of large-scale popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

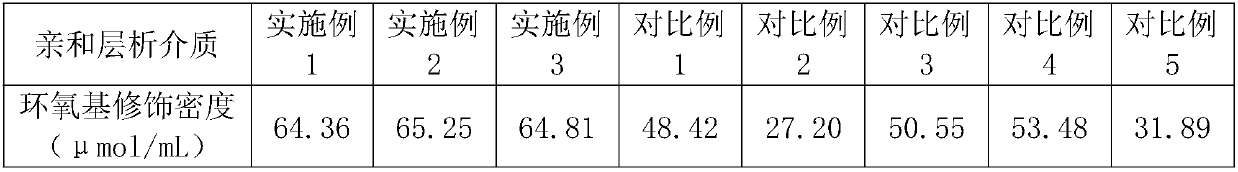

Examples

Embodiment 1

[0020] The preparation process is as follows:

[0021] (1) Soak 20 g of cellulose microspheres with a particle size of 30-100 μm in 100 mL of sulfuric acid solution with a concentration of 50 wt %, stir magnetically at 55-60° C. for 30 minutes, and filter to obtain activated cellulose microspheres;

[0022] (2) Mix 25g of 1,2-epoxydodecane, 10g of polylactic acid-glycolic acid copolymer, 20g of polyethylene glycol, and 0.2g of diethylenetriamine, and add 50mL of absolute ethanol. Stir at ℃ for 30 minutes and sonicate for 15 minutes to form a homogeneous liquid complex;

[0023] (3) Place the activated cellulose microspheres obtained in step (1) in the liquid compound of step (2), stir at 55-60°C for 3-4 hours, lower the temperature and stir at 45-50°C for 2- 3 hours, then lower the temperature to 20-25°C and stir for 1-2 hours, and finally stir at 5-10°C for 1-2 hours to end the reaction, filter the microspheres, rinse with deionized water and dry to obtain epoxy-activated af...

Embodiment 2

[0025] The preparation process is as follows:

[0026] In the step (2) of Example 1, 1,2-epoxydodecane was replaced with 35 g of 1,2-epoxyoctadecane, the amounts of the two substances were the same, and the rest of the preparation process was the same as in Example 1.

Embodiment 3

[0028] The preparation process is as follows:

[0029] In step (2) of Example 1, 1,2-epoxydodecane was replaced with 12g of 1,2-epoxyhexadecane and 23g of 1,2-epoxypentadecane, and the rest of the preparation process was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com