Patents

Literature

32 results about "Wood finishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood finishing refers to the process of refining or protecting a wooden surface, especially in the production of furniture where typically it represents between 5 and 30% of manufacturing costs. Finishing is the final step of the manufacturing process that gives wood surfaces desirable characteristics, including enhanced appearance and increased resistance to moisture and other environmental agents. Finishing can also make wood easier to clean and keep it sanitized, sealing pores that can be breeding grounds for bacteria. Finishing can also influence other wood properties, for example tonal qualities of musical instruments and hardness of flooring. In addition, finishing provides a way of giving low-value woods the appearance of ones that are expensive and difficult to obtain.

Ultraviolet-curing waterborne epoxy-polyurethane-acrylate copolymer resin anticorrosive coating and preparation method thereof

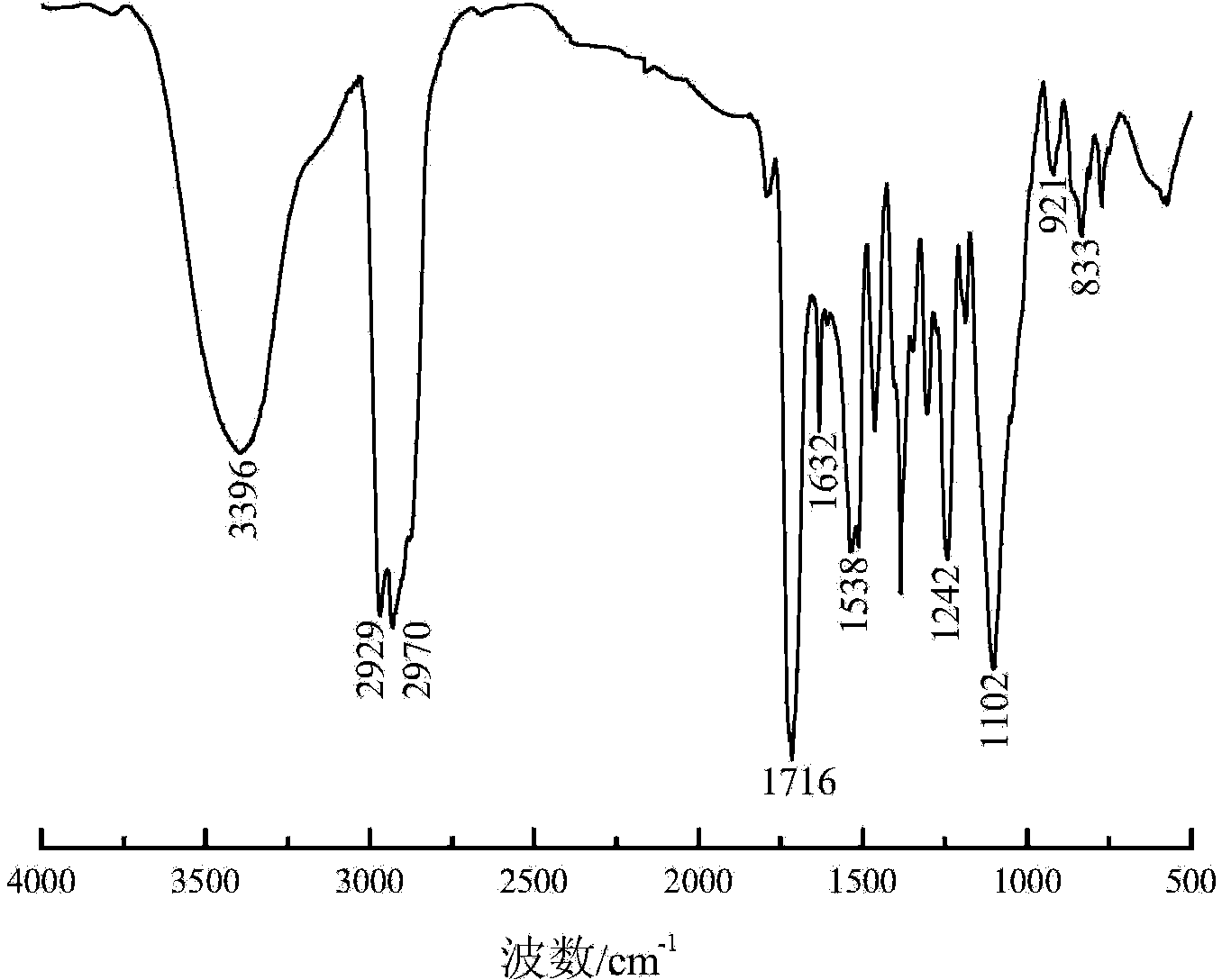

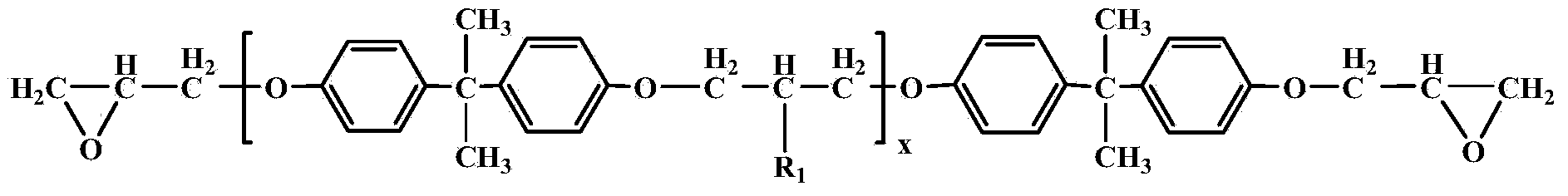

InactiveCN104031231AAchieve self-emulsificationAchieve UV curingAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention discloses an ultraviolet-curing waterborne epoxy-polyurethane-acrylate copolymer resin anticorrosive coating and a preparation method thereof. The matrix resin is prepared from three monomers, namely epoxy resin, polyurethane and acrylic resin in a copolymerization manner; self-emulsification of the matrix resin in water is achieved, so as to obtain epoxy-polyurethane-acrylate copolymer resin aqueous dispersion; and assistants such as a waterborne light initiator, an acrylic ester crosslinking agent and the like are added to the aqueous dispersion, so as to obtain the ultraviolet-curing waterborne epoxy-polyurethane-acrylate copolymer resin anticorrosive coating. The synthetic process disclosed by the invention is simple. Water is taken as a dispersion medium, so that the process is environment-friendly and non-toxic, and the storage period is long. The coating is solidified into a film by adopting ultraviolet light, and the coating technology is simple and efficient. The coating after the anticorrosive coating is solidified has good adhesive force, hardness and glossiness, and excellent corrosion resistance, and can be applied to the fields such as wood finishing coats, environment-friendly building antisepsis coatings, cabin corrosion prevention for aircrafts and ships and warships in an ocean environment.

Owner:HEFEI UNIV OF TECH

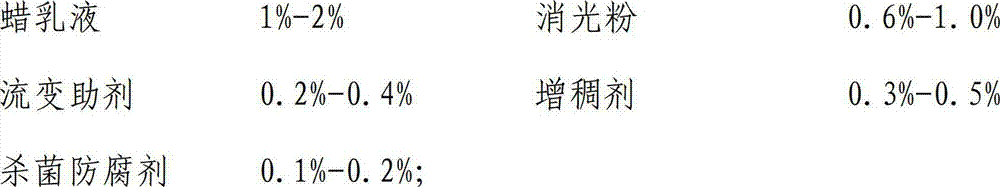

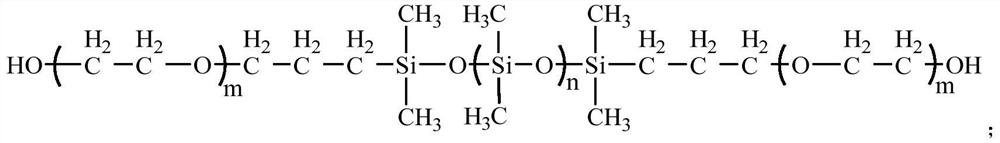

One-component water-borne semi-matt wood finishing varnish

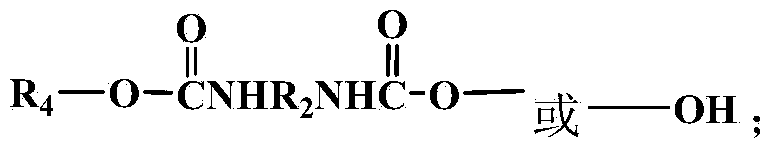

InactiveCN102964947AEnvironmentally friendlyImprove water resistanceCoatingsAcrylic polymerDefoaming Agents

The invention relates to one-component water-borne semi-matt wood finishing varnish. The one-component water-borne semi-matt wood finishing varnish comprises the following components in percentage by weight: crosslinked pure acrylic acid copolymerization emulsion, self-crosslinked pure acrylic polymer, a pH regulating agent, a defoaming agent, water, a coalescing agent, a dispersing agent, a substrate wetting agent, wax emulsion, a matting agent, a rheological additive, a thickening agent and a sterilization preservative. The one-component water-borne semi-matt wood finishing varnish disclosed by the invention has the characteristics of environmental friendliness, and excellent water resistance and chemical resistance.

Owner:GUANGDONG BADESE CHEM

Nano sterilizing anionic double-component aqueous wood paint

InactiveCN101880500ANo pollutionWon't hurtAntifouling/underwater paintsPaints with biocidesAcrylic resinLacquer

In order to solve the problem of environmental pollution of the conventional coating, the invention provides a novel nano sterilizing anionic double-component aqueous wood finishing paint and a preparation method thereof. The nano sterilizing anionic double-component aqueous wood finishing paint provided by the invention comprises a component A and a component B, wherein the component A comprises the following components in part by weight: 65 to 90 parts of acrylic resin, 0.2 to 0.4 part of antifoaming agent, 0.4 to 0.6 part of composite nano anionic powder, 0.1 to 0.3 part of dispersant, 0.5 to 1.5 parts of thickening agent and 15 to 25 parts of water; and the component B comprises the following component in part by weight: 40 to 60 parts of water-dispersed polyisocyanate, wherein the weight of the component A is 1.5 to 2.5 times that of the component B. The nano sterilizing anionic double-component aqueous wood finishing paint has the technical advantages of environmental protection, strong sterilization and mildew prevention, capability of constantly releasing anions and purification and indoor air.

Owner:QUANZHOU XINXIEZHI SPECIAL COATING

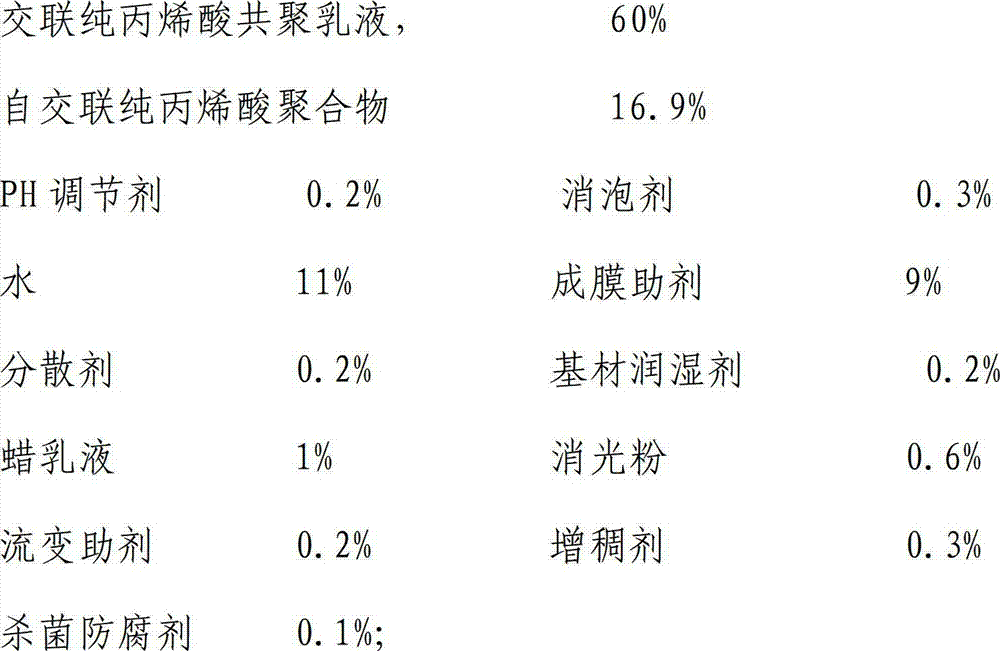

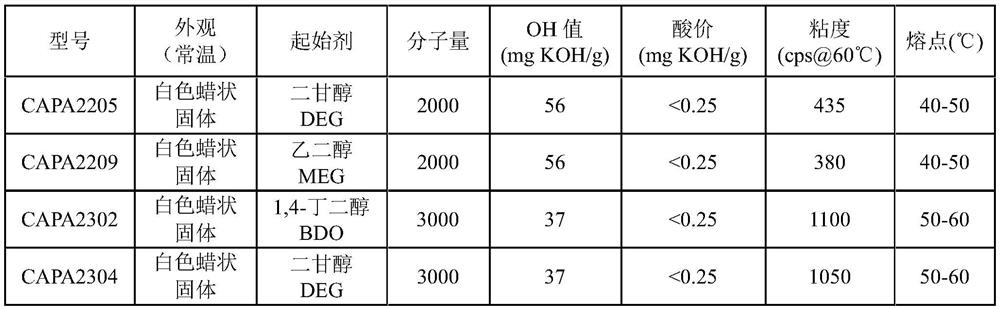

UV skin-feeling wood coating as well as preparation method and application thereof

PendingCN113122125AGood flexibilityImprove adhesionPolyurea/polyurethane coatingsPolymer sciencePolyethylene glycol

The invention discloses a UV skin-feeling wood coating which comprises the following raw materials in parts by weight: 10-40 parts of UV cured resin, 50-80 parts of a reactive diluent, 0.1-5 parts of a functional aid, 1-10 parts of functional filler and 1-10 parts of a photoinitiator; wherein the UV curing resin is a combination of 2-functionality elastic polyurethane acrylate, 2-functionality polysiloxane type polyurethane acrylate and 6-functionality polyurethane acrylate, and the reactive diluent is a combination of polyethylene glycol (200) diacrylate and ethyoxyl ethyoxyl ethyl acrylate. The invention further discloses application of the UV skin-feeling wood coating in preparation of wood finishing paint. According to the invention, the UV skin-feeling wood coating is coated on woodware, and the coating of the skin-touch paint can be realized and the skin-touch effect can be generated by curing by using an ultraviolet curing machine; the paint film is good in adhesive force, soft, smooth, fine, comfortable, good in skin-touch effect, low in cost and free of pollution.

Owner:JIANGSU LITIAN TECH

Nano anionic double-component aqueous wood paint

InactiveCN101880506ANo pollutionGood flexibilityPolyurea/polyurethane coatingsAcrylic resinMaterials science

In order to solve the problem of environmental pollution of the conventional coating, the invention provides a novel nano anionic double-component aqueous wood finishing paint and a preparation method thereof. The double-component aqueous wood finishing paint provided by the invention comprises a component A and a component B, wherein the component A comprises the following components in part by weight: 65 to 90 parts of acrylic resin, 0.2 to 0.4 part of antifoaming agent, 0.4 to 0.6 part of composite nano anionic powder, 0.1 to 0.3 part of dispersant, 0.5 to 1.5 parts of thickening agent and 15 to 25 parts of water; and the component B comprises the following component in part by weight: 40 to 60 parts of water-dispersed polyisocyanate, wherein the weight of the component A is 1.5 to 2.5 times that of the component B. The nano anionic double-component aqueous wood finishing paint has the technical advantages of environmental protection, capability of constantly releasing anions and purification and indoor air.

Owner:QUANZHOU XINXIEZHI SPECIAL COATING

Wood stain composition and finishing method

InactiveUS20100048787A1Improve efficiencyConsiderable costWood treatment detailsPolyester coatingsHydrocarbon solventsGlycol ethers

A stain composition includes a stable blend of a light fast dye, a pigment, a hydrocarbon solvent, an alkyd resin, and a compatibilizer solvent. The stain composition may further include one or more oxygenated solvents in addition to the compatibilizer solvent, which may be a glycol ether solvent. The compositions of the present invention facilitate replacing, in a single tinting step, the separate dye tinting and pigment tinting steps used in conventional wood finishing schedules.

Owner:THE SHERWIN-WILLIAMS CO

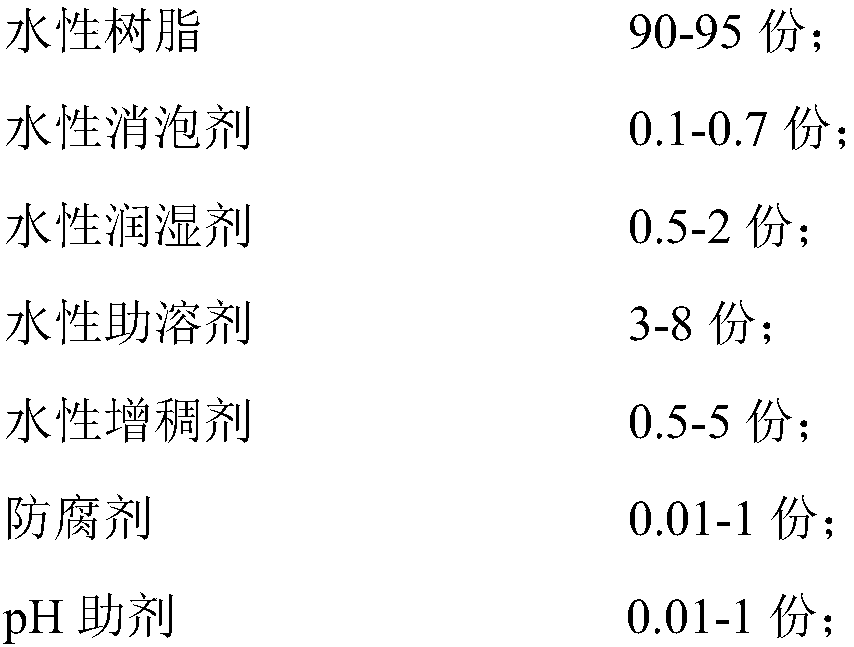

Waterborne furniture primer and preparation method thereof and wood finishing construction technology

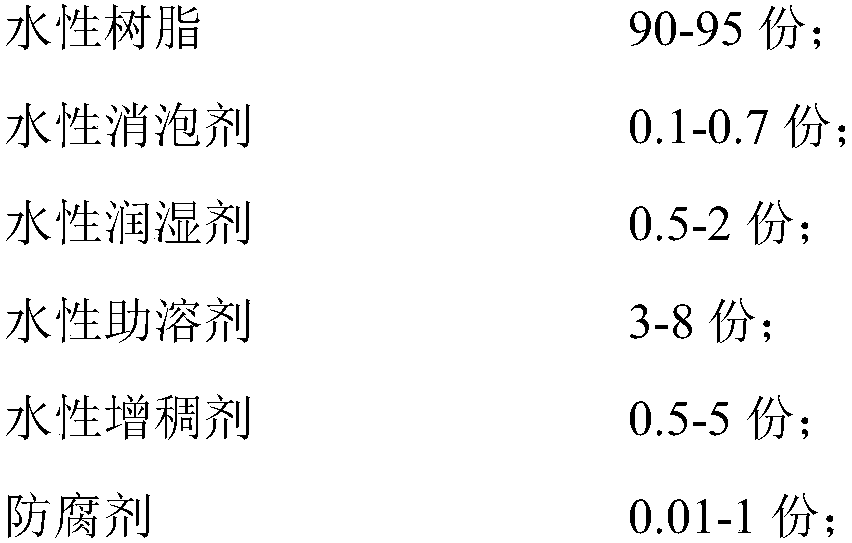

ActiveCN106010184AImprove stabilityEasy to fillLiquid surface applicatorsPolyurea/polyurethane coatingsDefoaming AgentsWood finishing

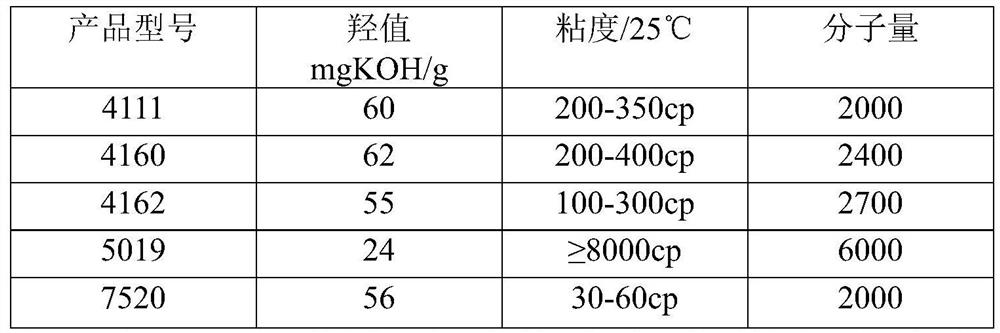

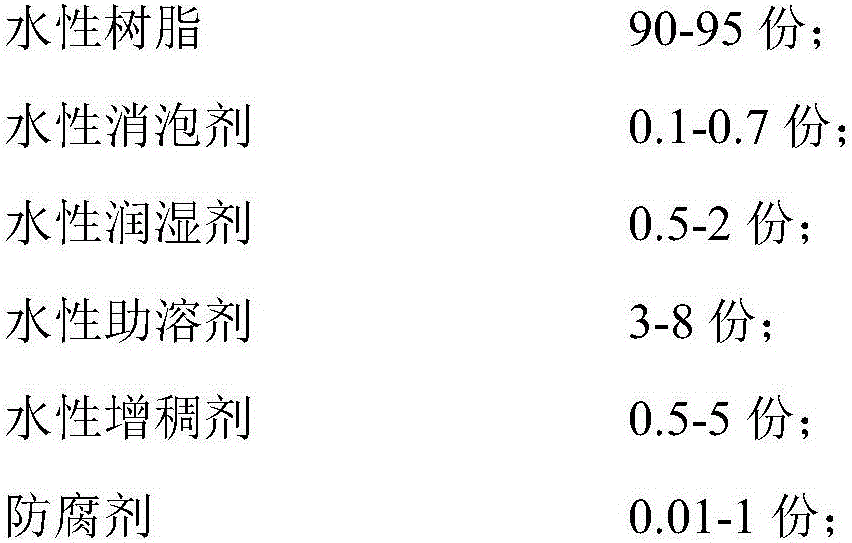

The invention provides waterborne furniture primer and a preparation method thereof and a wood finishing construction technology. The waterborne furniture primer is prepared from, by weight, 90-95 parts of waterborne resin, 0.1-0.7 part of waterborne defoaming agent, 0.5-2 parts of waterborne wetting agent, 3-8 parts of waterborne cosolvent, 0.5-5 parts of waterborne thickener, 0.01-0.1 part of preservative and 0.01-1 part of pH auxiliary, wherein the waterborne resin is prepared from, by weight, 30%-65% of waterborne polyurethane resin and 40%-75% of waterborne acrylic resin. The obtained waterborne transparent primer has excellent stability, filling performance, permeability and overlapping performance, the primer is put in a baking oven at 50 DEG C for 10 days, the coating does not have any exception, and a spray plate effect is not changed; after 'three primer' procedures are carried out, wet film can cover all fine needle holes and guide tubes of the surfaces of boards; the transparency effect is good, and the primer is neither dimming nor blushing.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

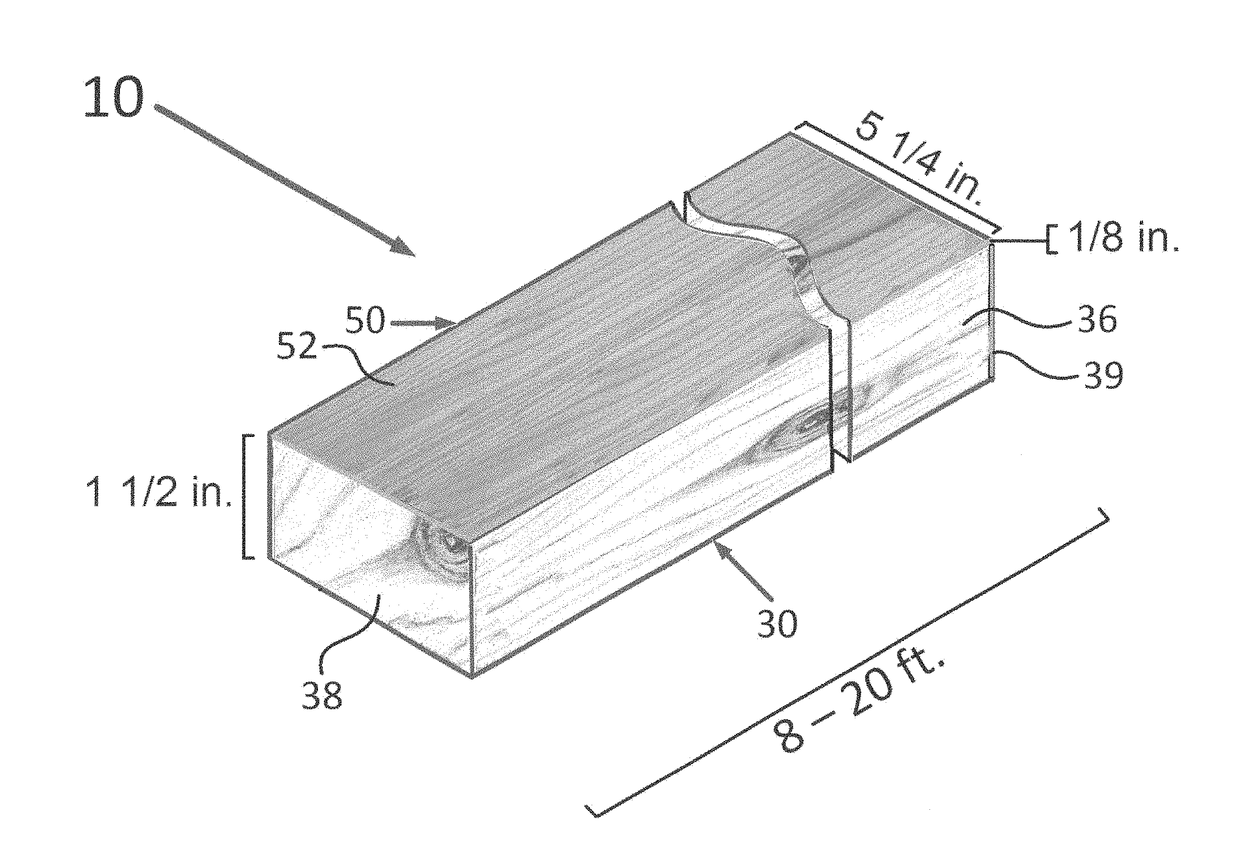

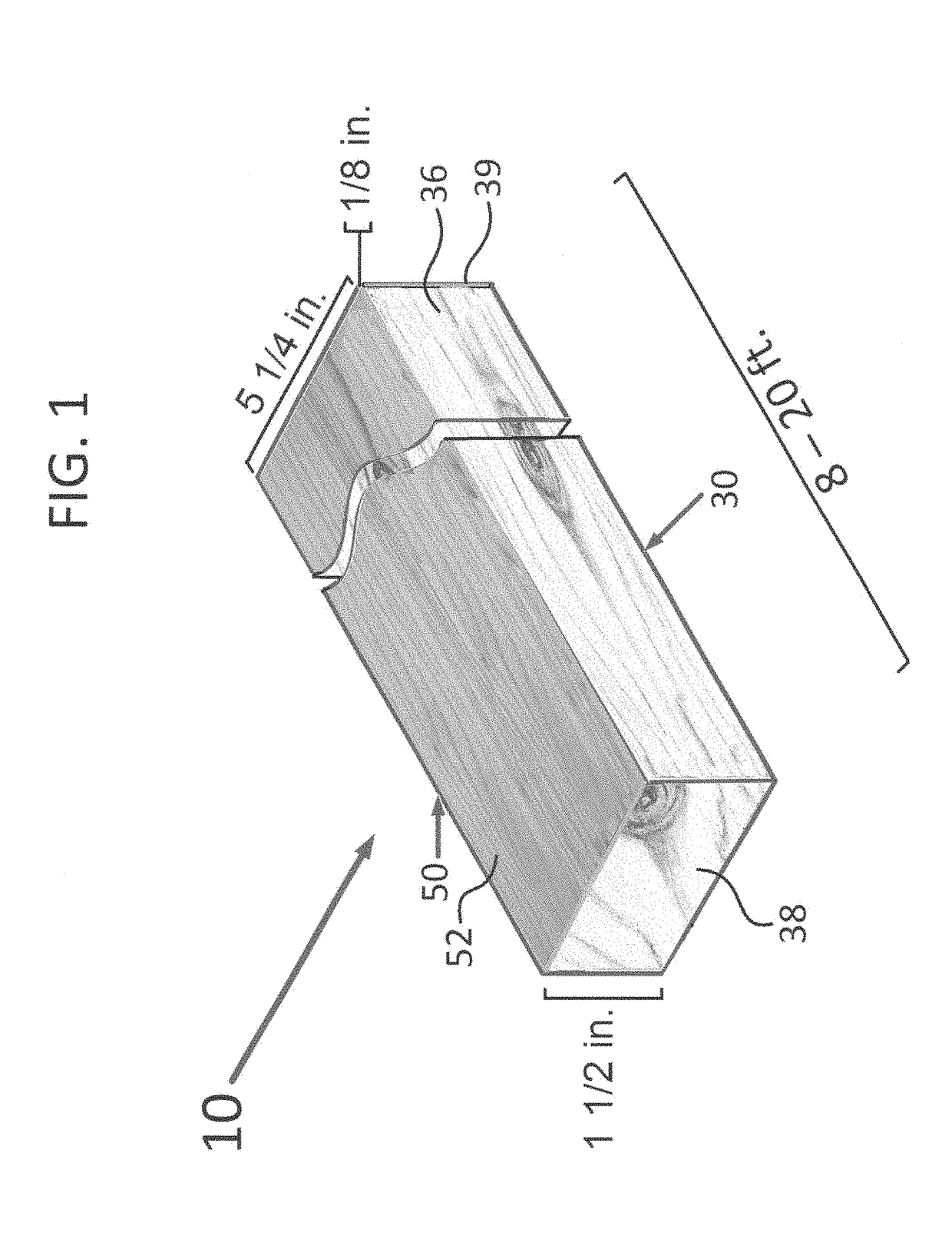

Sanding block

Owner:TRIM TEX

Finishing method of wood

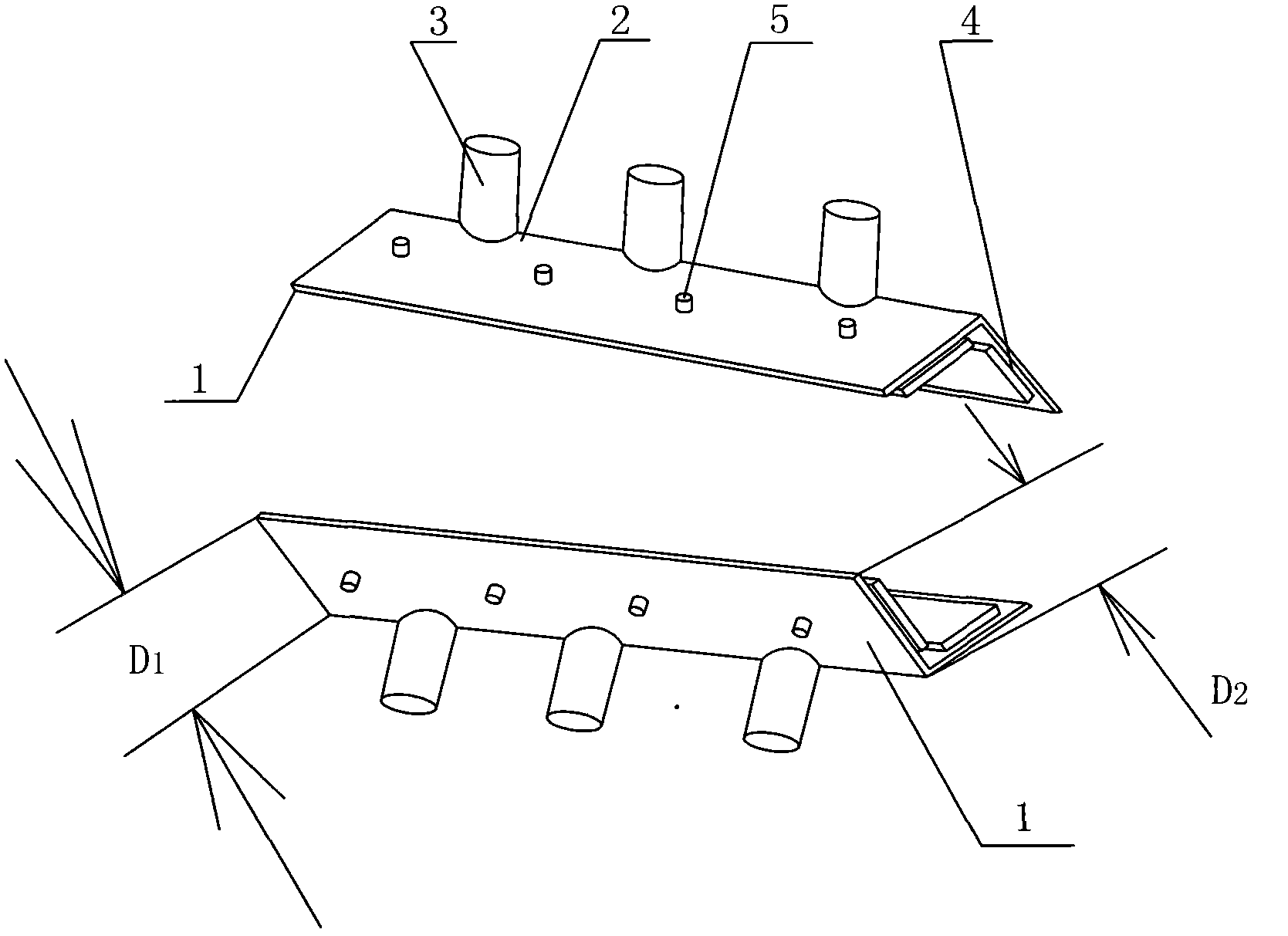

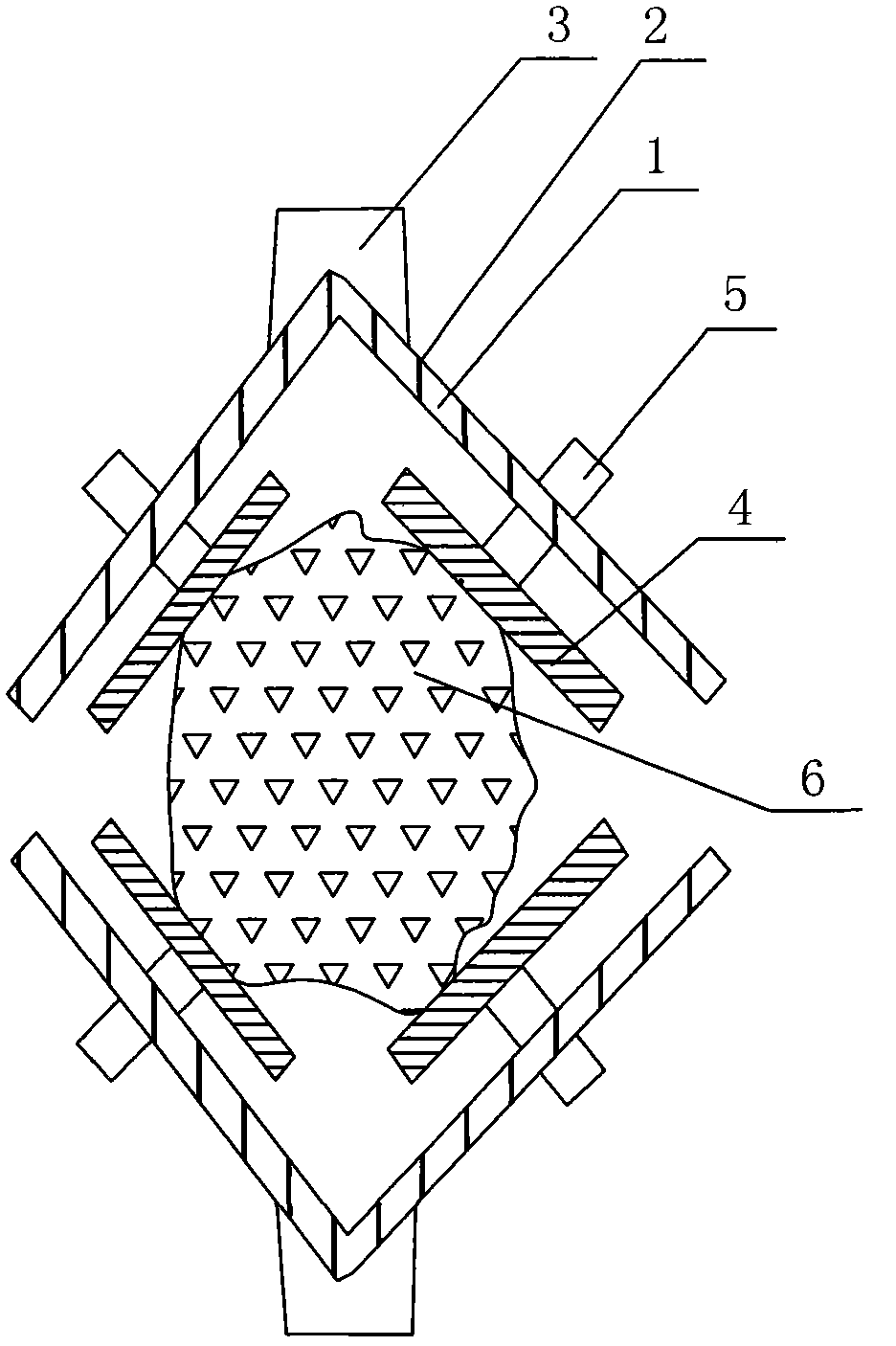

InactiveCN103831880AImprove the correction effectEasy to processWood compressionWood treatment detailsRoom temperatureTemperature difference

The invention relates to the technical field of wood finishing, and discloses a finishing method of wood. The finishing method comprises the following steps: a, heating the wood till the external temperature reaches 95-105 DEG C, and maintaining for a period of time, so that the temperature difference between inside and outside of the wood is not more than 20 DEG C; b, pressing and flattening the wood in step a by using a pressing machine, slowly cooling to room temperature for more than 60 min, and putting the wood in the step a in a dedicated mold, wherein the dedicated mold comprises two mold split bodies, each mold split body is of a long-strip-shaped structure with a V-shaped opening, mounting components mounted on the pressing machine are arranged at the back of the mold split bodies respectively, and the mounting components are arranged on the pressing machine when being used. The finishing method has the advantages that the log utilization rate is improved, a correction bending effect is good, the wood is unlikely to be deformed after correction, the wood does not need to be heated to an extra-high temperature and the waste is reduced.

Owner:杨建国

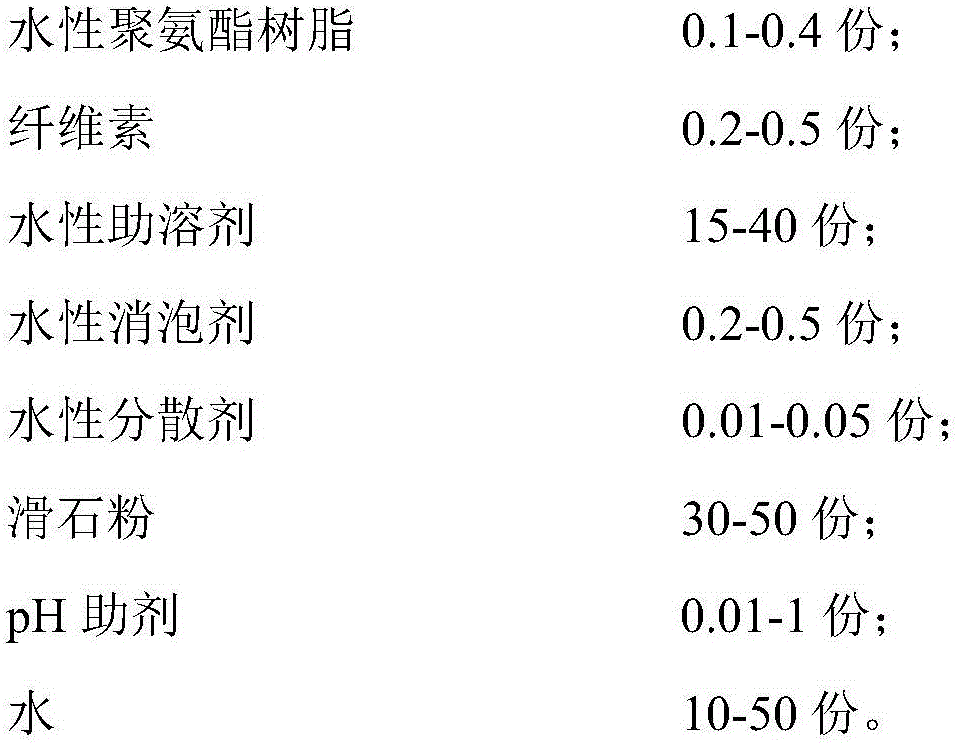

Modified aqueous glaze, preparation method, and wood finishing construction technology

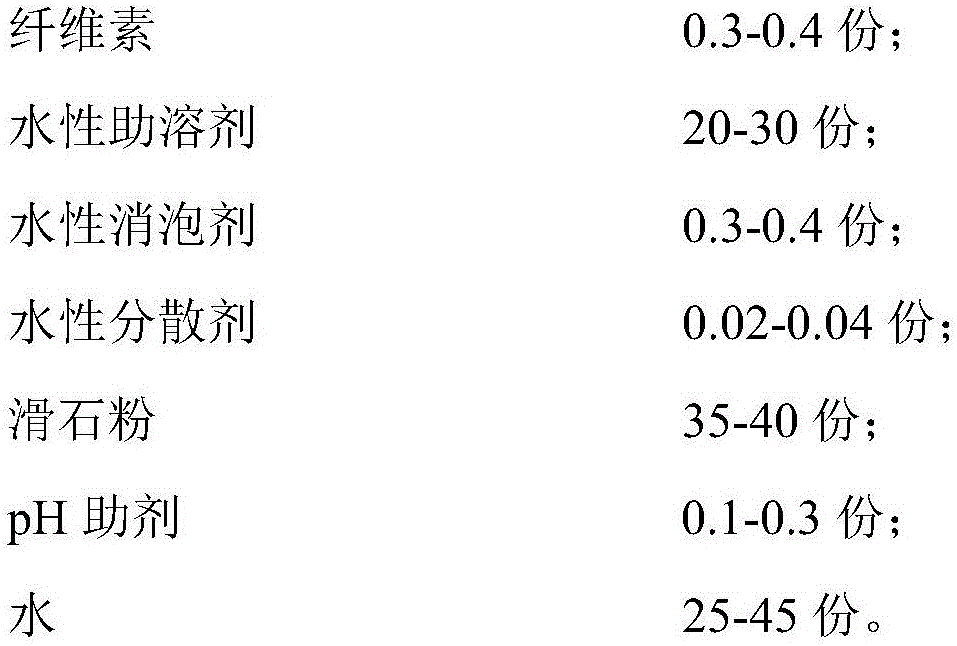

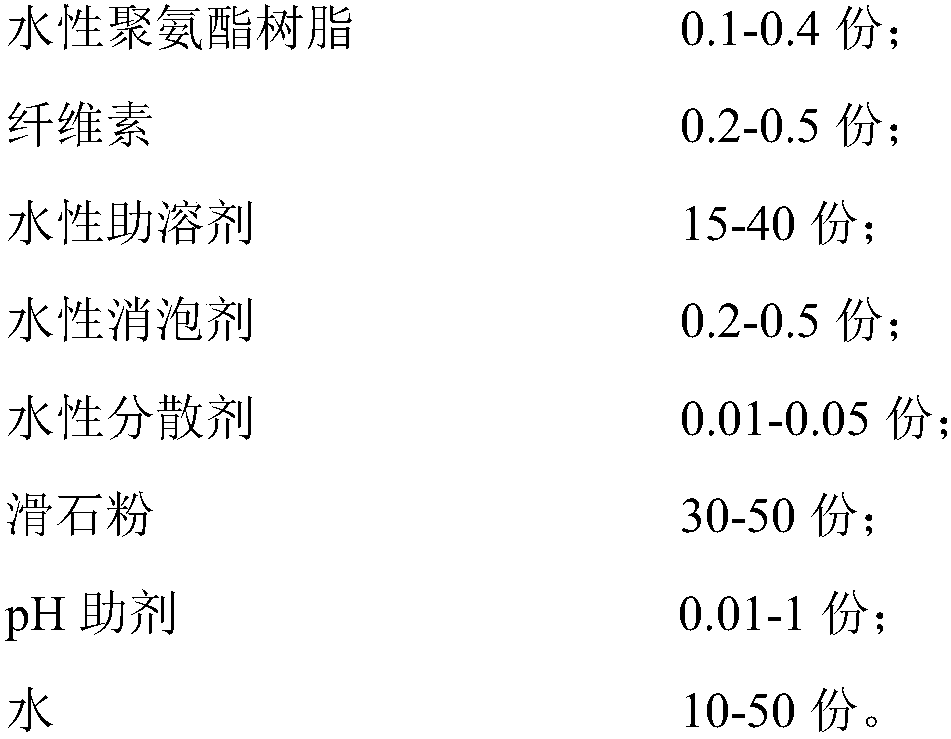

InactiveCN105936772AReduce drying speedNo precipitationLiquid surface applicatorsCoatingsCelluloseSolvent

The invention provides a modified aqueous glaze, a preparation method, and a wood finishing construction technology. The modified aqueous glaze comprises the following components in parts by weight: 0.1 to 0.4 part of aqueous polyurethane resin, 0.2 to 0.5 parts of cellulose, 15 to 40 parts of aqueous cosolvent, 0.2 to 0.5 part of aqueous antifoaming agent, 0.01 to 0.05 part of aqueous dispersant, 30 to 50 parts of talcum powder, 0.01 to 1 part of pH aid, and 10 to 50 parts of water. The drying speed of modified aqueous glaze is reduced in the brush-off technology, the modified aqueous glaze has a good filling effect without affecting the original color of sheets, and moreover, the obtained aqueous glaze will not precipitate and does not need to be stirred or diluted by water before using. The glaze can be applied to the aqueous woodware finishing technology, the compatibility between the glaze and various aqueous primers is good, the interlayer binding force between the glaze and various primers is strong, during the drying process, the glaze appears good transparency and permeability, and the glaze does not give off irritant smell.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

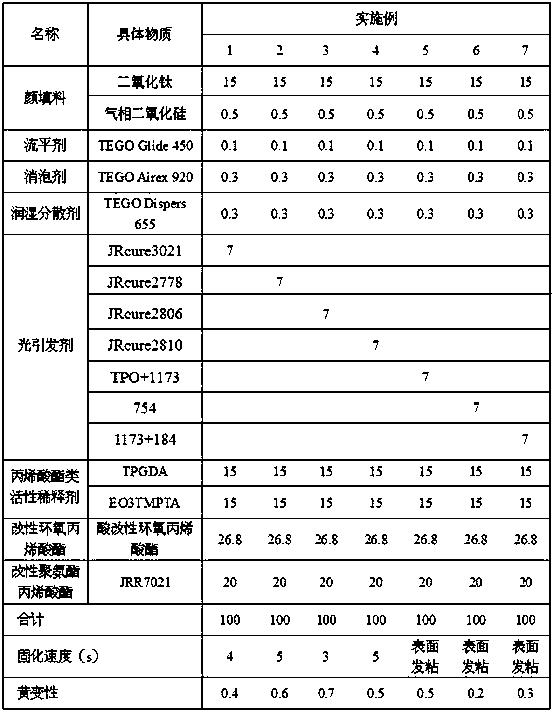

White wood finishing paint cured under UV (ultraviolet)-LED (light-emitting diode) light sources and preparation method of finishing paint

ActiveCN107722797AImprove adhesionHigh whitenessPolyurea/polyurethane coatingsEpoxy resin coatingsChemistryWood finishing

The invention aims to provide white wood finishing paint cured under UV (ultraviolet)-LED (light-emitting diode) light sources and a preparation method of the finishing paint. The wood finishing paintis prepared from, in weight percent, 30-40% of modified epoxy acrylate, 10-20% of modified urethane acrylate, 30-40% of acrylate reactive diluents, 5-10% of photo-initiators, 0.4-1% of additives, 15-20% of titanium dioxide and 0.1-2% of fumed silica. The wood finishing paint has the advantages that the wood finishing paint can be rapidly cured under the UV-LED light sources and has good adhesiveforce and yellowing resistance when being used for wood ware, and the wood finishing paint solves the problems of slow curing, poor surface dry and easiness in yellowing of the light-cured white woodfinishing paint under the UV-LED light sources.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

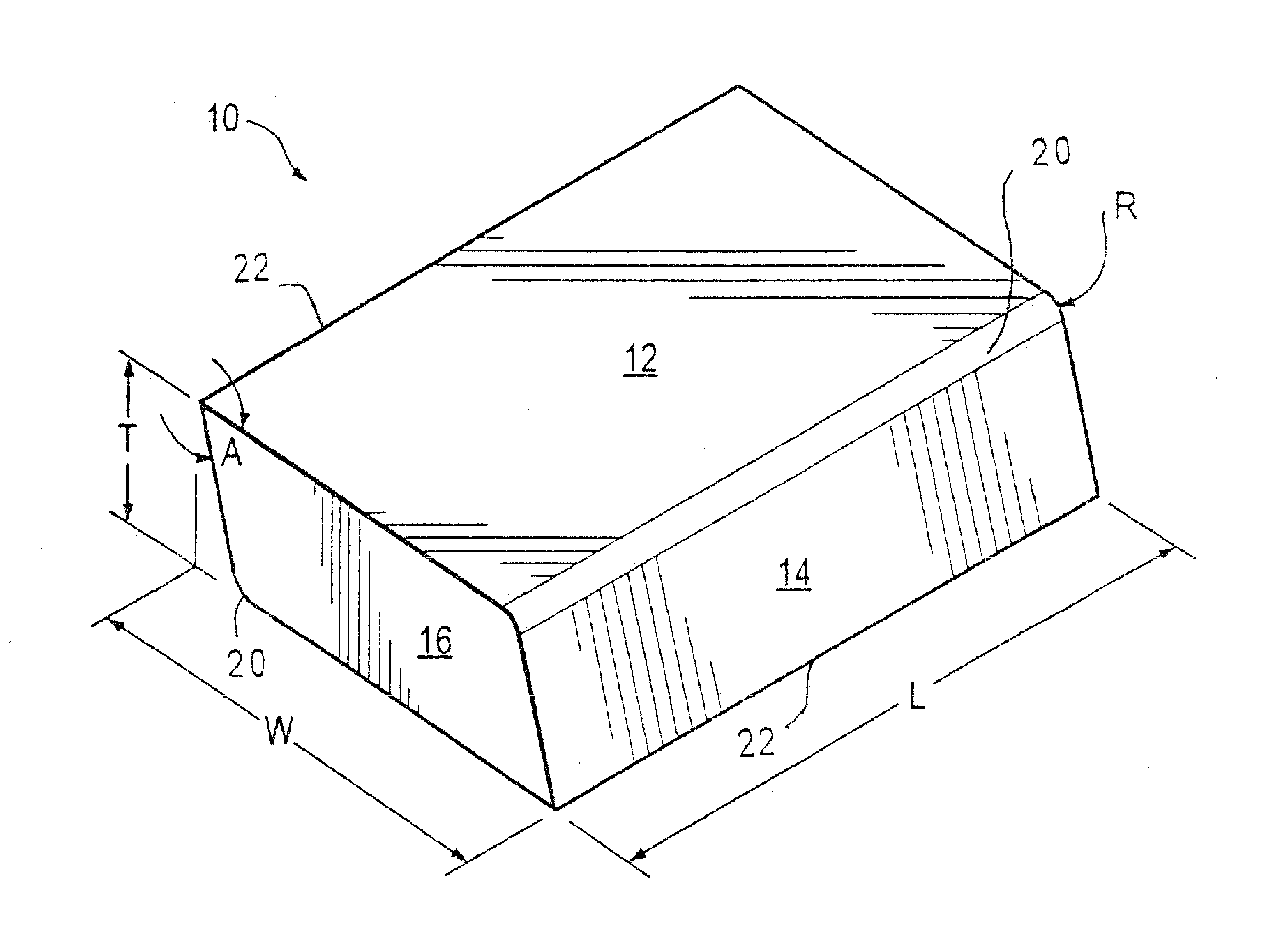

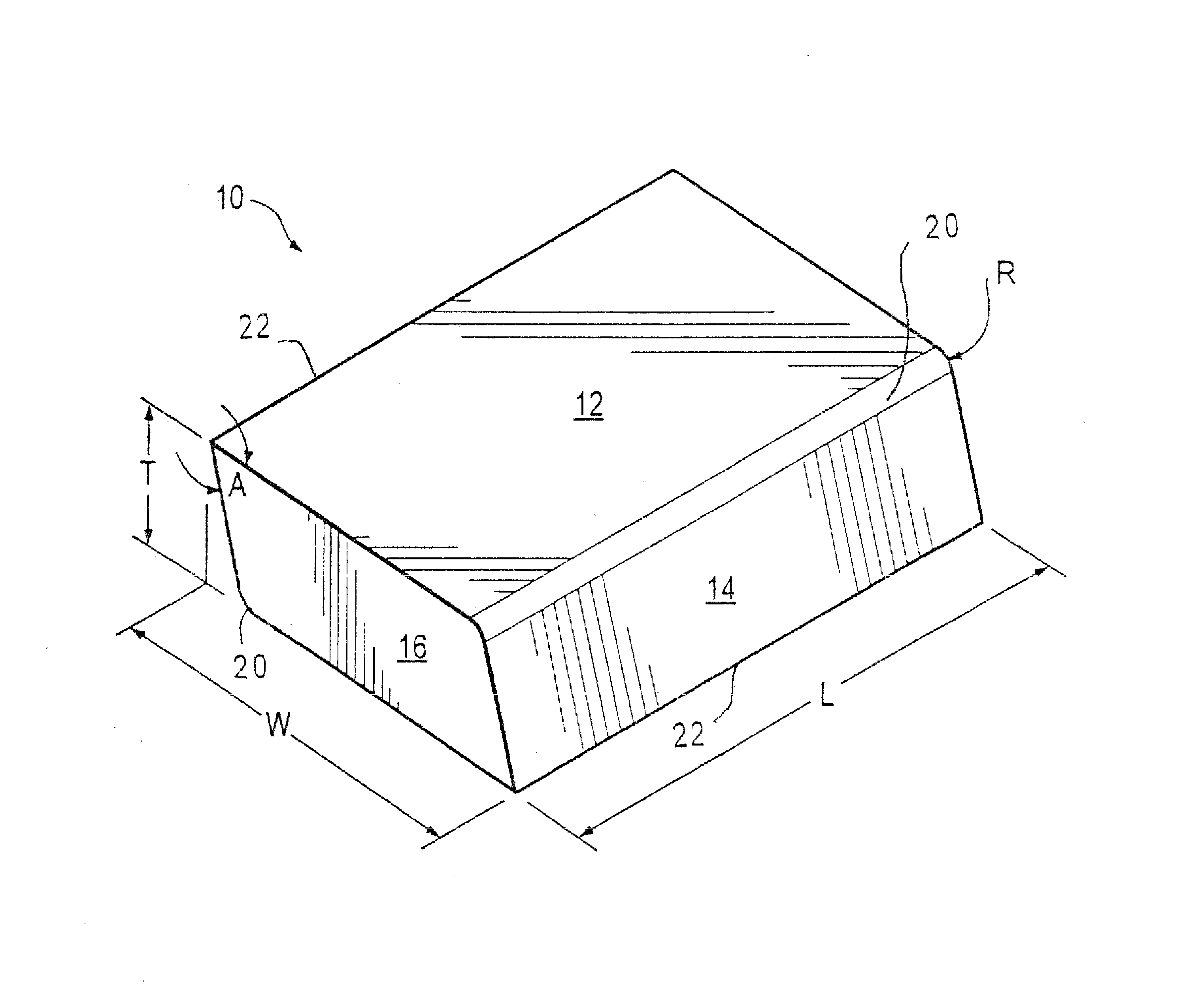

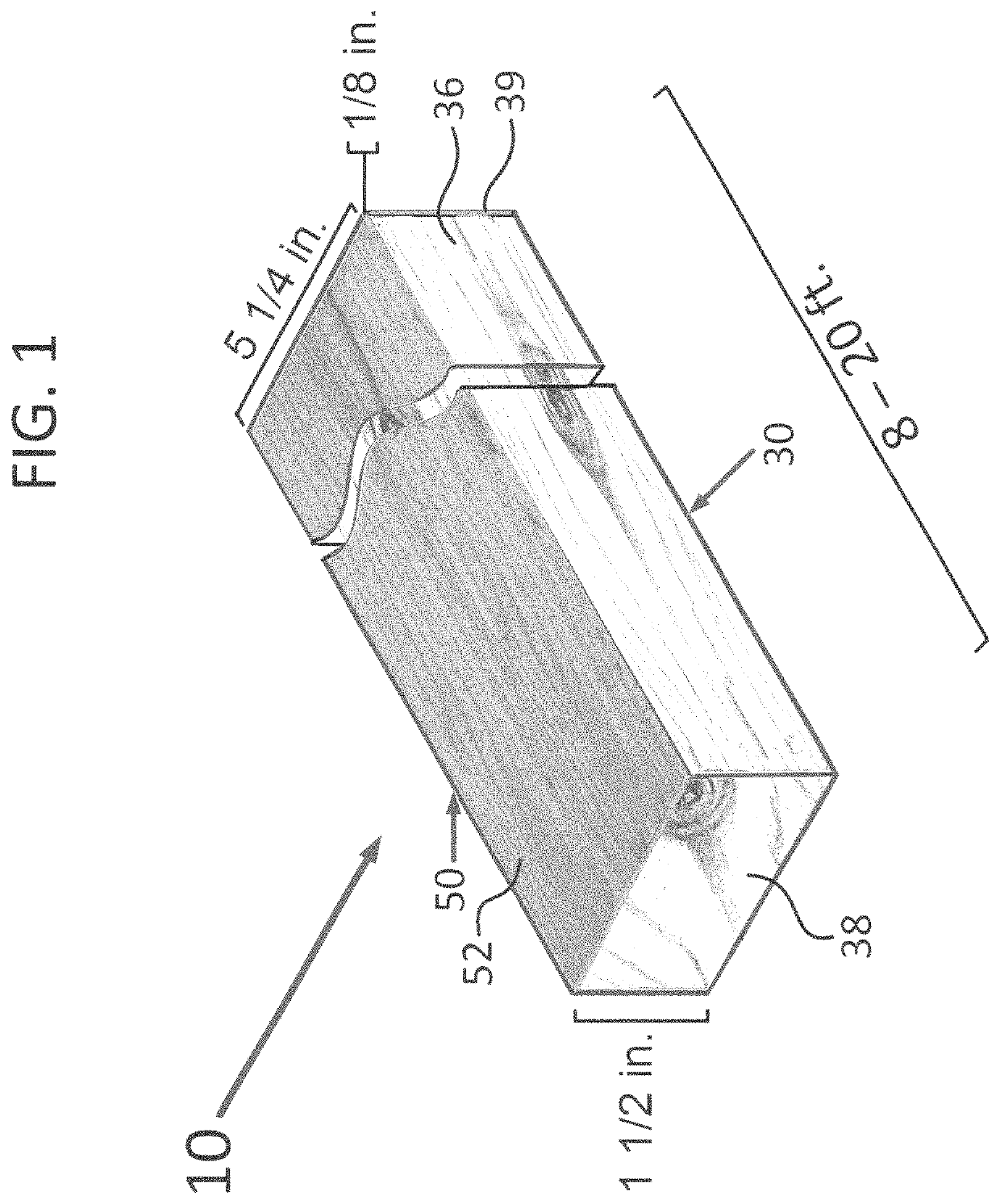

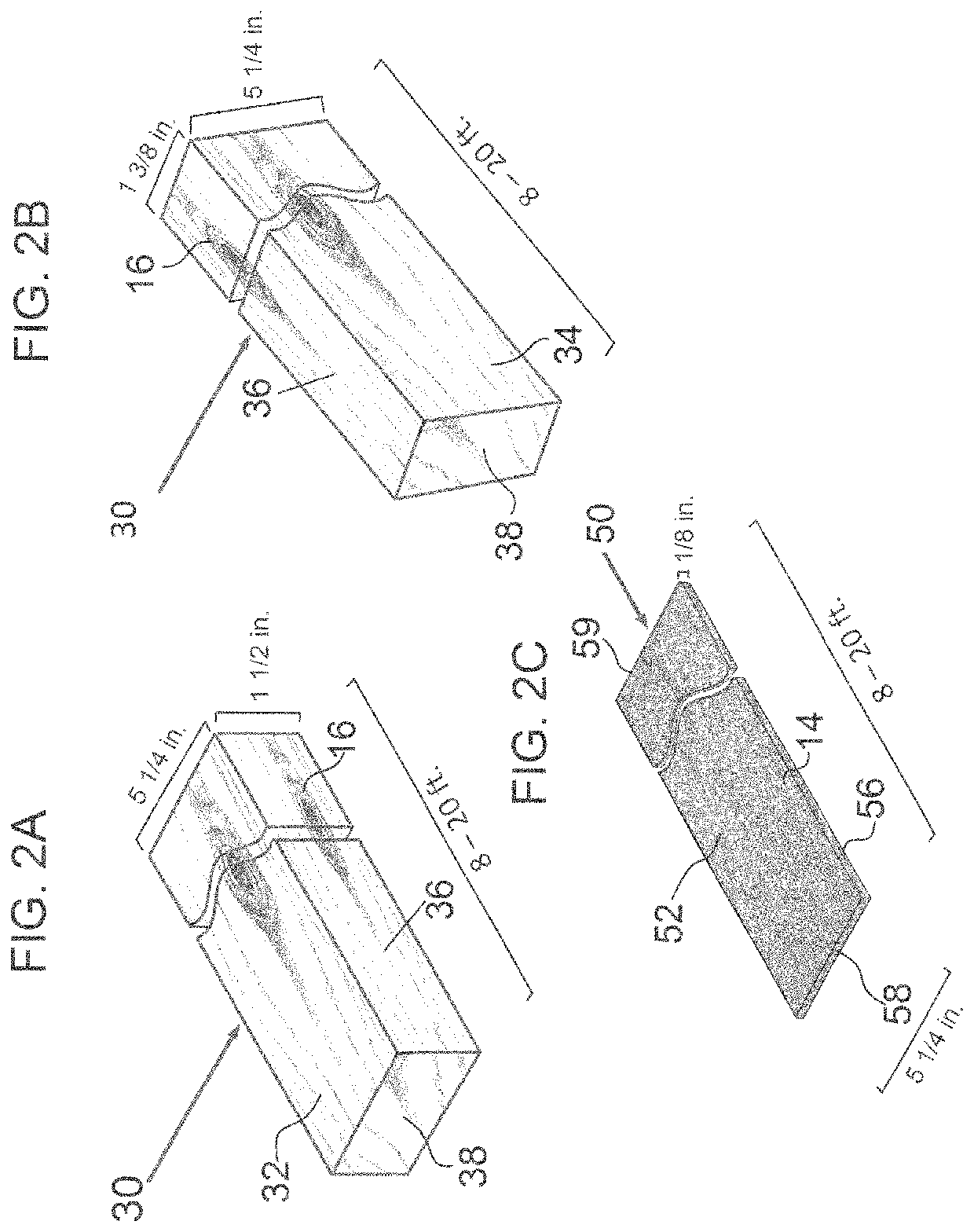

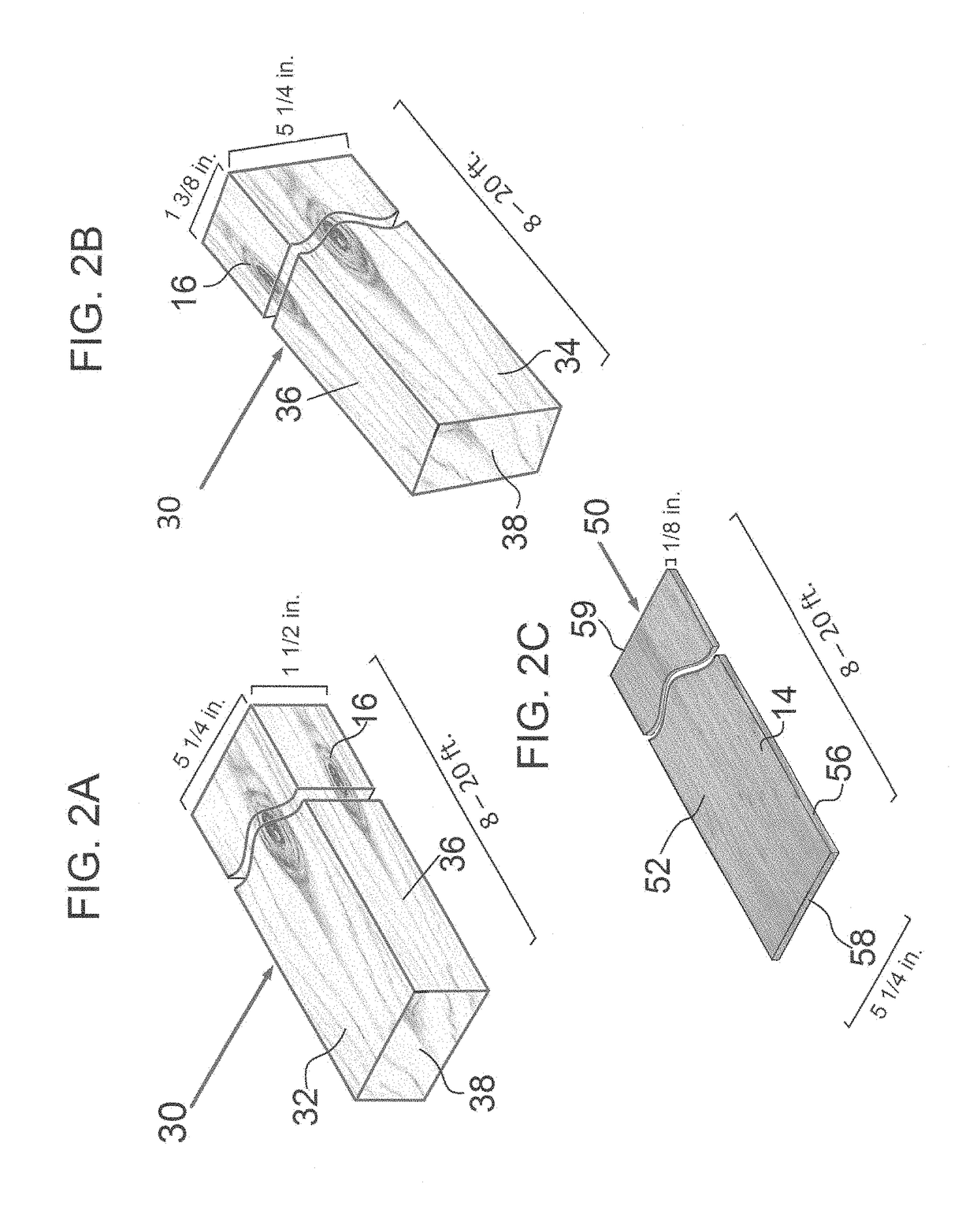

Outdoor wood decking board

An outdoor wood decking board for use in construction of an outdoor deck floor, the outdoor decking board including a wood core formed from a first wood species of common grade wood species as a three-dimensional solid rigid body. A facing wood veneer formed from a second wood species of superior grade wood species as a three-dimensional solid rigid wood finishing layer permanently directly seamlessly attached via an adhesive to a first wood face of the wood core thereby the wood core having an appearance of the second wood species. In another embodiment, the facing wood veneer is formed from a third wood species, exotic hardwood species. A two-part emulsion polymer isocyanate adhesive is used to bond the wood core against the facing wood veneer; to bond two wood cores together. In another embodiment, the adhesive is a two-part polyurethane emulsion polymer.

Owner:TEBB TERRY ALLEN +1

Coating composition for wood finishing

The present invention relates to a water-borne UV-curable coating composition for use in wood finishing of interior joinery, furniture, and in particular in kitchen industry.

Owner:SHERWIN WILLIAMS DEUT

Outdoor wood decking board

ActiveUS20180223529A1Improve stabilityReduce foam generationFloorsWood working apparatusIsocyanateWood finishing

An outdoor wood decking board for use in construction of an outdoor deck floor, the outdoor decking board including a wood core formed from a first wood species of common grade wood species as a three-dimensional solid rigid body. A facing wood veneer formed from a second wood species of superior grade wood species as a three-dimensional solid rigid wood finishing layer permanently seamlessly attached via an adhesive to a first wood face of the wood core thereby the wood core having an appearance of the second wood species. In another embodiment, the facing wood veneer is formed from a third wood species, exotic hardwood species. A two-part emulsion polymer isocyanate adhesive is used to bond the wood core against the facing wood veneer; to bond two wood cores together. In another embodiment, the adhesive is a two-part polyurethane emulsion polymer.

Owner:TEBB TERRY ALLEN +1

Powdery coating applied to wood finishing and production method thereof

InactiveCN108219625AGood weather resistanceImprove heat resistancePowdery paintsGrain treatmentsEpoxyAntioxidant

The invention provides a powdery coating applied to wood finishing. The powdery coating is prepared from the following raw materials in parts by weight: 25 to 40 parts of modified epoxy resin, 1 to 3parts of a curing agent, 0.5 to 1 part of a pigment, 0.5 to 1 part of a degassing agent, 0.2 to 0.5 part of a dispersant, 0.5 to 1 part of a toughening agent, 0.2 to 0.5 part of a luster enhancing agent, 0.1 to 0.5 part of a wetting agent, 0.1 to 0.3 part of a preservative, 0.1 to 0.3 part of an antioxidant and 0.2 to 0.5 part of a light stabilizer, wherein an electricity enhancing agent is beta-hydroxyalkylamide; the degassing agent is stearic acid; the dispersant is zinc thionate; the toughening agent is a pvc (polyvinyl chloride) toughening agent; the wetting agent is heptadecylimidazoline;the preservative is 5-chloro-2-methyl-4isothiazoline-3-one. The raw materials are mixed and crushed and then are extruded; then a mixture is subjected to sheet preparation, shearing, crushing and sieving to obtain the powdery coating. According to the powdery coating provided by the invention, the modified epoxy resin is added and the antioxidant and the light stabilizer are introduced, so that the problems that the storage stability is poor, the leveling property is not good and the curing temperature is too high are remarkably solved.

Owner:广西福宝信科技有限公司

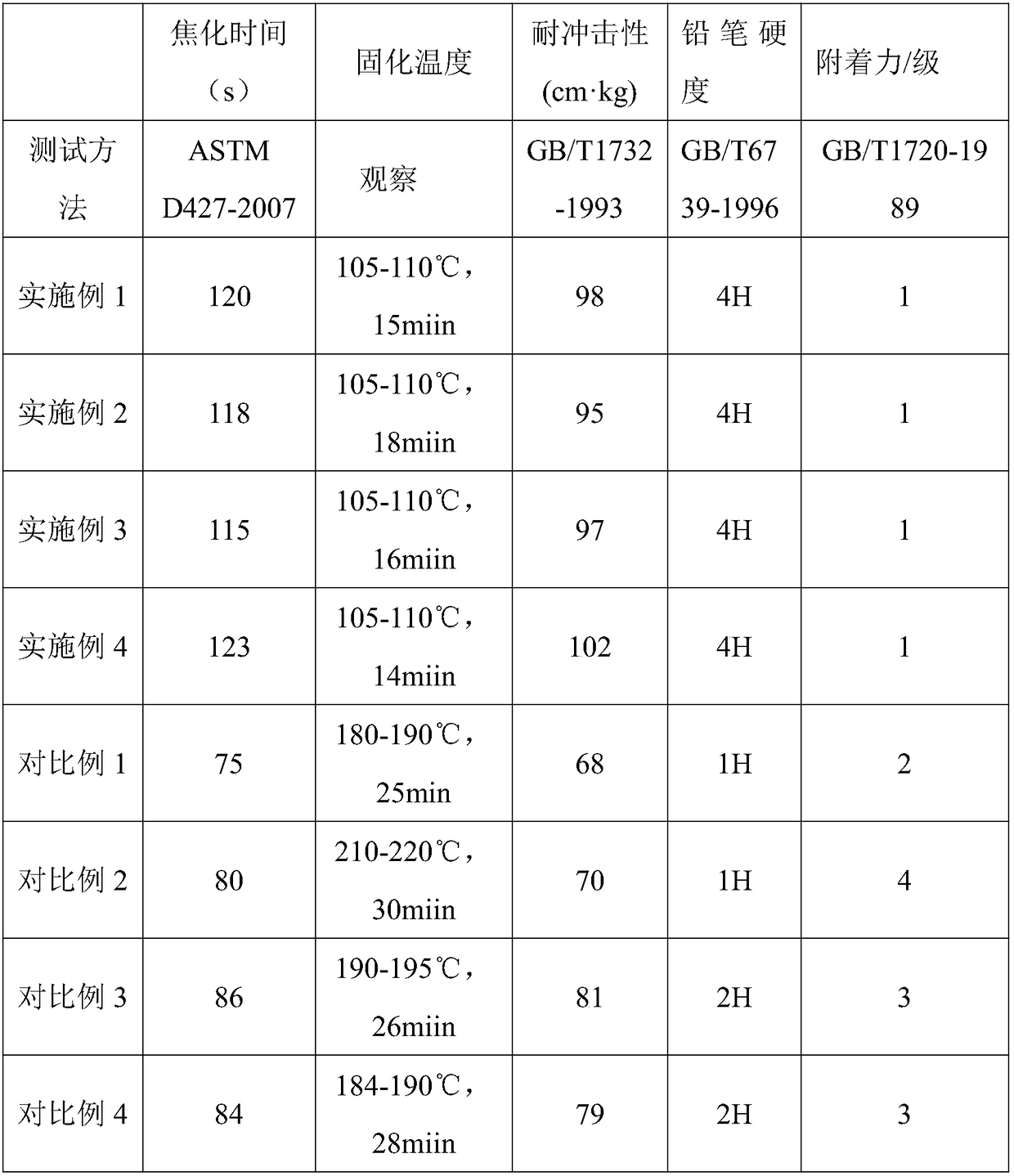

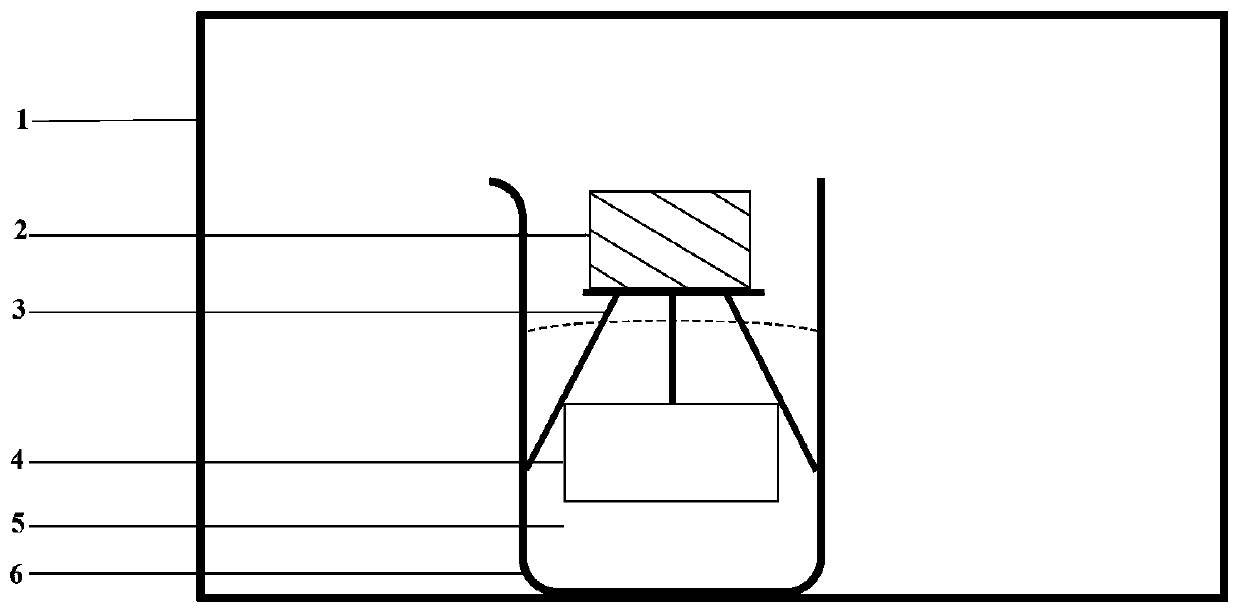

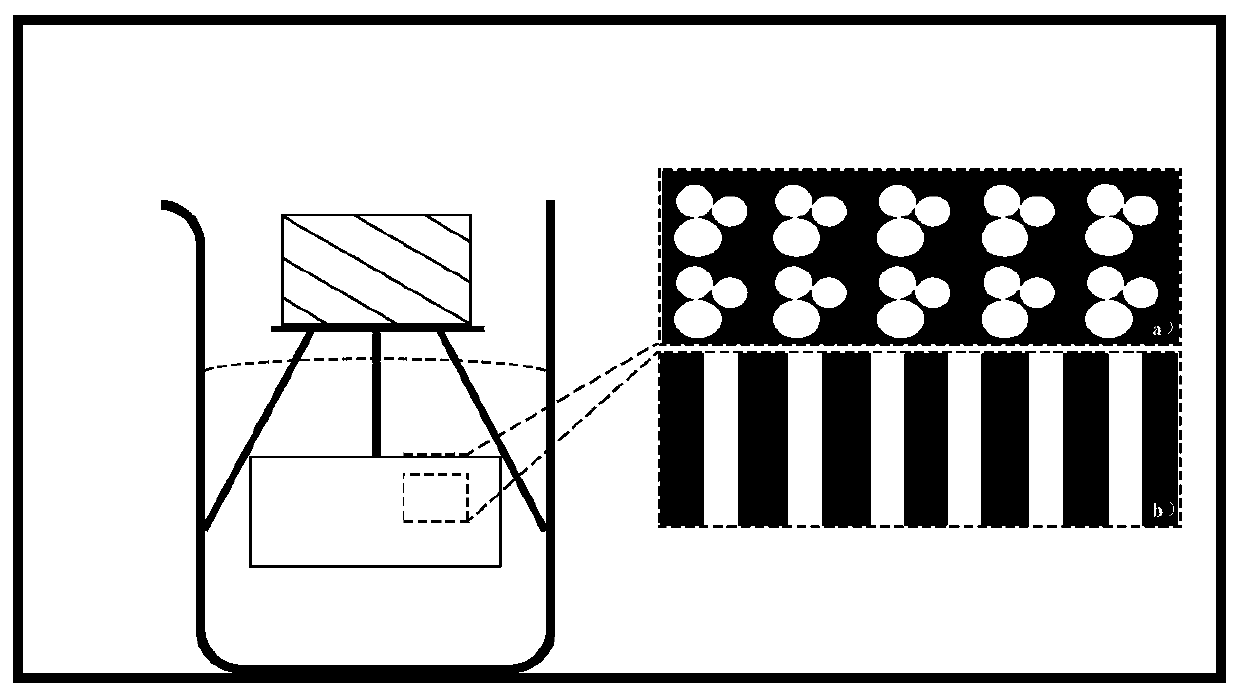

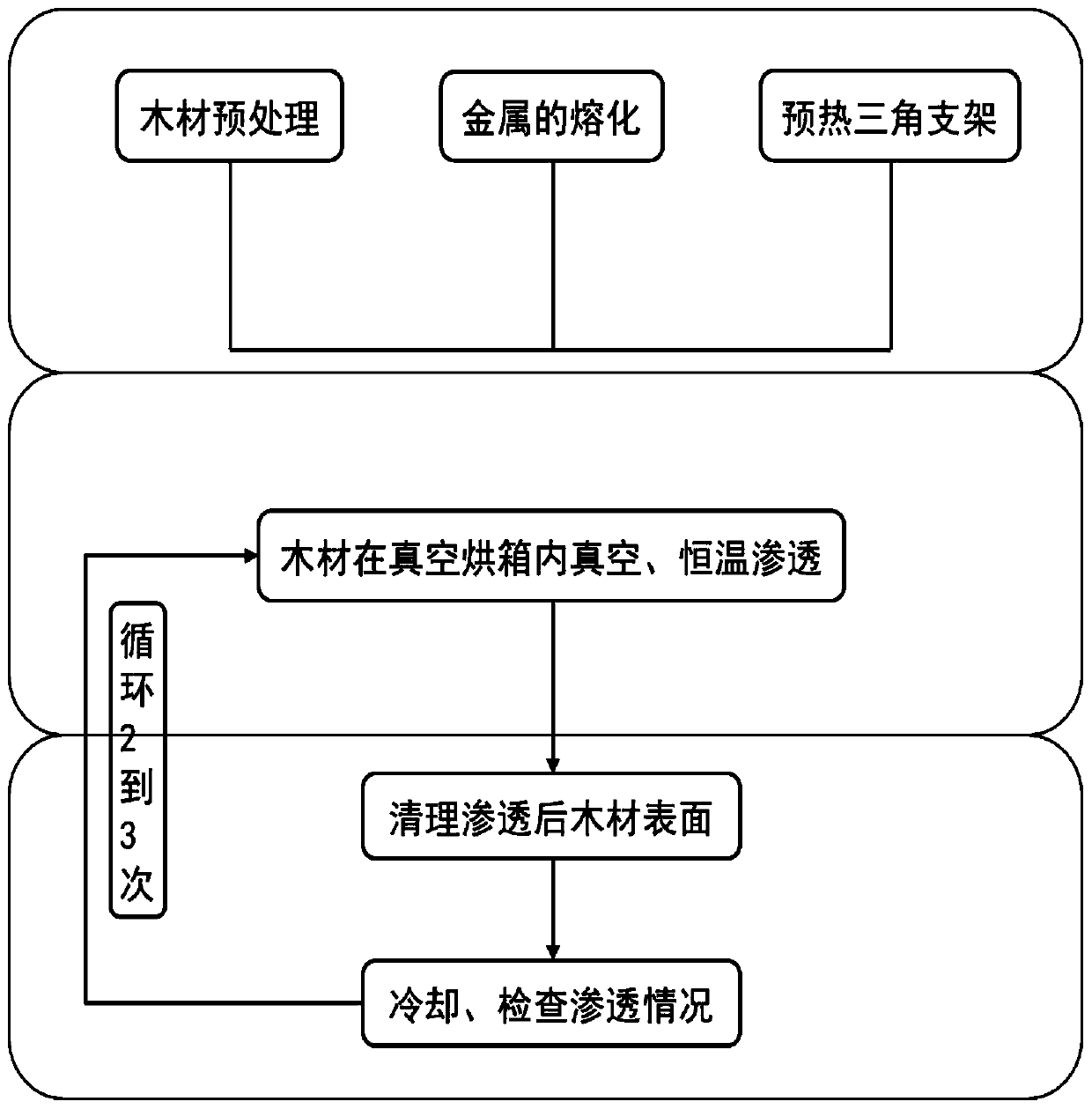

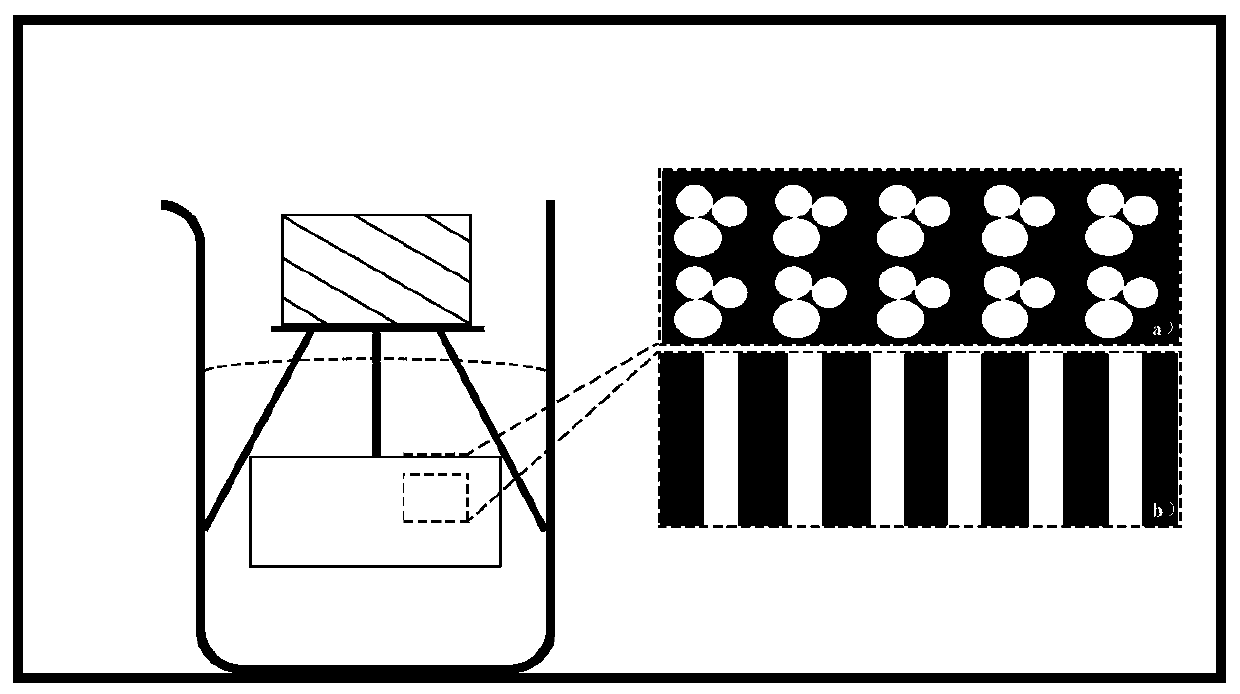

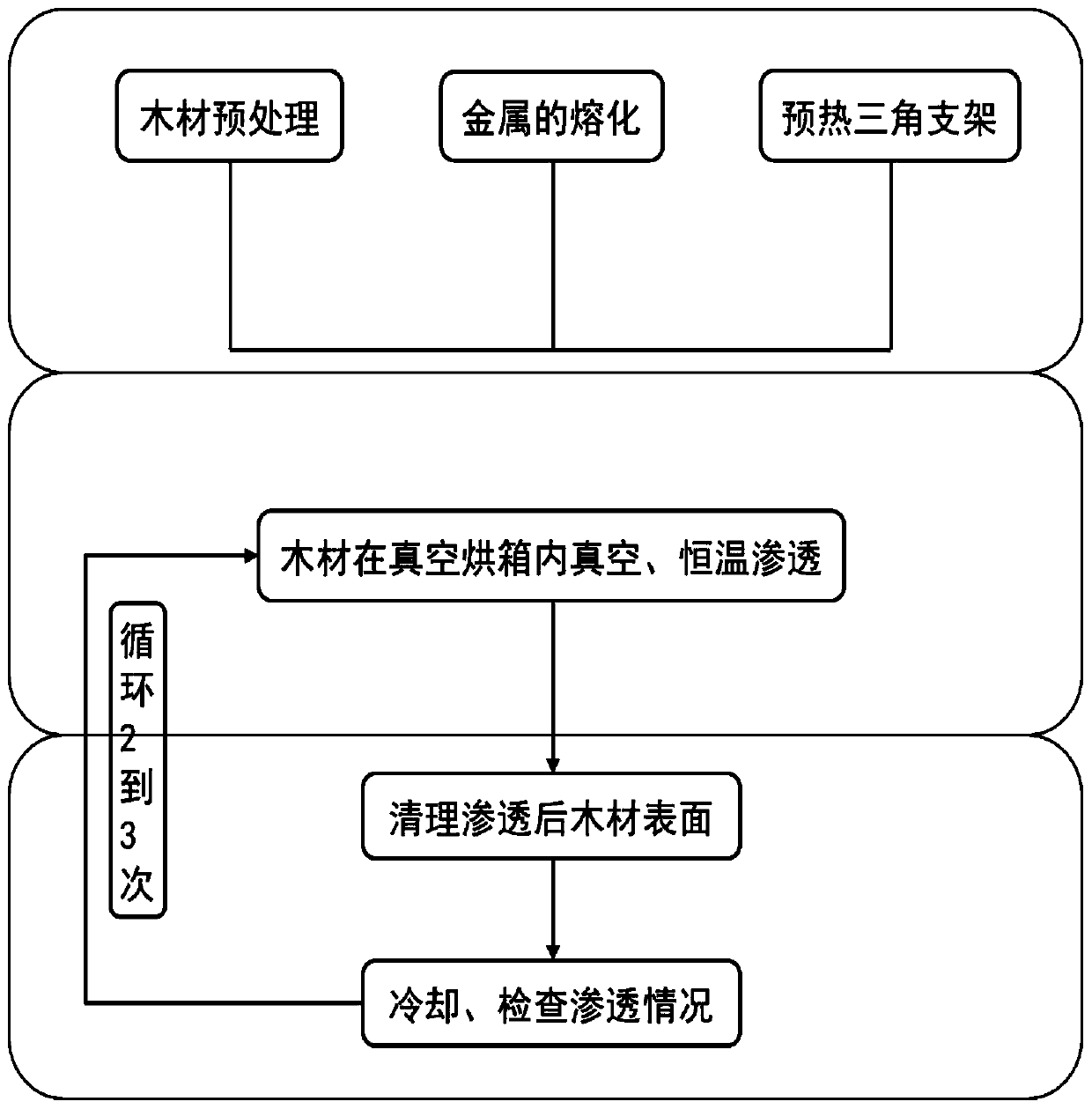

Preparation method of high-density anisotropic conductive metalized wood

ActiveCN109877927AMaintain structureMaintain strengthWood treatment detailsPressure impregnationVolumetric Mass DensityAlloy

The invention belongs to the field of preparation of composite performance materials, and provides a preparation method of high-density anisotropic conductive metalized wood, which comprises the following steps: pretreating a wood fiber structure; carrying out vacuum infiltration on metal liquid in a wood fiber channel; and carrying out surface treatment on the metalized wood. In the pretreatmentstep, lignin in a log fiber structure is washed away without destroying the fiber structure by adopting a mixed solvent of dilute ammonia water and an alkali metal halide aqueous solution, a good fiber channel is provided for permeation of molten metal, and meanwhile, nano halide molten salt particles precipitated from the wood fiber structure can achieve a flame retardant effect at a high temperature; the permeated metal is an alloy material, the metal is melt into a liquid state in a constant-temperature vacuum oven, then wood to be permeated is soaked into the molten metal, and permeation is carried out under a vacuum condition; and after the permeation is completed, the surface of the metalized wood finishing the permeation is polished through mechanical polishing equipment, and thus the large-density anisotropic metalized wood with a uniform surface and a good state is obtained.

Owner:UNIV OF SCI & TECH BEIJING

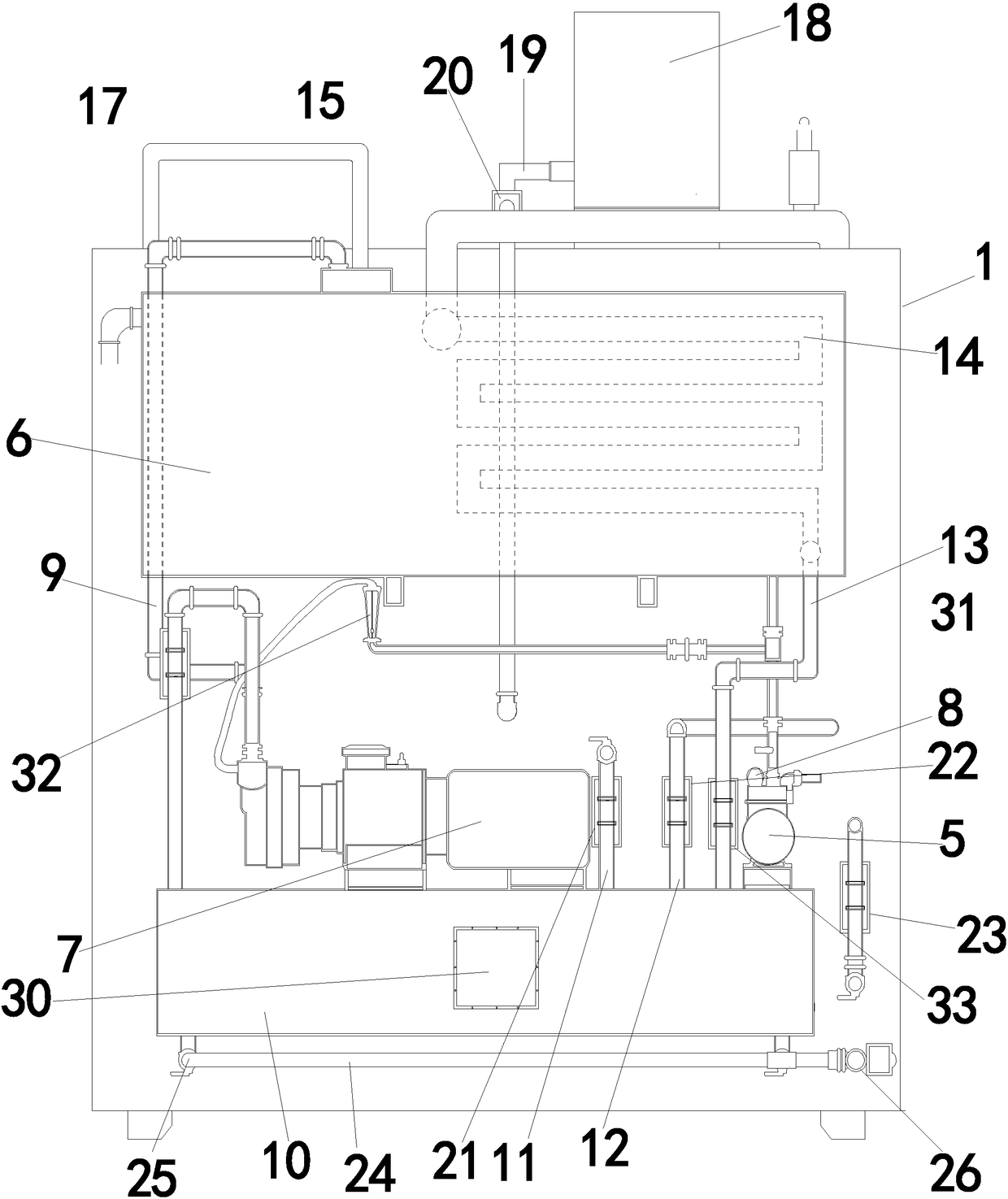

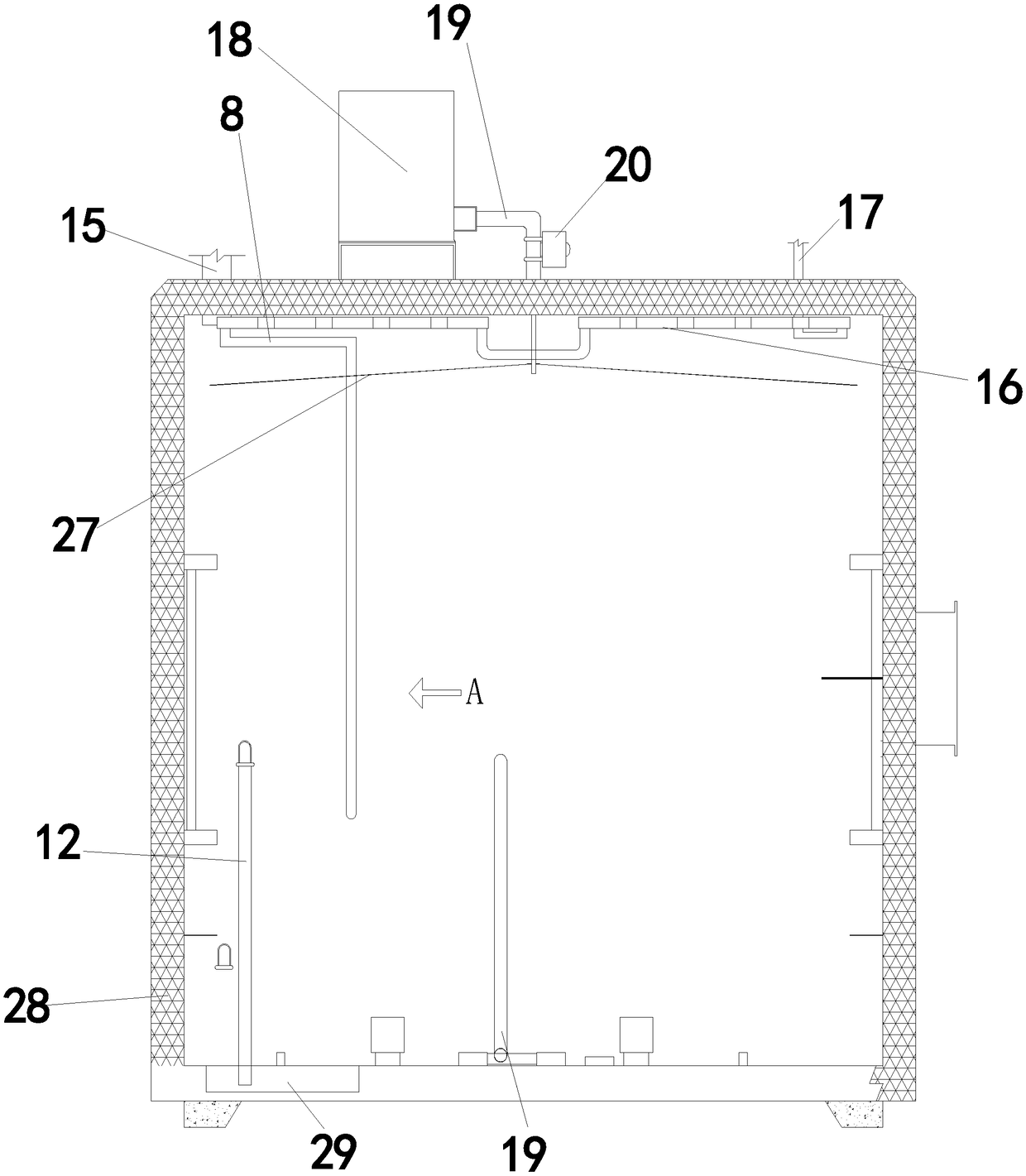

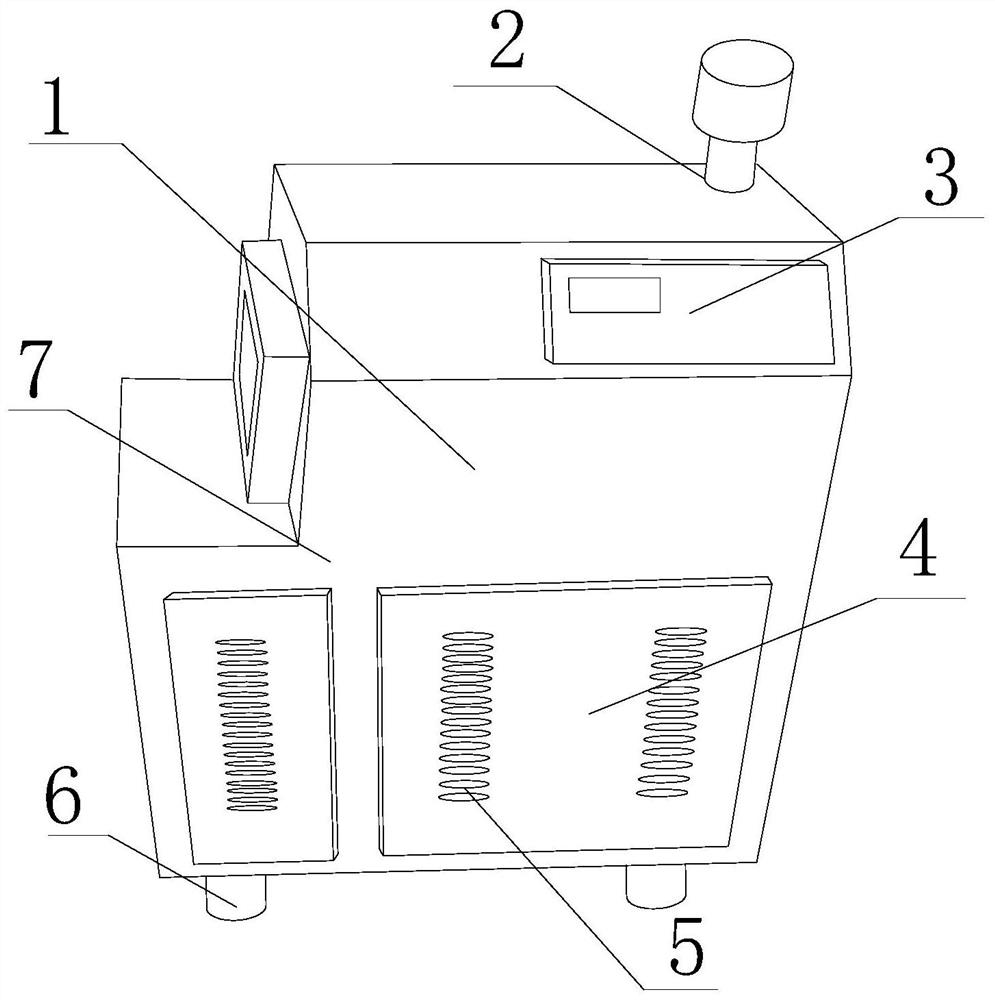

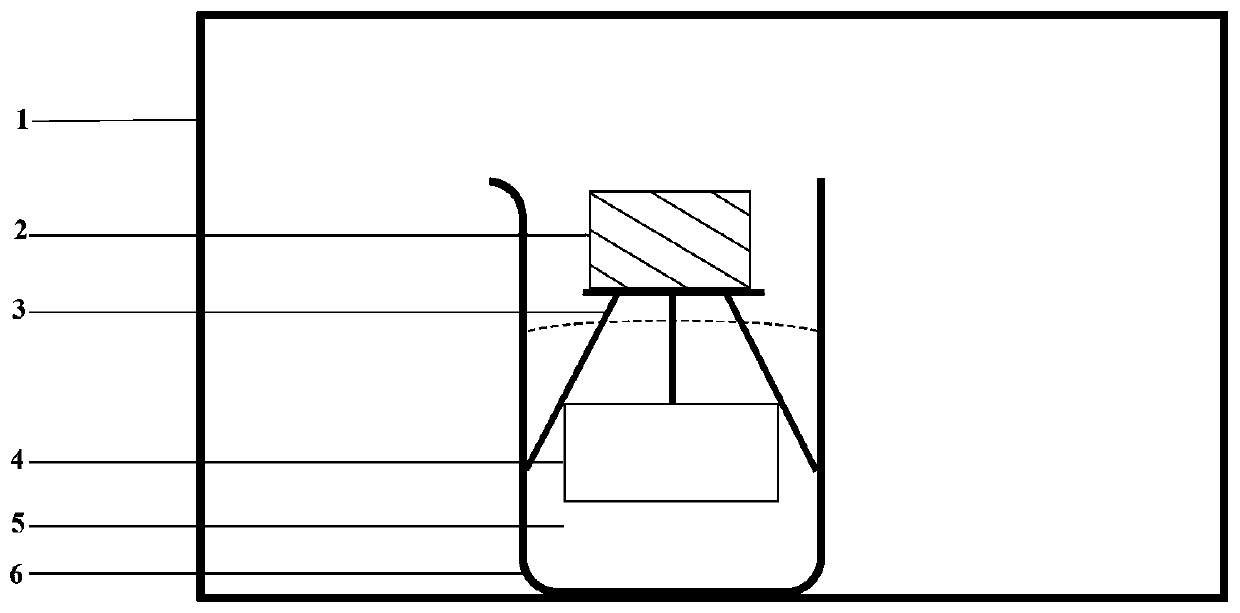

High-frequency steam vacuum drying box and achieving method thereof

InactiveCN108397991AImprove pass rateConvenience to workDrying solid materials without heatDrying gas arrangementsCirculating pumpVacuum pump

The invention discloses a high-frequency steam vacuum drying box and further discloses an achieving method of the high-frequency steam vacuum drying box. The high-frequency steam vacuum drying box comprises a box body, a movable type material vehicle, a high-frequency machine and a water circulating system, the water circulating system comprises a water circulating pump, an water upper box, a vacuum pump and a condensate water inlet pipe, and the vacuum pump is connected with the upper water tank through a vacuum pump exhaust pipeline and connected with a water collecting tank through a pipeline. A pressure relief pipe, a water pumping pipe and a gas extracting pipe are arranged on the water collecting tank, the water pumping pipe is inserted into the box body, the gas extracting pipe is connected with one end of a U-shaped pipe, and the other end of the U-shaped pipe is connected with one end of a wet pumping pipe. The other end of the wet pumping pipe is arranged in the box body, thecondensate water inlet pipe is connected with a condenser, and the outlet end of the condenser is connected with a condensing water outlet pipe. The condensing water outlet pipe is connected with theupper water tank, and a steam generating system for providing steam circulation for the interior of the box body is arranged on the upper portion of the box body. The high-frequency steam vacuum drying box has the characteristics of being simple in structure, low in manufacturing cost, high in production efficiency, wide in application range, high in wood finishing product rate, capable of savingenergy, environmentally friendly, good in using effect and the like.

Owner:东阳市尚德电器机械有限公司

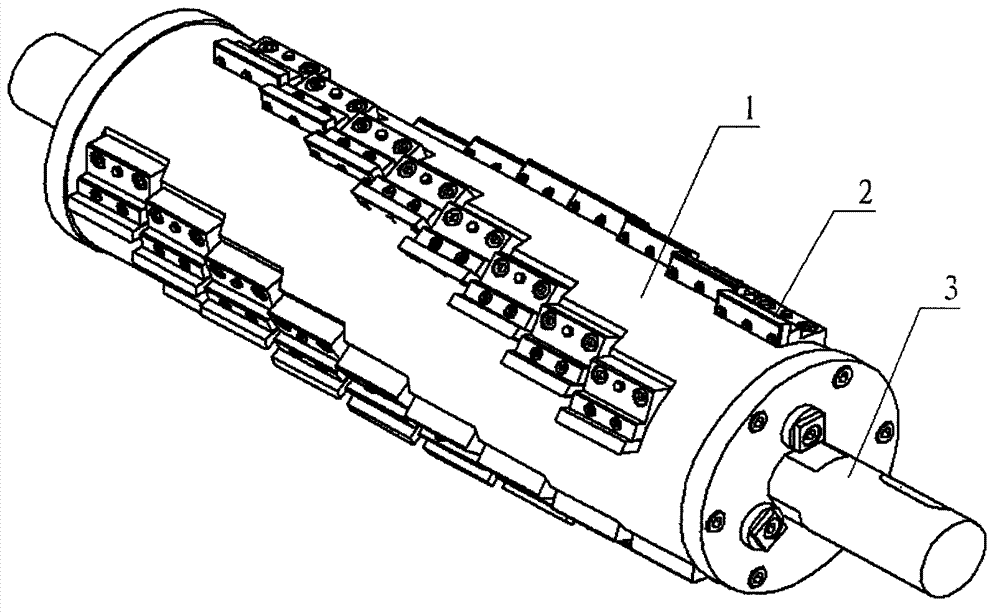

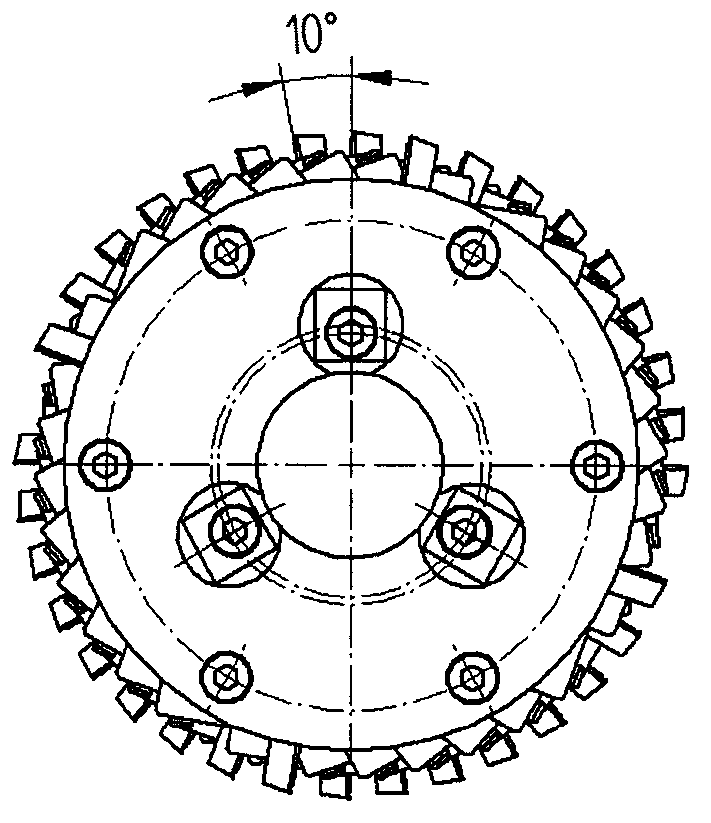

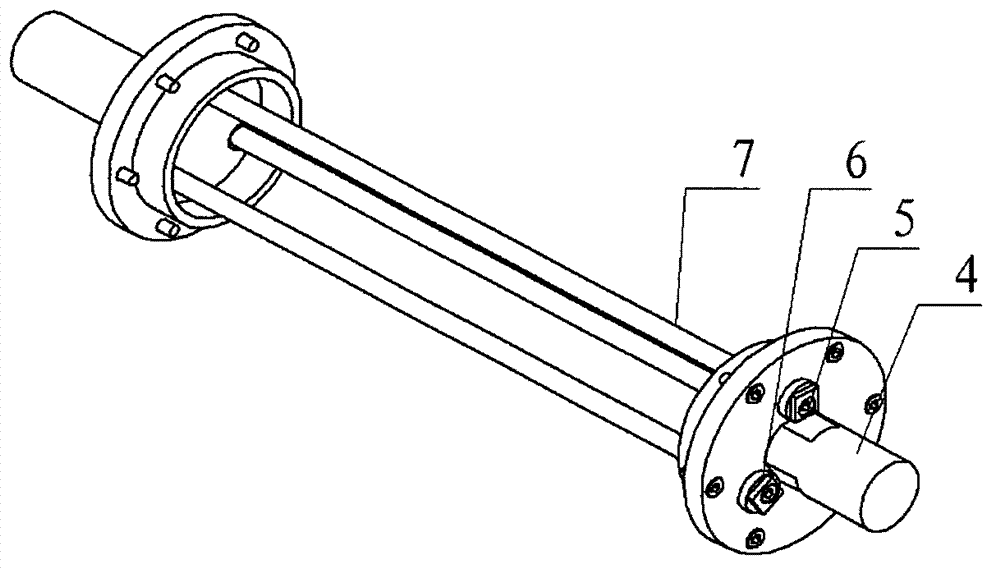

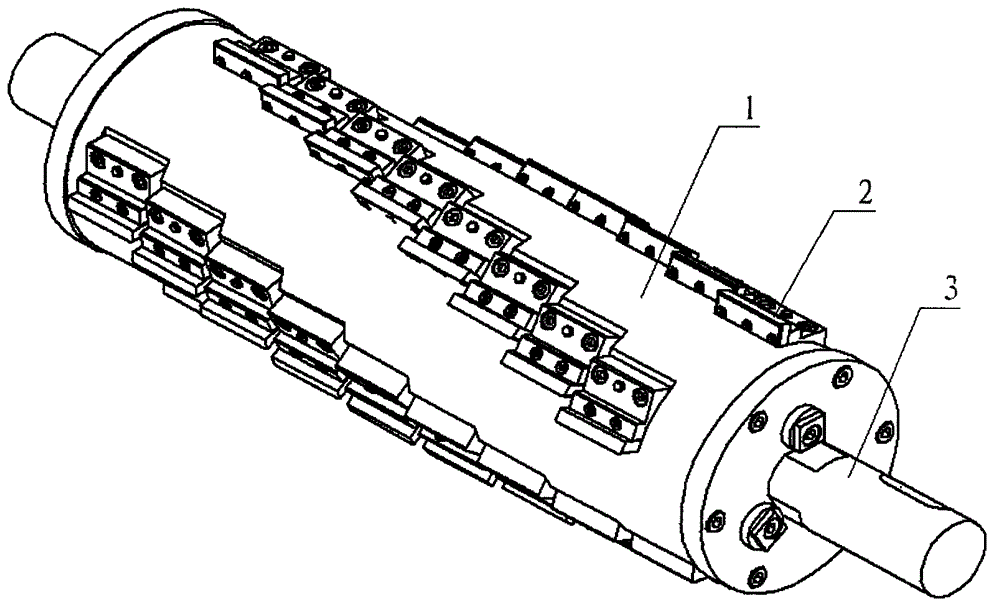

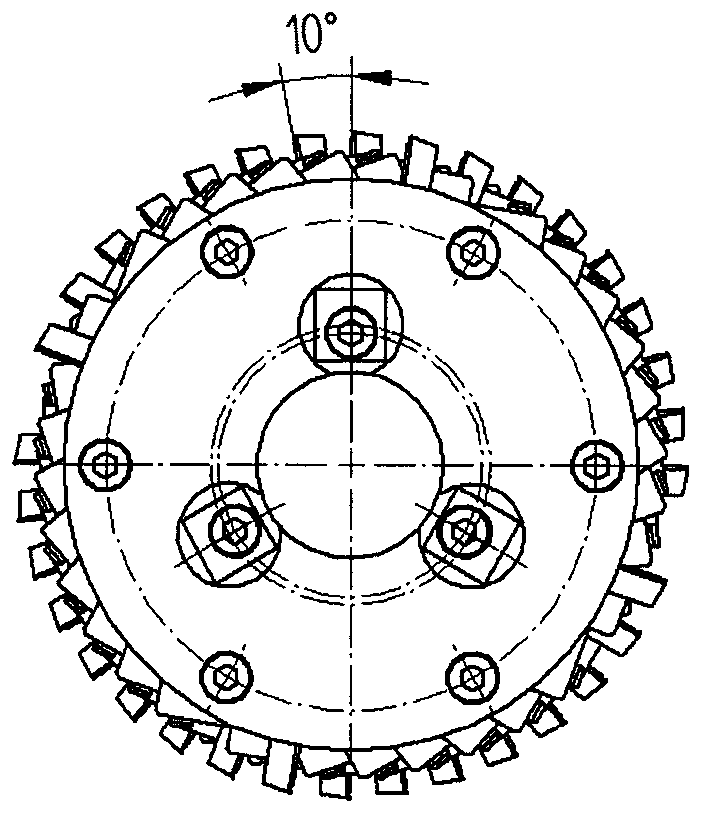

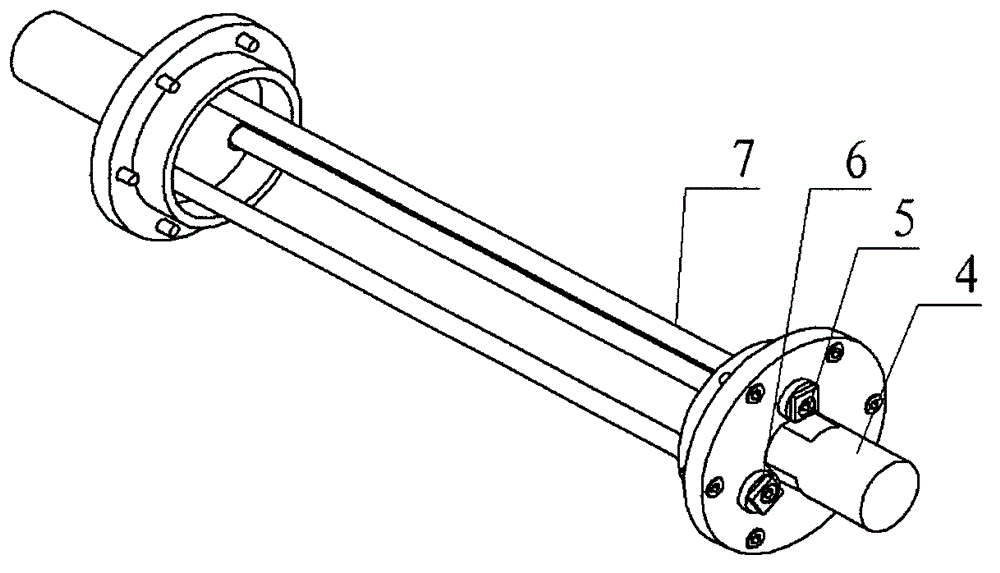

High-speed spiral corn-shaped milling cutter for wood

ActiveCN103192433AAvoid it happening againGentle milling processRotary cutting toolsMilling cutterWood machining

The invention provides a high-speed spiral corn-shaped milling cutter for wood and belongs to the technical field of wood machining. The milling cutter is in the shape of a corn and composed of a cutter body, cutters and an end cover counter weight, wherein the diameter phi of the cutters ranges from 160mm to 240mm, the rotating speed is 1000rpm-10000rpm, 2-6 rows of spiral grooves are evenly distributed on the cutter body, the width of the grooves ranges from 30mm to 70mm, the spiral included angles of adjacent grooves range from 5 degrees to 15 degrees, the adjacent spiral grooves are axially distributed in staggered mode, 6-10 cutters which are of a combined structure are evenly distributed on each row of groove, the front angle of a blade ranges from 20 degrees to 26 degrees, and the rear angle of the blade ranges from 9 degrees to 13 degrees, and a disc-shaped spring is installed under the cutters, so that compensation on abrasion of the cutters can be achieved. 2-4 groups of counter weight draw bars are installed on the counter weight end cover, 2mm-4mm of circumferential position adjusting on the counter weight draw bars can be achieved, and the requirement on movable balance of high-speed rotation of the corn-shaped milling cutter can be met. The high-speed spiral corn-shaped milling cutter can achieve high-speed cutting in the fine-machining process of wood, and has the advantages of being low in noise, power consumption and dust and high in quality.

Owner:BEIJING FORESTRY UNIVERSITY

Outdoor wood decking board

An outdoor wood decking board for use in construction of an outdoor deck floor, the outdoor wood decking board including a wood core, formed from a first wood species preselected from any one of a common grade North American Softwood, as a three dimensional solid rigid wood body. A facing wood veneer formed from a second wood species of superior grade North American Softwood species as a three dimensional solid rigid wood finishing layer is permanently seamlessly attached via a pressure sensitive liquid adhesive to a first wood face of the wood core. In another embodiment the facing wood veneer is formed of a third wood species including an exotic hardwood species. In another embodiment the wood core is formed from a wood plastic composite. In another embodiment, the wood core is formed from a cement board. Methods of manufacture of the outdoor wood decking board are embodied and disclosed.

Owner:TEBB TERRY ALLEN +1

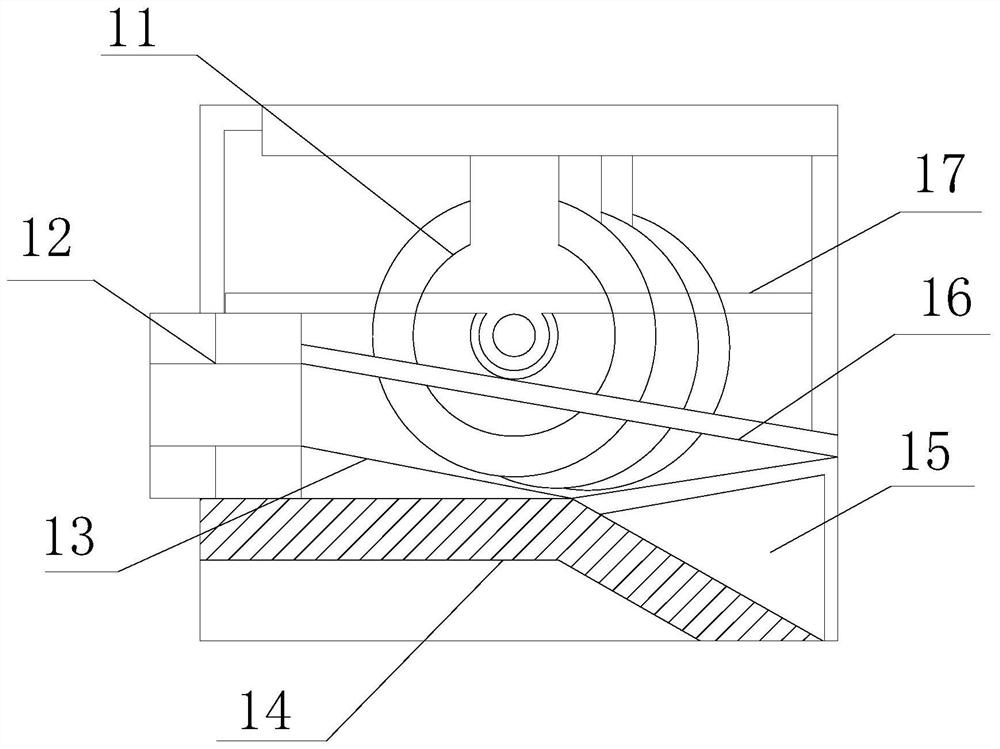

A kind of fine collection and utilization equipment for wood that does not meet the standards of building monitoring

InactiveCN109318306BAvoid damageReduce areaProfiling/shaping machinesArchitectural engineeringWood plank

Owner:南京溧水高新产业股权投资有限公司

Wood finishing paint

The invention discloses a wood finishing paint. The wood finishing paint comprises the following raw materials by weight: 15-25 Kg of alkyd resin, 2-4 Kg of nanosilicon dioxide, 3-5 Kg of an organic solvent, 5-7 Kg of ethyl alcohol, 8-10 Kg of low-arsenic iron oxide, 10-15 Kg of triethyl citrate, 0.1-1 Kg of a dispersant, 0.1-1 Kg of a feeling agent, 0.2-0.6 Kg of a pH regulator, 1-2 Kg of a thickener and 0.5-1.5 Kg of a defoamer. The wood finishing paint is high in wear resistance, good in surface glossiness and transparency, more attractive and high in adhesion force and has a certain environmental friendliness.

Owner:开平市马冈镇创冠木制品厂

A wood high-speed spiral corn milling cutter

ActiveCN103192433BAvoid it happening againGentle milling processRotary cutting toolsMilling cutterWood machining

Owner:BEIJING FORESTRY UNIVERSITY

A preparation method of large-density anisotropic conductive metallized wood

ActiveCN109877927BMaintain structureMaintain strengthWood treatment detailsPressure impregnationLiquid stateMolten salt

Owner:UNIV OF SCI & TECH BEIJING

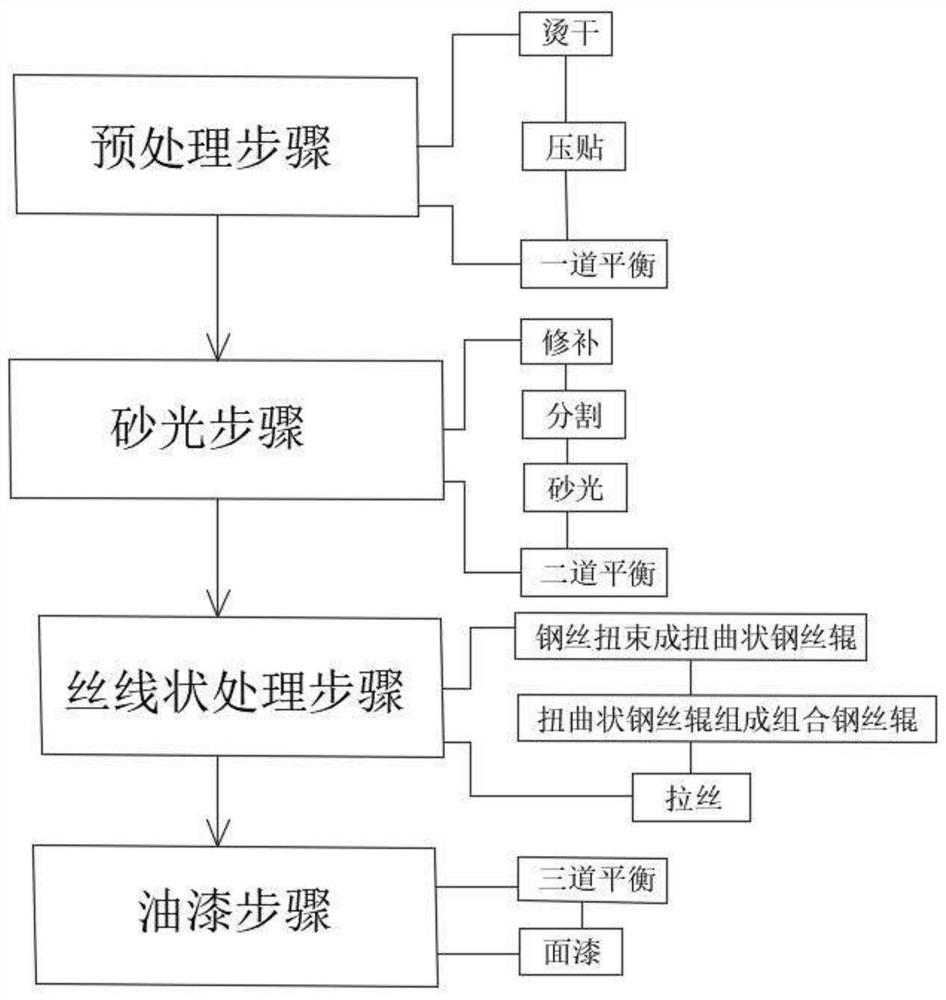

A production process of composite floor with irregular silk-like wood veneer

ActiveCN110154192BStrong three-dimensional senseNew visual experienceWood working apparatusGrinding machinesMechanical engineeringWood finishing

A manufacturing process for composite flooring with irregular thread-shaped wood veneer, characterized in that it includes the following steps: a pretreatment step, ironing the panel, pressing it, and balancing it together to complete the production of the primary floor; a sanding step, The surface of the primary floor is repaired, and then the primary floor is divided, and then the divided primary floor is sanded, and finally two balances are performed to complete the production of the sanded floor; the thread-like processing step A plurality of steel wires are twisted into a group of twisted steel wire rollers, and a plurality of twisted steel wire rollers with different diameters are formed into a combined steel wire roller, and the surface of the sanded floor is drawn by the combined steel wire rollers to achieve Complete the production of the silk-like floor. In the painting step, the silk-shaped floor is balanced three times and topcoated. The invention has strong three-dimensional effect and gives people a brand-new visual experience.

Owner:ZHEJIANG DADONGWU GREENHOME WOOD CO LTD

Coating composition for wood finishing

Owner:SHERWIN WILLIAMS DEUT

Craft machining and formaldehyde removing treatment method

InactiveCN109834800AImprove construction qualityUniform thicknessLiquid surface applicatorsWood working apparatusWood finishingSurface finishing

The invention provides a craft machining and formaldehyde removing treatment method. A preparation method comprises the following steps of sorting, peeling, pre-digging, base layer treatment, drying treatment, scraping and polishing, varnishing, flat lacquer painting and surface finishing. The technology steps are simple and convenient, the construction quality of wood finishing decorative board oil paint can be improved, so that the thickness of the oil paint is uniform, color losing cannot occur, the service life is ensured, and the problems that the construction process and process of existing wood finishing decorative board oil paint are complex, the construction quality cannot be ensured, places of painting missing occur frequently, and use and beauty are affected are solved. The craft machining and formaldehyde removing treatment method has the characteristics that the technology is simple, the operation is safe, the appearance is artistic, the cost is low, no pollution to the environment is achieved, and no damage to human body is achieved, sustainable development of furniture production is facilitated, and reduction of man-made damage of health is facilitated.

Owner:大邑县林源特种工艺品厂

Water-based furniture primer and its preparation method and wood finishing construction technology

ActiveCN106010184BImprove stabilityEasy to fillLiquid surface applicatorsPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention provides waterborne furniture primer and a preparation method thereof and a wood finishing construction technology. The waterborne furniture primer is prepared from, by weight, 90-95 parts of waterborne resin, 0.1-0.7 part of waterborne defoaming agent, 0.5-2 parts of waterborne wetting agent, 3-8 parts of waterborne cosolvent, 0.5-5 parts of waterborne thickener, 0.01-0.1 part of preservative and 0.01-1 part of pH auxiliary, wherein the waterborne resin is prepared from, by weight, 30%-65% of waterborne polyurethane resin and 40%-75% of waterborne acrylic resin. The obtained waterborne transparent primer has excellent stability, filling performance, permeability and overlapping performance, the primer is put in a baking oven at 50 DEG C for 10 days, the coating does not have any exception, and a spray plate effect is not changed; after 'three primer' procedures are carried out, wet film can cover all fine needle holes and guide tubes of the surfaces of boards; the transparency effect is good, and the primer is neither dimming nor blushing.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

Wood finishing coat

The invention discloses a wood finishing coat, prepared from the following components in parts by weight: 5-20 parts of titanium dioxide, 10-20 parts of phthalic anhydride, 10-20 parts of fatty acid,1-5 parts of nano silica, 5 to 7 parts of ethanol, 2 to 10 parts of iron oxide, 5 to 15 parts of triethyl citrate, 0.2 to 0.9 part of a dispersing agent, 0.2 to 0.9 part of citric acid. 1 to 2 parts of a thickener, 0.2 to 0.5 part of an antifoaming agent, 1 to 5 parts of styrene, 1 to 5 parts of perchloroethylene, 1 to 5 parts of trichloroethylene, and 1 to 5 parts of ethylene glycol ether. The wood finishing coat has the beneficial effects of good wear resistance, strong adhesion, low probability of falling off during collision, vibration, etc., and environmental protection.

Owner:芜湖益承木业包装有限公司

A wood shaving device capable of improving the surface smoothness of furniture wood and its working method

ActiveCN111618686BReduce work intensityImprove applicabilityGrinding carriagesGrinding drivesWood shavingsAgricultural engineering

The invention discloses a shaving device capable of improving the surface smoothness of furniture wood and a working method thereof, comprising a processing table and a feeding table arranged side by side along the horizontal direction, and the table top of the processing table is longitudinally There are guide plates on both sides, and a receiving plate is arranged horizontally between the guide plates on both sides. A transmission mechanism 1 and a transmission mechanism 2 are arranged between the guide plates on both sides of the processing table. The outer sides of the guide plate are respectively vertically provided with four vertical frames, and the tops of the vertical frames on both sides of the processing table are fixedly connected by quadrangular frames, and the inside of the processing table is sequentially arranged with Wood shaving stand and shaving finish stand, which combine wood polishing-smoothness detection-wood finishing on one device, which not only speeds up the efficiency of wood shaving processing, but also avoids multiple feedings during wood processing Repeated polishing, so that the flatness of the wood surface can be effectively protected.

Owner:安徽纬奥特工艺品有限公司

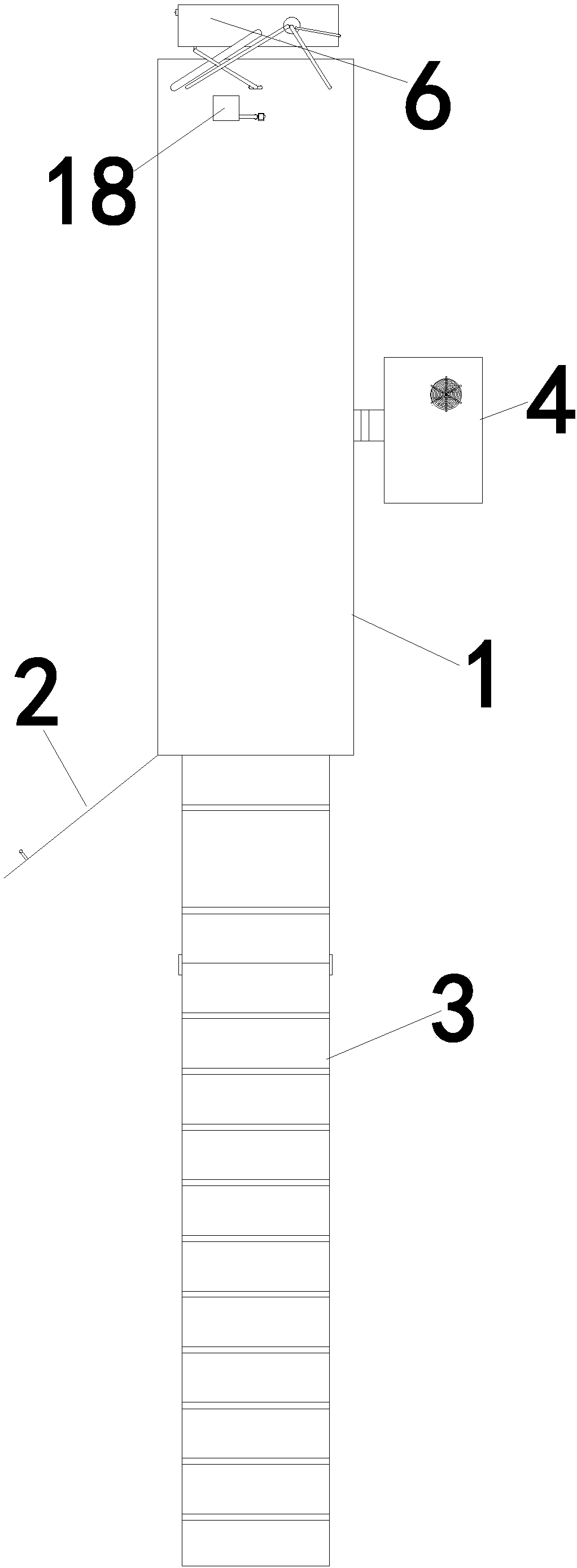

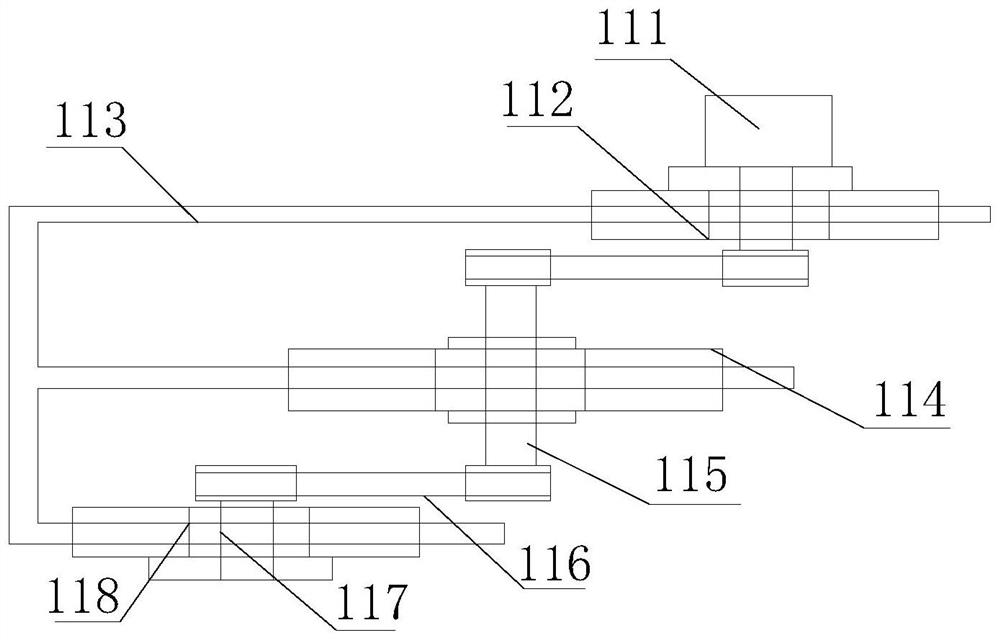

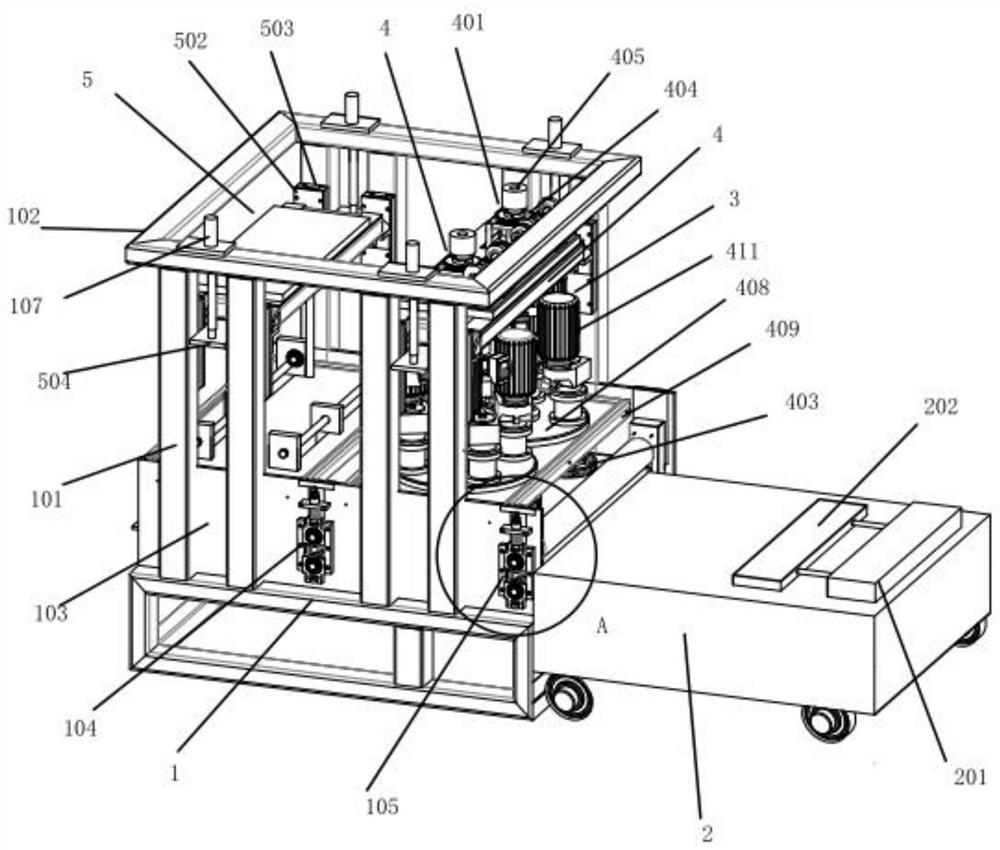

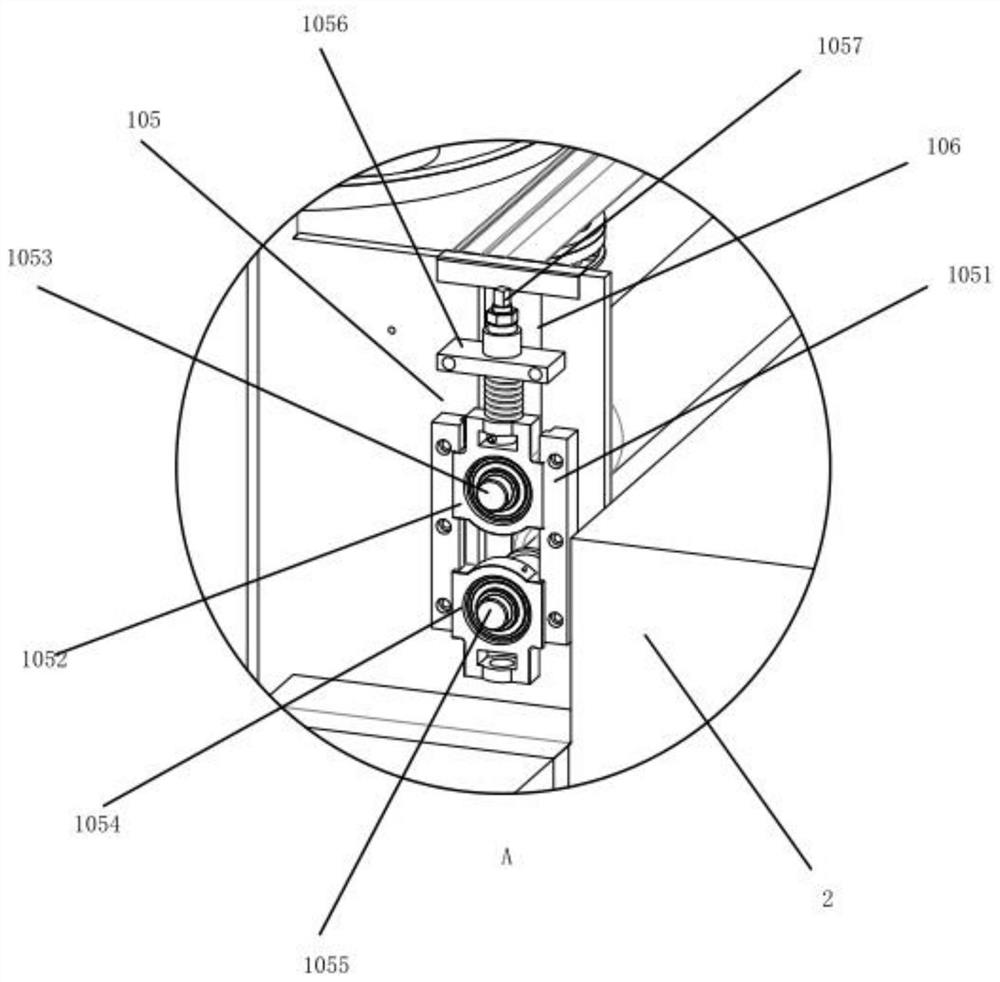

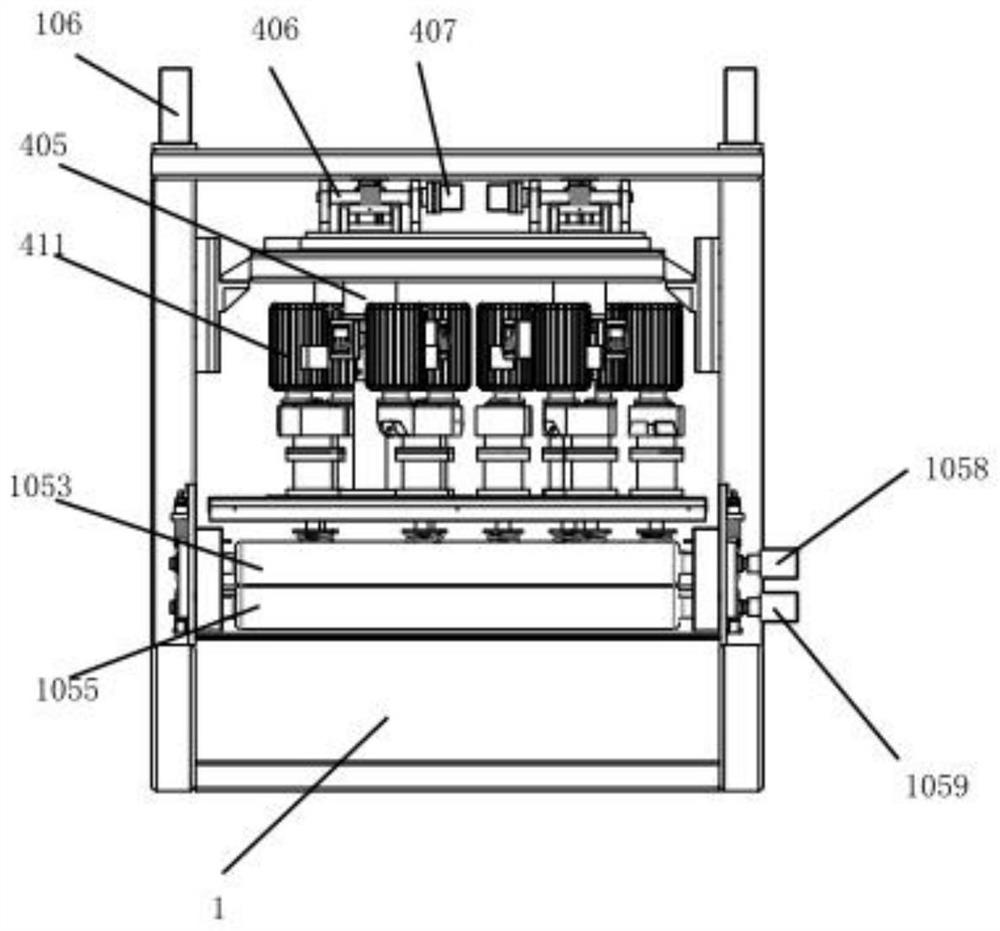

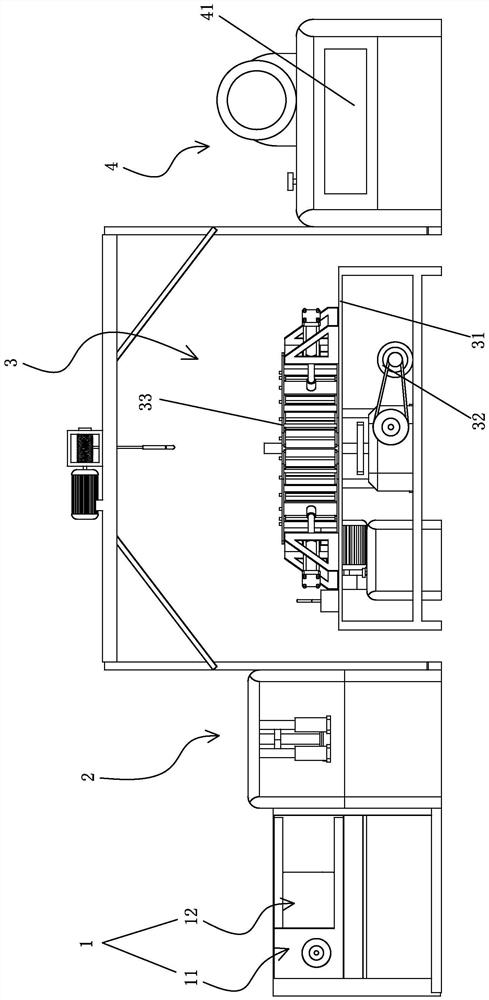

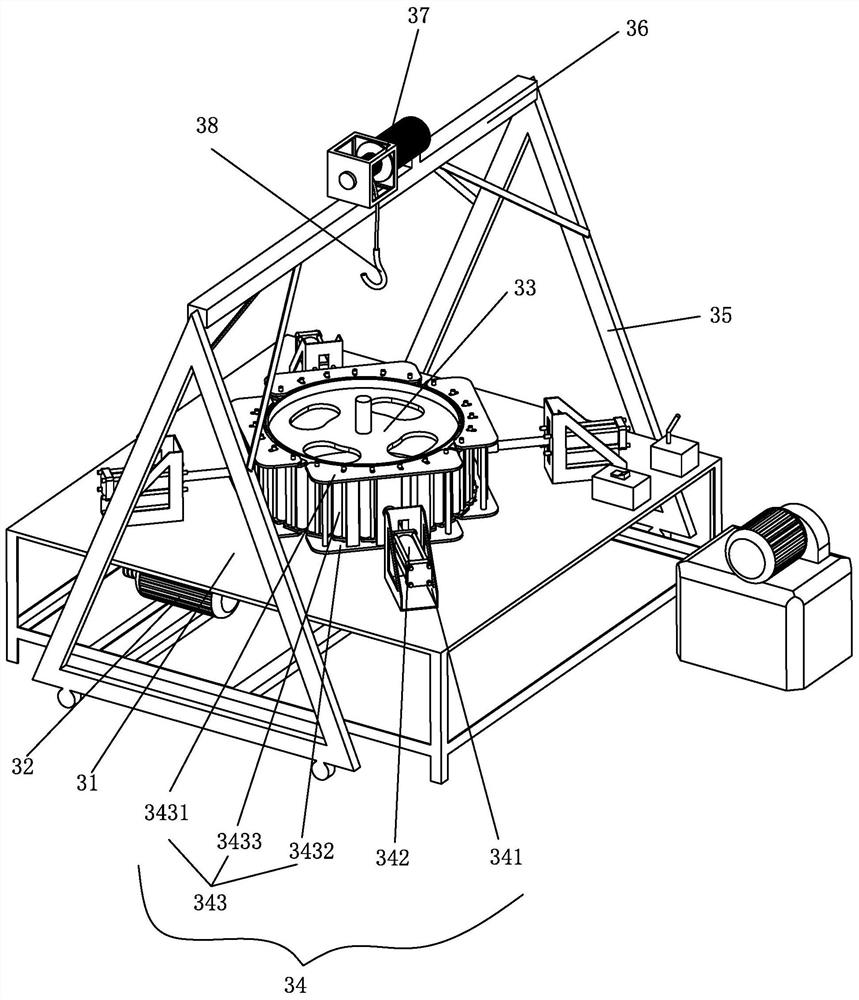

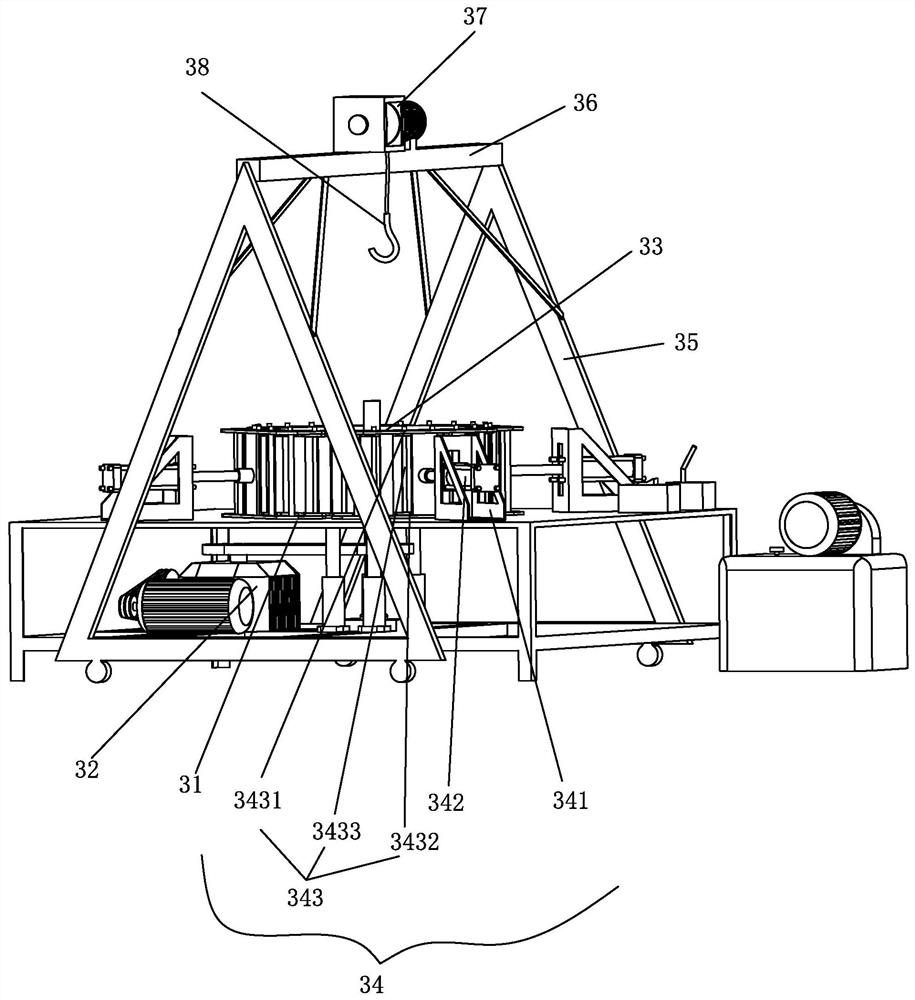

Automatic production line for circular wooden lamp bodies

PendingCN111844329AHigh precisionMeet appearance requirementsWood working apparatusProduction lineAutomatic processing

The invention discloses an automatic processing production line for circular wooden lamp bodies. The production line comprises a pre-processing device 1 which can cut wood. A wood finishing device 2 capable of finishing a plurality of treated wood is arranged behind the pre-treatment device 1. The rear of the wood finishing device 2 is provided with a rolling device 3 which can roll the laminatedwood. The rolling device 3 comprises a base 31. The base 31 is provided with a driving device 32 and a rolling rotating mold 33 which is separately connected to the driving device 32 and can rotate with the base 31 as the axis. The base 31 is further provided with a rolling dome pressing auxiliary device 34 which is arranged in a rotating array with the rolling rotating mold 33 as the axis. A rolling channel is formed between the rolling rotary mold 33 and the dome pressing auxiliary device 34 for the wood to extend. The rolling rotating mold 33 can drive the wood to rotate around the rollingrotating mold to make the wood roll into a ring shape. A post-processing device 4 capable of drying the circular wood lamp body after rolling is arranged behind the rolling device 3.

Owner:中山市硕洋灯饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com